Summary of Contents for WAGNER PP25S

- Page 1 Edition 08/2022 PP25S PP25C PP40S PP40C PP25Y PP40Y Peristaltic Pump System P_02893 II 3 D Ex h IIIB T85°C Dc...

-

Page 3: Table Of Contents

4.1.2 A Safe Work Environment 4.1.3 Personnel Qualifications Safety Instructions for the Personnel 4.2.1 Personal Safety Equipment 4.2.2 Safe Handling of WAGNER Powder Spray Devices 4.2.3 Grounding the Device 4.2.4 Product Hoses 4.2.5 Electrical Connection Cables 4.2.6 Cleaning and Flushing 4.2.7... - Page 4 11.2.3 Powder Hose Set for Recovery System DN20 1" 11.2.4 Powder Hose Set for Recovery System IPS DN14 SPARE PARTS 12.1 How to Order Spare Parts 12.2 Peristaltic Pump PP25S, Straight (Until 11/2020) 12.3 Peristaltic Pump PP25S, Straight (Starting 12/2020) 12.4 Peristaltic Pump PP25S, with Elbow (Until 11/2020)

- Page 5 Peristaltic pump EDITION 08/2022 ORDER NUMBER DOC2368104 12.5 Peristaltic Pump PP25S, with Elbow (Starting 12/2020) 12.6 Peristaltic Pump PP40S, Straight (Until 11/2020) 12.7 Peristaltic Pump PP40S, Straight (Starting 12/2020) 12.8 Peristaltic Pump PP40C, with Elbow (Until 11/2020) 12.9 Peristaltic Pump PP40C, with Elbow (Starting 12/2020) 12.10...

-

Page 6: About These Instructions

Peristaltic pump EDITION 08/2022 ORDER NUMBER DOC2368104 ABOUT THESE INSTRUCTIONS PREFACE The operating manual contains information about safely operating, maintaining, cleaning and repairing the device. The operating manual is part of the device and must be available to the operating and service personnel. -

Page 7: Languages

Polish 2406128 Swedish 2423300 Croatian 2431194 Japanese 2435049 Additional languages on request or at: www.wagner-group.com ABBREVIATIONS Order no. Order number Spare part Marking in the spare parts lists Position Number of pieces Recovery system Item not available as spare part... -

Page 8: Terminology For The Purpose Of This Manual

Peristaltic pump EDITION 08/2022 ORDER NUMBER DOC2368104 TERMINOLOGY FOR THE PURPOSE OF THIS MANUAL Cleaning Cleaning Manual cleaning of devices and device parts with cleaning agent Flushing Internal flushing of paint-wetted parts with compressed air Personnel qualifications Trained person Is instructed in the tasks assigned to him/her, the potential risks associated with improper behavior as well as the necessary protective devices and measures. -

Page 9: Using In Accordance With The Instructions

The device may only be operated under the following conditions: Use the device only to work with the products recommended by WAGNER. Do not deactivate safety fixtures. Use only WAGNER original spare parts and accessories. -

Page 10: Identification

EDITION 08/2022 ORDER NUMBER DOC2368104 IDENTIFICATION EXPLOSION PROTECTION IDENTIFICATION Device type: Single peristaltic pump Manufacturer: J. Wagner GmbH 88677 Markdorf Germany II 3 D Ex h IIIB T85°C Dc European Communities Symbol for explosion protection Device class II Category 3 (zone 22) -

Page 11: Basic Safety Instructions

Peristaltic pump EDITION 08/2022 ORDER NUMBER DOC2368104 BASIC SAFETY INSTRUCTIONS SAFETY INSTRUCTIONS FOR THE OPERATOR Keep this operating manual at hand near the device at all times. Always follow applicable directives concerning occupational safety and accident prevention regulations. 4.1.1 ELECTRICAL DEVICES AND EQUIPMENT Danger of electric shock! Danger to life from electric shock. -

Page 12: A Safe Work Environment

Peristaltic pump EDITION 08/2022 ORDER NUMBER DOC2368104 4.1.2 A SAFE WORK ENVIRONMENT Danger due to dust formation! Severe or fatal injuries due to explosion danger or inhalation, swallowing or contact with the skin or eyes. The floor in the working area must be electrostatically conductive (measurements according to EN 1081 and EN 61340-4-1). -

Page 13: Safety Instructions For The Personnel

Use a mask or breathing apparatus if necessary. For sufficient health and environmental protection, only operate the device with technical ventilation (extraction) switched on. 4.2.2 SAFE HANDLING OF WAGNER POWDER SPRAY DEVICES Danger due to dust formation! Do not point spray guns at people. -

Page 14: Grounding The Device

Danger due to damaged product hoses! The product hose may cause dangerous injuries. Use only an original WAGNER powder hose. Make sure that the hoses are laid only in suitable places. Hoses should not be laid in the following places under any circumstances: –... -

Page 15: Electrical Connection Cables

Peristaltic pump EDITION 08/2022 ORDER NUMBER DOC2368104 4.2.5 ELECTRICAL CONNECTION CABLES Risk caused by improperly laid cables! Risk of injury and damage to the device. Properly lay connection cables and check them regularly. Immediately replace damaged connection cables. Ensure that no work is ever performed with a damaged connection cable. Do not lay connection cables on routes used by product handling vehicles and not through doors/gates. -

Page 16: Maintenance And Repair

Danger due to improper maintenance and repair! Danger to life and equipment damage. Only a WAGNER service center or a specially trained person may carry out repairs and replace parts. Repair or replacement of devices or parts of devices are only allowed to be performed outside the hazard area by qualified personnel. -

Page 17: Description

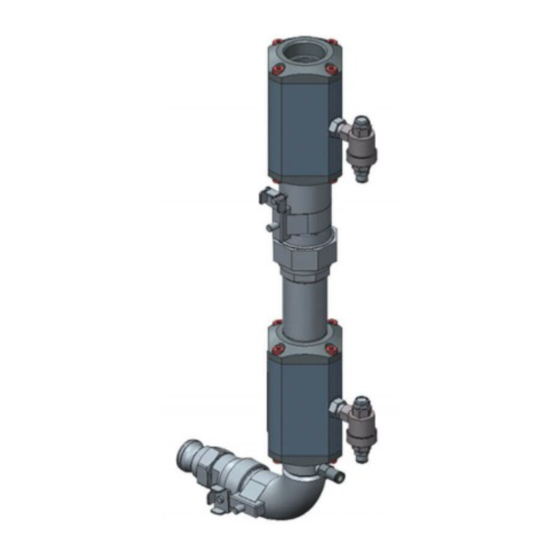

Peristaltic pump EDITION 08/2022 ORDER NUMBER DOC2368104 DESCRIPTION VARIANTS 5.1.1 PERISTALTIC PUMP PP25 Model, straight Model, with elbow P_02873 PP25S PP25C 5.1.2 PERISTALTIC PUMP PP40 Model, straight Model, with elbow P_02874 PP40S PP40C... -

Page 18: Peristaltic Pump Pp25Y

Peristaltic pump EDITION 08/2022 ORDER NUMBER DOC2368104 5.1.3 PERISTALTIC PUMP PP25Y Thread design Flange version P_02875 PP25Y PP25Y-FL 5.1.4 PERISTALTIC PUMP PP40Y Thread design P_03084 PP40Y... -

Page 19: Technical Data

Peristaltic pump EDITION 08/2022 ORDER NUMBER DOC2368104 TECHNICAL DATA 5.2.1 TECHNICAL DATA FOR PP25/PP40 PP25S PP25C PP40S PP40C Input air pressure (control cabinet) 0.6-0.8 MPa; 6-8 bar; 87-116 psi Air consumption 5 Nm3/h 5 Nm3/h 6 Nm3/h 6 Nm3/h Control cabinet dimensions... -

Page 20: Dimensions Of Pp25/Pp40

Peristaltic pump EDITION 08/2022 ORDER NUMBER DOC2368104 5.2.3 DIMENSIONS OF PP25/PP40 PP25S PP25C P_02848 PP40S PP40C P_04677... -

Page 21: Dimensions Of Pp25Y

Peristaltic pump EDITION 08/2022 ORDER NUMBER DOC2368104 5.2.4 DIMENSIONS OF PP25Y PP25Y-FL PP25Y P_02870 5.2.5 DIMENSIONS OF PP40Y PP40Y P_03085... -

Page 22: Extent Of Delivery

Peristaltic pump EDITION 08/2022 ORDER NUMBER DOC2368104 EXTENT OF DELIVERY Order no. Designation 2365807 Peristaltic pump PP25S, straight 2365797 Peristaltic pump PP25C, with elbow 2364025 Peristaltic pump PP40S, straight 2365826 Peristaltic pump PP40C, with elbow 2357381 Peristaltic pump PP25Y-FL, flange version... -

Page 23: Function Cycle Of Pp25/Pp40 (4 Cycles)

Peristaltic pump EDITION 08/2022 ORDER NUMBER DOC2368104 5.4.1 FUNCTION CYCLE OF PP25/PP40 (4 CYCLES) Legend: Q1 = squeeze valve 1 Q2 = squeeze valve 2 F = feed air W = vortex air Cycle 1 : 2.5 sec. Q1 open (LED off ) F off (LED off ) - Page 24 Peristaltic pump EDITION 08/2022 ORDER NUMBER DOC2368104 Cycle 3 : 2.5 sec. Q1 closed (LED lit up) F open (LED lit up) Q2 open (LED off ) W continuously open Powder product is fed one step towards the powder tank. Space X P_02878 Cycle 4 : 0.3 sec.

-

Page 25: Function Cycle Of Pp25/Pp40 (5 Cycles)

Peristaltic pump EDITION 08/2022 ORDER NUMBER DOC2368104 5.4.2 FUNCTION CYCLE OF PP25/PP40 (5 CYCLES) Legend: Q1 = squeeze valve 1 Q2 = squeeze valve 2 F = feed air W = vortex air Cycle 1 : 2.0 sec. Q1 open (LED off ) F off (LED off ) - Page 26 Peristaltic pump EDITION 08/2022 ORDER NUMBER DOC2368104 Cycle 3 : 1.4 sec. Q1 closed (LED lit up) F open (LED lit up) Q2 open (LED off ) W continuously open Powder product is fed one step towards the powder tank. Space X P_02878 Cycle 4 : 0.6 sec.

-

Page 27: Function Cycle Of Pp25Y/Pp40Y, Circulation Mode (4 Cycles)

Peristaltic pump EDITION 08/2022 ORDER NUMBER DOC2368104 5.4.3 FUNCTION CYCLE OF PP25Y/PP40Y, CIRCULATION MODE (4 CYCLES) Legend: Q1 = squeeze valve 1 Q2 = squeeze valve 2 Q3 = squeeze valve 3 F = feed air W1 = vortex air 1 (to PXS) W2 = vortex air 2 (waste) Cycle 1: PP25Y/PP40Y 1.5 sec. - Page 28 Peristaltic pump EDITION 08/2022 ORDER NUMBER DOC2368104 Cycle 3: PP25Y/PP40Y 1.5 sec. Q1 closed (LED lit up) F open (LED lit up) Q2 open (LED off ) Q3 closed (LED lit up) W1 continuously open W2 continuously closed Space X Powder product is fed one step towards the powder tank.

-

Page 29: Function Cycle Of Pp25Y/Pp40Y, Circulation Mode (5 Cycles)

Peristaltic pump EDITION 08/2022 ORDER NUMBER DOC2368104 5.4.4 FUNCTION CYCLE OF PP25Y/PP40Y, CIRCULATION MODE (5 CYCLES) Legend: Q1 = squeeze valve 1 Q2 = squeeze valve 2 Q3 = squeeze valve 3 F = feed air W1 = vortex air 1 (to PXS) W2 = vortex air 2 (waste) Cycle 1: PP25Y/PP40Y 2.0 sec. - Page 30 Peristaltic pump EDITION 08/2022 ORDER NUMBER DOC2368104 Cycle 3: PP25Y/PP40Y 1.4 sec. Q1 closed (LED lit up) F open (LED lit up) Q2 open (LED off ) Q3 closed (LED lit up) W1 continuously open W2 continuously closed Space X Powder product is fed one step towards the powder tank.

-

Page 31: Function Cycle Of Pp25Y/Pp40Y, Spray-To-Waste Mode (4 Cycles)

Peristaltic pump EDITION 08/2022 ORDER NUMBER DOC2368104 5.4.5 FUNCTION CYCLE OF PP25Y/PP40Y, SPRAY-TO-WASTE MODE (4 CYCLES) Legend: Q1 = squeeze valve 1 Q2 = squeeze valve 2 Q3 = squeeze valve 3 F = feed air W1 = vortex air 1 (to PXS) W2 = vortex air 2 (waste) Cycle 1: PP25Y/PP40Y 1.5 sec. - Page 32 Peristaltic pump EDITION 08/2022 ORDER NUMBER DOC2368104 Cycle 3: PP25Y/PP40Y 1.5 sec. Q1 closed (LED lit up) F open (LED lit up) Q2 closed (LED lit up) Q3 open (LED off ) W1 continuously closed W2 continuously open Space X Powder product is fed one step towards the waste tank.

-

Page 33: Function Cycle Of Pp25Y/Pp40Y, Spray-To-Waste Mode (5 Cycles)

Peristaltic pump EDITION 08/2022 ORDER NUMBER DOC2368104 5.4.6 FUNCTION CYCLE OF PP25Y/PP40Y, SPRAY-TO-WASTE MODE (5 CYCLES) Legend: Q1 = squeeze valve 1 Q2 = squeeze valve 2 Q3 = squeeze valve 3 F = feed air W1 = vortex air 1 (to PXS) W2 = vortex air 2 (waste) Cycle 1: PP25Y/PP40Y 2.0 sec. - Page 34 Peristaltic pump EDITION 08/2022 ORDER NUMBER DOC2368104 Cycle 3: PP25Y/PP40Y 1.4 sec. Q1 closed (LED lit up) F open (LED lit up) Q2 closed (LED lit up) Q3 open (LED off ) W1 continuously closed W2 continuously open Space X Powder product is fed one step towards the waste tank.

-

Page 35: Assembly And Commissioning

Peristaltic pump EDITION 08/2022 ORDER NUMBER DOC2368104 ASSEMBLY AND COMMISSIONING TRAINING OF ASSEMBLY/COMMISSIONING PERSONNEL The assembly and commissioning personnel must have the technical skills to safely commission the device. When assembling, commissioning and carrying out all work, read and follow the operating manuals and safety regulations for the additionally required system components. -

Page 36: Recommended Settings For Compressed Air

1 vortex air [bar] [bar] PP25S 2.0/0.3/1.4/0.6/0.6 PP25C 2.0/0.3/1.4/0.6/0.6 PP40S 2.0/0.3/1.4/0.6/0.6 PP40C 2.0/0.3/1.4/0.6/0.6 PP25Y/PP25Y-FL 2.0/0.3/1.4/0.6/0.6 PP40Y 8-10 2.0/0.3/1.4/0.6/0.6 CONNECTION DIAGRAM The connection diagrams of the WAGNER controls, for the peristaltic pump, are included in the supplied electrical circuit diagram. -

Page 37: Operation

Peristaltic pump EDITION 08/2022 ORDER NUMBER DOC2368104 OPERATION TRAINING THE OPERATING PERSONNEL The operating personnel must be qualified to operate the entire system. The operating staff must be familiar with the potential risks associated with improper behavior as well as the necessary protective devices and measures. Before work commences, the operating personnel must receive appropriate system training. -

Page 38: Cleaning And Maintenance

Switch off the system and secure against unauthorized reactivation. The cleaning intervals should be adapted by the operator depending on the level of use and if necessary the level of soiling. If in doubt, we recommend contacting WAGNER's specialist personnel. 8.1.3 CLEANING THE PERISTALTIC PUMP Work steps: 1. -

Page 39: Maintenance

Incorrect maintenance/repair! Danger to life and equipment damage. Only a WAGNER service center or a specially trained person may carry out repairs and replace parts. Only repair and replace parts that are listed in the "Spare parts" chapter and that are assigned to the device. -

Page 40: Maintenance Procedures

8.2.4 MAINTENANCE PROCEDURES The maintenance intervals should be adapted by the operator depending on the level of use and if necessary the level of soiling. If in doubt, we recommend contacting WAGNER's specialist personnel. Interval duration Activity Every 3 months Check the conductivity of the recovery hose (see chapter 8.2.5). -

Page 41: Processing The Hose Ends On The Spiral Hose

Peristaltic pump EDITION 08/2022 ORDER NUMBER DOC2368104 8.2.5 PROCESSING THE HOSE ENDS ON THE SPIRAL HOSE NOTE: Conductivity between the two hose fittings must be checked technically, by measuring, during assembly and then periodically (every 3 months)! 1. Release spiral wire from the sheath, from the outside by one revolution (maximum cutting depth up to the wire). - Page 42 Peristaltic pump EDITION 08/2022 ORDER NUMBER DOC2368104 (Hose example) P_03278 Conductivity between the contact points KP1/2, maximum of 1KΩ Carrying out the measurement: 1. Mount the hose coupling. 2. Measure the conductivity between the two contact points. 3. Log the measured value. 4.

-

Page 43: Note On The Use Of The Couplings

Peristaltic pump EDITION 08/2022 ORDER NUMBER DOC2368104 8.2.6 NOTE ON THE USE OF THE COUPLINGS P_05390 – Before coupling, always make sure that the system is depressurized. – Ensure that the sealing ring is present in the coupling body. – Ensure that the coupling partners match each other. –... -

Page 44: Replacing The Hose Sleeve

Peristaltic pump EDITION 08/2022 ORDER NUMBER DOC2368104 8.2.7 REPLACING THE HOSE SLEEVE Cross section, upper half: clamping cone removed P_02890 Cross section, lower half: clamping cone installed Removal of the defective sealing collar: 1. Remove fitted line connections on the squeeze valve. 2. -

Page 45: Replacing The Dn65 Hose Sleeve

Peristaltic pump EDITION 08/2022 ORDER NUMBER DOC2368104 8.2.8 REPLACING THE DN65 HOSE SLEEVE 45° P_05608 1 Housing groove 2 Locking pin 3 Wide tab 4 Stop pin 5 Housing 6 Hose sleeve 7 O-ring Removal of the defective hose sleeve: 1. - Page 46 Peristaltic pump EDITION 08/2022 ORDER NUMBER DOC2368104 Installation of the new hose sleeve: 1. Positioning: Align the housing (5) so that the side without stop pins points in the direction of the tab side of the new hose sleeve (6). The wide guide tab (3) of the hose sleeve (6) is aligned with the wide housing groove.

-

Page 47: Troubleshooting And Rectification

WAGNER devices, protective systems and safety, monitoring and control equipment may only be serviced/repaired as defined in Directive 2014/34/EC (ATEX) by trained WAGNER service personnel or skilled persons in accordance with TRBS 1203! Note national regulations! Service, repair or replacement of devices or parts of devices may only be performed... -

Page 48: Disassembly And Disposal

WAGNER or one of our dealers will take back your used WAGNER electric or electronic equipment and will dispose of it for you in an environmentally-friendly way. -

Page 49: Accessories

Peristaltic pump EDITION 08/2022 ORDER NUMBER DOC2368104 11 ACCESSORIES 11.1 ACCESSORIES FOR PP25/PP40 11.1.1 FLANGE SET FOR PP25 P_02871 Order no. Designation 2366526 Flange set, PP25 G1½" -> DN40 11.1.2 CYCLONE DISCHARGE ADAPTER P_02872 Order no. Designation 2333626 Cyclone discharge adapter, G2½" -> G1½" 11.1.3 POWDER HOSE Order no. -

Page 50: Accessories For Y Peristaltic Pump

Peristaltic pump EDITION 08/2022 ORDER NUMBER DOC2368104 11.2 ACCESSORIES FOR Y PERISTALTIC PUMP 11.2.1 POWDER HOSE SET FOR RECOVERY SYSTEM DN14 P_02900 Order no. Designation 2365857 Hose set, RG PXS DN14, 20 m 3/4" 11.2.2 POWDER HOSE SET FOR RECOVERY SYSTEM DN20 P_02901 Order no. -

Page 51: Powder Hose Set For Recovery System Ips Dn14

Peristaltic pump EDITION 08/2022 ORDER NUMBER DOC2368104 11.2.4 POWDER HOSE SET FOR RECOVERY SYSTEM IPS DN14 P_04383 Order no. Designation 2406771 IPS DN14 hose set recovery system... -

Page 53: Spare Parts

Incorrect maintenance/repair! Danger to life and equipment damage. Only a WAGNER service center or a specially trained person may carry out repairs and replace parts. Only repair and replace parts that are listed in the "Spare parts" chapter and that are assigned to the device. -

Page 54: Peristaltic Pump Pp25S, Straight (Until 11/2020)

Peristaltic pump EDITION 08/2022 ORDER NUMBER DOC2368104 12.2 PERISTALTIC PUMP PP25S, STRAIGHT (UNTIL 11/2020) P_02844... - Page 55 Peristaltic pump EDITION 08/2022 ORDER NUMBER DOC2368104 Order no. Designation 2365807 Peristaltic pump PP25S, straight 2365482 Connection sleeve 3144056 Squeeze valve 3102576 Quick exhaust valve 3136837 Non-return valve 2365756 Pipe elbow 2335588 Adapter with internal thread 3144058 Sealing collar for squeeze valve 3201587 Loctite®...

-

Page 56: Peristaltic Pump Pp25S, Straight (Starting 12/2020)

Peristaltic pump EDITION 08/2022 ORDER NUMBER DOC2368104 12.3 PERISTALTIC PUMP PP25S, STRAIGHT (STARTING 12/2020) P_04680... - Page 57 Peristaltic pump EDITION 08/2022 ORDER NUMBER DOC2368104 Order no. Designation 2365807 Peristaltic pump PP25S, straight 2365482 Connection sleeve 3144056 Squeeze valve 3102576 Quick exhaust valve 2418493 Non-return valve 2365756 Pipe elbow 2335588 Adapter with internal thread 3144058 Sealing collar for squeeze valve 3201587 Loctite®...

-

Page 58: Peristaltic Pump Pp25S, With Elbow (Until 11/2020)

Peristaltic pump EDITION 08/2022 ORDER NUMBER DOC2368104 12.4 PERISTALTIC PUMP PP25S, WITH ELBOW (UNTIL 11/2020) P_02845 Order no. Designation 2365797 Peristaltic pump PP25S, with elbow 3145249 Outlet connection* (Observe the notice on the following page.) 2360047 Pipe elbow 3136837 Non-return valve* (Observe notice on the following page.) - Page 59 Peristaltic pump EDITION 08/2022 ORDER NUMBER DOC2368104 Note: * When changing to non-return valve 2418493, the outlet connection 2418606 must be used. P_04685 Order no. Designation 9900318 Hexagon socket head cap screw 9920118 Washer 3050414 Ring tongue, M6, 4-6 mm2 2418493 Non-return valve 2418606...

-

Page 60: Peristaltic Pump Pp25S, With Elbow (Starting 12/2020)

Peristaltic pump EDITION 08/2022 ORDER NUMBER DOC2368104 12.5 PERISTALTIC PUMP PP25S, WITH ELBOW (STARTING 12/2020) P_04681 Order no. Designation 2365797 Peristaltic pump PP25S, with elbow 2418606 Outlet connection 2360047 Pipe elbow 2418493 Non-return valve 3102576 Quick exhaust valve 3144056 Squeeze valve... -

Page 62: Peristaltic Pump Pp40S, Straight (Until 11/2020)

Peristaltic pump EDITION 08/2022 ORDER NUMBER DOC2368104 12.6 PERISTALTIC PUMP PP40S, STRAIGHT (UNTIL 11/2020) P_02846... - Page 63 Peristaltic pump EDITION 08/2022 ORDER NUMBER DOC2368104 Order no. Designation 2364025 Peristaltic pump PP40S, straight 2439758 O-ring set 2438916 Clamping pin 2308075 Ho-Matic pinch valve 3136837 Non-return valve 3144056 Squeeze valve 3102576 Quick exhaust valve 2365756 Pipe elbow 2335588 Adapter with internal thread 3144058 Sealing collar for squeeze valve 2366460...

-

Page 64: Peristaltic Pump Pp40S, Straight (Starting 12/2020)

Peristaltic pump EDITION 08/2022 ORDER NUMBER DOC2368104 12.7 PERISTALTIC PUMP PP40S, STRAIGHT (STARTING 12/2020) P_04682... - Page 65 Peristaltic pump EDITION 08/2022 ORDER NUMBER DOC2368104 Order no. Designation 2364025 Peristaltic pump PP40S, straight 2439758 O-ring set 2438916 Clamping pin 2308075 Ho-Matic pinch valve 2418493 Non-return valve 3144056 Squeeze valve 3102576 Quick exhaust valve 2365756 Pipe elbow 2335588 Adapter with internal thread 3144058 Sealing collar for squeeze valve 2366460...

-

Page 66: Peristaltic Pump Pp40C, With Elbow (Until 11/2020)

Peristaltic pump EDITION 08/2022 ORDER NUMBER DOC2368104 12.8 PERISTALTIC PUMP PP40C, WITH ELBOW (UNTIL 11/2020) P_02847... - Page 67 Peristaltic pump EDITION 08/2022 ORDER NUMBER DOC2368104 Order no. Designation 2365826 Peristaltic pump PP40C, with elbow 2439758 O-ring set 2438916 Clamping pin 2308075 Ho-Matic pinch valve 2366162 Pipe elbow 3144056 Squeeze valve 3144058 Sealing collar for squeeze valve 3145249 Outlet connection* 3136837 Non-return valve* 3102576...

-

Page 68: Peristaltic Pump Pp40C, With Elbow (Starting 12/2020)

Peristaltic pump EDITION 08/2022 ORDER NUMBER DOC2368104 12.9 PERISTALTIC PUMP PP40C, WITH ELBOW (STARTING 12/2020) P_04683... - Page 69 Peristaltic pump EDITION 08/2022 ORDER NUMBER DOC2368104 Order no. Designation 2365826 Peristaltic pump PP40C, with elbow 2439758 O-ring set 2438916 Clamping pin 2308075 Ho-Matic pinch valve 2366162 Pipe elbow 3144056 Squeeze valve 3144058 Sealing collar for squeeze valve 2418606 Outlet connection 2418493 Non-return valve 3102576...

-

Page 70: Peristaltic Pump Pp25Y, Flange Connection (Until 11/2020)

Peristaltic pump EDITION 08/2022 ORDER NUMBER DOC2368104 12.10 PERISTALTIC PUMP PP25Y, FLANGE CONNECTION (UNTIL 11/2020) P_02835... - Page 71 Peristaltic pump EDITION 08/2022 ORDER NUMBER DOC2368104 Order no. Designation 2357381 Peristaltic pump PP25Y, flange connection 3109976 Sealing ring 3144058 Sealing collar for squeeze valve 2357369 Outlet 2349577 Squeeze valve 2349751 Sealing collar for squeeze valve 2333008 Dead space insert 3136837 Non-return valve 2357380...

-

Page 72: Peristaltic Pump Pp25Y, Flange Connection (Starting 12/2020)

Peristaltic pump EDITION 08/2022 ORDER NUMBER DOC2368104 12.11 PERISTALTIC PUMP PP25Y, FLANGE CONNECTION (STARTING 12/2020) P_03666... - Page 73 Peristaltic pump EDITION 08/2022 ORDER NUMBER DOC2368104 Order no. Designation 2357381 Peristaltic pump PP25Y, flange connection 3109976 Sealing ring 3144058 Sealing collar for squeeze valve 2357369 Outlet 2402046 Squeeze valve 2402257 Sealing collar for squeeze valve 2333008 Dead space insert 2416107 Quick exhaust valve 2418493...

-

Page 74: Peristaltic Pump Pp25Y, Threaded Connection (Until 11/2020)

Peristaltic pump EDITION 08/2022 ORDER NUMBER DOC2368104 12.12 PERISTALTIC PUMP PP25Y, THREADED CONNECTION (UNTIL 11/2020) P_02836... - Page 75 Peristaltic pump EDITION 08/2022 ORDER NUMBER DOC2368104 Order no. Designation 2364560 Peristaltic pump PP25Y, threaded connection 3144058 Sealing collar for squeeze valve 2357369 Outlet 2349577 Squeeze valve 2349751 Sealing collar for squeeze valve 2333008 Dead space insert 3136837 Non-return valve 2357380 Y-piece 3144056...

-

Page 76: Peristaltic Pump Pp25Y, Threaded Connection (Starting 12/2020)

Peristaltic pump EDITION 08/2022 ORDER NUMBER DOC2368104 12.13 PERISTALTIC PUMP PP25Y, THREADED CONNECTION (STARTING 12/2020) P_03667... - Page 77 Peristaltic pump EDITION 08/2022 ORDER NUMBER DOC2368104 Order no. Designation 2364560 Peristaltic pump PP25Y, threaded connection 3144058 Sealing collar for squeeze valve 2357369 Outlet 2402046 Squeeze valve 2402257 Sealing collar for squeeze valve 2333008 Dead space insert 2416107 Quick exhaust valve 2418493 Non-return valve 2357380...

-

Page 78: Peristaltic Pump Pp40Y, Threaded Connection (Until 11/2020)

Peristaltic pump EDITION 08/2022 ORDER NUMBER DOC2368104 12.14 PERISTALTIC PUMP PP40Y, THREADED CONNECTION (UNTIL 11/2020) P_03087... - Page 79 Peristaltic pump EDITION 08/2022 ORDER NUMBER DOC2368104 Order no. Designation 2372081 Peristaltic pump PP40Y, threaded connection 2439758 O-ring set 2438916 Clamping pin 2308075 Ho-Matic pinch valve 3102576 Quick exhaust valve 2357369 Outlet 2349577 Squeeze valve 2333008 Dead space insert 2349751 Sealing collar for squeeze valve 3136837 Non-return valve...

-

Page 80: Peristaltic Pump Pp40Y, Threaded Connection (Starting 12/2020)

Peristaltic pump EDITION 08/2022 ORDER NUMBER DOC2368104 12.15 PERISTALTIC PUMP PP40Y, THREADED CONNECTION (STARTING 12/2020) P_04684... - Page 81 Peristaltic pump EDITION 08/2022 ORDER NUMBER DOC2368104 Order no. Designation 2372081 Peristaltic pump PP40Y, threaded connection 2439758 O-ring set 2438916 Clamping pin 2308075 Ho-Matic pinch valve 3102576 Quick exhaust valve 2357369 Outlet 2416107 Quick exhaust valve 2402046 Squeeze valve 2333008 Dead space insert 2402257 Sealing collar for squeeze valve...

-

Page 82: Powder Hose Set Dn14

Peristaltic pump EDITION 08/2022 ORDER NUMBER DOC2368104 12.16 POWDER HOSE SET DN14 P_02902 Order no. Designation 2365857 Hose set, RG PXS DN14, 20 m 3/4" 2365849 Hose fitting, DN14 3/4" 2369917 Heavy duty clamp 20 m 2359121 Powder hose, d14 2365794 Coupling female thread, 3/4"... -

Page 83: Powder Hose Set Dn20 1", 20 M

Peristaltic pump EDITION 08/2022 ORDER NUMBER DOC2368104 12.18 POWDER HOSE SET DN20 1", 20 M P_03071 Order no. Designation 3303443 Hose set, RG DN20, 1" 20 m (4 couplings) 2439131 Kamlok coupling, female thread, 1" 2439130 Hose fitting, D20 external thread, G1" 2323505 Heavy duty clamp 20 m... -

Page 84: Control Cabinets

Peristaltic pump EDITION 08/2022 ORDER NUMBER DOC2368104 12.20 CONTROL CABINETS The spare parts lists for the WAGNER controls, for the peristaltic pump, are included in the supplied electrical circuit diagram. 12.21 VALVE TERMINAL Order no. Designation 2325006 Silencer... -

Page 85: Eu Declaration Of Conformity

II 3 D Ex h IIIB T85°C Dc Declaration of Conformity The declaration of conformity is enclosed with this product. If needed, further copies can be ordered through your WAGNER dealer by specifying the product name and serial number. Order number:... - Page 88 Order no. 2368104 Edition 08/2022 ts-powder@wagner-group.com www.wagner-group.com...

Need help?

Do you have a question about the PP25S and is the answer not in the manual?

Questions and answers