Subscribe to Our Youtube Channel

Summary of Contents for GESTRA BVA300 Series

- Page 1 IM-P370-02-EN-ISS3 CTLS Pneumatic Actuators for use with GBV Ball Valves BVA300 Series Original Installation Instructions 819763-02 English...

- Page 2 819763-02 IM-P370-02-EN-ISS3 CTLS...

-

Page 3: Table Of Contents

Contents 1 Safety information 2 General product information 3 Installation 4 Commissioning 5 Spare parts and maintenance 6 Fault finding BVA300S pneumatic actuator IM-P370-02-EN-ISS3 819763-03 CTLS... -

Page 4: Safety Information

1 Safety information These products comply with the ATEX Directive 2014/34/EU for use in potentially explosive atmospheres caused by a mixture of air, gases, vapours, mist or suspended dust within Group II, Category 2. II 2 G D c T5 T1000 º C Safe operation of these products can only be guaranteed if they are properly installed, commissioned, used and maintained by qualified personnel (see Section 1.11) in compliance with the operating instructions. -

Page 5: Intended Use

Determine the correct installation situation and orientation of the connected valve. iv) GESTRA products are not intended to withstand external stresses that may be induced by any system to which they are fitted. It is the responsibility of the installer to consider these stresses and take adequate precautions to minimise them. -

Page 6: Pressure Systems

1.8 Tools and consumables Before starting work ensure that you have suitable tools and/or consumables available. Use only genuine GESTRA replacement parts. 1.9 Protective clothing Consider whether you and/or others in the vicinity require any protective clothing to protect against the hazards of, for example, chemicals, high/low temperature, radiation, noise, falling objects, and dangers to eyes and face. -

Page 7: Returning Products

Customers and stockists are reminded that under EC Health, Safety and Environment Law, when returning products to GESTRA they must provide information on any hazards and the precautions to be taken due to contamination residues or mechanical damage which may present a health, safety or environmental risk. -

Page 8: General Product Information

Electrical and mechanical accessories are not covered by this statement and will have to carry their own certificate of conformity in order to be assembled with GESTRA actuators. The suitability of the materials and design of the actuator type in terms of its working conditions are the responsibility of the actuator’s end user. -

Page 9: Technical Data

Technical standards and Accessories assembly according to standard NAMUR VDI/VDE 3845 applied specifications Connections to valves according to standard EN ISO 5211 Compressed air consumption for BVA300 series actuators 2.4.1 Compressed air consumption N m³/stroke BVA _ _ _ Single Acting 0.0001 0.0002... - Page 10 2.4.2 Stroke Time 2.4.2.1 Stroke Time (seconds) - Opening BVA _ _ _ Single Acting 0.15 0.25 0.35 0.40 0.60 0.85 1.25 BVA _ _ _ Single Acting 2.4.2.2 Stroke Time (seconds) - Closing BVA _ _ _ Single Acting 0.16 0.27 0.38...

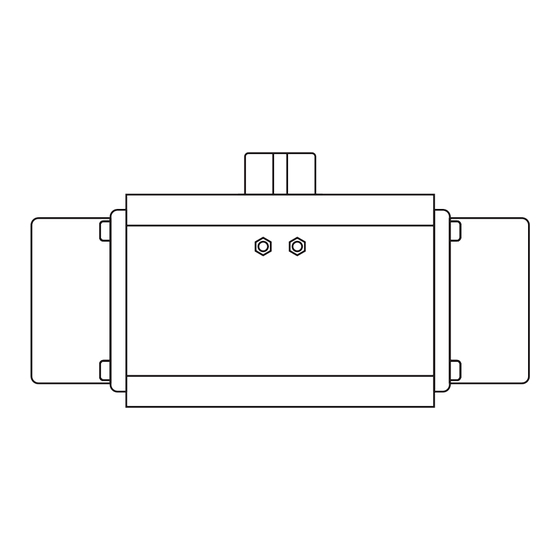

- Page 11 Fig. 1 BVA300S pneumatic actuators IM-P370-02-EN-ISS3 819763-03 CTLS...

- Page 12 2.6 Spring combination by type of actuator BVA300 pneumatic actuators use a maximum of seven identical pre-compressed springs on each rack. The quantity of springs is identified as follows: Example: BVA3_ _S14 S = springs and 14 is the total number of springs assembled in the actuator. 2.6.1 Actuator size BVA310S The actuator BVA310S uses a combination of 2, 3, or 4 springs on each rack, depending on the required spring combination, as indicated in the diagrams below.

- Page 13 Table 1 BVA300 series range BVA_ _ _S /_ _ Spring return Spring combinations Actuator BVA310S / _ Ô BVA315S /_ _ Ô BVA320S /_ _ Ô BVA325S /_ _ Ô BVA330S /_ _ Ô BVA335S /_ _ Ô BVA340S /_ _ Ô...

-

Page 14: Installation

3 Installation Note: Before actioning any installation observe the 'Safety information' in Section 1. Referring to the Installation and Maintenance Instructions, body markings and Technical Information sheet, check that the product is suitable for the intended installation: The handling and transportation of actuators must be carried out with extreme caution and using the necessary and appropriate means depending on their size and weight in order to avoid risks to the operators handling them. -

Page 15: Commissioning 4

It is advisable to operate the actuator twice before fully tightening the coupling bolts . The BVA300 series pneumatic actuators are provided with bi-directional pinion travel stops. Side located stops allow a full ±5º travel adjustment between 85º and 95º. -

Page 16: Spare Parts And Maintenance

5 Spare parts and maintenance Note: Before actioning any maintenance programme observe the 'Safety information' in Section 1. Any parts replacement must be implemented with original GESTRA spare parts, or any warranty implied or expressed is null and void. The manufacturer will not be responsible for any actuator malfunction, if original GESTRA parts have not been used. - Page 17 Note: all the spares mentioned above are sold together in one spare part kit. Example: 1 - BVA300 series maintenance kit with 'O' rings in NBR for a GESTRA BVA320S/08 pneumatic actuator.

-

Page 18: Preventitive Maintenance

As soon as this happens, proceed with the disassembly of the actuator and replacement of all the 'O' rings, bushings, slide guides and washers as listed in the spare parts. Exploded view of the spring set Fig. 5 BVA300 series shown 819763-02 IM-P370-02-EN-ISS3 CTLS... -

Page 19: Disassembly And Reassembly

Important: Carefully examine the inside of the cylinder. If everything is in good condition, continue to replace the new 'O' rings, bushings, slide guides and washers included in the GESTRA BVA300 series maintenance kit before reassembling the actuator - see Section 5.4.3. -

Page 20: Fault Finding

6 Fault finding Before dismantling the actuator, consult the instructions given below: 6.1 Actuator with solenoid valve A If the actuator does not function check that: The valve is free to rotate. The actuator is of the correct size. The correct voltage is supplied to the solenoid (the valve coil is tagged with the correct voltage). Sufficient compressed air is available at the solenoid valve. - Page 21 With spring return actuators, check for misplaced or broken springs. If springs are broken, check the body for scoring. If the actuator and valve are free, reassemble the actuator and retest. If the unit still fails to operate, consult GESTRA. IM-P370-02-EN-ISS3 819763-03...

- Page 22 819763-02 IM-P370-02-EN-ISS3 CTLS...

- Page 23 IM-P370-02-EN-ISS3 819763-03 CTLS...

- Page 24 Agencies all over the world: www.gestra.com GESTRA AG Münchener Straße 77 28215 Bremen Deutschland Telefon +49 421 3503-0 Telefax +49 421 3503-393 E-mail info@de.gestra.com Web www.gestra.com 819763-02/06-2024sxsmp · GESTRA AG · Bremen · Printed in Germany...

Need help?

Do you have a question about the BVA300 Series and is the answer not in the manual?

Questions and answers