Table of Contents

Advertisement

Quick Links

Instructions

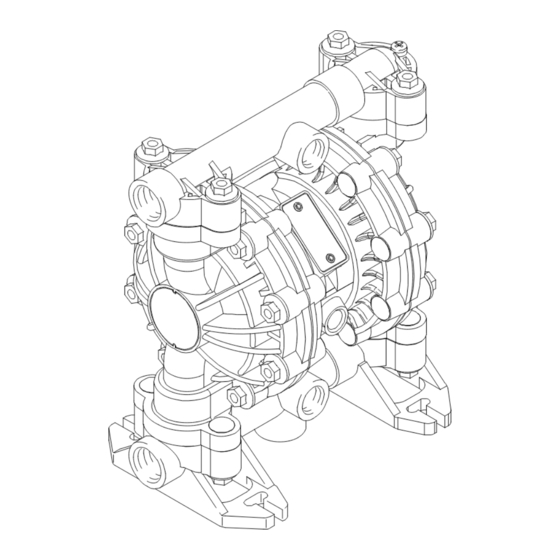

Air-Operated

Diaphragm Pumps

For fluid transfer applications. For professional use only. Only models marked with (*) are

approved for use in European explosive atmosphere locations.

100 psi (0.7 MPa, 7 bar) Maximum Fluid Working Pressure

100 psi (0.7 MPa, 7 bar) Maximum Air Input Pressure

ACETAL*, POLYPROPYLENE, AND PVDF

Husky™ 515

Model No. D 5 1 _ _ _ Acetal NPT Pumps

Model No. D 5 2 _ _ _ Polypropylene Pumps

Model No. D 5 5 _ _ _ PVDF NPT Pumps

Model No. D 5 A _ _ _ Acetal BSPT Pumps

Model No. D 5 B _ _ _ Polypropylene BSPT Pumps

Model No. D 5 E _ _ _ PVDF BSPT Pumps

Model No. D 9 1 _ _ _ Acetal NPT Pumps

Model No. D 9 A _ _ _ Acetal BSPT Pumps

For Additional Models, see Table of Contents

ALUMINUM* AND STAINLESS STEEL*

Husky™ 716

Model No. D 4 D _ _ _ Stainless Steel BSPT Pumps, Remote

Model No. D 5 3 _ _ _ Aluminum NPT Pumps

Model No. D 5 4 _ _ _ Stainless Steel NPT Pumps

Model No. D 5 C _ _ _ Aluminum BSPT Pumps

Model No. D 5 D _ _ _ Stainless Steel BSPT Pumps

Model No. D 9 4 _ _ _ Stainless Steel NPT Pumps

Model No. D 9 D _ _ _ Stainless Steel BSPT Pumps

For Additional Models, see Table of Contents

*These models are certified:

II 2 GD

Ex h IIC 66°C...135°C Gb

Ex h IIIC T135°C Db

Important Safety Instructions

Read all warnings and instructions in this manual.

Save these instructions.

Refer to the Pump Matrix on page 23 to determine

the model number of your pump.

ATEX T-code rating is dependent on the temperature

of the fluid being pumped. Fluid temperature is

limited by the materials of the pump interior wetted

parts. See Technical Data for the maximum fluid

operating temperature for your specific pump model.

308981ZBB

EN

9065A

Husky 515

9246A

Husky 716

Advertisement

Table of Contents

Summarization of Contents

Introduction and Safety

Important Safety Instructions

Essential safety guidelines for operating the pumps.

Symbols

Explanation of warning and caution symbols used in the manual.

Hazardous Conditions

Details toxic fluid and fire/explosion hazards.

Installation

General Installation and Preparation

Covers general info, fasteners, temperatures, mountings, and fluid handling.

Air Line Installation

Details air line connections and accessories.

Fluid System Installation

Covers fluid suction and outlet lines, and remote pilot air.

Safety Systems and Grounding

Covers pressure relief, air exhaust ventilation, and grounding procedures.

Grounding Procedures

Instructions for grounding the pump and system to prevent hazards.

Component Configuration

Covers changing port orientation and installing the reed switch.

Operation

Pressure Relief and Priming

Procedures for relieving pressure, flushing, and starting the pump.

Operating Modes and Shutdown

Covers remote piloted operation and pump shutdown procedures.

Maintenance and Troubleshooting

Lubrication and Storage

Guidelines for pump lubrication, flushing, and storage.

Connection Tightening and Schedule

Covers tightening connections and establishing a preventive maintenance schedule.

Troubleshooting Guide

Lists common pump problems, their causes, and solutions.

Pump Service

Air Valve Service

Instructions for servicing air valves for Husky 515 and 716 pumps.

Air Section Service

Procedures for disassembling and reassembling the air section.

Check Valve Service

Covers service for check valves and configurations for duckbill pumps.

Diaphragm Replacement (Husky 515)

Step-by-step guide for replacing diaphragms in Husky 515 pumps.

Diaphragm Replacement (Husky 716)

Step-by-step guide for replacing diaphragms in Husky 716 pumps.

Pump Identification and Parts

Pump Model Matrix

Guide to determining pump model numbers based on specifications.

Additional Pump Models

Lists additional Husky 515 and 716 pump variations and exceptions.

Repair Kits

Information on ordering air valve, fluid section, and diaphragm repair kits.

Common Parts List

Lists common parts for Husky 515 and 716 pumps.

Component Drawings and Lists

Husky 515 Parts Drawing

Exploded diagram of Husky 515 pump components.

Husky 515 Fluid Section Parts List

Detailed list of parts for Husky 515 fluid sections.

Husky 716 Parts Drawing

Exploded diagram of Husky 716 pump components.

Husky 716 Fluid Section Parts List

Detailed list of parts for Husky 716 fluid sections.

Technical Data and Performance

Torque Sequence

Recommended torque values and sequences for fastener tightening.

Husky 515 Technical Data

Specifications, operating ranges, and material data for Husky 515 pumps.

Husky 515 Dimensions

Physical dimensions and mounting hole pattern for Husky 515 pumps.

Husky 716 Technical Data

Specifications, operating ranges, and material data for Husky 716 pumps.

Reed Switch Technical Data

Technical specifications and ratings for the reed switch.

Husky 716 Dimensions

Physical dimensions and mounting hole pattern for Husky 716 pumps.

Performance Charts

Charts showing fluid outlet pressure and air consumption versus flow.

Graco Standard Warranty

Warranty Terms

Details Graco's limited warranty for equipment defects.

Need help?

Do you have a question about the D5A and is the answer not in the manual?

Questions and answers