Summary of Contents for KIESELMANN 5093 Series

- Page 1 Operating instruction Translation of the original Non-return valve Type 5093 EPDM: Type 5093xxx000-xxx HNBR: Type 5093xxx700-xxx FKM: Type 5093xxx140-xxx O-ring - Model Intermediate flange with welding ends ENGLISH...

- Page 2 . k i e s e l m a n n . d e • i n f o @ k i e s e l m a n n . d e Copyright: © KIESELMANN FLUID PROCESS GROUP...

-

Page 3: Table Of Contents

KIESELMANN GmbH Table of contents T a b l e o f c o n t e n t s 1 General informations .............................. 4 Informations for your safety ............................... 4 Marking of security instructions............................ 4 General designated use .............................. 4 Personnel ..................................... 4 Modifications, spare parts, accessories .......................... 5 General instructions ................................ 5... -

Page 4: General Informations

We will be at your disposal also after expiration of the warranty. In addition, you will also find all necessary instructions and spare part data for maintenance in this instruction manual. If you don't want to carry out the maintenance by yourself, our KIESELMANN GmbH - service team will naturally be at your disposal. -

Page 5: Modifications, Spare Parts, Accessories

KIESELMANN GmbH | Operating instruction General informations | 1 1.5 Modifications, spare parts, accessories Unauthorized modifications, additions or conversions which affect the safety of the fitting are not permitted. Safety devices must not be bypassed, removed or made inactive. Only use original spare parts and accessories recommended by the manufacturer. -

Page 6: Safety Instructions

2 | Safety instructions Operating instruction | KIESELMANN GmbH 2 S a f e t y i n s t r u c t i o n s 2.1 Intended use This type of non-return valve is used as an independent non-return stop valve for liquid and gas me- dia in systems used in the food and drinks industry, the pharmaceutical industry and the biotechno- logy industry. -

Page 7: Delivery, Transport And Storage

KIESELMANN GmbH | Operating instruction Delivery, transport and storage | 3 3 D e l i v e r y , t r a n s p o r t a n d s t o r a g e 3.1 Delivery... -

Page 8: Function And Operation

4 | Function and operation Operating instruction | KIESELMANN GmbH 4 F u n c t i o n a n d o p e r a t i o n 4.1 Description of function The valve open against spring power with flow pressure > x,xx bar in flow direction “A“ (see Tab.). -

Page 9: Service

KIESELMANN GmbH | Operating instruction Function and operation | 4 4.2.1.3 ATEX - Guidelines For valves or plants/installations that are operated in the ATEX area, sufficient bonding (grounding) must be ensured (see valid ATEX Guidelines EG). 4.2.2 Service RECOMMENDATION Replacement of seals To achieve optimal maintenance cycles, the following points must be observed! –... -

Page 10: Technical Data

5 | Technical data Operating instruction | KIESELMANN GmbH 5 T e c h n i c a l d a t a 5.1 Check valves Type 5093 Model Non-return valve Intermediate flange with welding connection Design: Sealing = O-ring... -

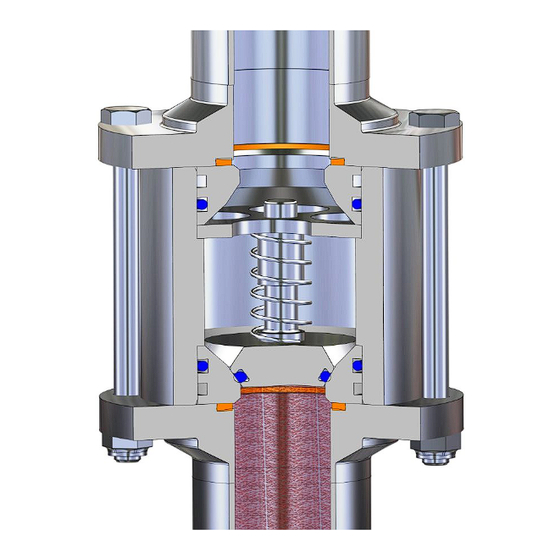

Page 11: Disassembly And Assembly | 6

KIESELMANN GmbH | Operating instruction Disassembly and assembly | 6 6 D i s a s s e m b l y a n d a s s e m b l y 6.1 Disassembly Mounting tools Combination wrench-Set SW 8 - SW 24 Allen key - Set 1.5 - 10... - Page 12 7 | Drawings and dimensions Operating instruction | KIESELMANN GmbH 7 D r a w i n g s a n d d i m e n s i o n s 7.1 Drawings Piston plate guidance DN 25 - DN 100, 1‘‘ - 4‘‘...

-

Page 13: Drawings And Dimensions | 7

KIESELMANN GmbH | Operating instruction Drawings and dimensions | 7 7.2 Dimensions 29x1.5 DN 25 - DN 100, 1‘‘ - 4‘‘ 35x1.5 41x1.5 53x1.5 70x2 85x2 104x2 129x2 154x2 1 Inch 25,4x1,65 1½ Inch 38,1x1,65 2 Inch 50,8x1,65 2½ Inch... -

Page 14: Wearing Parts

8 | Wearing parts Operating instruction | KIESELMANN GmbH 8 W e a r i n g p a r t s 8.1 Wear parts kit Wear parts set (WPS) EPDM O-ring - Model • for Check valves 5093 xxx 000-xxx Pos. - Page 15 KIESELMANN GmbH | Operating instruction Wearing parts | 8 Wear parts set (WPS) HNBR O-ring - Model for Check valves 5093 xxx 700-xxx Pos. 3 Pos. D1 Pos. D2 Pos. D3 HNBR Spring O-ring O-ring Seal Inch 1.4310/AISI301 HNBR HNBR...

Need help?

Do you have a question about the 5093 Series and is the answer not in the manual?

Questions and answers