Summary of Contents for Struers LaboPol-20

- Page 1 LaboPol-20 Instruction Manual Original Instructions Doc. no.: 16327025-02_A_en-us Date of release: 2023.03.02...

- Page 2 Copyright The contents of this manual are the property of Struers ApS. Reproduction of any part of this manual without the written permission of Struers ApS is not allowed. All rights reserved. © Struers ApS 2023.03.02. LaboPol-20...

-

Page 3: Table Of Contents

2.2.1 Read carefully before use 2.3 Safety messages 2.4 Safety messages in this manual 3 Getting started 3.1 Device description 3.2 LaboPol-20 - Front view 3.2.1 Control panel/Specimen mover 3.3 LaboPol-20 - Rear view 3.4 Struers knowledge 3.5 Accessories and consumables 4 Transport and storage 4.1 Transport... - Page 4 7.2.9 Removing the specimens 7.2.10 Changing the specimen mover plate 8 LaboDoser-10 8.1 Unpack the machine 8.2 Check the packing list 8.3 Installation 8.4 Operating LaboDoser-10 8.5 Changing lubricant/suspension 9 Maintenance and service 9.1 General cleaning 9.2 Daily 9.3 Weekly LaboPol-20...

- Page 5 9.5.1 Test the safety devices 9.5.2 Emergency stop 9.6 Spare parts 9.7 Service and repair 9.8 Disposal 10 Troubleshooting 10.1 Troubleshooting - LaboPol-20 10.2 LaboForce-50 11 Technical data 11.1 Technical data 11.2 Safety Circuit Categories/Performance Level 11.3 Noise and vibration levels 11.4 Technical data - equipment units...

-

Page 6: About This Manual

Intended use The machine is for use in a professional working environment (e.g. a materialographic laboratory). The equipment is designed to be used only with Struers consumables specifically designed for this purpose and this type of machine. The machine is for professional manual or semi-automatic materialographic preparation (grinding or polishing) of materials for further materialographic inspection. -

Page 7: Labopol-20 Safety Precautions

2 Safety LaboPol-20 safety precautions 2.2.1 Read carefully before use In combination with: LaboUI, LaboForce-50. Ignoring this information and mishandling of the equipment can lead to severe bodily injuries and material damage. Specific safety precautions - residual risks The operator must read the Instruction Manual and, where applicable, the Safety Data Sheets for the applied consumables. -

Page 8: Safety Messages

2 Safety Struers recommends that the main water supply is shut off or disconnected if the machine is to be left unattended. Consumables: only use consumables specifically developed for use with this type of materialographic machine. Alcohol-based consumables: follow the current safety rules for handling, mixing, filling, emptying and disposing of alcohol-based liquids. -

Page 9: Safety Messages In This Manual

This sign indicates that additional information and hints are available. Safety messages in this manual WARNING Struers equipment must only be used in connection with and as described in the Instruction Manual supplied with the equipment. CRUSHING HAZARD Take care of your fingers when handling the machine. -

Page 10: Getting Started

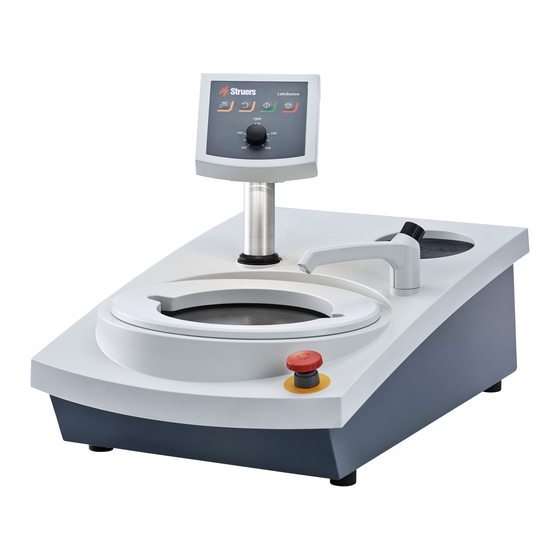

Safety critical components must be replaced after a maximum lifetime of 20 years. Contact Struers Service. Getting started Device description LaboPol-20 is for materialographic preparation (grinding/polishing) using a preparation disc of 200 mm in diameter. LaboPol-20 is for manual preparation when used with LaboUI. LaboPol-20... -

Page 11: Labopol-20 - Front View

3 Getting started LaboPol-20 is for semi-automatic preparation when used with LaboForce-50. The operator selects the grinding/polishing surface and the cooling fluid/abrasive suspension to be applied. Cooling water is applied when the operator opens the water tap. Other fluids are applied manually or by a separate dosing unit. -

Page 12: Control Panel/Specimen Mover

LaboUI • Control panel functions ►21. LaboForce-50 • Control panel functions ►30. LaboPol-20 - Rear view A Main switch B Fuses C Electrical power socket D Water inlet from main water supply E Waste water outlet F Type plate LaboPol-20... -

Page 13: Struers Knowledge

Specimens can be prepared to the perfect finish, the true structure, or the preparation can be stopped when the surface is acceptable for a specific examination. Hint For further information, see the section on Grinding and Polishing on the Struers website. Accessories and consumables... -

Page 14: Long-Term Storage Or Shipping

• Place the machine and accessories in their original packaging. • Secure the boxes on a pallet with straps. At the new location At the new location, make sure that the facilities required are in place. LaboPol-20... -

Page 15: Installation

Optional accessories may be included in the packing box. The packing box contains the following items: Pcs. Description LaboPol-20 Electrical power supply cables Disposable bowl liner, clear plastic Splash guard for manual preparation Water inlet hose. Diameter: 19 mm/¾". Length: 2 m/6.6' Filter gasket Reduction ring with gasket, ¾"... -

Page 16: Location

5 Installation Weight LaboPol-20 22 kg (49 lbs) Lift the machine by gripping the base of the machine from beneath, from both the left side and the right side. – Alternatively, use a crane and two lifting straps to lift the machine. -

Page 17: Power Supply

The leads must be connected as follows: Yellow/Green Earth (ground) Brown Line (live) Blue Neutral 5.5.2 2-phase supply The 3-pin plug (North American NEMA) is for use on 2-phase electrical power connections. The leads must be connected as follows: LaboPol-20... -

Page 18: Connection To The Machine

Lead the other end of the waste water hose to the waste water drain.If needed, shorten the hose. Note Make sure that the hose slopes downward towards the waste water drain throughout its entire length. Make sure that there are no sharp bends in the waste water hose. LaboPol-20... -

Page 19: Installing The Preparation Disc

Semi-automatic preparation To lower the noise, decrease the rotational speed and/or the force with which the specimens are pressed against the preparation surface. The processing time may increase. Vibration For information on the total vibration exposure to hand and arm, see this section: Technical data ►45. LaboPol-20... -

Page 20: Laboui

Cut the packing tape on the top of the box. Remove the loose parts. Remove the unit from the box. 6.1.2 Check the packing list Optional accessories may be included in the packing box. The packing box contains the following items: LaboPol-20... -

Page 21: Installation - Laboui

Do not tighten the screws completely. Cover the holes with the two cover caps. Allen key and cover caps are supplied with LaboPol. A V-ring B Fastening screws Operate the device 6.2.1 Control panel functions CAUTION Keep clear of rotating parts during operation. LaboPol-20... -

Page 22: Water Tap

During polishing, close the nozzle on the water tap. Note Close the water tap before you start a polishing process. For optimal results and to avoid splashing, position the water tap between the center and the left edge of the polishing disc. LaboPol-20... -

Page 23: The Spin Function

Wet grinding (for plain-back SiC • Use the splash guard for the Wet Grinding Disc. Paper) 6.2.5 Manual preparation When you perform manual preparation, you hold the specimen in your hand and press it firmly onto and across the preparation surface. LaboPol-20... -

Page 24: Starting And Stopping The Machine

Starting and stopping the machine Start the machine WARNING Do not use the machine with defective safety devices. Contact Struers Service. CAUTION When working at machines with rotating parts, take care to prevent clothes and/or hair from being caught by the rotating parts. -

Page 25: Laboforce-50

Turn the emergency stop button to release the emergency stop. LaboForce-50 Front view A Control panel B Disc speed control C LED light (not shown) D Specimen mover head E Control panel column LaboPol-20... -

Page 26: Installation

Cut the packing tape on the top of the box. Remove the loose parts. Remove the unit from the box. 7.1.2 Check the packing list Optional accessories may be included in the packing box. The packing box contains the following items: LaboPol-20... -

Page 27: Installation - Laboforce-50

Install the specimen mover in the connection hole of the machine. Remove the plastic disc protecting the communication cable. Connect the communication cable on the column to the connection port on the machine. Guide the column down into the connection hole. LaboPol-20... -

Page 28: Adjusting The Specimen Mover

Push the specimen mover plate upwards and use the Allen key to tighten the screw to secure it in position. See Make sure that the specimen mover plate is securely mounted. Lower the housing back into position. A Screw LaboPol-20... - Page 29 Use the locking handle to lock the specimen mover head in operating position. A Spacing disc Lower the column until the specimen mover plate rests on the spacing disc. Adjust the horizontal position of the specimen mover plate. LaboPol-20...

-

Page 30: Operate The Device

Tighten the 2 fastening screws firmly. The specimen mover will now remain in position. Cover the holes with the two caps. Allen key and cover caps are included in the package. Operate the device 7.2.1 Control panel functions CAUTION Keep clear of rotating parts during operation. LaboPol-20... -

Page 31: Water Tap

During polishing, close the nozzle on the water tap. Note Close the water tap before you start a polishing process. For optimal results and to avoid splashing, position the water tap between the center and the left edge of the polishing disc. LaboPol-20... -

Page 32: The Spin Function

Lift the pressure feet on the force adjustment screw to make room for the specimen. Place the specimen in one of the holes of the specimen mover plate and lower the pressure feet. Each position is marked for easy identification of the individual specimen. LaboPol-20... -

Page 33: Adjusting The Force

Newton. Indication Force 0 - 5 N 10 N 20 N 30 N 7.2.7 Manual preparation If you cannot prepare a specimen by using a standard specimen mover plate or specimen holder, you can prepare it manually. LaboPol-20... -

Page 34: Starting And Stopping The Machine

For manual preparation you can use the switch on the side of the specimen mover head to disable rotation of LaboForce-50. A Switch 7.2.8 Starting and stopping the machine Start the machine WARNING Do not use the machine with defective safety devices. Contact Struers Service. LaboPol-20... - Page 35 Press the emergency stop button to activate an emergency stop. WARNING Before you release the emergency stop, investigate the reason for activating the emergency stop and take any necessary corrective action. Turn the emergency stop button to release the emergency stop. LaboPol-20...

-

Page 36: Removing The Specimens

LaboDoser-10 is a drip lubricator for delivering an uninterrupted flow of suspension or lubricant on a preparation disc in the preparation (grinding or polishing) of materials for further materialographic inspection. The device is designed to be used with Struers consumables specially designed for this purpose and this type of device. LaboDoser-10 can be mounted on: •... -

Page 37: Unpack The Machine

LaboDoser-10 mounted on LaboPol A LaboDoser-10 suspension/lubricant bottle B Adjustable valve C Dosing nozzle D Preparation disc LaboDoser-10 mounted on a LaboDoser-10 table stand Unpack the machine Note We recommend that you keep all original packaging and fittings for future use. LaboPol-20... -

Page 38: Check The Packing List

If lubricant or suspension is not to be used for a prolonged period of time, remove the bottle from the bottle holder and store it upright. LaboDoser-10 can be mounted on the column of the following units: • LaboUI • LaboForce-50 • LaboForce-Mi LaboPol-20... -

Page 39: Operating Labodoser-10

D Dosing nozzle Use the bracket and the two screws to mount the dosing arm on the column of the machine. Attach the bottle cap with adjustable valve onto a Struers suspension/lubricant bottle. Insert the bottle into the doser arm. -

Page 40: Maintenance And Service

9 Maintenance and service Put the bottle cap on a Struers lubricant/suspension bottle. Maintenance and service Proper maintenance is required to achieve the maximum up-time and operating lifetime of the machine. Maintenance is important in ensuring continued safe operation of your machine. -

Page 41: Monthly

The safety devices must be tested at least once a year. WARNING Do not use the machine with defective safety devices. Contact Struers Service. WARNING Safety critical components must be replaced after a maximum lifetime of 20 years. Contact Struers Service. -

Page 42: Emergency Stop

If you have technical questions or when you order spare parts, state the serial number. The serial number is stated on the type plate of the unit. For further information, or to check the availability of spare parts, contact Struers Service. Contact information is available on Struers.com. -

Page 43: Service And Repair

9 Maintenance and service Note Replacement of safety critical components must only be performed by a Struers engineer or a qualified technician (electromechanical, electronic, mechanical, pneumatic, etc.). Note Safety critical components must only be replaced by components with at least the same safety level. -

Page 44: 10 Troubleshooting

10 Troubleshooting 10 Troubleshooting 10.1 Troubleshooting - LaboPol-20 Error Cause Action Noise when the machine The belt is not tight enough. The belt must be tightened. starts, or the turntable will not Contact Struers Service. turn. The machine does not The main switch is off. -

Page 45: 11 Technical Data

Frequency inverter has Switch the equipment off. stopped the equipment. Wait for a few minutes then restart. If the error remains: Contact Struers Service. The specimen mover starts to Column screws loose. Tighten the screws immediately. turn. Bad or unusual preparation... -

Page 46: Safety Circuit Categories/Performance Level

2.5 m/s2. Dimensions and weight Width 40 cm (15.7") Depth 67.3 cm (26.5") Height 28 cm (8.7") Weight 22 kg (49 lbs) 11.2 Safety Circuit Categories/Performance Level Safety Circuit Emergency stop PL c, Category 1 Categories/Performance Stop category 0 Level LaboPol-20... -

Page 47: Noise And Vibration Levels

SRP/CS (safety-related parts of a control system) are parts that have an influence on safe operation of the machine. Note Replacement of safety critical components must only be performed by a Struers engineer or a qualified technician (electromechanical, electronic, mechanical, pneumatic, etc.). -

Page 48: Diagrams

Relay 24 V DC DPDT Water valve 21A2KV20, 2YM12120 BDV08024CY 11.6 Diagrams If you wish to view specific information in detail, see the online version of this manual. 11.6.1 Diagrams - LaboPol-20 Title LaboPol-20, Block diagram 16323051 A LaboPol-20, Water diagram 16321001 A LaboPol-20... - Page 49 11 Technical data 16323051 A LaboPol-20...

- Page 50 11 Technical data 16321001 A LaboPol-20...

-

Page 51: Diagrams - Equipment Units

Responsibility of the manufacturer The following restrictions should be observed, as violation of the restrictions may cause cancellation of Struers legal obligations. The manufacturer assumes no responsibility for errors in the text and/or illustrations in this manual. The information in this manual is subject to change without notice. The manual may mention accessories or parts not included in the supplied version of the equipment. -

Page 53: Declaration Of Conformity

Based on: 16327902 D Declaration of Conformity Manufacturer Struers ApS • Pederstrupvej 84 • DK-2750 Ballerup • Denmark Name LaboPol-20 Model Function Grinding/Polishing machine Type Cat. no. 06326127 In combination with: 06206901 (LaboUI), 06356127 (LaboForce-50) Serial no. Module H, according to global approach... - Page 54 Tõlked leiate aadressilt Katso käännökset osoitteesta Pour les traductions, voir Za prijevode idite na A fordítások itt érhetők el Per le traduzioni consultare www.struers.com/Library 翻 訳 については、 Vertimai patalpinti Tulkojumus skatīt Voor vertalingen zie For oversettelser se Aby znaleźć tłumaczenia, sprawdź...

Need help?

Do you have a question about the LaboPol-20 and is the answer not in the manual?

Questions and answers