Table of Contents

Advertisement

Quick Links

Definition: A hydraulic pump delivers hydraulic fluid under pressure through the use of compressed air or

an electric motor as a power source.

NOTE:

• For a detailed parts list or to locate a Power Team

Authorized Hydraulic Service Center, contact your

nearest Power Team facility.

• Carefully inspect the pump upon arrival. The carrier,

not the manufacturer, is responsible for any damage

resulting from shipment.

• The customer can choose from a variety of motors,

controls, reservoirs, and other options. These

instructions will include directions for options that

your particular pump may not have.

• Do not change motors without consulting the pump

manufacturer's Technical Services Department.

Safety symbols are used to identify any action or lack of action that can cause personal injury. Your reading

and understanding of these safety symbols is very important.

DANGER - Danger is used only when your action or lack of action will cause serious human injury or

death.

WARNING - Warning is used to describe any action or lack of action where a serious injury can occur.

DANGEROUS VOLTAGE - Dangerous voltage is used to describe any action or lack of action that

IMPORTANT - Important is used when action or lack of action can cause equipment failure, either

immediate or over a long period of time.

Litho in USA

®

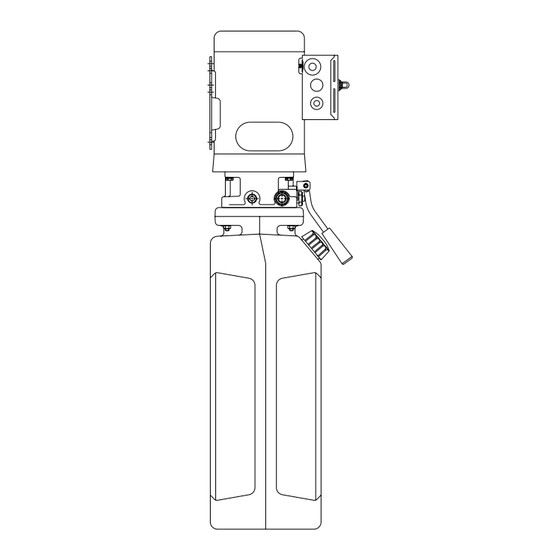

HYDRAULIC PUMP

Max. Capacity: See Pump Data Plate

SAFETY DEFINITIONS

could cause serious personal injury or death from high voltage electricity.

Operating Instructions for:

Sheet No.

Rev. 1

Form No. 103517

GPM Series

GPN Series

GPS Series

1 of 6

Date: 14 Feb. 2000

Advertisement

Table of Contents

Summary of Contents for SPX POWER TEAM GPM Series

- Page 1 Form No. 103517 ® Operating Instructions for: GPM Series GPN Series GPS Series HYDRAULIC PUMP Max. Capacity: See Pump Data Plate Definition: A hydraulic pump delivers hydraulic fluid under pressure through the use of compressed air or an electric motor as a power source.

-

Page 2: Safety Precautions

Operating Instructions, Form No. 103517, Back sheet 1 of 6 SAFETY PRECAUTIONS These instructions are intended for end-user application needs. Many problems with new equipment are caused by improper operation or installation. For a detailed parts list or to locate a Power Team Authorized Hydraulic Service Center contact your nearest Power Team facility. -

Page 3: Power Supply

Operating Instructions Form No. 103517 SAFETY PRECAUTIONS CONTINUED - POWER SUPPLY Electric Electrical Shock or Electrocution • Any electrical work must be done and tested by a qualified electrician per applicable codes and standards. • Disconnect the pump from the power supply and relieve pressure before removing the motor case cover or performing maintenance or repair. -

Page 4: Hydraulic Fluids

Operating Instructions, Form No. 103517, Back sheet 2 of 6 SAFETY PRECAUTIONS CONTINUED - PUMP • Do not exceed the hydraulic pressure rating noted on the pump nameplate or tamper with the internal high pressure relief valve. Creating pressure beyond rated capacities can result in personal injury. •... - Page 5 Operating Instructions Form No. 103517 SET-UP INSTRUCTIONS CONTINUED - Hydraulic Connections Remove the thread protectors or dust covers from the hydraulic ports if applicable. Clean the areas around the fluid ports of the pump and cylinder. Inspect all threads and fittings for signs of wear or damage, and replace as needed. Clean all hose ends, couplers and union ends.

-

Page 6: Pump Operation

Operating Instructions, Form No. 103517, Back sheet 3 of 6 PUMP OPERATION When operating the pump for the first time: 1. Valve and hose connections must be tight, and the reservoir must be filled to the proper fluid level. Start the motor. 2. -

Page 7: Directional Control Valve Options

Operating Instructions Form No. 103517 DIRECTIONAL CONTROL VALVE OPTIONS 2-Position, 2-Way Manual Valve Used With Single-acting Cylinder 1. This valve is spring-loaded to the “closed” position. 2. Activate the pump unit to advance the cylinder. 3. When the cylinder has advanced to the desired position, deactivate the switch or remote switch, or turn the pump unit OFF. -

Page 8: Preventive Maintenance

Operating Instructions, Form No. 103517, Back sheet 4 of 6 PREVENTIVE MAINTENANCE WARNING: To help prevent personal injury, • Disconnect the pump from the power supply before performing maintenance or repair procedures. • Repairs and maintenance are to be performed in a dust-free area by a qualified technician. Checking The Hydraulic Fluid And Filling The Reservoir The hydraulic fluid level should be checked after initial set-up and after each ten hours of use. -

Page 9: Troubleshooting Guide

Operating Instructions Form No. 103517 TROUBLE-SHOOTING GUIDE WARNING • To help prevent personal injury, any repair work or trouble-shooting must be done by qualified personnel familiar with this equipment. • Use the proper gauges and equipment when trouble-shooting. NOTE: • For a detailed parts list or to locate a Power Team Authorized Hydraulic Service Center contact your nearest Power Team facility. - Page 10 Operating Instructions, Form No. 103517, Back sheet 5 of 6 TROUBLE-SHOOTING GUIDE CONTINUED - PROBLEM CAUSE SOLUTION Pump builds pressure but cannot External leaks. Seal leaking pipe fittings with maintain pressure. pipe sealant. Replace leaking pipes or hoses. Internal or external leakage on Remove the cylinder from hydraulic cylinder.

-

Page 11: Electrical Schematics

(SEE MOTOR NAMEPLATE OR CHART FOR MOTOR CONNECTIONS ON DUAL VOLTAGE MOTOR) 208-230V 115V GPM SERIES - 3 PHASE MOTOR 208-230/460 V, 60 Hz, 3 PHASE 208-230/380-415 V, 50 Hz, 3 PHASE 575 V, 60 Hz, 3 PHASE IMPORTANT MOTOR ROTATION MUST BE CLOCKWISE (CW) WHEN VIEWED FROM SHAFT END. IF PUMP DOES NOT EXTEND CYLINDER OR BUILD PRESSURE, REVERSE THE MOTOR ROTATION BY INTERCHANGING ANY TWO LINE LEADS. -

Page 12: Power Team Facilities

Operating Instructions, Form No. 103517, Back sheet 6 of 6 POWER TEAM FACILITIES ® AUSTRALIA KOREA UNITED EAST 28 Clayton Road So-Anyang P.O. Box 50 STATES C E R T I F I E D Clayton North 19 Joo Koon Road Kyounggi-Do SPX Corporation-Fluid Power Singapore 628978...

Need help?

Do you have a question about the GPM Series and is the answer not in the manual?

Questions and answers