Summary of Contents for Struers Labotom-20

- Page 1 Labotom-20 Instruction Manual Original Instructions Doc. no.: 16937025-01_D_en Date of release: 2024.03.22...

- Page 2 Copyright The contents of this manual are the property of Struers ApS. Reproduction of any part of this manual without the written permission of Struers ApS is not allowed. All rights reserved. © Struers ApS. Labotom-20...

-

Page 3: Table Of Contents

Table of Contents 1 About this manual 2 Safety 2.1 Intended use 2.2 Safety devices 2.3 Labotom-20 safety precautions 2.3.1 Read carefully before use 2.4 Safety messages 2.4.1 Safety messages in this manual 3 Get started 3.1 Device description 3.2 Overview 3.3 Struers knowledge... - Page 4 6.4 Basic operation 6.4.1 Control panel functions 6.4.2 Clamping the workpiece 6.4.3 Start and stop the cutting process 7 Maintenance and service - Labotom-20 7.1 Daily 7.1.1 Flushing gun 7.1.2 Cleaning the cutting chamber using AxioWash 7.1.3 Cleaning the cooling system 7.1.4 Checking the safety guard...

- Page 5 11.1 The machine 11.2 Cutting problems 12 Technical data 12.1 Technical data 12.2 Safety Circuit Categories/Performance Level 12.3 Safety Related Parts of the Control System (SRP/CS) 12.4 Diagrams Labotom-20 12.5 Legal and regulatory information 13 Manufacturer Declaration of Conformity Labotom-20...

-

Page 6: About This Manual

1 About this manual About this manual CAUTION Struers equipment must only be used in connection with and as described in the Instruction Manual supplied with the equipment. Note Read the Instruction Manual carefully before use. Note If you want to view specific information in detail, see the online version of this manual. -

Page 7: Labotom-20 Safety Precautions

In case of fire, alert bystanders and the fire brigade. Cut off the power. Use a powder fire extinguisher. Do not use water. Struers equipment must only be used in connection with and as described in the Instruction Manual supplied with the equipment. -

Page 8: Safety Messages

If the equipment is subjected to misuse, incorrect installation, alteration, neglect, accident or incorrect repair, Struers will accept no responsibility for damage to the user or the equipment. Dismantling of any part of the equipment, during service or repair, should always be performed by a qualified technician (electromechanical, electronic, mechanical, pneumatic, etc.). -

Page 9: Safety Messages In This Manual

The safety guard must be replaced immediately if the protective screen has been weakened by collision with projectile objects or if you see any visible signs of deterioration or damage. Contact Struers Service. WARNING The safety guard screen must be replaced every 5 years to ensure its intended safety. - Page 10 ELECTRICAL HAZARD For electrical installations with Residual Current Circuit Breakers For Labotom-20 a residual current circuit breaker Type B, 30 mA is required (EN 50178/5.2.11.1). For electrical installations with Residual Current Circuit Breakers For Labotom-20 a residual current circuit breaker Type A, 30 mA is required (EN 50178/5.2.11.1).

- Page 11 Take care of your fingers when handling the machine. Wear safety shoes when handling heavy machinery. CAUTION Struers equipment must only be used in connection with and as described in the Instruction Manual supplied with the equipment. CAUTION Laser radiation. Do not stare into beam or expose users of telescopic optics.

-

Page 12: Get Started

It must be equipped with a recirculation system for cooling liquid. Labotom-20 for tunnels can be fitted with tunnels on each side or both sides in case the operator needs to cut long workpieces. -

Page 13: Overview

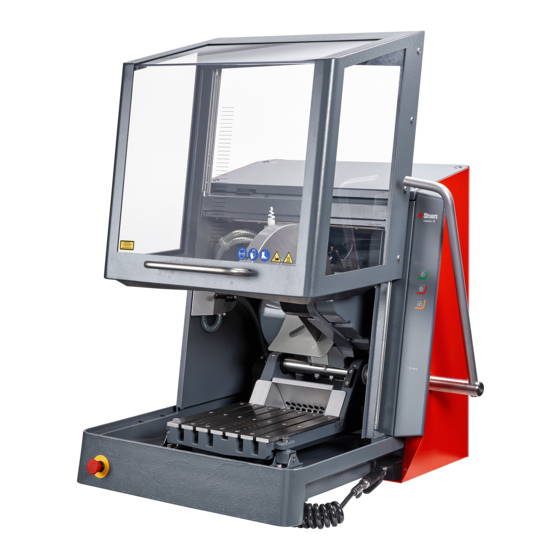

3 Get started Overview Front view A Safety guard B Handle for safety guard C Emergency stop D Control panel E Cut-off wheel handle F Cutting guiding lines Labotom-20... - Page 14 Left side A Safety lock release B Main switch Rear view A Motor turn-on counter B Power socket C Compartment for service technician D Water inlet E Socket for cooling sytem connection F Connection for exhaust G Water outlet Labotom-20...

-

Page 15: Struers Knowledge

The Struers Website (http://www.struers.com) Consumables The machine is designed to be used only with Struers consumables specifically designed for this purpose and this type of machine. Other products may contain aggressive solvents, which dissolve e.g. rubber seals. The warranty may not cover damaged machine parts (e.g. seals and tubes), where the damage can be directly related to the use of consumables not supplied by Struers. -

Page 16: Installation

Optional accessories may be included in the packing box. The packing box contains the following items: Pcs. Description Labotom-20 Open-end wrench, 300 mm, for changing the cut-off wheel Triangular key, for opening the safety guard when the power is off. Elbow pipe for water outlet Water outlet hose, 2 m (79") -

Page 17: Lift The Machine

Be careful when placing the lifting straps, as these can damage the safety guard. Make sure that the straps are parallel to each other and position the lifting bar so that both straps are kept apart below the lifting points. Labotom-20... - Page 18 4 Installation Center of gravity 37.5 cm (14.7") 40 cm (15.6") 73.5 cm (29") 90 cm (35.5") 38 cm (15") 31.5 cm (12.4") 86.5 cm (34") Labotom-20...

-

Page 19: At The New Location

(B). Unlock the safety guard by turning the triangular key included in the packing box clockwise. Check the packing list ►16 To reset the lock on the safety guard, turn the triangular key counter-clockwise. Labotom-20... - Page 20 Use a 30 mm (1.18") wrench, and a 13 mm (0.51") wrench. 10. Remove the transport bracket. 11. Place the M20 nut into place again. 12. Unpack the water hose by removing the cover foil and cable ties. Labotom-20...

-

Page 21: Power Supply

(A). 4.5.2 Power supply cable - recommended specifications Local standards can override the recommendations for the main electrical power supply cable. Always contact a qualified electrician to verify which option is suitable for the local installation setup. Labotom-20... - Page 22 The machine must always be protected by external fuses. See the table below for the fuse size required. Voltage/frequency: 3 x 200 V/50 Hz Power, nominal load S3 60%: 5.5 kW (7.4 hp) S3 15%: 7.5 kW (10 hp) Number of phases 3 (3L + PE) Labotom-20...

- Page 23 Voltage/frequency: 3 x 380-415V/50 Hz Power, nominal load S3 60%: 5.5 kW (7.4 hp) S3 15%: 7.5 kW (10 hp) Number of phases 3 (3L + PE) Power, nominal load 12 A Power, Max. load 24 A Ampere rating, largest motor 11 A Labotom-20...

-

Page 24: External Short Circuit Protection

ELECTRICAL HAZARD The pump of the recirculation cooling unit must be earthed (grounded). Make sure that the electrical power supply voltage corresponds to the voltage stated on the type plate of the pump. Incorrect voltage can damage the electrical circuit. Labotom-20... -

Page 25: Connect The Water Outlet To The Cooling System

Before you connect the recirculation unit to the machine, you must prepare it for use. See the Instruction Manual for this unit. Note Struers recommends that the flushing gun is operated at a pressure of max. 3 bar. Note Consumables •... -

Page 26: Connect The Water Inlet From The Cooling System

Labotom-20 must be connected to an external exhaust system. You can connect Labotom-20 to an exhaust system via a hole on the rear of the cabinet. If you are not using an exhaust system, use the red plug supplied to cover the hole on the rear of the cabinet. -

Page 27: Noise

Handling vibration during operation Manual cutting may cause vibrations in hand and arm. To lower the vibration, decrease the pressure or use a vibration-reducing glove. Always use recommended Struers clamping solutions to reduce the source of vibration. 4.10 Extension tunnels (option) Extension tunnels (option) can be useful if you are working with large workpieces. - Page 28 Mount the 2 washers and 2 M6x34 screws in the part of the extension tunnel that is inside the cutting chamber. Use a 5 mm (0.19") hexagonal bit. Tighten the screws loosely. Labotom-20...

-

Page 29: Transport And Storage

• Package the unit securely before transportation. Insufficient packaging could cause damage to the unit and will void the warranty. Contact Struers Service. • We recommend that you use the original packaging and fittings. - Page 30 Place the crate on the pallet. Make sure that the front of the crate faces the safety guard (A). Screw the screws into place to fasten the crate to the pallet. Use a screwdriver PH 2. A Front of the crate Labotom-20...

-

Page 31: Storage

Cut-off wheels are ordered separately. 6.1.1 Selecting a cut-off wheel For information on how to select the correct cut-off wheel, see the section on Cutting on the Struers website. 6.1.2 Mount and dismount a cut-off wheel Push the cutting handle backwards until the cutting unit is in its rear-most position. -

Page 32: Clamping Devices

Lines on the cutting table help you place the workpiece in the correct position. You obtain the best results when the lower quadrant of the cut-off wheel enters the workpiece (the shaded area on the illustration). Labotom-20... -

Page 33: Vertical Quick Clamping Devices

Adjust the clamping devices until they fit the workpiece. Tighten the screws with the spanner. The illustration shows a cylindrical workpiece secured with a quick clamping device. Labotom-20... -

Page 34: Line Laser

Basic operation CAUTION Always close the safety guard carefully to avoid injuries. CAUTION Always wear safety shoes when handling workpieces. HEAT HAZARD Wear suitable gloves to protect fingers from abrasives and warm/sharp specimens. 6.4.1 Control panel functions Labotom-20... -

Page 35: Clamping The Workpiece

Lower the cut-off wheel to check the position of the cut. Turn the handle on the clamping device to the vertical position. Push the clamping device downwards on the workpiece and lock it in place pushing the locking handle forward. See : Vertical quick clamping devices ►33. Labotom-20... -

Page 36: Start And Stop The Cutting Process

10. When you finish cutting through the workpiece, return the cutting handle to the start position. 11. Press Stop to stop the cut-off wheel and the coolant. 12. Wait until the safety lock is released before you open the safety guard. Labotom-20... -

Page 37: Maintenance And Service - Labotom-20

Note The safety guard on Labotom-20 has a safety guard lock. The motor will not start as long as the safety guard is open. Leave the safety guard open when the machine is not in use to let the cutting chamber dry completely. -

Page 38: Flushing Gun

7 Maintenance and service - Labotom-20 7.1.1 Flushing gun CAUTION Avoid skin contact with the coolant additive. Do not start flushing until the flushing gun points into the cutting chamber. Only use the flushing gun for cleaning inside the cutting chamber. -

Page 39: Cleaning The Cooling System

7 Maintenance and service - Labotom-20 Open the safety guard. Move the lever to the horizontal position. Close the safety guard. Press the Start button. The motor starts and water is sprayed through the AxioWash nozzle. Move the handle for the cut-off wheel up and down to optimize the cleaning of the cutting chamber. -

Page 40: Weekly

7 Maintenance and service - Labotom-20 • Check the safety guard lock tongue for correct function. It must slide unobstructed into the locking mechanism. Weekly 7.2.1 Weekly cleaning Clean the machine regularly to avoid damaging effects to the machine and the specimens from abrasive grains or metal particles. -

Page 41: Maintaining Cutting Tables

7 Maintenance and service - Labotom-20 CAUTION Avoid skin contact with the coolant additive. Always use goggles or a protective shield, and chemical-resistant gloves. CAUTION Do not start flushing until the flushing gun points into the cutting chamber. Note Only use the flushing gun for cleaning inside the cutting chamber. -

Page 42: Cut-Off Wheels

7 Maintenance and service - Labotom-20 Cut-off wheels CAUTION Do not use the machine with non-compatible accessories or consumables. Cut-off wheels are ordered separately. 7.5.1 Testing cut-off wheels Cut-off wheels must be tested before use. Testing an abrasive cut-off wheel for damage Visually inspect the surface for cracks and chips. -

Page 43: Test The Safety Devices

7 Maintenance and service - Labotom-20 Test the safety devices WARNING Do not use the machine with defective safety devices. Testing must be performed at least once a year. Contact Struers Service. Note Testing should always be performed by a qualified technician (electromechanical, electronic, mechanical, pneumatic, etc.). -

Page 44: Safety Guard Switch

7 Maintenance and service - Labotom-20 Testing the safety guard Test 1 Open the safety guard. Make sure that the safety guard stays up in the highest position. If the safety guard does not stay open in the highest position, close the safety guard. -

Page 45: Flushing Function

Stop button. If you can open the safety guard before the 4 seconds have passed, close the safety guard again. Do NOT use the machine. Contact Struers Service. Test 3 Close the safety guard. Press Start to start a cutting process. -

Page 46: Service And Repair

9 Service and repair For further information, or to check the availability of spare parts, contact Struers Service. Contact information is available on Struers.com. Service and repair Struers recommends that a general preventive maintenance be carried out once every calendar year or after <6600 cuts. -

Page 47: 11 Troubleshooting

Error Cause Action The cut-off wheel does not The safety guard is open. Close the safety guard. If the rotate. error remains, contact Struers Service. The safety lock has been Reactivate the safety lock deactivated. release before operating the machine. - Page 48 Adjust the two clamping column cannot hold the workpiece balanced. screws. Clamping heart worn. Contact Struers Service. The laser line does not The line laser is not aligned Adjust it with the 2 screws on the correspond to the place of with the inner flange.

-

Page 49: Cutting Problems

The cut bends to a side. Initial cutting rate too fast. Let the cut-off wheel make a small notch into the workpiece before you make the actual cut. The force on the cut-off- Apply lower force. wheel is too high. Labotom-20... - Page 50 The cut-off wheel is too soft Select a harder cut-off wheel. for the task. The machine vibrates. Contact Struers Service. The cut-off wheel does not Incorrect choice of cut-off Select an appropriate cut-off cut through the workpiece wheel.

-

Page 51: 12 Technical Data

Exert more force on the cut-off wheel. Cutting force too high. Reduce the force on the cut-off wheel. Worn bearings. Contact Struers Service. Certain workpieces can be Contact Struers Service. difficult to clamp adequately and may result in resonance and vibration. - Page 52 Display Safety standards CE-labeled according to EU directives REACH For information about REACH, contact your local Struers office. Operating environment Surrounding temperature 5 - 40 °C (41 - 104 °F) Humidity 35 - 85 % RH non-condensing Power supply 1...

- Page 53 3L + (N) + PE Power S1 Power S3 60% 6.6 kW (8.8 hp) Power S3 15 % 8.5 kW (11.4 hp) Current, nominal load 22.5 A Current, max. 45 A Ampere rating of the largest 21.5 A motor or load Labotom-20...

- Page 54 Current, nominal load 12.4 A Current, max. 24.8 A Ampere rating of the largest 11.4 A motor or load Cooling system Option Cooling System 4 Exhaust Recommended capacity 150 m /h (5300 ft /h) at 0 mm (0") water gauge. Labotom-20...

- Page 55 Width (one tunnel) Left: 134 cm (52,8") Right: 126 cm (49.4") Width (two tunnels) 170 cm (67") Depth 94 cm (37.1") Height (guard closed, handle 90 cm (35.6") included) Height (guard open) 122 cm (48") Weight 225 kg (496 lbs) Labotom-20...

-

Page 56: Safety Circuit Categories/Performance Level

SRP/CS (safety-related parts of a control system) are parts that have an influence on safe operation of the machine. Note Replacement of safety critical components must only be performed by a Struers engineer or a qualified technician (electromechanical, electronic, mechanical, pneumatic, etc.). -

Page 57: Diagrams Labotom-20

Struers 16930363 Cut-off wheel Struers 16930275 guard Extension Struers 16930036 tunnel Right side Extension Struers 16930037 tunnel Left side 12.4 Diagrams Labotom-20 Note If you want to view specific information in detail, see the online version of this manual. Labotom-20... - Page 58 12 Technical data Title Labotom-20 Block diagram 16933050 ►59 Water diagram 16931002 ►60 Safety diagram 16933100 ►61 Circuit diagram See the diagram number on the type plate of the equipment, and contact Struers Service via Struers.com. Labotom-20...

- Page 59 12 Technical data 16933050 Labotom-20...

- Page 60 12 Technical data 16931002 Labotom-20...

- Page 61 12 Technical data 16933100 Labotom-20...

-

Page 62: Legal And Regulatory Information

Responsibility of the manufacturer The following restrictions should be observed, as violation of the restrictions may cause cancellation of Struers legal obligations. The manufacturer assumes no responsibility for errors in the text and/or illustrations in this manual. The information in this manual is subject to change without notice. The manual may mention accessories or parts not included in the supplied version of the equipment. -

Page 63: Declaration Of Conformity

Based on: 16937900 B Declaration of Conformity Manufacturer Struers ApS • Pederstrupvej 84 • DK-2750 Ballerup • Denmark Name Labotom-20 Model Function Cut-off machine Type Cat. no. Machine without tunnels 06936129, 06936130, 06936135, 06936136, 06936146, 06936147, 06936154 Machine with tunnels... - Page 64 Tõlked leiate aadressilt Katso käännökset osoitteesta Pour les traductions, voir Za prijevode idite na A fordítások itt érhetők el Per le traduzioni consultare www.struers.com/Library 翻 訳 については、 Vertimai patalpinti Tulkojumus skatīt Voor vertalingen zie For oversettelser se Aby znaleźć tłumaczenia, sprawdź...

Need help?

Do you have a question about the Labotom-20 and is the answer not in the manual?

Questions and answers