Summary of Contents for Atlanta Attachment Company 1331B

- Page 1 1331B Models 1331BC 1331BD Revision 1 Created July 9, 2024(wr) Technical Manual & Part Lists 362 Industrial Park Drive Lawrenceville, GA 30046 +1 (770-963) 7369 www.atlatt.com...

- Page 3 The materials contained herein are confidential and proprietary information of Atlanta Attachment Company. In addition to any confidentiality and non-disclosure obligations that currently exist between you and Atlanta Attachment Company, your use of these materials serves as an acknowledgment of the confidential and proprietary nature of these materials and your duty not to make any unauthorized use or disclosure of these materials.

-

Page 4: Table Of Contents

Contents CONFIDENTIAL AND PROPRIETARY INFORMATION ............0 SAFETY INSTRUCTION ......................0 Important Notices............................3 Maintenance ..............................5 INSTALLATION ........................8 1.1......................8 ARTS AND OMPONENTS 1.2........................9 ECHNICAL 1.3........................... 10 CCESSORIES 1.4..........................11 OOTPRINT 1.5....................11 ACHINE DENTIFICATION ABEL... - Page 5 2.3.3. Reloading the Staplers....................23 ............................. 25 AINTENANCE 2.3.4. General Safety Instructions ..................... 25 2.3.5. Preventive Maintenance 8 Hrs..................26 SERVICE ..........................27 3.1....................27 OCKOUT AGOUT ROGRAM 3.2......................28 PERATION EQUENCE 3.3...................... 29 ECHANICAL DJUSTMENTS 3.3.1.

- Page 6 3.7.6. General Safety Instructions ..................... 49 3.7.7. Preventive Maintenance 40 Hrs..................50 3.7.8. Preventive Maintenance 960 Hrs..................51 3.8........................52 ROUBLESHOOTING 3.8.6. Screen Messages ......................52 ASSEMBLY DRAWINGS & PARTS LISTS ................55 11331B S/A FOUNDATION STRETCHER ................56 11331BC S/A FOUNDATION STRETCHER ................

- Page 7 1331563 COVER STRETCH ROLLER ASSEMBLY (BD) ............108 1331565 SQUARE TABLE LIFT ASSEMBLY (BD) ............... 110 1331-PD2 REV 8 PNEUMATIC DIAGRAM (B, BC & BD MODELS) ........112 1331-WD REV 6 WIRING DIAGRAM (B & BD MODELS) ............. 113 1331-WD REV 8 (GATEWAY) WIRING DIAGRAM (BC MODEL) .......... 114 STATEMENT OF WARRANTYMANUFACTURED PRODUCTS ...........

-

Page 8: Safety Instruction

Mandatory Information All persons operating and/or working on the Workstation 1331B&BD, should read and understand all parts of the Safety Instructions. This applies, in particular, for persons who only operate and/or work on the unit occasionally (e.g. for maintenance and repair). Persons who have difficulty reading must receive particularly thorough instruction. - Page 9 Safety The personnel's awareness of the dangers and compliance with the safety regulations should be checked at irregular intervals. Choice and Qualification of Personnel Ensure that work on the machine is only carried out by reliable persons who have been appropriately trained for such work - either within the company, by our field staff or at our office - and who have not only been duly appointed and authorized but are also fully familiar with the local regulations.

- Page 10 Safety shift. Damage found shall be immediately remedied by a duly authorized person before resuming operation of machine. The machine should only be operated when in perfect working order and when all protective mechanisms and safety equipment, such as detachable protective mechanisms, emergency STOP systems, etc.

-

Page 11: Important Notices

Safety Important Notices Reporting and Fighting Fires Read the instructions posted in the factory with regard to reporting fires and the emergency exits. Make sure you know exactly where the fire extinguishers and sprinkler systems are located and how they are operated. Pass on the corresponding information to the firemen when they arrive. - Page 12 The packaging and machine must immediately be examined for signs of damage in transit. Such damage must be reported to the shipper/transporter within the applicable time limits. Contact Atlanta Attachment Company and/or your transport insurer immediately, if signs of damage are visible. Never operate a damaged machine.

-

Page 13: Maintenance

Safety Local Regulations Particular attention must be paid to local and statutory regulations, etc. when installing machines and the plant (e.g. with regard to the specified escape routes). Note the safety zones in relation to adjacent machines. Maintenance General Safety Instructions The machine shall be switched off, come to a standstill, and be secured so that it cannot be switched on again inadvertently before starting any maintenance work whatsoever. - Page 14 Safety rating. The machine must be switched off immediately if a fault develops in the electrical power supply. The electrical equipment of our machines must be checked at regular intervals and any defects found must be remedied immediately. If it is necessary to carry out work on live parts, a second person should be on hand to operate the emergency OFF switch or master switch with voltage release in the event of an emergency.

- Page 15 Safety • Follow daily and weekly checklists, making sure hoses are tightly secured and bolts are tightened. • ALWAYS watch and avoid holes or deep depressions. ALWAYS wear adequate eye protection when servicing the hydraulic system and battery. • NEVER operate a poorly maintained machine. •...

-

Page 16: Installation

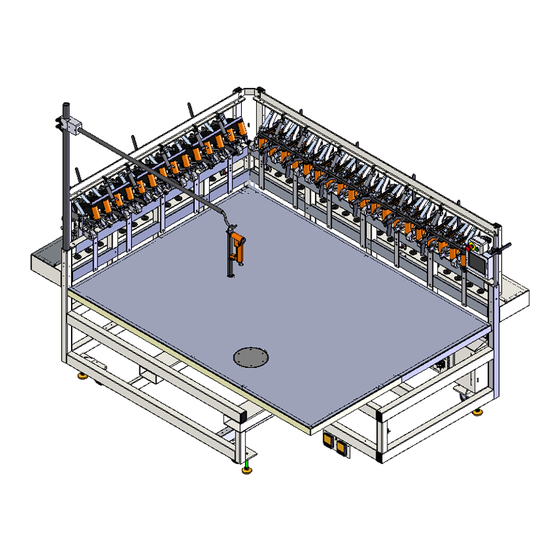

Installation INSTALLATION NOTE: It is important that the machine technician read this manual and is familiar with all the functions and safety concerns of the unit before Installing and operating. 1.1. Parts and Components Emergency Stop Feed Stops Start Button 10 Forklift Channels Touch Screen Panel 11 Leveling Bolts... -

Page 17: Technical Data

Installation 1.2. Technical Data... -

Page 18: Accessories

Installation 1.3. Accessories... -

Page 19: Footprint

Installation 1.4. Footprint Machine footprint 120 x 120 inches (304 x 304 cm) Leave enough free space around to be able to open all doors and have access for maintenance. 1.5. Machine Identification Label Machine identification is located on top behind the table. Its contents are the machine class, technical data and the Serial Number. -

Page 20: Leveling

Installation 1.6.2. Leveling Level and adjust the machine height using the four leveling bolts (11) at the base of the machine. 1.6.3. Electrical Have a qualified electrician connect 208-230 volts, single-phase, 50/60Hz electrical power protected by a 20Amp circuit breaker to the machine. -

Page 21: Electric Eyes

Installation 1.6.8. Electric Eyes Turn on power. Examine all electric eyes and ensure they are all adjusted and functioning properly. See service section for instructions 1.6.9. Lift Table Pedal Step on the table up / table down pedals and verify proper function. -

Page 22: Operation

Operation Instructions OPERATION NOTE: It is important that the machine operator read this manual and is familiar with all the functions and safety concerns of the unit before operating. 2.1. Individual Components Main 1.- Control Panel 4.- Manual Staple 2.- Table Lift Pedals 5.- Automatic Staples 3.- Rotation Plate Pedal 6.- Proximity Eye... -

Page 23: Control Panel

Operation Instructions 2.1.1. Control Panel The Control Panel allows the operator to start and stop the automatic function of the machine, shut off power to the machine in the event of an emergency. Caution: Unlocking the button with the Power “ON” engaged will turn on power to the machine. -

Page 24: Manual Staple

Operation Instructions 2.1.4. Manual Staple It is used to preset manually the corners of the cover or the dustcover to the wood. 2.1.5. Automatic Staples They are the one that apply the staples on the automatic process. 2.1.6. Proximity Eyes There are 3 located on the edges of the machine. -

Page 25: Touch-Screen

Operation Instructions 2.2. Touch-Screen 2.2.1. General Operation Twist the Emergency Stop Red button “B” to return to its normal position. Turn the machine “ON” by pressing the green button “A” on the box just above the touch screen. The machine will first display the language choices and after several seconds its show the “MAIN READY”... -

Page 26: Navigation

Operation Instructions 2. Navigation The row of buttons across the bottom or top of the screen are called Standard buttons. They will appear or change based on the needs of the current screen RESET: Always brings the machine back to its original power up state. LANGUAGE: Return to the language screen. -

Page 27: Available Menus

Operation Instructions 2.2.2. Available Menus The following is a summary of the different screens and their functions available for the Operator. 1. READY SEMI-AUTOMATIC. This screen is the main operating screen. The entire cycle of clamping, table lifting, material tensioning, stapling and rotary plate lifting are sequenced automatically by the computer 2. -

Page 28: Set Up Screen

Operation Instructions 2.2.3. Set up Screen From the Semiautomatic Screen, the operator may adjust various machine parameters by tapping the button [SET UP]. Some adjustments may be restricted and require a security password to allow changes. 1. Reset Staple Left Returns the remaining staple count to the maximum value. -

Page 29: Operation Description

Operation Instructions 2.3. Operation Description The machine has been designed to perform two main functions: A. Tension the sides of the Foundation and staple it to the wood border. B. Attach the dust cover using staples to the Foundation wooden frame. These operations may be performed individually or sequentially depending on the program selected. -

Page 30: Dust Cover Stapling Cycle

Operation Instructions 2.3.2. Dust Cover Stapling Cycle To use this cycle, the option [Enable Dustcover] in the Advanced Options Screen (Screen #8) must be in position 1. When activated the touch screen displays READY-SEMIAUTO Mode ARMED and that the “CURRENT SIDE” is displaying a “1” A. -

Page 31: Reloading The Staplers

Operation Instructions F. While the machine is performing “SIDE 3”, begin securing the dust guard corners to the wooden frame using the manual stapler. Try to align and stretch the dust guard as much as possible to prevent tangling in the machine and having insufficient area to staple. - Page 32 Operation Instructions Squeeze the locking lever on the Stapler magazine and open the stapler compartment. Introduce a new strip of staples into all of the staplers. Depending on the usage, the staplers on the ends may have sufficient staples. Add more staples as required. NOTE: The machine uses the following types of staples: # Part Description...

-

Page 33: Maintenance

Operation Instructions Maintenance It is important that the machine operator read this manual and is familiar with all the functions and safety concerns of the unit before operating. 2.3.4. General Safety Instructions Maintenance should only be performed by trained, qualified personnel. Before performing any maintenance or repair work, switch off the electrical, pneumatic, etc. -

Page 34: Preventive Maintenance 8 Hrs

Operation Instructions 2.3.5. Preventive Maintenance 8 Hrs. Preventive Maintenance 8 Hrs 1331 Series Required Materials Model: Oilcan Serial #: Stapler Operation: Clean cloth Compressed air Serial #: Before starting the day's shift with "The Machine Off" Add one drop of lubricant in the stapler magazine A prior to the start of each work shift. -

Page 35: Service

Service Instructions SERVICE NOTE: Maintenance should only be performed by trained, qualified personnel. 3.1. Lockout/Tagout Program "Lockout/Tagout (LOTO)" refers to specific practices and procedures to safeguard employees from the unexpected energization or startup of machinery and equipment, or the release of hazardous energy during service or maintenance activities. -

Page 36: Operation Sequence

Service Instructions 3.2. Operation Sequence. A. The operator introduces a Foundation into the machine until the load sensors “A” on the sides of the machine are activated. B. The tension wheels lower, the clamps lower, and the table begins the raising sequence. C. -

Page 37: Mechanical Adjustments

Service Instructions 3.3. Mechanical Adjustments 3.3.1. Table Column Lift Rule: The square table column has a lift height of 6 inches (15.24 cm). With time and usage, there may be wearing of the interior Teflon guides that support it and this may present problems at the moment of stretching or stapling the Foundation material. -

Page 38: Rotation

Service Instructions Adjustment: Readjust all of the motion components of the tension wheels. Loosen the bolts on cylinders “A” and adjust the heights to comply with the rule. 2. Rotation 3.3.the material sufficiently to maintain adequate tension. Adjustment: Adjust the stop rings on the tension wheel cylinders to measure 2.5 inches (6.35mm) as shown. -

Page 39: Position

Service Instructions Adjustment: Introduce a Foundation frame into the machine and raise it until the distance “A” is 1/2 inch. (12.7mm) With the staplers located in their firing position, loosen the bolts on the activation cylinder shafts “D” and adjust the shaft until the exterior staplers rest on the wooden frame of the Foundation. -

Page 40: Pneumatic

Service Instructions 3.4. Pneumatic NOTE: All maintenance should be performed by a qualified service technician. 3.4.1. Air Maintenance Unit FRL The FR (Filter Regulator).unit assembly is located behind the table. It has 3 components the Pressure Relief Valve (A) , the Pressure Regulator (B) and the Air Filters (C). -

Page 41: Solenoid Valve Stacking Manifold

Service Instructions 3.4.2. Solenoid Valve Stacking Manifold They are located inside the control box Control System voltage 24DC Each valve can be activated manually by pushing the blue bottom. Red light means the valve is energized 3.4.3. Pressures Adjustments The machine has four pressure regulators. 1. -

Page 42: Electrical

Service Instructions 3.5. Electrical NOTE: All maintenance should be performed by a qualified service technician. 3.5.1. Ground This unit need to be connected to ground (earth) for several reasons. In main powered equipment, exposed metal parts are connected to ground to prevent user contact with dangerous voltage when electrical insulation fails. -

Page 43: Settings

Service Instructions 3.5.5 Settings Set the output function • Setting D dark-on mode • Setting L light-on mode Set the range • Increase range: turn the setting screw of the potentiometer clockwise. • Decrease range: turn the setting screw of the potentiometer counter-clockwise Objects that are beyond these set switch point are suppressed. - Page 44 Service Instructions 3.5.6. Signal Output Verification of Sensors Tuirn on the machine and press MACHINE/MANUAL MACHINE MANUAL SECURITY CODE ENTER SENSOR VERIFICATION SENSOR CONFIRMATION...

-

Page 45: Serial Bus

Service Instructions 3.6. Serial Bus The Serial Bus System, based on only four wires, is self- diagnostic and offers helpful solutions to solve the problem. An operator using a touch screen control panel manages this rugged, uncomplicated system. Designed to international standards, this multi-lingual, easy to operate interface will allow parameters to be saved, allow technician access with password protection, and offers a built-in production performance monitor which can be... -

Page 46: Installing New Screen

Service Instructions C. When the screen is touched, the display will change to two lines intersecting at the lower right of the screen NOTE: The implementation of step 2 and step 3 directly affects the validity of all the buttons in the entire program. It is very important to be accurate. - Page 47 Service Instructions E. Screen will begin to process the up-loading of existing program. This will take 60 - 90 seconds F. After reading the "Last Warning Message” press continue again. G. Screen will begin to process information again for 15 - 30 seconds H.

-

Page 48: Modules

Service Instructions 3.6.7. Modules Standard Modules A. Program Module…4080-150 Stores the program information. It is also used to load program modifications or updates. For update procedures please refer to the next chapter. B. Data Module….4080-930 Stores the unique data required to operate this particular machine; such as serial number, original factory parameters, etc. -

Page 49: Program Update

Service Instructions 3.6.8. Program Update NOTE: Very Important Before starting the procedure below, go to Advanced Settings and write down all the settings shown in these screens. 1. Turn off power to the machine. 2. Replace the existing Program Module with the Program Module that contains the updated program. -

Page 50: Expiration Count 911

• The machine serial number • The security key • The master clock Here is what the 911 warning currently says: Warning 911 Instructions 1. Contact the Atlanta Attachment Company Service Department (USA). Phone: +1 (770) 963-7369 Fax: +1 (770) 963-7641 Email: techsupport@atlatt.com 2. - Page 51 Service Instructions 7. A MECHANIC SECURITY SCREEN should appear. Type your 5-digit security code 8. The Controller Setup show up; press continue 9. In the screen CONFIG UTILITIES, press EXP CODE. 10. Report the three numbers at the top to the AAC Service department staff.

-

Page 52: Technical Screens

Service Instructions 3.6.10. Technical Screens 1. Introduction The touch screen is divided into two major categories: Functions accessible to the operator and advanced functions accessible to the technician. The advanced functions consist of five security levels: Supervisor, Mechanic, Chief Mechanic, Technician, and Engineer. To access the technical functions, a security key must be entered The [MACHINE ADJUSTMENTS] screen and [ADVANCED ADJUSTMENTS] screen require a verification key code. -

Page 53: Show All Settings

Service Instructions 2. Show All Settings Shows the current parameter values being used by the machine. It doesn’t show the function, only the value. Before any program or module change, take notes of these values or a picture in case of any program issues. -

Page 54: Advanced Set Up

Service Instructions 4. Advanced Set Up This consists of two major series of screens. [ADVANCED SET UP 1] [ADVANCED SET UP 2] and [ADVANCED SET UP 3.] To navigate to the various screens, lightly tap the arrow buttons located at the upper corners of the touch screen. -

Page 55: Advanced Manual

Service Instructions Advanced Manual This area of the program allows access to the Input Output modules. There are three principal screens. move between screens, tap the arrow buttons on the upper top corners of the touch screen... - Page 56 Service Instructions A. Input In the Input Sensor screen you can verify the function of the input sensors. A double line will appear on the sensor’s window indicating that the sensor is activated. B. Output In the output screen you may activate the machine’s output devices (such as valves) by tapping the corresponding output control window.

-

Page 57: Maintenance

Service Instructions 3.7. Maintenance NOTE: Always wear proper safety equipment when operating or performing maintenance on any equipment. It is important that the machine operator read this manual and is familiar with all the functions and safety concerns of the unit before operating. 3.7.6. -

Page 58: Preventive Maintenance 40 Hrs

Service Instructions 3.7.7. Preventive Maintenance 40 Hrs. Preventive Maintenance 40 Hrs 1331 Series Required Materials Model: Oilcan Serial #: Operation: Stapler Clean cloth Needle: Open covers, With an air gun blow the machine out and remove accumulated dirt in hard to reach areas Lubricate all machine slides in the staplers, stretchers and Tension wheels Check the state of air filters “A”... -

Page 59: Preventive Maintenance 960 Hrs

Service Instructions 3.7.8. Preventive Maintenance 960 Hrs. -

Page 60: Troubleshooting

Service Instructions 3.8. Troubleshooting 3.8.6. Screen Messages Error Cause: Corrective action: The lift table did not reach the Check the wheel cylinder sensor if it is working properly wheel in a reasonable time No foundation detected Review that all proximity sensors are covered. Readjust eyes if required Error Cause:... - Page 61 Service Instructions Machine ran out of staples Reload the staples and press continue Cycle is not in automatic Reset and change to automatic mode or press the Skip to continue the cycle Reset bottom was pressed Wait until machine finish the reset cycle. Machine does not Turn Emergency Stop Activated Verify that the Emergency Stop bottom is not on the lock down position.

- Page 62 Service Instructions Problem Cause: Corrective action: Machine do not turn ON No Power Check the green button on the lock out switch inside the right door of the machine. If it is not pressed in and lit, press the green button. If it doesn’t light up when pressed, check the voltage at the top of the contactor.

-

Page 63: Assembly Drawings & Parts Lists

Company. In addition to any confidentiality and non-disclosure obligations that currently exist between you and Atlanta Attachment Company, your use of these materials serves as an acknowledgment of the confidential and proprietary nature of these materials and your duty not to make any unauthorized use or... -

Page 64: 11331B S/A Foundation Stretcher

Service Instructions 11331B S/A Foundation Stretcher AAC Drawing Number 9005254 Rev 0 ITEM QTY. PART NUMBER DESCRIPTION 1331-PD2 DIAGRAM, PNEUMATIC 1331-WD DIAGRAM, WIRING 1331100 GENERIC ASSY,1331B/BC 1331140 TABLE TOP ASSY. AA2000F-03 FLOW CONTROL,INLINE,5/32 AA3001F-03 FLOW CONT,INLINE,1/4 LINE AAFP28 MUFFLER,1/4 NPT AAQMC-4-8... -

Page 65: 11331Bc S/A Foundation Stretcher

Service Instructions 11331BC S/A Foundation Stretcher AAC Drawing Number 9005255 Rev 0 ITEM QTY. PART NUMBER DESCRIPTION 1331100 GENERIC ASSY,1331B/BC 1331393 TABLE TOP ASSY AA2000F-03 FLOW CONTROL,INLINE,5/32 AA3001F-03 FLOW CONT,INLINE,1/4 LINE AAFP28 MUFFLER,1/4 NPT AAQMC-4-8 QUICK MALE CONNECT,1/4NPT AAQME-4-8 QUICK MALE ELBOW, 1/4T... -

Page 66: 11331Bd S/A Divan Foundation Stretcher

Service Instructions 11331BD S/A Divan Foundation Stretcher AAC Drawing Number 9003551 Rev 0... - Page 67 Service Instructions 11331BD parts list...

-

Page 68: 1331100 Main Assembly (B & Bc Models)

Service Instructions 1331100 Main Assembly (B & BC models) AAC Drawing Number 1331100 Rev 11... - Page 69 Service Instructions...

- Page 70 Service Instructions 1331100 parts list NO QTY PART # DESCRIPTION PART # DESCRIPTION 40-112A MOUNT, TOUCH SCREEN CCCL12F CLAMP COLLAR- 3/4 0411-1063 THREADED ROD FF06H205 EYE, BKGND SUPPRESS,ADJ 1278-6010 START/STOP BUTTON ASSY MM132-2X2A END CAP, SQUARE, BLACK 1331-WD DIAGRAM, WIRING MM132-2X3 END CAP, RECT,BLACK,2X3 1536-069A...

-

Page 71: 1331567 Main Assembly (Bd Model)

Service Instructions 1331567 Main Assembly (BD model) AAC Drawing Number 1331567 Rev 1... - Page 72 Service Instructions 1331567 parts list...

-

Page 73: 1278-6010 Start / Stop Button Assembly (All Models)

Service Instructions 1278-6010 Start / Stop Button Assembly (all models) AAC Drawing Number 191058B Rev 3 QTY PART # DESCRIPTION EEPCB65GM Enclosure Modif. EEPMTS44 E-Stop Button EEPF3 Start Button EEA3L Mounting latch EE3X01 Contact Block N.C. EE3X10 Contact Block N.O. EE15Y Legend Plate FF3210... -

Page 74: 1331-Kit5 Table Height Adjustment Kit (All Models)

Service Instructions 1331-KIT5 Table Height Adjustment Kit (all models) AAC Drawing Number 9002273 Rev 0 QTY PART # DESCRIPTION 1331114 SPACER,COLUMN HUB SUPPORT 1331117 SPACER,TABLE TOP,1.5 1331118 WASHER PLATE,COLUMN LIFT NNE1/2-13 NUT,NYLOCK,1/2-13 NNE3/8-16 NUT, ELASTIC 3/8-16 SSHC25064 3/8-16X1,HEX CAP SSHC25288 3/8-16X4-1/2,HEX CAP SSHC45160 1/2-13X4 HEX CAP... -

Page 75: 1331042 Pivot Lift Assembly (All Models)

Service Instructions 1331042 Pivot Lift Assembly (all models) AAC Drawing Number 1331042 Rev 1 QTY PART # DESCRIPTION 1331040 ROTATE LIFT CYL ASSY. 1331041 ROTATION PLATE ASSY 1331068 PLATE, TABLE TOP, UPPER 1331071 HUB, BEARING 1331111 MOUNT, FOUNDATION LIFT 1331161 MOUNT, ROTATION PLATE BB62062RS1 BEARING,BALL,DP GROOVE... -

Page 76: 1331185 Overhead Staple Gun Holder(All Models)

Service Instructions 1331185 Overhead Staple Gun Holder(all models) AAC Drawing Number 1331185 Rev 0... -

Page 77: 1331903 Long Sidetrack Assembly (All Models)

Service Instructions 1331903 Long Sidetrack Assembly (all models) AAC Drawing Number 1331903 Rev 3... - Page 78 Service Instructions 1331903 parts list QTY PART # DESCRIPTION AR 1331-PD2 DIAGRAM, PNEUMATIC AR 1331-PD3 SHORT SIDE FITTING ASSY 1331902 CHANNEL, AIRLINES, LONG 1331905 COVER HALF, LONG CHANNEL AAFP28 MUFFLER,1/4 NPT AAQMC-3-4 QUICK MALE CONNECTOR AAQME-5-8 QUICK MALE ELBOW AAQMF-145 10-STATION AIR MANIFLD AAQPR-5-4 QUICK PLUG-IN REDUCER...

-

Page 79: 1331908 Short Side Track Assembly (All Models)

Service Instructions 1331908 Short Side Track Assembly (all models) AAC Drawing Number 1331908 Rev 2... - Page 80 Service Instructions 1331908 parts list QTY PART # DESCRIPTION 1331-PD2 DIAGRAM, PNEUMATIC 1331-PD4 SHORT,SIDE FITTING ASSY 1331906 COVER, SHORT SIDE CHANNEL 1331907 CHANNEL, AIRLINES, SHORT AAFP28 MUFFLER,1/4 NPT AAQMC-3-4 QUICK MALE CONNECTOR AAQME-4-8 ELBOW,QUICK MALE,1/4X1/8 AAQMF-144 6-STATION AIR MANIFOLD AAQMF-145 10-STATION AIR MANIFLD AAQPR-5-4 QUICK PLUG-IN REDUCER...

-

Page 81: 1331077 Long Side Staple Gun Assembly (B & Bc)

Service Instructions 1331077 Long Side Staple Gun Assembly (B & BC) AAC Drawing Number 1331077 Rev 10... - Page 82 Service Instructions...

- Page 83 Service Instructions...

- Page 84 Service Instructions 1331077 parts list...

-

Page 85: 1331078 Short Staple Gun Assembly (B & Bc)

Service Instructions 1331078 Short Staple Gun Assembly (B & BC) AAC Drawing Number 1331078 Rev 7... - Page 86 Service Instructions...

- Page 87 Service Instructions...

- Page 88 Service Instructions...

- Page 89 Service Instructions 1331078 parts list ITEM QTY. PART NUMBER DESCRIPTION 1331079 COVER STRETCH ROLLER ASSY 1331080 COVER STRETCH ROLLER ASSY 1331094 TOP CLAMP 1331167 MOUNT,W HEEL ASSY,INNER 1331168 MOUNT, W HEEL ASSY, OUTER 1331231 ANGLE, STAPLE GUN ALIGN 1331233 ANGLE, STAPLE GUN ALIGN 1331278 BRACKET, AIR VALVE 1331279...

-

Page 90: 1331349 Staple Gun Assembly (All Models)

Service Instructions 1331349 Staple Gun Assembly (all models) AAC Drawing Number 1331349 Rev 5 QTY PART # DESCRIPTION 1331282 STAPLER ASSY WITH CYL 1331308 PLATE, MNT. STAPLE GUN 1331310 CLAMP, STAPLE PIVOT 1331338 PRESSURE PLATE AAQME-4-4 ELBOW, MALE,1/4X1/4NPT NNK10-32 KEP NUT, 10-32 SSFC98096 10-32 X 1-1/2 FLAT ALLEN SSHC10128GR8... -

Page 91: 1331914 Manual Stapler Assembly (All)

Service Instructions 1331914 Manual Stapler Assembly (all) AAC Drawing Number 1331914 Rev 1... -

Page 92: 1331079 Cover Stretch Roller Assembly (B & Bc)

Service Instructions 1331079 Cover Stretch Roller Assembly (B & BC) AAC Drawing Number 1331079 Rev 5... - Page 93 Service Instructions 1331079 parts list QTY PART # DESCRIPTION 1331204 SHAFT, TENSION WHEEL 1331205 YOKE, TENSION WHEEL 1331206 PIVOT ARM, TENSION ROLLER 1331210 BRKT, AIR CYL 1331212 SPACER,1/4X5/8X1.88X1.25O 1331216 BLADE, BORDER TENSION 1331285 SLEEVE,STOP,TENSION CYL. 1331311 ARM, STAPLE PIVOT 1331312 PLATE, SUPPORT STAPLE 1331313 SPACER, .257IDX.63OD...

-

Page 94: 1331080 Cover Stretch Roller Assembly (B & Bc)

Service Instructions 1331080 Cover Stretch Roller Assembly (B & BC) AAC Drawing Number 1331080 Rev 2... - Page 95 Service Instructions 1331080 parts list QTY PART # DESCRIPTION 1331204 SHAFT, TENSION WHEEL 1331205 YOKE, TENSION WHEEL 1331206 PIVOT ARM, TENSION ROLLER 1331212 SPACER,1/4X5/8X1.88X1.25O 1331213 BRKT, AIR CYL 1331216 BLADE, BORDER TENSION 1331285 SLEEVE,STOP,TENSION CYL. 1331712 WHEEL, TENSION 1331714 ARM,TENSION WHEEL 1331715 TENSION ROLLER MT ANGLE 1331718...

-

Page 96: 1331081 Cover Stretch Roller Assembly (B & Bc)

Service Instructions 1331081 Cover Stretch Roller Assembly (B & BC) AAC Drawing Number 1331081 Rev 5... - Page 97 Service Instructions 1331081 parts list QTY PART # DESCRIPTION 1331204 SHAFT, TENSION WHEEL 1331205 YOKE, TENSION WHEEL 1331206 PIVOT ARM, TENSION ROLLER 1331212 SPACER,1/4X5/8X1.88X1.25O 1331213 BRKT, AIR CYL 1331216 BLADE, BORDER TENSION 1331285 SLEEVE,STOP,TENSION CYL. 1331312 PLATE, SUPPORT STAPLE 1331712 WHEEL, TENSION 1331714 ARM,TENSION WHEEL...

-

Page 98: 1331393 Tabletop Assembly (Bc & Bd)

Service Instructions 1331393 Tabletop Assembly (BC & BD) AAC Drawing Number 1331393 Rev 1... -

Page 99: 1331140 Tabletop Assembly (B)

Service Instructions 1331140 Tabletop Assembly (B) AAC Drawing Number 1331140 Rev 3 NO QTY PART # DESCRIPTION 1331147 PLATE, TOP, FRONT 1331151 BUMPER, TABLE CORNER 1331163 PLATE, TOP, REAR 1331395 TABLE TOP FRAME ASSY. 1331922 CUTOUT TO FULL FRAME SSHC01032 1/4-20 X 1/2 HHCS SSHC01056 1/4-20 X 7/8 HEX CAP... -

Page 100: 1331178 Pneumatic Panel (All)

Service Instructions 1331178 Pneumatic Panel (all) AAC Drawing Number 1331178 Rev 4... -

Page 101: 1331247 Corner Support Assembly, Rh (All Models)

Service Instructions 1331247 Corner Support Assembly, RH (all models) AAC Drawing Number 1331247 Rev 0... -

Page 102: 1331504 Table Lift Pedal Assembly (All Models)

Service Instructions 1331504 Table Lift Pedal Assembly (all models) AAC Drawing Number 1331504 Rev 2 QTY PART # DESCRIPTION 1278-5051A PLATE, FOOT SW, DUAL 1278-6161 FOOT SWITCH MODIFICATION 12788-502A CABLE, DUAL FOOT SWITCH AAF3/16 CLAMP, BLACK PLASTIC WWFS6 WASHER, FLAT, #6 NNK6-32 KEP NUT, 6-32 SSFC80024... -

Page 103: 1331900 Control Box (All Models)

Service Instructions 1331900 Control Box (all models) AAC Drawing Number 1331900 Rev 9... - Page 104 Service Instructions 1331900 parts list I TEM QTY. PART NUMBER DESCRI PTI ON 1331-WD DI AGRAM, WI RI NG 13311129 CABLE PACKAGE 1331901 BACK CONTROL PANEL, BACK-PLATE 13459004 MOUNTI NG BRACKET, CAPACI T 40-320 BREAKER, MAI N PWR, 2P, 20A, WI TH 4080-110 MODULE,QUAD I NPUT 4080-140...

-

Page 105: 13452000C Square Table Lift Assembly (B & Bc)

Service Instructions 13452000C Square Table Lift Assembly (B & BC) AAC Drawing Number 9003089 Rev 7... - Page 106 Service Instructions 13452000C parts list Hardware ITEM NO. PART NUMBER DESCRIPTION Shown/QTY. 1322020 ACTUATOR,ELEC,6" 1345093 BKT,EDGE GUIDE 1345131 PLATE,SLIDE, ADJ 1345132 BAR, BRACE,.25 THK 1345134 SPACER,COLUMN CONCAVE 1345135 PLATE, SLIDE 1345136 BKT,LOWER GIB STOP 1345231 COLUMN ASSY 1345234 PLATE,ACTUATOR MNTNG,UPR 13451003 PLATE, COLUMN SUPPORT 13452004A...

-

Page 107: 1536-069A Footswitch Assembly (All)

Service Instructions 1536-069A Footswitch Assembly (all) AAC Drawing Number 125863A Rev 0 QTY PART # DESCRIPTION FF59F1802 2 Pin Male Conn. FF31F1022 Male Pin .093 2" ZTH1/2B Boot Material EE18-2 2 Cond 18AWG TT1818 Female Quick Slide EE24F163 Threadlite Footswitch... -

Page 108: 26254C Air Reservoir(All Models)

Service Instructions 26254C Air Reservoir(all models) AAC Drawing Number 298348B Rev 1 QTY PART # DESCRIPTION 261007 Air Tank MM44605K24 Reducer AAQBY-3-2 1/2 x 3/8 "Y"... -

Page 109: 1331559 Long Side Staple Gun Assembly (Bd)

Service Instructions 1331559 Long Side Staple Gun Assembly (BD) AAC Drawing Number 1331559 Rev 0... - Page 110 Service Instructions 1331559 parts list...

-

Page 111: 1331564 Short Staple Gun Assembly (Bd)

Service Instructions 1331564 Short Staple Gun Assembly (BD) AAC Drawing Number 1331564 Rev 0 NO. QTY PART # DESCRIPTION NO. QTY PART # DESCRIPTION 1331167 MOUNT,WHEEL ASSY,INNER 1331727 HANDLE 1331168 MOUNT, WHEEL ASSY, OUTER AAVSMAV-3 VALVE,SUB MIN,3-WAY SPOOL 1331231 ANGLE, STAPLE GUN ALIGN BBTT1001 WASHER,THRUST,BRONZE 1331233... -

Page 112: 1331558 Cover Stretch Roller Assembly (Bd)

Service Instructions 1331558 Cover Stretch Roller Assembly (BD) AAC Drawing Number 1331558 Rev 0... - Page 113 Service Instructions 1331558 parts list ITEM PART NUMBER DESCRIPTION 1331125 BLOCK, FILLER, PULL WHEEL 1331204 SHAFT, TENSION WHEEL 1331205 YOKE, TENSION WHEEL 1331210 BRKT, AIR CYL 1331212 SPACER,1/4X5/8X1.88X1.25O 1331287 PIVOT ARM, TENSION ROLLER 1331311 ARM, STAPLE PIVOT 1331312 PLATE, SUPPORT STAPLE 1331313 SPACER, .257IDX.63OD 1331579...

-

Page 114: 1331560 Cover Stretch Roller Assembly (Bd)

Service Instructions 1331560 Cover Stretch Roller Assembly (BD) AAC Drawing Number 1331560 Rev 0... - Page 115 Service Instructions 1331560 Parts list ITEM PART NUMBER DESCRIPTION 1331125 BLOCK, FILLER, PULL WHEEL 1331204 SHAFT, TENSION WHEEL 1331205 YOKE, TENSION WHEEL 1331212 SPACER,1/4X5/8X1.88X1.25O 1331213 BRKT, AIR CYL 1331287 PIVOT ARM, TENSION ROLLER 1331579 BLADE, BORDER TENSION 1331712 WHEEL, TENSION 1331714 ARM,TENSION WHEEL 1331715...

-

Page 116: 1331563 Cover Stretch Roller Assembly (Bd)

Service Instructions 1331563 Cover Stretch Roller Assembly (BD) AAC Drawing Number 1331563 Rev 0... - Page 117 Service Instructions 1331563 Parts list ITEM PART NUMBER DESCRIPTION 1331125 BLOCK, FILLER, PULL WHEEL 1331204 SHAFT, TENSION WHEEL 1331205 YOKE, TENSION WHEEL 1331212 SPACER,1/4X5/8X1.88X1.25O 1331213 BRKT, AIR CYL 1331287 PIVOT ARM, TENSION ROLLER 1331312 PLATE, SUPPORT STAPLE 1331579 BLADE, BORDER TENSION 1331712 WHEEL, TENSION 1331714...

-

Page 118: 1331565 Square Table Lift Assembly (Bd)

Service Instructions 1331565 Square Table lift Assembly (BD) AAC Drawing Number 1331565 Rev 0... - Page 119 Service Instructions 1331565 Parts list I TEM QTY. PART NUMBER DESCRI PTI ON 1331114 SPACER,COLUMN HUB SUPPORT 1331118 WASHER PLATE,COLUMN LI FT 1345050 ACTUATOR ASSEMBLY,12.5" 1345093 BKT,EDGE GUI DE 1345131 PLATE,SLI DE, ADJ 1345132 BAR, BRACE,.25 THK 1345134 SPACER,COLUMN CONCAVE 1345135 PLATE, SLI DE 1345136...

-

Page 120: 1331-Pd2 Rev 8 Pneumatic Diagram (B, Bc & Bd Models)

Service Instructions 1331-PD2 Rev 8 Pneumatic Diagram (B, BC & BD models) 125723B... -

Page 121: 1331-Wd Rev 6 Wiring Diagram (B & Bd Models)

Service Instructions 1331-WD Rev 6 Wiring Diagram (B & BD models) 125700C... -

Page 122: 1331-Wd Rev 8 (Gateway) Wiring Diagram (Bc Model)

Service Instructions 1331-WD Rev 8 (Gateway) Wiring diagram (BC model) -

Page 123: Statement Of Warrantymanufactured Products

Atlanta Attachment Company (AAC) Statement of WarrantyManufactured Products Atlanta Attachment Company warrants manufactured products to be free from defects in material and workmanship for a period of eight hundred (800) hours of operation or one hundred (100) days whichever comes first. Atlanta Attachment Company warrants all electrical components of the Serial Bus System to be free from defects in material or workmanship for a period of thirty-six (36) months. -

Page 124: Trainning

Service Instructions TRAINNING Check Description Time Hrs. Safety Instructions Installation • Set up • Power On cycle Operation • Individual components • Serial Bus operator label • Operation Description • With / without dustcover • Maintenance Operator Label Service • Lock out tag out •... -

Page 125: Notes

Notes: Atlanta Attachment Company 362 Industrial Park Drive, Lawrenceville, GA 30046 E-mail: Sales@atlatt.com Phone: +1 (770) 9637369... -

Page 126: Index

PAUSED Troubleshooting Pedal types of staples Photoelectric Sensors General Operation PIECE COUNT Ground PIECE COUNTER Pneumatic 0, 6, 27, 32 Update Controller Power “ON” Atlanta Attachment Company 362 Industrial Park Drive, Lawrenceville, GA 30046 E-mail: Sales@atlatt.com Phone: +1 (770) 9637369... - Page 128 Atlanta Attachment Company Inc. 362 Industrial Park Drive Lawrenceville, GA 30046 Phone: +1 (770) 963-7369 www.atlatt.com Printed in USA Digital Version of this Manual Available at: http://atlatt.com/tech_manuals.php...

Need help?

Do you have a question about the 1331B and is the answer not in the manual?

Questions and answers