Table of Contents

Advertisement

Quick Links

P815 OWNER'S MANUAL CONTENTS

1. INTRODUCTION ................................................................................ 2

2. SAFETY PRECAUTIONS ..................................................................

3. LIST OF PARTS .................................................................................

4. ASSEMBLE THE PRODUCT .............................................................

STEP 1 Cover Support Plate and the Connector Installation ................

STEP 2 Weight Stack Installation ......................................................... 13

STEP 3 Press Handle Installation ......................................................... 17

STEP 4 Cable Installation .................................................................... 19

STEP 5 Seat Back and Seat Bottom Installation .................................. 21

STEP 6 Apply the Weight Stack Sticker ................................................ 22

STEP 7 Install the Front and Rear Covers ............................................... 23

STEP 8 Install Plastic Cover .................................................................. 24

STEP 9 Install Cap Nut ......................................................................... 25

STEP 10 Secure the Product ...............................................................

STEP 11 Level the Product ..................................................................

STEP 12 Cable Adjustment .................................................................. 28

STEP 13 Stack Fork Inspections .......................................................... 29

STEP 14 Unit Inspection ......................................................................

5. OPERATION INSTRUCTION ............................................................ 31

OPERATION Safety Operating Area ..................................................... 31

OPERATION Exercising Instructions ..................................................... 32

6. MAINTENANCE ................................................................................ 34

MAINTENANCE Safety Precautions .................................................... 34

MAINTENANCE Guide Rod Cleaning and Lubricating ......................... 35

MAINTENANCE Schedule .................................................................... 36

MAINTENANCE Task List .................................................................... 37

MAINTENANCE One-Year Maintenance Log ....................................... 38

7. CONSIGNES DE SÉCURITÉ IMPORTANTES ................................. 39

8. APPENDIXES ................................................................................... 40

APPENDIXES Exploded Diagram ........................................................ 40

Disclaimer

The information in this user manual is subject to change without prior

notice.

Sports Art Industrial Co., Ltd. makes no representation or warranty of any

kind, express or implied, regarding the marketability of this manual, the

suitability for a special purpose, or any other matters.

SportsArt Industrial Co., Ltd. accepts no responsibility for any errors in

this manual, or any damages incurred directly, indirectly, accidently, or

continually from the modification, display, or other use of this manual.

*We reserve the right to revise this manual at any time without notice.

3

4

9

9

26

27

30

Advertisement

Table of Contents

Summary of Contents for SportsArt Fitness P815

-

Page 1: Table Of Contents

P815 OWNER’S MANUAL CONTENTS 1. INTRODUCTION ................2 2. SAFETY PRECAUTIONS ..............3. LIST OF PARTS ................. 4. ASSEMBLE THE PRODUCT ............. STEP 1 Cover Support Plate and the Connector Installation ....STEP 2 Weight Stack Installation ............13 STEP 3 Press Handle Installation ............17 STEP 4 Cable Installation .............. -

Page 2: Introduction

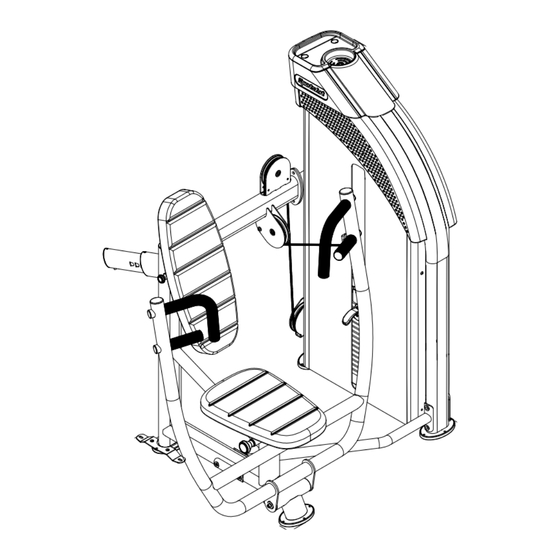

1. INTRODUCTION Congratulations on the purchase of a high quality SportsArt product, the P815 Dependent Chest Press machine. Constructed of high quality materials and designed for years of reliable performance, this product was made for full commercial use. Before this product is assembled or operated, we recommend that you familiarize yourself with this manual. -

Page 3: Safety Precautions

2. SAFETY PRECAUTIONS This product was designed and built for optimum safety. However certain precau- tions apply during the use of this product. Please note the following safety precau- tions: • Please read the entire manual before assembly and operation. Make sure the product is installed and operated as instructed in this manual. -

Page 4: List Of Parts

3. LIST OF PARTS Box A A3 A4 A9-2 A9-1... - Page 5 Box B Box C + Box D...

- Page 6 Box A - Main Frame Components Name Qty. Name Qty. Left/right perforated Cover support plate A boards Left/right side cover Top cover Main frame Anchor bracket Cover support plate B-2 Rear cover Cover support plate B-1 Front cover Front cover A Bracket Stack fork Bracket...

- Page 7 Components in the Hardware Kit Name Qty. Specification Notes Screw socket SGN-07 batch Mushroom top inner hex screw M6*P1.0*L12 Mushroom top Phillips screw M5*L15 Mushroom top Phillips screw M5*0.8*L8 Round head Phillips screw M6*P1.0*L12 Round head inner hex screw M6*P1.0*20 Bushing D21.5*10.5 Hex head screw...

- Page 8 Components on the Product Name Specification Notes Hex head ØD10*L23 Axle Washer D16*d10.2*t1.0 Flat washer D16*d6.3*t2 Nylon hex lock nut Round head inner hex screw M8*P1.25*L20 Spring washer Flat washer D26*d8.5*t2 Axle E D20*L197 Mushroom top inner hex screw M6*P1.0*L12 Spring washer Flat washer D20*d6.3*t1.5...

-

Page 9: Assemble The Product

4. ASSEMBLE THE PRODUCT Follow instructions below to assemble this product. Note that in this manual the words “left” and “right” are used to refer to the product and its parts. As such, these designations correspond to the “left” and “right” sides of a person in position to exercise on this product. - Page 10 STEP 1 Cover Support Plate & Connector Installation (CONT.) (a) Insert the screw sockets (10) into place in the main frame (A3) as shown, and then use screws (11) (12) to secure the brackets (A16) (A17) in place. (Note: The bracket (A16) must be secured to the top of maim frame as shown.)

- Page 11 STEP 1 Cover Support Plate & Connector Installation (CONT.) (b) Secure the plate slots (A10) to the straight frame of the weight stack tower (A3) with the screws (13) and then cover the cap nuts (60). The plate slots (A4, A5) are secured to the left and right side of the curved frame, re- spectively.

- Page 12 STEP 1 Cover Support Plate & Connector Installation (CONT.) (c) Use screws (17) to secure the connecting board A (A27) to the connector B (A24) and the main frame (A3) in area A. Use screws (17) to secure the connecting board (A26) to the connector B (A24) and the seat frame (A22) in area B.

-

Page 13: Step 2 Weight Stack Installation

STEP 2 Weight Stack Installation... - Page 14 STEP 2 Weight Stack Installation (CONT.) (a) Hold the upper stack carriage set (33), and then cut the zip tie. Gently lower the upper stack carriage set (33) into place as shown. (b) Remove screws (34). Set the guide rod (35) downward into place as shown.

- Page 15 STEP 2 Weight Stack Installation (Continued) (d) Insert the weight stack rod (A8) into the central mounting position of the upper stack carriage set (33) and the round weight plate (A18) and then use screws (36) to secure the stack fork (A7) into place of the round weight plate (A18) as shown.

- Page 16 STEP 2 Weight Stack Installation (CONT.) (f) Tilt the guide rods (35) back into place and then lift them up to their mounting position, and then secure the assembly with screws (34).

-

Page 17: Step 3 Press Handle Installation

STEP 3 Press handle Installation... - Page 18 STEP 3 Press handle Installation (CONT.) (a) Loosen and remove screws (30) (31) from the press handle (A23) as shown. (b) Place the press handle (A23) on the top of the seat frame (A22) and align holes and then secure with screws (31) as shown. (Note: The stopper’s direction of the press handle (A23) should face inside.)

-

Page 19: Step 4 Cable Installation

STEP 4 Cable Installation (a) Insert the cable nut as indicated by the arrows onto the weight stack rod (A8) at least 15-20mm deep as shown. (b) Loosen and remove screws (32) and the pulley from the connector A (A25) in area A and screws (32) (37) from the connector A (A25) in area B as shown. - Page 20 STEP 4 Cable Installation (CONT.) (c) Loosen the cable and thread the cable as indicated by the arrows through the top of the pulley of the connector A (A25) in area A and secure the pulley back into to place with screws (32) and then thread the cable under the pulley of the connector A (A25) and secure screws (32) (37) in area B.

-

Page 21: Step 5 Seat Back And Seat Bottom Installation

STEP 5 Seat Back and Seat Bottom Installation (a) Loosen and remove screws (38) (39) from the seat back (A20), the seat bottom (A21) and the seat frame (A22) as shown. (b) Use screws (39) to secure the seat back plate and the seat bottom plate to the seat frame (A22) as shown. -

Page 22: Step 6 Apply The Weight Stack Sticker

STEP 6 Apply the Weight Stack Sticker Note: Before applying weight plate stickers, please wipe the area clean, and clean your hands before proceeding to the next step. (a) Align and tape the cardboard to the upper left corner of the weight plate (A30). -

Page 23: Step 7 Install The Front And Rear Covers

STEP 7 Install the front and rear covers (a) Install the square snap bushings (10) to the anchor brackets of shroud (square hole) (A9-1). Secure the anchor brackets of shroud (square hole) (A9-1) with the square snap bushings (10) to the front and back of the up- per crossmember assembly of weight stack tower (A3) with screws (11). -

Page 24: Step 8 Install Plastic Cover

STEP 8 Install plastic cover (a) Install the square snap bushing (10) and fastener (59) to the anchor bracket (A12) and remove the screws (47) on the main frame. Secure the anchor bracket (A12) to the main frame with the screws (47). (b) Secure the left/right perforated boards (A1) to the main frame with the screws (21). -

Page 25: Step 9 Install Cap Nut

STEP 9 Install cap Install the cap nuts to the corresponding positions according to the following numbers. *The cap nuts in the following table are for reference only. The provided cap nuts will depend upon the needs of the different devices. GBA-P019 GBA-P024 GBA-P014... -

Page 26: Step 10 Secure The Product

STEP 10 Secure the Product (a) Remove screws (40) from the floor fixing bracket (A19). (b) Insert the U clip (A20) onto the machine (Make sure the U clip with the correct side downward as shown below), and then secure the floor fixing bracket (A19) with screws (40). -

Page 27: Step 11 Level The Product

STEP 11 Level the Product If the product is installed on an uneven surface to cause the instability of the product, place the support spacer under the foot pad to make sure its stabil- ity. (A few support spacers are provided in the packaging of this product.) -

Page 28: Step 12 Cable Adjustment

STEP 12 Cable Adjustment * Insert the stack fork into the gap under the lowest weight plate, and then adjust the large nut at area C. Adjust until the upper stack carriage set moves slightly. To adjust the cable, first insert the (Z) rod and loosen the (Y) nut, and then adjust the (X) nut. -

Page 29: Step 13 Stack Fork Inspections

STEP 13 Stack Fork Inspections * Please follow operating instructions on the product sticker to test operation and confirm that the equipment is working properly. * Insert the stack fork to make sure that every weight plate can be engaged easily. -

Page 30: Step 14 Unit Inspection

STEP 14 Unit Inspection After completing the assembly or regular maintenance, please follow instruc- tions (a) through (c) below to inspect the unit. If the unit is disassembled or has been damaged in any way, it might cause injuries or cause the unit to fail. -

Page 31: Operation Instruction

5. OPERATION THE PRODUCT OPERATION Safety Operating Area (a) Make sure operate the unit in safety area as shown. Do not allow people to be near this area when operating. (b) Noise emission under load is higher than without load. (c) Over exercising or improper workout position may result in serious injury. -

Page 32: Operation Exercising Instructions

OPERATION Exercising Instructions (a) Select the appropriate weight plates according to your recommended exercise level. (b) Adjust the seat height and seat back to the most comfortable position and make sure the knob is engaged to secure the position. (c) Perform the exercise in a controlled manner. Inhale when pushing up against resistance and exhale when returning to original position. - Page 33 OPERATION Exercising Instructions (CONT.) (a) Seat back height positioning can be adjusted. Simply, put out the related knob, make the adjustment, and release the knob to secure the desired position. (b) Seat bottom height positioning can be adjusted. Simply, put out the related knob, make the adjustment, and release the knob to secure the desired position.

-

Page 34: Maintenance

6. MAINTENANCE This section covers maintenance topics and includes a maintenance schedule, task list, and log. MAINTENANCE Safety Precautions ● Please follow standard safety precautions when servicing this product. ● Do NOT use a water damp towel to clean the product and do perform the following maintenances. -

Page 35: Maintenance Guide Rod Cleaning And Lubricating

MAINTENANCE Guide Rod Cleaning and Lubricating 1. Apply lubricant to the guide rods every week. Procedure: (a) Put some lubricant on a clean, lint-free cloth. Rub the lubricated cloth on the guide rods. (b) Load the upper stack carriage set. Exercise to test operation. (c) Repeat steps (a) and (b) 2-3 times. -

Page 36: Maintenance Schedule

MAINTENANCE Schedule If there is a need for maintenance of components, please visit the SportsArt website. cleaning requirements 1.directive 93/42/CEE 2.directive biocide 98/8/CEE The disinfectant has to be in compliance with Medical Device Directive 93/42/EEC (MDD) and Biocidal Products Directive 98/8/EC (BPD). It is suited for sensitive synthetic surfaces such as synthetic leather, poly- carbonate (PC), acrylic glass and polysulfone, and for the keyboards and control panels. -

Page 37: Maintenance Task List

MAINTENANCE Task List Like cars, fitness products require maintenance. Regular maintenance ex- tends product life, and failure to maintain products can void the manufac- turer’s warranty. Copy the maintenance log sheet, and record maintenance work for each fitness product. Daily tasks 1. -

Page 38: Maintenance One-Year Maintenance Log

MAINTENANCE One-Year Maintenance Log Facility:_______________________ Supervisor:____________________ Product model number:__________ Serial number:_________________ Start date: ____________________ End date:_____________________ Daily Tasks Weeks 1-7 Weeks 8-14 Weeks 15-21 Week 22-28 Completed Daily Tasks Week 29-35 Week 36-42 Week 43-49 Week 50-52 Completed Weekly Tasks Weeks 1-7 Weeks 8-14 Weeks 15-21 Weeks 22-28... -

Page 39: Consignes De Sécurité Importantes

7. CONSIGNES DE SÉCURITÉ IMPORTANTES Le produit SportsArt a été conçu et fabriqué afin d’assurer une sécurité optimale. Cependant certaines précautions s’appliquent chaque fois que vous utilisez votre produit. • Lisez entièrement le manuel avant l’assemblage et l’utilisation. Veuillez aussi noter les consignes de sécurité... -

Page 40: Appendixes

8. APPENDIXES APPENDIXES Optional accessories Top weight(100 kg = (5KG × 1 pcs) + (5KG × 7 pcs) + (7.5KG × 8 pcs)) - Page 41 APPENDIXES (CONT.) Select a resistance level that enables you to perform the movement correctly. Adjust seat height so that handles are at www.sportsart tness.com chest level. CAUTION Push handles forward. Do not lock arms. Do not use this machine if you are unfamiliar Avoid excessive arching of the back when or do not know how to operate it.

- Page 42 Your Authorized Distributor...

Need help?

Do you have a question about the P815 and is the answer not in the manual?

Questions and answers