Table of Contents

Advertisement

Quick Links

Instructions – Parts List

Parts

POLYPROPYLENE AND KYNARR

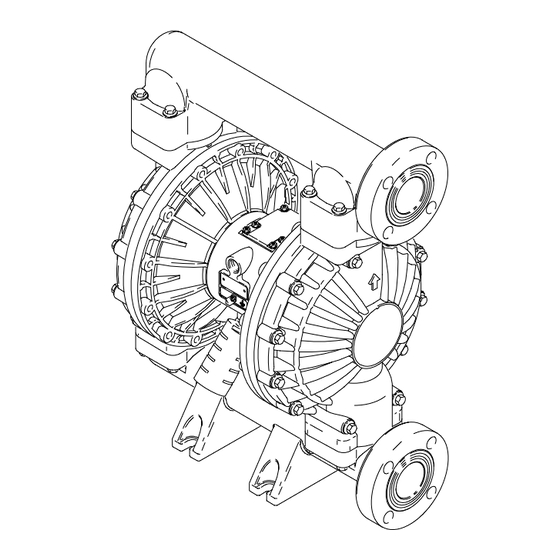

Huskyt 2150 Air-Operated

Diaphragm Pumps

120 psi (0.8 MPa, 8 bar) Maximum Fluid Working Pressure

120 psi (0.8 MPa, 8 bar) Maximum Air Input Pressure

*Model No. DF2

*Model No. DG2

*Model No. DF5

*Model No. DG5

*Model No. DV2

*Model No. DW2

*Model No. DV5

*Model No. DW5

Model No. 232504 Private-Label Polypropylene 2150 Pump (See page 24.)

* NOTE: Refer to the Pump Matrix on page 24 to

determine the Model No. of your pump.

NOTE: Plus models include stainless

steel center sections.

US Patent No. 5,368,452.

Other US and Foreign Patents Pending.

Read warnings and instructions.

See page 2 for table of contents.

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440-1441

Copyright 1995, Graco Inc. is registered to I.S. EN ISO 9001

Polypropylene Pumps

Polypropylene Pumps, Remote

Kynarr Pumps

Kynarr Pumps, Remote

Polypropylene Plus Pumps

Polypropylene Plus Pumps, Remote

Kynarr Plus Pumps

Kynarr Plus Pumps, Remote

308550S

04613B

Advertisement

Table of Contents

Summary of Contents for Graco DF2 Series

- Page 1 US Patent No. 5,368,452. Other US and Foreign Patents Pending. Read warnings and instructions. See page 2 for table of contents. 04613B GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440-1441 Copyright 1995, Graco Inc. is registered to I.S. EN ISO 9001...

-

Page 2: Table Of Contents

D Read all instruction manuals, tags, and labels before operating the equipment. D Use the equipment only for its intended purpose. If you are not sure, call your Graco distributor. D Do not alter or modify this equipment. Use only genuine Graco parts and accessories. - Page 3 WARNING TOXIC FLUID HAZARD Hazardous fluid or toxic fumes can cause serious injury or death if splashed in the eyes or on the skin, inhaled, or swallowed. D Know the specific hazards of the fluid you are using. D Store hazardous fluid in an approved container. Dispose of hazardous fluid according to all local, state and national guidelines.

-

Page 4: Installation

This keeps the manifolds from interfering with tance in planning a system to suit your needs. tightening the fluid covers. See the Service section for D Always use Genuine Graco Parts and Accessories. torque specifications. Be sure all accessories are adequately sized and After the first day of operation, check and retorque the pressure-rated to meet the system’s requirements. - Page 5 Installation Grounding Ground all of this equipment: D Air Motor: Connect a ground wire and clamp as shown in Fig. 1. Loosen the grounding screw (W). Insert one end of a 12 ga (1.5 mm@) minimum ground wire (Y) behind the grounding screw and WARNING tighten the screw securely.

- Page 6 Installation Air Line b. Locate one bleed-type master air valve (B) close to the pump and use it to relieve trapped air. See the WARNING at left. Locate the other WARNING master air valve (E) upstream from all air line accessories and use it to isolate them during A bleed-type master air valve (B) is required in cleaning and repair.

- Page 7 3. Connect remaining ends of tubes to external air (0.1 MPa, 1 bar), diaphragm life will be shortened. signal, such as Graco’s Cycleflo (P/N 195264) or Cycleflo II (P/N195265) controllers. 4. See the Technical Data on page 31 for maximum suction lift (wet and dry).

- Page 8 Installation Flange Connections 1. Place a flat washer (E) on each bolt (C). Refer to Fig. 3. The fluid inlet and outlet ports are 2” raised face, standard 150 lb class pipe flanges. Connect 2” flanged 2. Align the holes in the gasket (B) and the pipe plastic pipe to the pump as follows.

- Page 9 Installation Changing the Orientation of the Fluid Inlet Fluid Pressure Relief Valve and Outlet Ports CAUTION The pump is shipped with the fluid inlet (R) and outlet (S) ports facing the same direction. See Fig. 4. To Some systems may require installation of a pres- change the orientation of the inlet and/or outlet port: sure relief valve at the pump outlet to prevent overpressurization and rupture of the pump or...

- Page 10 Installation Air Exhaust Ventilation The air exhaust port is 3/4 npt(f). Do not restrict the air exhaust port. Excessive exhaust restriction can cause erratic pump operation. WARNING FIRE AND EXPLOSION HAZARD To provide a remote exhaust: Be sure to read and follow the warnings and precautions regarding TOXIC FLUID HAZARD, and FIRE OR EXPLO- 1.

-

Page 11: Operation

Operation Pressure Relief Procedure 1. Be sure the pump is properly grounded. Refer to Grounding on page 5. WARNING 2. Check all fittings to be sure they are tight. Be sure PRESSURIZED EQUIPMENT HAZARD to use a compatible liquid thread sealant on all The equipment stays pressurized until pressure is male threads. - Page 12 Operation Operation of Remote Piloted Pumps NOTE: Leaving air pressure applied to the air motor for extended periods when the pump is not running may shorten the diaphragm life. Using a 3–way solenoid 1. Fig. 2 and Parts Drawings. Follow preceding steps valve to automatically relieve the pressure on the air 1 through 7 of Starting and Adjusting Pump.

-

Page 13: Maintenance

Maintenance Lubrication Tightening Threaded Connections The air valve is designed to operate unlubricated. Before each use, check all hoses for wear or damage, However, if lubrication is desired, every 500 hours of and replace as necessary. Check to be sure all operation (or monthly) remove the hose from the pump threaded connections are tight and leak free. -

Page 14: Troubleshooting

Troubleshooting 1. Relieve the pressure before checking or servicing WARNING the equipment. To reduce the risk of serious injury whenever you are instructed to relieve pressure, always follow the 2. Check all possible problems and causes before Pressure Relief Procedure on page 11. disassembling the pump. - Page 15 Troubleshooting PROBLEM CAUSE SOLUTION Fluid in exhaust air. Diaphragm ruptured. Replace. See pages 19–21. Loose fluid side diaphragm plate Tighten or replace. See pages (105). 19–21. Pump exhausts excessive air at Worn air valve block (7), o-ring (6), Inspect; replace. See pages 16–17. stall.

-

Page 16: Repairing The Air Valve

Service Repairing the Air Valve Tools Required D Torque wrench D Torx (T20) screwdriver or 7 mm (9/32”) socket wrench D Needle-nose pliers D O-ring pick D Lithium base grease NOTE: Air Valve Repair Kit 236273 is available. Refer to page 28. Parts included in the kit are marked with a symbol, for example (4{). - Page 17 Service Install with lips facing Rounded side must face down. Insert narrow end first. narrow end of piston (11). Grease. Insert wide end first. Tighten screws until they bottom out on the housing. 03947 Fig. 10 04901 Fig. 9 Reassembly 1.

-

Page 18: Ball Check Valve Repair

Service Ball Check Valve Repair Torque to 80–90 in-lb (9–10 N.m). Tools Required Arrow (A) must point toward outlet manifold (103). D Torque wrench Not used on some models. D 10 mm socket wrench D O-ring pick Disassembly NOTE: A Fluid Section Repair Kit is available. Refer to page 25 to order the correct kit for your pump. -

Page 19: Diaphragm Repair

Service Diaphragm Repair WARNING Tools Required To reduce the risk of serious injury whenever you D Torque wrench are instructed to relieve pressure, always follow the Pressure Relief Procedure on page 11. D 13 mm socket wrench D Adjustable wrench D 19 mm socket wrench 1. - Page 20 Service 4. Unscrew one outer plate (105) from the diaphragm Reassembly shaft (24). Remove one diaphragm (401), and the 1. Grease the shaft u-cup packings (402*) and install inner plate (104). See Fig. 13. them so the lips face out of the housing (1). See Fig.

- Page 21 Service 402* 403* 401* 04708 03982 Cutaway View, with Diaphragms in Place Cutaway View, with Diaphragms Removed 401* 403* Lips face out of housing (1). Air Side must face center housing (1). Grease. Used on Models with PTFE diaphragms only. Apply medium-strength (blue) LoctiteR or equivalent.

-

Page 22: Bearing And Air Gasket Removal

Service Bearing and Air Gasket Removal 7. Use a bearing puller to remove the diaphragm shaft bearings (19), air valve bearings (12) or pilot Tools Required pin bearings (15). Do not remove undamaged D Torque wrench bearings. D 10 mm socket wrench 8. - Page 23 Service Insert bearings tapered end first. Press-fit bearings flush with surface of center housing (1). Torque to 130–150 in-lb (15–17 N.m). Detail of Air Valve Bearings 03951 03952B Fig. 14 308550...

-

Page 24: Pump Matrix

Pump Matrix Husky 2150 Polypropylene and Kynar Pumps, Series A Your Model No. is marked on the pump’s serial plate. To determine the Model No. of your pump from the following matrix, select the six digits which describe your pump, working from left to right. The first digit is always D, designating Husky diaphragm pumps. -

Page 25: Repair Kit Matrix

Repair Kit Matrix For Husky 2150 Polypropylene and Kynar Pumps, Series A Repair Kits may be ordered separately. To repair the air valve, order Part No. 236273 (see page 28). Parts included in the Air Valve Repair Kit are marked with a symbol in the parts list, for example (4{). To repair your pump, select the six digits which describe your pump from the following matrix, working from left to right. -

Page 26: Parts

Parts Air Motor Parts List (Matrix Column 2) Ref. Ref. Digit Part No. Description Digit Part No. Description 188838 HOUSING, center; Same as F with the following exceptions aluminum 195921 HOUSING, center; 188854 COVER, air valve; remote, aluminum aluminum 195919 COVER, air;... - Page 27 Parts Fluid Section Parts List (Matrix Column 3) Ref. 189795 COVER, fluid; Kynar Digit Part No. Description 189789 MANIFOLD, inlet; Kynar 189793 COVER, fluid; polypropylene 189792 MANIFOLD, outlet; Kynar 189787 MANIFOLD, inlet; 189298 PLATE, air side; polypropylene aluminum 189790 MANIFOLD, outlet; 189798 PLATE, fluid side;...

- Page 28 Parts 401* 301* 403* 201* 202* *402 *301 *201 202* Not used on some models. 04622C * These parts are included in the Pump Repair Kit, which may be purchased separately. Refer to the Repair Kit Matrix on page 25 to determine the correct kit for your pump. { These parts are included in Air Valve Repair Kit 236273, which may be purchased separately.

- Page 29 Parts Seat Parts List (Matrix Column 4) Diaphragm Parts List (Matrix Column 6) Ref. Ref. Digit Part No. Description Digit Part No. Description 201* 189288 SEAT; 316 stainless steel 401* 189296 DIAPHRAGM, backup; Santoprene 202* 112358 O-RING; PTFE 402* 112181 PACKING, u-cup;...

-

Page 30: Dimensions

Dimensions FRONT VIEW 220.5 mm 280.5 mm 1/2 npt(f) 3/4 npt(f) Air Inlet 654 mm Air Exhaust (muffler included) 578 mm 489 mm 350.5 mm 89 mm 152.5 mm 501.5 mm SIDE VIEW PUMP MOUNTING HOLE PATTERN 6.25 in. Port Diameter: (159 mm) 2.20 in. -

Page 31: Technical Data

Technical Data Maximum fluid working pressure ..............120 psi (0.8 MPa, 8 bar) Air pressure operating range... -

Page 32: Performance Chart

Performance Chart Example of Finding Pump Air Consumption and Air Pressure at a Specific Fluid Delivery and Discharge Head: To supply 60 gpm (227 liters) fluid flow (horizontal scale) at 40 psi (0.28 MPa, 2.8 bar) discharge head pressure (vertical scale) re- quires approximately 60 scfm (1.68 m /min) air consumption at 70 psi (0.48 MPa, 4.8 bar) inlet air pressure. - Page 33 Notes 308550...

-

Page 34: Graco Standard Warranty

Graco distributor to the original purchaser for use. With the exception of any special, extended, or limited warranty published by Graco, Graco will, for a period of five years from the date of sale, repair or replace any part of the equipment determined by Graco to be defective.

Need help?

Do you have a question about the DF2 Series and is the answer not in the manual?

Questions and answers