Summary of Contents for Struers Labotom-5

- Page 1 Labotom-5 Instruction Manual Original Instructions Doc. no.: 16047025-03_C_en Date of release: 2024.03.22...

- Page 2 Copyright The contents of this manual are the property of Struers ApS. Reproduction of any part of this manual without the written permission of Struers ApS is not allowed. All rights reserved. © Struers ApS. Labotom-5...

-

Page 3: Table Of Contents

Table of Contents 1 About this manual 2 Safety 2.1 Intended use 2.2 Safety devices 2.3 Labotom-5 safety precautions 2.3.1 Read carefully before use 2.4 Safety messages 2.4.1 Safety messages in this manual 3 Get started 3.1 Device description 3.2 Overview 3.3 Struers knowledge... - Page 4 6.3 Line laser (option) 6.4 Basic operation 6.4.1 Control panel functions 6.4.2 Clamping the workpiece 6.4.3 Start and stop the cutting process 7 Maintenance and service - Labotom-5 7.1 Daily 7.1.1 Flushing gun 7.1.2 Cleaning the cooling system 7.1.3 Checking the safety guard 7.1.4 Checking the cut-off wheel guard...

- Page 5 9 Service and repair 10 Disposal 11 Troubleshooting 11.1 The machine 11.2 Cutting problems 12 Technical data 12.1 Technical data 12.2 Safety Related Parts of the Control System (SRP/CS) 12.3 Diagrams Labotom-5 12.4 Legal and regulatory information 13 Manufacturer Declaration of Conformity Labotom-5...

-

Page 6: About This Manual

For professional semi-automatic or manual materialographic preparation (wet abrasive cutting) of materials for further materialographic inspection and only to be operated by skilled/trained personnel. The machine is designed to be used with Struers consumables specially for this purpose and this type of machine. -

Page 7: Labotom-5 Safety Precautions

2 Safety Labotom-5 safety precautions 2.3.1 Read carefully before use Specific safety precautions - residual risks Ignoring this information and mishandling of the equipment can lead to severe bodily injuries and material damage. The machine must be installed in compliance with local safety regulations. -

Page 8: Safety Messages

In case of fire, alert bystanders and the fire brigade. Cut off the power. Use a powder fire extinguisher. Do not use water. Struers equipment must only be used in connection with and as described in the Instruction Manual supplied with the equipment. -

Page 9: Safety Messages In This Manual

The safety guard must be replaced immediately if the protective screen has been weakened by collision with projectile objects or if you see any visible signs of deterioration or damage. Contact Struers Service. WARNING The safety guard screen must be replaced every 5 years to ensure its intended safety. - Page 10 CRUSHING HAZARD Take care of your fingers when handling the machine. Wear safety shoes when handling heavy machinery. CAUTION Struers equipment must only be used in connection with and as described in the Instruction Manual supplied with the equipment. Labotom-5...

- Page 11 Only use the flushing gun for cleaning inside the cutting chamber. Always wear safety goggles while using the flushing gun. CAUTION Do not start flushing until the flushing gun points into the cutting chamber. CAUTION Always use goggles or a protective shield, and chemical-resistant gloves. Labotom-5...

-

Page 12: Get Started

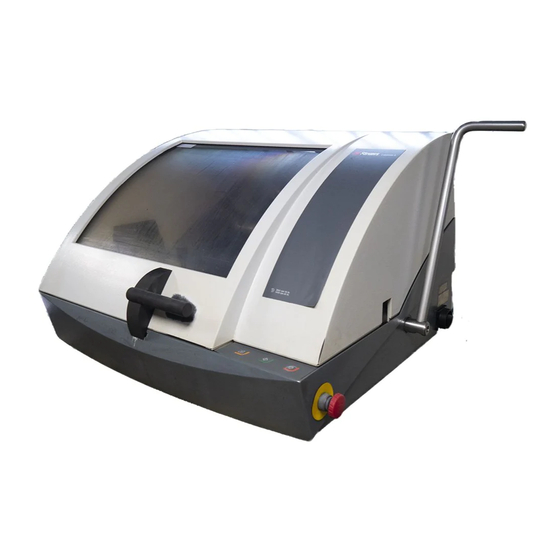

The machine should be connected to an external exhaust system to remove fumes from the cutting process. Labotom-5 can be fitted with an Extension tunnel (option) on the left side in case the operator needs to cut long workpieces. -

Page 13: Overview

C Handle for safety guard Note To open the safety guard on Labotom-5 when the machine is not connected to a power supply and/or the main power switch is off, lift the front of the machine to access the safety lock release. Use the triangle key to release the safety lock. - Page 14 3 Get started Side view, right side A Emergency stop button C Cut-off wheel handle B Opening for protruding workpieces D Main switch Labotom-5...

- Page 15 B Removable plate for mounting of extension tunnel (option) Rear view A Connection for exhaust E Water outlet B Socket for cooling sytem connection F Type plate C Electrical cable for power supply G Water inlet D Compartment for service technician Labotom-5...

-

Page 16: Struers Knowledge

Accessories and consumables Accessories For information about the available range, see the Labotom-5 brochure: • The Struers Website (http://www.struers.com) Consumables The machine is designed to be used only with Struers consumables specifically designed for this purpose and this type of machine. Labotom-5... -

Page 17: Installation

Other products may contain aggressive solvents, which dissolve e.g. rubber seals. The warranty may not cover damaged machine parts (e.g. seals and tubes), where the damage can be directly related to the use of consumables not supplied by Struers. For information about the available range, see: The Struers Website (http://www.struers.com). -

Page 18: Lift The Machine

The machine is heavy. Always use a crane and lifting strap. Weight Labotom-5 75 kg (165 lbs) Lift Labotom-5 with a crane by placing straps underneath the base of the machine, on the left side and on the right side. Lift the machine onto the table. Remove the straps. -

Page 19: At The New Location

Install the machine in a room with sufficient light. Place the machine on a rigid, stable workbench with a horizontal surface and an adequate height. You can easily adjust the position of the machine with the 2 wheels on Labotom-5 at the rear. -

Page 20: Electrical Data And External Short Circuit Protection

Local standards can override the recommendations for the main electrical power supply cable. Always contact a qualified electrician to verify which option is suitable for the local installation setup. Requirements for electrical installations With Residual Current Circuit Breakers (RCCB) - Type A, 30 mA or better Required Labotom-5... -

Page 21: Connect The Cooling System

Before you connect the recirculation unit to the machine, you must prepare it for use. See the Instruction Manual for this unit. Note Struers recommends that the flushing gun is operated at a pressure of max. 3 bar. Note Consumables •... -

Page 22: Connect The Water Outlet To The Cooling System

Labotom-5 must be connected to an external exhaust system as workpieces may emit harmfull or unpleasant gases when cut. You can connect Labotom-5 to an exhaust system via a hole on the rear of the cabinet. Remove the red plug from the exhaust hole. -

Page 23: Noise

4 Installation Note Check that the end of the pipe is level with the wall of the Labotom-5 and does not protrude into the cutting chamber. Mount the exhaust hose from your exhaust system onto the pipe. Clamp the exhaust hose using a hose clamp. - Page 24 Insert the door blinder (C) and mark the 2 holes on the cabinet. Mark 2 holes on the cabinet and drill 3 mm screw holes in the marked positions (D). Fix the door blinder with the 2 screws (D). Labotom-5...

- Page 25 4 Installation Remove the 2 hole plugs (E) in the base of the cabinet. Fix the foot using the 4 M5 screws and washers (F). Labotom-5...

- Page 26 4 Installation Mount the extension tunnel on the left hand side of the cutting chamber using the 2 M8 screws (G). Mount the rubber curtain with the M4 screws (H). Labotom-5...

-

Page 27: Transport And Storage

• Package the unit securely before transportation. Insufficient packaging could cause damage to the unit and will void the warranty. Contact Struers Service. • We recommend that you use the original packaging and fittings. - Page 28 Place the lifting straps on the inside of the rubber feet. Straps must be approved of at least twice the weight of the machine. Lift Labotom-5 with a crane by placing straps underneath the base of the machine, on the left side and on the right side.

-

Page 29: Storage

6.1.1 Selecting a cut-off wheel For information on how to select the correct cut-off wheel, see the section on Cutting on the Struers website. 6.1.2 Mount and dismount a cut-off wheel Push the cutting handle backwards until the cutting unit is in its rear-most position. -

Page 30: Clamping Devices

For workpieces larger than 40 mm dia.: • Place the vertical quick clamping tool closer to the back. Note Make sure that the nut on the cutting unit cannot come into contact with the clamping plate. Labotom-5... -

Page 31: Mount A Quick Clamping Device

For more information on the line laser, see:. The laser beam (A) indicates the position of the cut for a precise placement of the workpiece. The laser is automatically activated when the machine is switched on, and it is deactivated when you start the machine. Labotom-5... -

Page 32: Basic Operation

6.4.2 Clamping the workpiece The most convenient method for clamping workpieces is using the Struers quick clamping device (sold separately). Use the flushing gun to clean the cutting table. Place the workpiece under the clamp of a quick clamping device, on the left side of the cutting table. -

Page 33: Start And Stop The Cutting Process

If a new cut-off wheel is used, position the cut-off wheel so that it just touches the workpiece until the edge of the cut-off wheel is worn equally around the entire diameter. Pull the handle to continue cutting with force and speed suited to the material and the cut-off wheel. Labotom-5... -

Page 34: Maintenance And Service - Labotom-5

Check that there is a steady flow of coolant from the nozzles. Note The safety guard on Labotom-5 has a safety guard lock. The motor will not start as long as the safety guard is open. Leave the safety guard open when the machine is not in use to let the cutting chamber dry completely. -

Page 35: Daily

7 Maintenance and service - Labotom-5 Technical questions and spare parts If you have technical questions or when you order spare parts, state serial number and voltage/frequency. The serial number and the voltage are stated on the type plate of the machine. -

Page 36: Cleaning The Cooling System

Clean all painted surfaces and the control panel with a soft damp cloth and common household detergents. For heavy duty cleaning, use Struers Cleaner (Cat. No.49900027). Clean the safety guard with a soft damp cloth and a common household anti-static window cleaning agent. -

Page 37: Cutting Chamber

Note Leave the safety guard open to allow the cutting chamber to dry and to avoid corrosion. Note Clean the cutting chamber thoroughly if Labotom-5 is not used for a longer period of time. 7.2.3 Cleaning the clamping devices Clean and lubricate the clamping devices thoroughly. -

Page 38: Maintaining Cutting Tables

7 Maintenance and service - Labotom-5 Note Only use the flushing gun for cleaning inside the cutting chamber. • Replace the coolant at least once a month. 7.3.2 Maintaining cutting tables • Replace the stainless steel bands if they are damaged or worn. -

Page 39: Cut-Off Wheels

7 Maintenance and service - Labotom-5 Cut-off wheels CAUTION Do not use the machine with non-compatible accessories or consumables. Cut-off wheels are ordered separately. 7.5.1 Testing cut-off wheels Cut-off wheels must be tested before use. Testing an abrasive cut-off wheel for damage Visually inspect the surface for cracks and chips. -

Page 40: Test The Safety Devices

7 Maintenance and service - Labotom-5 Test the safety devices WARNING Do not use the machine with defective safety devices. Testing must be performed at least once a year. Contact Struers Service. Note Testing should always be performed by a qualified technician (electromechanical, electronic, mechanical, pneumatic, etc.). -

Page 41: Safety Guard Switch

7 Maintenance and service - Labotom-5 Testing the safety guard Test 1 Open the safety guard. Close the safety guard. If the safety-catch does not slide unobstructed into the locking mechanism, do NOT use the machine. Contact Struers Service. 7.6.3... -

Page 42: Flushing Function

7 Maintenance and service - Labotom-5 Test 2 Close the safety guard. Press Start to start a cutting process. The machine starts the cutting process and coolant. Press the Stop button. The safety guard must remain locked for minimum 4 seconds after pressing the Stop button. -

Page 43: Adjust The Cutting Handle

Use the 24 mm spanner to adjust the friction in the bearing (A). 7.7.2 Adjust the cutting handle The cutting handle is factory-mounted in a position which will suit most people when Labotom-5 is placed on a table or workbench 80 cm high. To change the position: Loosen the 2 screws (A). -

Page 44: Spare Parts

For further information, or to check the availability of spare parts, contact Struers Service. Contact information is available on Struers.com. Service and repair Struers recommends that a regular service check be carried out after every 1500 hours of use. Note Service must only be performed by a qualified technician (electromechanical, electronic, mechanical, pneumatic, etc.). -

Page 45: 11 Troubleshooting

Error Cause Action The cut-off wheel does not The safety guard is open. Close the safety guard. If the rotate. error remains, contact Struers Service. The safety lock has been Reactivate the safety lock deactivated. release before operating the machine. - Page 46 Quick clamping device The clamping device is not Adjust the two clamping column cannot hold the workpiece balanced. screws. Clamping heart worn. Contact Struers Service. Labotom-5...

-

Page 47: Cutting Problems

Select another type of cut-off wheel. Too high force on the cut-off Reduce the cutting force near wheel near the end of the the end of the operation. operation. Lack of support. If possible, support the workpiece on both sides. Labotom-5... - Page 48 Use a softer cut-off wheel. The force on the cut-off- Apply a lower force on the cut-off wheel is too high. wheel. Inadequate cooling. Make sure that there is enough water in the recirculation cooling unit. Check the cooling water hoses. Labotom-5...

- Page 49 The cut-off wheel is too soft Select a harder cut-off wheel. for the task. The machine vibrates. Contact Struers Service. The direction of the cut-off Incorrect electrical Switch 2 of the phases. wheel rotation is wrong connection.

-

Page 50: 12 Technical Data

Option (Laser class up to 2M) Software and electronics Controls Button foil Display Safety standards See the Declaration of Conformity Operating environment Surrounding temperature 5 - 40 °C (41 - 104 °F) Humidity 35 - 85 % RH non-condensing Labotom-5... - Page 51 3L + (N) + PE Power S3 60% 2.2 kW (3 hp) Power S3 15 % 3.2 kW (4.3 hp) Current, nominal load 8.5 A Current, max. 17 A Ampere rating of the largest 7.5 A motor or load Labotom-5...

- Page 52 3L + (N) + PE Power S3 60% 2.2 kW (3 hp) Power S3 15 % 3.2 kW (4.3 hp) Current, nominal load 5.7 A Current, max. 11.4 A Ampere rating of the largest 4.7 A motor or load Labotom-5...

- Page 53 LpA = 70.5 dB(A) (measured pressure level at workstations value). Uncertainty K = 4 dB(A) Measurements made in accordance with EN ISO 11202 Vibration level Declared vibration emission Total vibration exposure to upper parts of the body does not exceed 2.5 m/s Labotom-5...

-

Page 54: Safety Related Parts Of The Control System (Srp/Cs)

SRP/CS (safety-related parts of a control system) are parts that have an influence on safe operation of the machine. Note Replacement of safety critical components must only be performed by a Struers engineer or a qualified technician (electromechanical, electronic, mechanical, pneumatic, etc.). -

Page 55: Diagrams Labotom-5

If you want to view specific information in detail, see the online version of this manual. Title Block diagram 16043051 ►56 Water diagram 16041002 ►57 Safety diagram 16043101 ►58 Circuit diagram See the diagram number on the type plate of the equipment, and contact Struers Service via Struers.com. Labotom-5... - Page 56 12 Technical data 16043051 Labotom-5...

- Page 57 12 Technical data 16041002 Labotom-5...

- Page 58 12 Technical data 16043101 Labotom-5...

-

Page 59: Legal And Regulatory Information

Responsibility of the manufacturer The following restrictions should be observed, as violation of the restrictions may cause cancellation of Struers legal obligations. The manufacturer assumes no responsibility for errors in the text and/or illustrations in this manual. The information in this manual is subject to change without notice. The manual may mention accessories or parts not included in the supplied version of the equipment. -

Page 61: Declaration Of Conformity

Based on: 16047902 E Declaration of Conformity Manufacturer Struers ApS • Pederstrupvej 84 • DK-2750 Ballerup • Denmark Name Labotom-5 Model Function Cut-off machine Type 0604 Cat. no. Labotom-5 06046229, 06046235, 06046246, 06046254, 06046230, 06046236, 06046247 Accessories, equipment 06046903, 06046912 Serial no. - Page 62 Tõlked leiate aadressilt Katso käännökset osoitteesta Pour les traductions, voir Za prijevode idite na A fordítások itt érhetők el Per le traduzioni consultare www.struers.com/Library 翻 訳 については、 Vertimai patalpinti Tulkojumus skatīt Voor vertalingen zie For oversettelser se Aby znaleźć tłumaczenia, sprawdź...

Need help?

Do you have a question about the Labotom-5 and is the answer not in the manual?

Questions and answers

We need a replacement hold down block - it no longer grips the part as the cam/bushing is worn

The documents do not mention a "hold down block" or where to find a replacement for it. To obtain replacement parts for the Struers Labotom-5, including parts not listed specifically, you should contact Struers Service and provide the year of production, which is engraved on the cylinder frame.

This answer is automatically generated

How do you rewire a new schermal safety switch? Old switch has #32 terminal spot for wire coming from the struers - labotom-5, new switch doesn’t have a #32 term spot. Where do I need to put that wire now?