Table of Contents

Advertisement

Quick Links

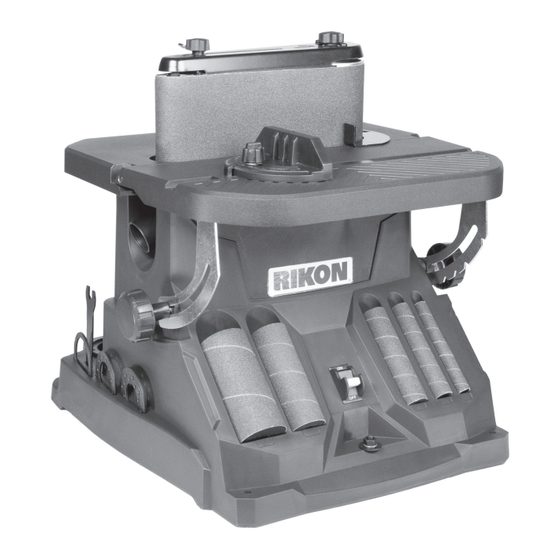

50-310

Oscillating Belt / Spindle Sander

Operator's Manual

Record the serial number and date of purchase in your manual for future reference.

The serial number can be found on the specification label on the rear of your machine.

Serial Number: _________________________

Date of purchase: _________________________

For technical support, email techsupport@rikontools.com - For parts questions, email parts@rikontools.com

www.rikontools.com

50-310M1

Advertisement

Table of Contents

Summary of Contents for Rikon Power Tools 50-310

- Page 1 50-310 Oscillating Belt / Spindle Sander Operator’s Manual Record the serial number and date of purchase in your manual for future reference. The serial number can be found on the specification label on the rear of your machine. Serial Number: _________________________ Date of purchase: _________________________ For technical support, email techsupport@rikontools.com - For parts questions, email parts@rikontools.com...

- Page 2 Troubleshooting Parts Diagrams & Parts Lists 15-17 Wiring Diagram Accessories Notes Warranty SPECIFICATIONS - 50-310 Motor 1/2 HP, 4 A, 120V, 60Hz, 10,000 RPM Spindle Speed (no load) 2,000 RPM Table Size (LxW) 16” x 15-3/4” (405mm x 400mm) Spindle Length x Diameter 4-1/2”...

-

Page 3: Safety Instructions

SAFETY INSTRUCTIONS IMPORTANT! Safety is the single most important consideration in the operation of this equipment. The following instructions must be followed at all times. Failure to follow all instructions listed below may result in electric shock, fire, and/or serious personal injury. There are certain applications for which this tool was designed. - Page 4 SAFETY INSTRUCTIONS 12. KEEP PROTECTIVE GUARDS IN PLACE AND IN 25. ALWAYS WEAR A DUST MASK TO PREVENT WORKING ORDER. INHALING DANGEROUS DUST OR AIRBORNE PARTICLES, including wood dust, crystalline silica dust 13. AVOID ACCIDENTAL STARTING. Make sure that and asbestos dust. Direct particles away from face and the power switch is in the “OFF”...

-

Page 5: Electrical Safety

SAFETY INSTRUCTIONS EXTENSION CORDS ELECTRICAL SAFETY THE USE OF AN EXTENSION CORD THIS TOOL MUST BE GROUNDED WITH THIS MACHINE IS NOT RECOMMENDED. For WHILE IN USE TO PROTECT THE OPERATOR FROM best power and safety, plug the machine directly into a ELECTRIC SHOCK. - Page 6 SAFETY INSTRUCTIONS SPECIFIC SAFETY INSTRUCTIONS FOR SANDERS This machine is intended for the surfacing of natural, solid woods and composite materials. Any other use not as specified, including modification of the machine or use of parts not tested and approved by the equipment manufacturer can cause unforeseen damage, and invalidate the warranty.

-

Page 7: Contents Of Package

CONTENTS OF PACKAGE CONTENTS OF PACKAGE A Sanding Base B Table Bracket I Wrench 10mm & 13mm C Rubber Sanding Drums (4): 3/4”, 1”, 1-1/2”, 2” J Miter Gauge D Sanding Sleeves (5): 1/2”, 3/4”, 1”, 1-1/2”, 2” K Spindle Nut & Washer M8 E Table Inserts (5): 1/2”, 3/4, 1”, 1-1/2”, 2”... -

Page 8: Getting To Know Your Machine

2-Sanders-in-1. - Use the various diameter vertical spindles for sand- The 50-310 Sander’s table can be tilted from 0° to 45° ing those hard to reach curves and holes that are in for bevel sanding with the spindle or belt. - Page 9 ASSEMBLY INSTALL SPINDLE SANDER DRUM & PAPER The sander is supplied with 1 universal spindle (drive shaft) that the 4 rubber Sanding Drums slide onto TABLE BRACKET and then hold sandpaper sleeves of various grits for sanding. NOTE: The 1/2” sanding sleeve installs directly onto the machine’s 1/2”...

- Page 10 ASSEMBLY INSTALL BELT SANDER ATTACHMENT To configure the machine for Belt sanding, you must first remove any installed Spindle sanding components as referenced in the directions on page 9 and below. 1. UNPLUG THE MACHINE 2. Remove the Spindle Nut, Lock Washer and Washer, to remove the Sanding Sleeve and Sanding Drum from the machine’s Drive Shaft.

-

Page 11: On/Off Switch

FIG. 10 USING THE OSCILLATING SPINDLE SANDER 1. Start the machine and wait until the motor has build up to full speed. The 50-310 Sander features a spindle that automatically oscillates (moves up and SPINDLE down) 16mm (5/8”). This movement ensures that OSCILLATES the spindle’s sandpaper gets maximum sanding use... -

Page 12: Belt Tension Lever

USING THE OSCILLATING BELT SANDER Start the machine and wait until the motor has build up to full speed. The 50-310 Sander features a 2” x 4” Sanding Belt that automatically oscillates (moves up and down) 16mm (5/8”). This movement ensures that the Belt’s sandpaper gets maximum... -

Page 13: Using The Miter Gauge

OPERATION TILTING THE TABLE FOR BEVEL SANDING The work table on the 50-310 can tilt from 0 to 45 degrees. The curved Table Adjustment Support has detents at 0, 15, 22.5, 30 and 45 degrees. This allows you to sand or add bevels to your work. FIG. 16. -

Page 14: Maintenance Required

MAINTENANCE Turn the power switch “OFF” and disconnect the plug from the outlet prior to adjusting or maintaining the sander. DO NOT attempt to repair or maintain the electrical components of the motor. Take the sander to a qualified service technician for this type of maintenance. MAINTENANCE REQUIRED FREQUENCY Check the power cord and plug for any damage. -

Page 15: Parts Diagram

PARTS DIAGRAM OSCILLATING BELT/SPINDLE SANDER 50-310 7 7 0 0 7 7 8 8 7 7 5 5 3 3 1 1 8 8 8 8 6 6 8 8 8 8 2 2 9 9 0 0 8 8 5 5... - Page 16 PARTS LIST - 50-310 PART NO. KEY NO. QTY. DESCRIPTION Base P50-310-1 Baseplate P50-310-2 P50-310-3 Fixed work table P50-310-4 Movable work table P50-310-5 Pin shaft Phillips screw, spring washer, flat washer assembly M5x12 P50-320-15 Rubber washer 282x110x1.5mm P50-310-7 P50-310-8 Dust port...

- Page 17 PARTS LIST - 50-310 KEY NO. PART NO. QTY. DESCRIPTION P50-320-50 0.75” (19mm) Sanding sleeve 80# P50-320-47 1” (26mm) Sanding sleeve 80# P50-320-42 Flat washer 8 Nut M8 P50-320-43 Wrench P50-320-58 P50-310-56 Power cord with plug 3x18x1.8m P50-320-59 Spring Shaft sleeve 1...

-

Page 18: Wiring Diagram

WIRING DIAGRAM This machine must be grounded. Replacement of the power supply cable should only be done by a qualified electrician. See page 5 for additional electrical information. RED RECTIFIER BRIDGE BLACK � LIVE BLACK FUSE MOTOR NUTRAL WHITE WHITE BLACK BLACK EARTH... -

Page 19: Warranty

® 5-Year Limited Warranty RIKON Power Tools Inc. (“Seller”) warrants to only the original retail consumer/purchaser of our products that each product be free from defects in materials and workmanship for a period of five (5) years from the date the product was purchased at retail. This warranty may not be transferred. - Page 20 50-310 For more information: 25 Commerce Way, Suite 4 North Andover, MA 01845 877-884-5167 / 978-528-5380 techsupport@rikontools.com Link to RIKON Website www.rikontools.com 50-310M1...

Need help?

Do you have a question about the 50-310 and is the answer not in the manual?

Questions and answers