Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Calomax ECLIPSE HS3C10

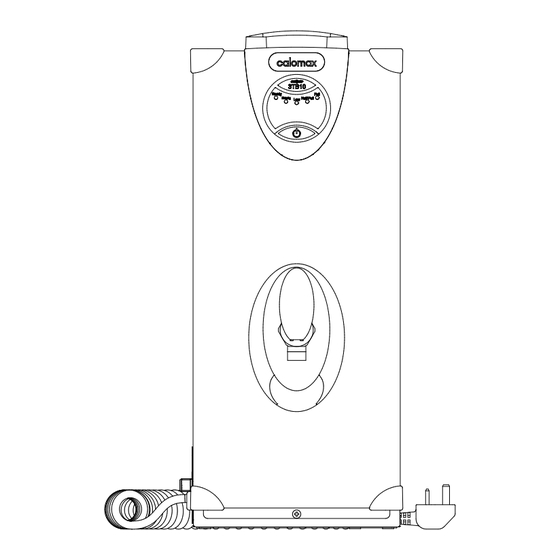

- Page 1 INSTALLATION, OPERATION AND SERVICING INSTRUCTIONS FOR THE ECLIPSE HS3C10 WATER BOILER Please read these instructions carefully before operating your boiler for the first time Calomax Limited Lupton Avenue, Leeds LS9 7DD Tel. 0113 249 6681 email: service@calomax.co.uk www.calomax.co.uk...

-

Page 2: Table Of Contents

CONTENTS PAGE INTRODUCTION APPROVALS CONSTRUCTION INSTALLATION AND MAINTENANCE LOCATION MOUNTING THE UNIT ELECTRICAL CONNECTIONS USER INSTRUCTIONS COMMISSIONING GENERAL OPERATION SCALE DRAINING CLEANING ACCESS INSTRUCTIONS BASIC TROUBLE SHOOTING SPARE PARTS EXPLODED DIAGRAMS 12 & 13 SERVICE INSTRUCTIONS DE-SCALE GENERAL FUNCTION PCB REPLACEMENT ADJUSTING WATER TEMPERATURE WIRING DIAGRAM DIMENSIONS AND WEIGHTS... -

Page 3: Introduction

For assistance in finding a suitable engineer in your area, visit our website www.calomax.co.uk, contact our service department on 0113 249 6681 or email: service@calomax.co.uk APPROVALS This product conforms to the CE and UKCA marking directive through... -

Page 4: Construction

Install the boiler on a surface suitable for the working weight of the boiler. Allow clearance for ventilation and for the easy removal of the front panel and drain access plate. Calomax recommend a minimum clearance of 50mm on all sides of the boiler. A suitably qualified engineer must install this unit. -

Page 5: Mounting The Unit

4 of these should be used to bolt the unit to the trolley using suitable M6 bolts (M6 bolts are NOT provided by Calomax). The bolts should be long enough to protrude from the mounting surface by at least 20mm. -

Page 6: Electrical Connections

In the event of the power supply lead to the boiler becoming damaged, the appliance must be removed from service. A replacement genuine part is available from Calomax Ltd, and must be fitted by a suitably qualified engineer. COMMISSIONING Before turning the boiler on you must fill the unit with at least 4 litres of clean drinking water to fully cover the element. -

Page 7: General Operation

Light Light State What This Means Water level is below the safety Flashing level sensor and needs to be filled for further operation Red “Empty” LED Water level is inbetween the Solid safety level sensor and the low level and needs to be filled Water level is above the Blue “Low”... -

Page 8: Scale

SCALE The production of scale is a natural phenomenon and commonly occurs in hot water systems. The nature of the scale produced and its rate of formation varies widely throughout the country. To ensure continuous, reliable operation, the boiler should be regularly de-scaled by a suitably qualified engineer. -

Page 9: Cleaning

CLEANING Avoid using any abrasive materials. Wiping the outer casing with a damp cloth should be sufficient. Some stainless steel cleaning products may not be suitable for plastic and must not come in contact with the plastic facia parts. Always disconnect the electrical supply before cleaning. -

Page 10: Basic Trouble Shooting

Faulty Triac Printed Circuit Board Replace Triac Printed Circuit Board The HS3C10 has an inbuilt thermal cutout device to protect the element in a boil dry situation. Should the cutout be activated, contact an approved Calomax service provider for advice. Page 10... -

Page 11: Spare Parts

SPARE PARTS Spare parts are usually available ex-stock. Please quote Model & Serial Number. ETTBK (black) CBTCW CBTS CBTSS TAP TOP TAP CUP WASHER TAP SPRING TAP SLOTTED ASSEMBLY STEM DOTTK E3BRK EHSPCBT HSLPCBT DRAW OFF TAP ECLIPSE HS P.C.B HS LIGHT P.C.B ELEMENT 3kW BODY... -

Page 12: Exploded Diagrams 12

EXPLODED PARTS VIEW FOR ECLIPSE HS3C10 Page 12... - Page 13 EXPLODED PARTS VIEW FOR ECLIPSE HS3C10 (BEHIND MOULDING) (BEHIND MOULDING) If parts required are not present please contact Calomax Limited Page 13...

-

Page 14: Service Instructions

Abrasive cleaning materials containing scouring powders and detergents must not be used, as such materials can cause taste problems. The integral scale-inhibitor in every Calomax boiler allows for a manual / chemical-free descale. Caustic chemical de-scalants should not be used. -

Page 15: General Function

Heat transfer compound is also supplied with all replacement circuit boards. ADJUSTING THE WATER TEMPERATURE SET POINT The temperature potentiometer (Pot) is pre-set at Calomax and will only require adjustment in exceptional circumstances. Contact Calomax for advice. -

Page 16: Wiring Diagram

Page 16... -

Page 17: Dimensions And Weights

DIMENSIONS AND WEIGHTS Model HS3C10 Weight (Empty) 12.5KG Weight (Full) 28.5KG Page 17... -

Page 18: Warranty

WARRANTY GUARANTEE (UK mainland customers only) Calomax have manufactured water boilers in the UK for over 70 years. We are proud of our products and the back-up service we provide. Properly maintained and serviced, a Calomax boiler should last many years and we have no hesitation in providing a 2 year warranty. - Page 19 Page 19...

- Page 20 Calomax Limited Lupton Avenue Leeds LS9 7DD Tel: 0113 249 6681 email: service@calomax.co.uk web: www.calomax.co.uk...

Need help?

Do you have a question about the ECLIPSE HS3C10 and is the answer not in the manual?

Questions and answers