Table of Contents

Advertisement

Quick Links

P_02893

Peristaltic pump system

PP25S, PP25C, PP40S, PP40C, PP25Y, PP40Y

Original Operating Manual

II 3 D Ex h IIIB T85°C Dc

For professional use.

Always observe the information in this manual, particularly the safety

instructions and the warning instructions. Store the manual in a safe place.

Edition: 05/2023

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for WAGNER PP25S

- Page 1 P_02893 Peristaltic pump system PP25S, PP25C, PP40S, PP40C, PP25Y, PP40Y Original Operating Manual II 3 D Ex h IIIB T85°C Dc For professional use. Always observe the information in this manual, particularly the safety instructions and the warning instructions. Store the manual in a safe place.

-

Page 3: Table Of Contents

Operating manual Peristaltic pump system PP25S, PP25C, PP40S, PP40C, PP25Y, PP40Y Table of contents TABLE OF CONTENTS About these instructions Preface Warnings, notices and symbols in these instructions General Characters and Symbols Languages Abbreviations Terminology for the Purpose of this Manual... - Page 4 Operating manual Peristaltic pump system PP25S, PP25C, PP40S, PP40C, PP25Y, PP40Y Table of contents 5.4.5 Function cycle of PP25Y/PP40Y, spray-to-waste mode (4 cycles) 5.4.6 Function cycle of PP25Y/PP40Y, spray-to-waste mode (5 cycles) Assembly and commissioning Training of assembly/commissioning personnel Storage Conditions...

- Page 5 Operating manual Peristaltic pump system PP25S, PP25C, PP40S, PP40C, PP25Y, PP40Y Table of contents 12.7 Peristaltic pump PP25Y, flange connection 12.8 Peristaltic pump PP25Y, threaded connection 12.9 Peristaltic pump PP40Y, threaded connection 12.10 Powder hose set DN14 12.11 Powder hose set DN20 12.12 Powder hose set DN20 1", 20 m...

-

Page 6: About These Instructions

Operating manual Peristaltic pump system PP25S, PP25C, PP40S, PP40C, PP25Y, PP40Y 1 About these instructions 1 ABOUT THESE INSTRUCTIONS 1.1 PREFACE The operating manual contains information about safely operating, maintaining, cleaning and repairing the device. The operating manual is part of the device and must be available to the operating and service personnel. -

Page 7: Languages

Operating manual Peristaltic pump system PP25S, PP25C, PP40S, PP40C, PP25Y, PP40Y 1 About these instructions – Non-numbered list, first level – Non-numbered list, second level = cross-reference on page ♦ = wearing parts ⋆ = included in service set ● = not part of the standard equipment but available as a special accessory 1.4 ... - Page 8 Operating manual Peristaltic pump system PP25S, PP25C, PP40S, PP40C, PP25Y, PP40Y 1 About these instructions Personnel qualifications Trained person Is instructed in the tasks assigned to him/her, the potential risks associ- ated with improper behavior as well as the necessary protective devices and measures.

-

Page 9: Using In Accordance With The Instructions

(e.g., powder feed center) in a way that creates very little dust. The device may only be operated under the following conditions: 4 Use the device only to work with the materials recommended by WAGNER. 4 Do not deactivate safety fixtures. -

Page 10: Identification

Operating manual Peristaltic pump system PP25S, PP25C, PP40S, PP40C, PP25Y, PP40Y 3 Identification 3 IDENTIFICATION 3.1 EXPLOSION PROTECTION IDENTIFICATION Device type Single peristaltic pump Manufacturer Wagner International AG 9450 Altstätten Switzerland II 3 D Ex h IIIB T85°C Dc UKCA UK Conformity Assessed Symbol for explosion protection... -

Page 11: Basic Safety Instructions

Operating manual Peristaltic pump system PP25S, PP25C, PP40S, PP40C, PP25Y, PP40Y 4 Basic safety instructions 4 BASIC SAFETY INSTRUCTIONS 4.1 SAFETY INSTRUCTIONS FOR THE OPERATOR 4 Keep this operating manual at hand near the device at all times. 4 Always follow statutory provisions concerning occupational safety and accident prevention regulations. -

Page 12: Personnel Qualifications

Operating manual Peristaltic pump system PP25S, PP25C, PP40S, PP40C, PP25Y, PP40Y 4 Basic safety instructions 4 Protective clothing, including gloves, must comply with BS EN 1149-5:2018. The measured insulation resistance must not exceed 100 MΩ. 4 Ensure that there are no ignition sources such as naked flames, sparks, glowing wires, or hot surfaces in the spray booth. -

Page 13: Safe Handling Of Wagner Powder Spray Devices

Operating manual Peristaltic pump system PP25S, PP25C, PP40S, PP40C, PP25Y, PP40Y 4 Basic safety instructions 4 For sufficient health and environmental protection, only operate the device with technical ventilation (extraction) switched on. 4.2.2 Safe Handling of WAGNER Powder Spray Devices Danger due to dust formation! 4 Do not point spray guns at people. -

Page 14: Electrical Connection Cables

Operating manual Peristaltic pump system PP25S, PP25C, PP40S, PP40C, PP25Y, PP40Y 4 Basic safety instructions 4 on sharp edges 4 on moving parts 4 on hot surfaces 4 Ensure that the hoses are never run over by vehicles (e.g., fork lifts), or that the hoses are never put under pressure from the outside in any other way. -

Page 15: Maintenance And Repair

Danger due to improper maintenance and repair! Danger to life and equipment damage. 4 Only a WAGNER service center or a specially trained person may carry out repairs and replace parts. 4 Repair or replacement of devices or parts of devices are only allowed to be performed outside the hazard area by qualified personnel. -

Page 16: Protective And Monitoring Equipment

Operating manual Peristaltic pump system PP25S, PP25C, PP40S, PP40C, PP25Y, PP40Y 4 Basic safety instructions 4.2.8 Protective and monitoring equipment Danger due to removal of protective and monitoring equipment! Danger to life and equipment damage. 4 Protective and monitoring equipment must not be removed, modified or rendered unusable. -

Page 17: Description

Operating manual Peristaltic pump system PP25S, PP25C, PP40S, PP40C, PP25Y, PP40Y 5 Description 5 DESCRIPTION 5.1 VARIANTS 5.1.1 Peristaltic pump PP25 P_02873 PP25S PP25C Model, straight Model, with elbow 5.1.2 Peristaltic pump PP40 P_02874 PP40S PP40C Model, straight Model, with elbow... -

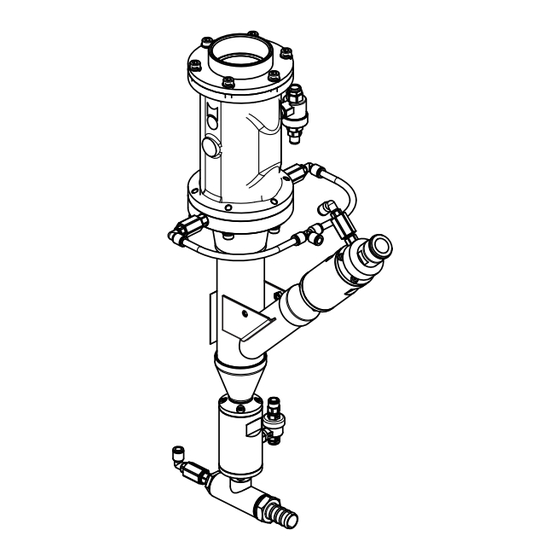

Page 18: Peristaltic Pump Pp25Y

Operating manual Peristaltic pump system PP25S, PP25C, PP40S, PP40C, PP25Y, PP40Y 5 Description 5.1.3 Peristaltic pump PP25Y P_02875 PP25Y PP25Y-FL Thread design Flange version 5.1.4 Peristaltic pump PP40Y P_03084 PP40Y Thread design Order number 2445679 | Edition 05/2023... -

Page 19: Technical Data

Operating manual Peristaltic pump system PP25S, PP25C, PP40S, PP40C, PP25Y, PP40Y 5 Description 5.2 TECHNICAL DATA 5.2.1 Technical Data for PP25/PP40 PP25S PP25C PP40S PP40C Input air pressure (control cabinet) 0.6 – 0.8 MPa; 6 – 8 bar; 87 – 116 psi Air consumption 5 Nm... -

Page 20: Dimensions Of Pp25/Pp40

Operating manual Peristaltic pump system PP25S, PP25C, PP40S, PP40C, PP25Y, PP40Y 5 Description WARNING Exhaust air containing oil! Risk of poisoning if inhaled. Insufficient paint application quality. 4 The compressed air must meet the following quality requirements: (Quality Standard 6.5.2 according to ISO 8573.1, 2010) 6.5.2 = particle density ≤ 5 mg/m³;... -

Page 21: Dimensions Of Pp25Y

Operating manual Peristaltic pump system PP25S, PP25C, PP40S, PP40C, PP25Y, PP40Y 5 Description PP40S PP40C P_04677 Measurements in mm 5.2.4 Dimensions of PP25Y PP25Y-FL PP25Y P_02870 Measurements in mm Order number 2445679 | Edition 05/2023... -

Page 22: Dimensions Of Pp40Y

Operating manual Peristaltic pump system PP25S, PP25C, PP40S, PP40C, PP25Y, PP40Y 5 Description 5.2.5 Dimensions of PP40Y PP40Y P_03085 Measurements in mm 5.3 EXTENT OF DELIVERY Order no. Designation 2365807 Peristaltic pump PP25S, straight 2365797 Peristaltic pump PP25C, with elbow... -

Page 23: Functional Description

Operating manual Peristaltic pump system PP25S, PP25C, PP40S, PP40C, PP25Y, PP40Y 5 Description for PP25/PP40 for PP25Y/PP40Y DN20 1" 20 m DN20 3/4" 2365828 3303443 DN20 1" 25 m 3308855 5.4 FUNCTIONAL DESCRIPTION The powder lacquer separated in the cyclone arrives at the sieve surface with the help of the rotational flow. -

Page 24: Function Cycle Of Pp25/Pp40 (5 Cycles)

Operating manual Peristaltic pump system PP25S, PP25C, PP40S, PP40C, PP25Y, PP40Y 5 Description Q1 closed LED lights up F open LED lights up Q2 open LED off W continuously open Powder product is fed one step towards the powder tank. - Page 25 Operating manual Peristaltic pump system PP25S, PP25C, PP40S, PP40C, PP25Y, PP40Y 5 Description Cycle 2: 0.3 sec. Q1 closed LED lights up F off LED off Q2 closed LED lights up W continuously open P2877 Cycle 3: 1.4 sec. Q1 closed LED lights up...

-

Page 26: Function Cycle Of Pp25Y/Pp40Y, Circulation Mode (4 Cycles)

Operating manual Peristaltic pump system PP25S, PP25C, PP40S, PP40C, PP25Y, PP40Y 5 Description Q1 closed LED lights up F off LED off Q2 closed LED lights up W continuously open P_02879 5.4.3 Function cycle of PP25Y/PP40Y, circulation mode (4 cycles) - Page 27 Operating manual Peristaltic pump system PP25S, PP25C, PP40S, PP40C, PP25Y, PP40Y 5 Description Q1 closed LED lights up F off LED off Q2 closed LED lights up Q3 closed LED lights up W1 continuously open W2 continuously closed P_02886 Cycle 3: 1.5 sec.

-

Page 28: Function Cycle Of Pp25Y/Pp40Y, Circulation Mode (5 Cycles)

Operating manual Peristaltic pump system PP25S, PP25C, PP40S, PP40C, PP25Y, PP40Y 5 Description 5.4.4 Function cycle of PP25Y/PP40Y, circulation mode (5 cycles) Pinch valve 1 W1 Vortex air (to PXS) Pinch valve 2 W2 Vortex air 2 (waste) Pinch valve 3... -

Page 29: Function Cycle Of Pp25Y/Pp40Y, Spray-To-Waste Mode (4 Cycles)

Operating manual Peristaltic pump system PP25S, PP25C, PP40S, PP40C, PP25Y, PP40Y 5 Description Q1 closed LED lights up F closed LED lights up Q2 open LED off Q3 closed LED lights up W1 continuously open W2 continuously closed Powder product is fed one step towards the powder tank. - Page 30 Operating manual Peristaltic pump system PP25S, PP25C, PP40S, PP40C, PP25Y, PP40Y 5 Description Q1 open LED off F off LED off Q2 closed LED lights up Q3 closed LED lights up W1 continuously closed W2 continuously open Powder product falls from the funnel into space X P_02885 Cycle 2: 0.3 sec.

-

Page 31: Function Cycle Of Pp25Y/Pp40Y, Spray-To-Waste Mode (5 Cycles)

Operating manual Peristaltic pump system PP25S, PP25C, PP40S, PP40C, PP25Y, PP40Y 5 Description Q1 closed LED lights up F off LED off Q2 closed LED lights up Q3 closed LED lights up W1 continuously closed W2 continuously open P_02888 5.4.6 Function cycle of PP25Y/PP40Y, spray-to-waste mode (5 cycles) - Page 32 Operating manual Peristaltic pump system PP25S, PP25C, PP40S, PP40C, PP25Y, PP40Y 5 Description Q1 closed LED lights up F off LED off Q2 closed LED lights up Q3 closed LED lights up W1 continuously closed W2 continuously open P_02886 Cycle 3: 1.4 sec.

- Page 33 Operating manual Peristaltic pump system PP25S, PP25C, PP40S, PP40C, PP25Y, PP40Y 5 Description Q1 closed LED lights up F off LED off Q2 closed LED lights up Q3 closed LED lights up W1 continuously closed W2 continuously open P_02888 Order number 2445679 | Edition 05/2023...

-

Page 34: Assembly And Commissioning

Operating manual Peristaltic pump system PP25S, PP25C, PP40S, PP40C, PP25Y, PP40Y 6 Assembly and commissioning 6 ASSEMBLY AND COMMISSIONING 6.1 TRAINING OF ASSEMBLY/COMMISSIONING PERSONNEL – The assembly and commissioning personnel must have the technical skills to safely commission the device. -

Page 35: Grounding

P_05677 Connection for grounding cable 1. For the versions with two grounding strap clamps (PP25S straight) or with a grounding strap clamp and a discharge connection (PP25S elbow, PP40C elbow) connect both grounding strap clamps (A) or grounding strap clamp (A) and discharge connection (C) with the supplied grounding cable. -

Page 36: Start Up

Operating manual Peristaltic pump system PP25S, PP25C, PP40S, PP40C, PP25Y, PP40Y 6 Assembly and commissioning P_05681 6.5 START UP 6.5.1 Preparation Before the initial commissioning, the default settings of the pneumatic controller, configured in the factory, must be checked. This inspection takes place by switching the main switch on the peristaltic pump system's control cabinet. - Page 37 Operating manual Peristaltic pump system PP25S, PP25C, PP40S, PP40C, PP25Y, PP40Y 6 Assembly and commissioning P_03086 Pressure of feed/vortex air Vortex air throttle 2 Pressure of control air Feed air throttle 1 Vortex air throttle 1 Peristaltic Pressure of Pressure of...

-

Page 38: Connection Diagram

Operating manual Peristaltic pump system PP25S, PP25C, PP40S, PP40C, PP25Y, PP40Y 6 Assembly and commissioning 6.6 CONNECTION DIAGRAM The connection diagrams of the WAGNER controls, for the peristaltic pump, are included in the supplied electrical circuit diagram. Order number 2445679 | Edition 05/2023... -

Page 39: Operation

Operating manual Peristaltic pump system PP25S, PP25C, PP40S, PP40C, PP25Y, PP40Y 7 Operation 7 OPERATION 7.1 TRAINING THE OPERATING PERSONNEL – The operating personnel must be qualified to operate the entire system. – The operating staff must be familiar with the potential risks associated with improper behavior as well as the necessary protective devices and measures. -

Page 40: Cleaning And Maintenance

Operating manual Peristaltic pump system PP25S, PP25C, PP40S, PP40C, PP25Y, PP40Y 8 Cleaning and maintenance 8 CLEANING AND MAINTENANCE 8.1 CLEANING 8.1.1 Cleaning Personnel Cleaning work should be undertaken regularly and carefully by qualified and trained personnel. They should be informed of specific hazards during their training. -

Page 41: Maintenance Instructions

DANGER Incorrect maintenance/repair! Danger to life and equipment damage. 4 Only a WAGNER service center or a specially trained person may carry out repairs and replace parts. 4 Use only WAGNER original spare parts and accessories. 4 Only repair and replace parts that are listed in the spare parts chapter and that are assigned to the device. -

Page 42: Maintenance Procedures

Operating manual Peristaltic pump system PP25S, PP25C, PP40S, PP40C, PP25Y, PP40Y 8 Cleaning and maintenance 8.2.4 Maintenance procedures The maintenance intervals should be adapted by the operator depending on the level of use and if necessary the level of soiling. - Page 43 Operating manual Peristaltic pump system PP25S, PP25C, PP40S, PP40C, PP25Y, PP40Y 8 Cleaning and maintenance 2. On the opposite side of the wire outlet (180 °), drill a hole with a 1 mm ⌀ through the hose wall, approx. 10-25 mm distance to the hose end.

-

Page 44: Note On The Use Of The Couplings

Operating manual Peristaltic pump system PP25S, PP25C, PP40S, PP40C, PP25Y, PP40Y 8 Cleaning and maintenance 8.2.6 Note on the use of the couplings P_05390 1. Before coupling, always make sure that the system is depressurized. 2. Ensure that the sealing ring is present in the coupling body. -

Page 45: Replacing The Hose Sleeve

Operating manual Peristaltic pump system PP25S, PP25C, PP40S, PP40C, PP25Y, PP40Y 8 Cleaning and maintenance 8.2.7 Replacing the hose sleeve P_02890 Cross section, upper half: clamping cone removed Cross section, lower half: clamping cone installed Removal of the defective sealing collar: 1. -

Page 46: Replacing The Hose Sleeve Dn65

Operating manual Peristaltic pump system PP25S, PP25C, PP40S, PP40C, PP25Y, PP40Y 8 Cleaning and maintenance 8.2.8 Replacing the hose sleeve DN65 45° P_05608 Housing groove Housing Locking pin Hose sleeve Wide tab O-ring Stop pin Removal of the defective hose sleeve: 1. - Page 47 Operating manual Peristaltic pump system PP25S, PP25C, PP40S, PP40C, PP25Y, PP40Y 8 Cleaning and maintenance 4. Securing: Be sure to reinsert the black locking pin (2) to the left of the wide tab (3)! The hose sleeve (6) is now fixed in the housing and the pinch valve is ready for use again.

-

Page 48: Troubleshooting And Rectification

Operating manual Peristaltic pump system PP25S, PP25C, PP40S, PP40C, PP25Y, PP40Y 9 Troubleshooting and Rectification 9 TROUBLESHOOTING AND RECTIFICATION DANGER Incorrect maintenance/repair! Danger to life and equipment damage. 4 The maintenance/repair of WAGNER devices, protective systems, safety, monitoring and control equipment, as defined by UK statutory requirement SI 2016 No. 1107, is... -

Page 49: Disassembly And Disposal

Operating manual Peristaltic pump system PP25S, PP25C, PP40S, PP40C, PP25Y, PP40Y 10 Disassembly and Disposal 10 DISASSEMBLY AND DISPOSAL 10.1 DISASSEMBLY WARNING Incorrect disassembly! Risk of injury and damage to the device. 4 Before starting disassembly: 4 Switch off the energy and compressed air supply. -

Page 50: Accessories

Operating manual Peristaltic pump system PP25S, PP25C, PP40S, PP40C, PP25Y, PP40Y 11 Accessories 11 ACCESSORIES 11.1 ACCESSORIES FOR PP25/PP40 11.1.1 Flange set for PP25 Order no. Designation 2366526 Flange set, PP25 G1 1/2" -> DN40 P_02871 11.1.2 Cyclone discharge adapter Order no. -

Page 51: Powder Hose Set For Recovery System Dn20 1

Operating manual Peristaltic pump system PP25S, PP25C, PP40S, PP40C, PP25Y, PP40Y 11 Accessories 11.2.3 Powder hose set for recovery system DN20 1" Order no. Designation 3303443 Hose set, RG DN20 1" 20 m (4 couplings) 3308855 Hose set, RG DN20 1" 25 m... -

Page 52: Spare Parts

DANGER Incorrect maintenance/repair! Danger to life and equipment damage. 4 Only a WAGNER service center or a specially trained person may carry out repairs and replace parts. 4 Use only WAGNER original spare parts and accessories. 4 Only repair and replace parts that are listed in the spare parts chapter and that are assigned to the device. -

Page 53: Peristaltic Pump Pp25S, Straight

Operating manual Peristaltic pump system PP25S, PP25C, PP40S, PP40C, PP25Y, PP40Y 12 Spare parts 12.3 PERISTALTIC PUMP PP25S, STRAIGHT P_04680 Order no. Designation 2365807 Peristaltic pump PP25S, straight 2365482 Connection sleeve 3144056 Squeeze valve 3102576 Quick exhaust valve ♦ ♦... -

Page 54: Peristaltic Pump Pp25S, With Elbow

Loctite® 577 ♦ = wearing parts Spare parts list is valid from 12/2020. For previous spare parts list, see operating manual for Peristaltic Pump System PP25S, PP25C, PP40S, PP40C, PP25Y, PP40Y, version B (11/2020). 12.4 PERISTALTIC PUMP PP25S, WITH ELBOW P_04681 Order no. -

Page 55: Peristaltic Pump Pp40S, Straight

Operating manual Peristaltic pump system PP25S, PP25C, PP40S, PP40C, PP25Y, PP40Y 12 Spare parts 12.5 PERISTALTIC PUMP PP40S, STRAIGHT P_04682 Order no. Designation 2364025 Peristaltic pump PP40S, straight 2439758 O-ring set 2438916 Clamping pin 2308075 Ho-Matic pinch valve ♦ 2418493... - Page 56 ♦ = wearing parts Spare parts list is valid from 12/2020. For previous spare parts list, see operating manual for Peristaltic Pump System PP25S, PP25C, PP40S, PP40C, PP25Y, PP40Y, version B (11/2020). Info When replacing the sealing collars, it must be ensured that the correct sealing collars are installed in the respective squeeze valves (Observe figure!).

-

Page 57: Peristaltic Pump Pp40C, With Elbow

Operating manual Peristaltic pump system PP25S, PP25C, PP40S, PP40C, PP25Y, PP40Y 12 Spare parts 12.6 PERISTALTIC PUMP PP40C, WITH ELBOW P_04683 Order no. Designation 2365826 Peristaltic pump PP40C, with elbow 2439758 O-ring set 2438916 Clamping pin 2308075 Ho-Matic pinch valve... - Page 58 ♦ = wearing parts Spare parts list is valid from 12/2020. For previous spare parts list, see operating manual for Peristaltic Pump System PP25S, PP25C, PP40S, PP40C, PP25Y, PP40Y, version B (11/2020). Info When replacing the sealing collars, it must be ensured that the correct sealing collars are installed in the respective squeeze valves (Observe figure!).

-

Page 59: Peristaltic Pump Pp25Y, Flange Connection

Operating manual Peristaltic pump system PP25S, PP25C, PP40S, PP40C, PP25Y, PP40Y 12 Spare parts 12.7 PERISTALTIC PUMP PP25Y, FLANGE CONNECTION P_03666 Order no. Designation 2357381 Peristaltic pump PP25Y, flange connection 3109976 Sealing ring ♦ 3144058 Sealing collar for squeeze valve... - Page 60 ♦ = wearing parts Spare parts list is valid from 12/2020. For previous spare parts list, see operating manual for Peristaltic Pump System PP25S, PP25C, PP40S, PP40C, PP25Y, PP40Y, version B (11/2020). Info When replacing the sealing collars, it must be ensured that the correct sealing collars are installed in the respective squeeze valves (Observe figure!).

-

Page 61: Peristaltic Pump Pp25Y, Threaded Connection

Operating manual Peristaltic pump system PP25S, PP25C, PP40S, PP40C, PP25Y, PP40Y 12 Spare parts 12.8 PERISTALTIC PUMP PP25Y, THREADED CONNECTION P_03667 Order no. Designation 2364560 Peristaltic pump PP25Y, threaded connection ♦ 3144058 Sealing collar for squeeze valve 2357369 Outlet 2402046 Squeeze valve ♦... - Page 62 ♦ = wearing parts Spare parts list is valid from 12/2020. For previous spare parts list, see operating manual for Peristaltic Pump System PP25S, PP25C, PP40S, PP40C, PP25Y, PP40Y, version B (11/2020). Info When replacing the sealing collars, it must be ensured that the correct sealing collars are installed in the respective squeeze valves (Observe figure!).

-

Page 63: Peristaltic Pump Pp40Y, Threaded Connection

Operating manual Peristaltic pump system PP25S, PP25C, PP40S, PP40C, PP25Y, PP40Y 12 Spare parts 12.9 PERISTALTIC PUMP PP40Y, THREADED CONNECTION P_04684 Order no. Designation 2372081 Peristaltic pump PP40Y, threaded connection 2439758 O-ring set 2438916 Clamping pin 2308075 Ho-Matic pinch valve ♦... -

Page 64: Powder Hose Set Dn14

♦ = wearing parts Spare parts list is valid from 12/2020. For previous spare parts list, see operating manual for Peristaltic Pump System PP25S, PP25C, PP40S, PP40C, PP25Y, PP40Y, version B (11/2020). Info When replacing the sealing collars, it must be ensured that the correct sealing collars are installed in the respective squeeze valves (Observe figure!). -

Page 65: Powder Hose Set Dn20

Operating manual Peristaltic pump system PP25S, PP25C, PP40S, PP40C, PP25Y, PP40Y 12 Spare parts 12.11 POWDER HOSE SET DN20 P_02903 Order no. Designation 2365828 Hose set, RG PXS DN20, 20 m 3/4" 2436025 Hose fitting, DN20 2323505 Heavy duty clamp 20 m... -

Page 66: Powder Hose Set Dn20 1", 25 M

Heavy duty clamp 25 m 2359121 Powder hose, D14 TPU 3201587 Loctite® 577 12.15 CONTROL CABINETS The spare parts lists for the WAGNER controls, for the peristaltic pump, are included in the supplied electrical circuit diagram. Order number 2445679 | Edition 05/2023... -

Page 67: Valve Terminal

Operating manual Peristaltic pump system PP25S, PP25C, PP40S, PP40C, PP25Y, PP40Y 12 Spare parts 12.16 VALVE TERMINAL Order no. Designation 2325006 Silencer Order number 2445679 | Edition 05/2023... -

Page 68: Declaration Of Conformity

II 3 D Ex h IIIB T85°C Dc UK Declaration of Conformity The UK Declaration of Conformity is enclosed with this product. If needed, further copies can be ordered through your WAGNER dealer by specifying the product name and serial number. Order number: 2371649 Order number 2445679 | Edition 05/2023... - Page 69 Operating manual Peristaltic pump system PP25S, PP25C, PP40S, PP40C, PP25Y, PP40Y 13 UK Declaration of Conformity Order number 2445679 | Edition 05/2023...

- Page 70 Operating manual Peristaltic pump system PP25S, PP25C, PP40S, PP40C, PP25Y, PP40Y 13 UK Declaration of Conformity Order number 2445679 | Edition 05/2023...

- Page 72 Order number 2445679 Edition 05/2023 United Kingdom Germany Wagner Spraytech (UK) ltd. J. Wagner GmbH Innovation Centre Otto-Lilienthal-Strasse 18 Silverstone Park Silverstone Postfach 1120 NN12 8GX Northants D-88677 Markdorf Telephone: +44 (0) 1327 368 410 Telephone: +49 (0)7544 5050 E-Mail: enquiries@wagner-group.com Fax: +49 (0)7544 505200 E-mail: ts-powder@wagner-group.com Switzerland Wagner International AG Industriestrasse 22...

Need help?

Do you have a question about the PP25S and is the answer not in the manual?

Questions and answers