Subscribe to Our Youtube Channel

Summary of Contents for Henny Penny SpaceSaver Plus Team

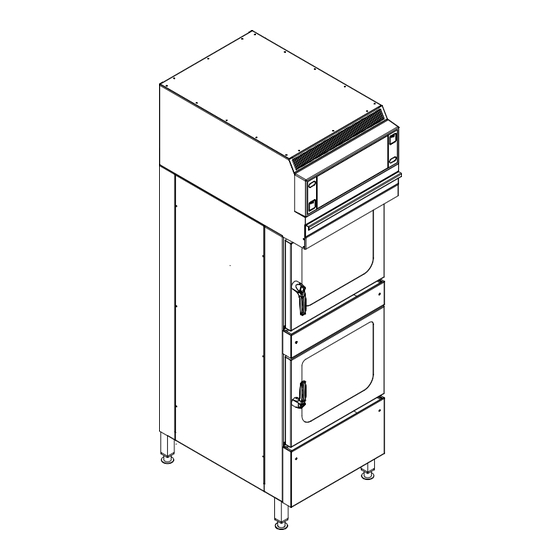

- Page 1 Service- instructions SpaceSaver Plus Team & SpaceSaver Team Model FSD 610.610 FSDH 610.610 FM06-078B en-US...

- Page 2 Henny Penny Corporation P.O.Box 60 Eaton, OH 45320 Phone +1 937 456-8400 Fax +1 937 456-8402 Toll free in USA Phone +1 937 417-8417 Fax +1 937 417-8434 www.hennypenny.com Service-instructions...

-

Page 3: Table Of Contents

Directory of contents 1 Password overview ............ 7 2 Introduction ................. 8 2.1 About this manual ................ 8 2.2 Warranty .................... 8 3 Safety instructions ............. 9 4 Component overview ............ 10 4.1 Installation compartment ............... 10 4.2 Operating panel ................ 11 4.3 Right view .................. 12 4.4 Rear side .................. 13 Upper unit ... - Page 4 Directory of contents 5.26 Background lighting .............. 37 5.27 Hour meter .................. 37 6 Status overview direct access ........ 38 7 Software ................ 39 7.1 Overview .................. 39 7.2 Software update ................ 39 7.3 Importing additional content ............ 41 7.4 Importing the manufacturer's cookbook ........ 42 8 Trade show mode ............. 43 9 Electronics ...

- Page 5 Directory of contents 5013: Application could not be restored! Restore to factory settings with OK. .. 5027: The application could not be started. Perform a software update .. 69 Unit was restarted after power failure .............. 69 The operating unit battery is empty (1478) ............ 70 Door is open - cooking program was stopped ...

- Page 6 Directory of contents Service-instructions...

-

Page 7: 1 Password Overview

Password overview 1 Password overview Range Password Description Described in Installation / 2100 Setting all basic parameters (for Installation instructions commissioning example time / date). Network settings 2000 Input network addressing. Only Installation instructions for units with touchscreen control. Basic settings / user Setting of basic values ... -

Page 8: 2 Introduction

Introduction 2 Introduction 2.1 About this manual This service manual contains information needed by the service technician for professional and correct fault isolation, repair and maintenance of the unit. The service technician must also observe the contents of the installation instructions and the user manual. Target group Target group for this service manual is qualified personnel who are familiar with the technical functioning and operation of the unit and have been trained to work on electrical units. -

Page 9: 3 Safety Instructions

Safety instructions 3 Safety instructions For servicing tasks, the service technician must be familiar with and observe regional regulations. In addition, the notes in the service manual must be observed. Organizational measures Risk of property damage and personal injury from lack of organizational measures •... -

Page 10: 4 Component Overview

Component overview 4 Component overview 4.1 Installation compartment 1F4.1 2F4.1 1-T10 2-T10 Q4.1 Q4.2 2-T1 1-T1 1- = Upper unit. 2-Lower = unit A1 Control board A3 Lighting circuit board F4 Fuse 6.25 A, slow-blow F4.1 Fuse 6.25 A, slow-blow K2 Relay; 8 A; 230 V Q1 Main contactor 32 A, 230 V Q2 Solid-state relay (SSR), 50 A Q4.1 Reversing contactor 18 A, 230... -

Page 11: Operating Panel

Component overview 4.2 Operating panel A2 Operating panel, complete with a On/Off switch (10020346) housing b Loudspeaker (10016690) c USB interface (10020348) Service-instructions... -

Page 12: Right View

Component overview 4.3 Right view 1- = Upper unit. 2-Lower = unit B1 Core temperature sensor B2 Cooking chamber sensors Service-instructions... -

Page 13: Rear Side

Component overview 4.4 Rear side Upper unit 1-B11 1-M10 1-E1 2-B11 1-G16 1-G24 1- = Upper unit. 2-Lower = unit B0 Thermal switch 85°C B4 Vapor sensor B11 Safety temperature limiter 330°C E1 Heating element G16 Circulation pump G24 Drain pump M1 Fan M8 Lift magnet M10 Fan motor... -

Page 14: Lower Unit

Component overview Lower unit 2-M10 2-G24 2-G16 2-K20 1-K20 1- = Upper unit. 2-Lower = unit B4 Vapor sensor E1 Heating element G16 Circulation pump G24 Drain pump K12 Magnetic valve water vapor K20 Steaming unit elimination M10 Fan motor N1 Ethernet interface X1 Power connection Service-instructions... -

Page 15: 5 Service Menu - Appliance Test

Service menu - appliance test 5 Service menu - appliance test 5.1 Service menu The service area permits functional testing of individual components, adjustment of basic settings and updating of the software. Access to service area Switch on the unit. Tap the "Unit functions"... -

Page 16: Appliance Information

Service menu - appliance test 5.2 Appliance information Overview Image: Unit information display Display of the appliance-specific information 1. Software version 2. Cookbook version 3. Unit configuration 4. Serial number 5. Date of last CombiDoctor diagnosis. 6. Saved contact data Leaving the area Touch the Back field. - Page 17 Service menu - appliance test Status 2 Climate control system, fan B14: Pressure switch on the DynaSteam unit PWM: heat requirement in %. Temperature sensors B3, B5 are not present. Status 3 WaveClean (option) K04: Magnetic valve for water vapor elimination & siphon filling B15: Reed contact switch B14: Pressure switch on the DynaSteam unit Temperature sensors B3, B5 are not present.

-

Page 18: Combidoctor

Service menu - appliance test 5.4 CombiDoctor Description The CombiDoctor offers an automatic check of the climate control system and WaveClean automatic cleaning. The tests are possible individually or as overall test. For instructions on performing, see the touchscreen. Image: Select CombiDoctor test CombiDoctorStart Selecting a program Select a program by adjusting the roller. - Page 19 Service menu - appliance test Step 3 (heat output) 1. Check of heat output. Display switches to green = test successful. Display switches to red = test not successful. Check of on-site voltage supply. Check of heating element Check of solid-state relay Check of internal fuse for load circuit (depends on unit version).

- Page 20 Service menu - appliance test Step 8 (WaveClean siphon pump) 1. Check of WaveClean siphon pump. Display switches to green = test successful. Display switches to red = test not successful. Check of siphon pump via relay test. A fault is present on the component or the control board.

-

Page 21: Relay Test

Service menu - appliance test 5.5 Relay test Overview Overview Image: Relay test page 1 Image: Relay test page 2 Relay overview Relay Connect Description Info Main contactor Q1 208V AC POS A 208V AC POS B 208V AC Not in use 208V AC Magnetic valve for water vapor 208V AC... -

Page 22: Waveclean Test

Service menu - appliance test Relay Connect Description Info Not in use Cooking chamber light 24V DC Supply for control panel (MMI) 24V DC Circulating pump G16 208V AC 1 -4 Steaming unit (switched directly, 24V DC not via relay) Description The test permits separate activation of various functions. - Page 23 Service menu - appliance test Rinse and fill up siphon. Draining by pump G24. Filling by magnetic valve K12. Circulation and heating. The circulation pump G16 is switched on. Heating of the cooking chamber to 55 °C (131 °F). Rinse DynaSteam and siphon The valve for steaming is energized.

-

Page 24: Calibrating The Cooking Chamber Sensor

Service menu - appliance test 5.7 Calibrating the cooking chamber sensor Description Calibration function for the cooking chamber sensor. Testing the calibration. Performing the calibration. The units are factory calibrated. Recalibration is required only in exceptional INFORMATION cases. Image: Overview a Back b Offset setting "Start/Stopp"... - Page 25 Service menu - appliance test Check calibration Prerequisite Calibrated digital temperature measurement device. The temperature in the cooking chamber is < 100 °C (212 °F). Fix temperature sensor of external measurement device in the cooking chamber. Use a grill rack for this. Point the sensor tip upward in order to prevent measurement errors.

- Page 26 Service menu - appliance test Calibrate cooking chamber sensor Prerequisite Execute Check calibration and do not switch appliance off. Temperature display on the touch screen indicates 100 °C (212 °F). Calibration Adjust offset value by adjusting the roller. Let 10 minutes adjustment time elapse. The external measurement device must display a temperature between 99 °C (210,2 °F) –...

-

Page 27: Dynasteam Test

Service menu - appliance test 5.8 DynaSteam test Description The DynaSteam test allows a function test of DynaSteam steaming. Calibration is not possible / necessary. Prerequisite Access to the water supply pipe in the cooking chamber. Remove both hook-in points. Dismount water supply pipe. -

Page 28: Emptying The Water

Service menu - appliance test 5.9 Emptying the water Description Water drainage removes water residue from the unit to prevent frost damage during transport and idle period. Prerequisite Both water connections are connected to compressed air. The pressure may not exceed 6 bar. The cooking chamber temperature is <... -

Page 29: Audio Settings

Service menu - appliance test Canceling the selection Tap the "Back" field. 5.11 Audio settings Image: Overview Setting the volume Use the slider to set the desired volume. Tap the "OK" field. Changes saved. Canceling the selection Tap the "Back" field. 5.12 Select signal tones Set signal tones Set the profile by adjusting the rollers. -

Page 30: Log Data Export

Service menu - appliance test Changing the setting Touch the "OK" field. Change saved. Automatic restart of the software. Canceling the selection Touch the "Back" field. 5.14 Log data export Description Log data export to an external USB flash drive. The function is only required after consultation. -

Page 31: Software Update

Service menu - appliance test 5.15 Software update Description Update of the software via the USB interface. Sounds, cookbooks, help texts and videos are not part of the software update. INFORMATION These require importing via "Importing additional content". Performing the update Perform according to instructions on the touchscreen and software description. -

Page 32: Backing Up Data

Service menu - appliance test 5.18 Backing up data Description Backup function for parameters (for example, customer settings, calibration values). Saving data on the internal SD card and USB stick (if plugged in). Backing up data Prerequisite Service menu is displayed Tap the "... -

Page 33: Setting Units

Service menu - appliance test 5.21 Setting units Overview Changing values 1. Select the desired temperature and volume. 2. Tap the "OK" button. 5.22 Backup relay Description The control board has a spare relay, which allows alternative use in case of a relay failure. This is only possible with the listed relays. Locate defective relay Call relay test in the service menu. -

Page 34: Settings Parameters

Service menu - appliance test Touch the "OK" field. Changes saved. Canceling the selection Touch the "Back" field. Relay overview Relay Connect Description Instruction Main contactor Q1 Reconnect the line from X10.2 to X12.5 and to assign a reserve relay to it. POS A Reconnect the line from X11.1 to X12.5 and to assign a reserve relay to it. - Page 35 Service menu - appliance test Selecting parameters Selecting parameters by adjusting the caster. Tap the "Read" button. Display of set parameters. Changing parameters Use the number block to set the desired value. Tap the "Write" button. Changes saved. Parameter overview Basic setting Standard Adjustment...

- Page 36 Service menu - appliance test Basic setting Standard Adjustment Explanation worth range Interval for saving the 120 s 1 – 180 temperatures in the HACCP seconds Ready to Cook – Finished 60 s 0 – 300 Reminder interval after reaching the message interval seconds Ready2Cook temperature SES status...

-

Page 37: Backing Up The Sd Card

Service menu - appliance test 5.24 Backing up the SD card Description Export the data from the internal SD card and external USB stick. Backing up data Perform according to instructions on the touchscreen. Tap the OK button. Back-up of the data. A confirmation then appears on the touchscreen. -

Page 38: 6 Status Overview Direct Access

Status overview direct access 6 Status overview direct access 6.1 Description Direct access allows display of all processes and temperatures during operation. The status overview is intended only for the service technician. INFORMATION Overview a Hidden field for access to status overview 6.2 Opening the status overview Tap the invisible field three times quickly. -

Page 39: 7 Software

Software 7 Software 7.1 Overview a USB port for top unit b USB port for bottom unit 7.2 Software update Update each of the two units separately. Two independent controls are in- INFORMATION volved. Preparing the USB stick Prerequisite USB stick. Maximum size 64 GB. - Page 40 Software Updating the software 1. Insert the USB stick 2. Switch the appliance on. 3. Tap the "Unit functions" field. Display menu Unit functions . 4. Tap the "Unit settings" field. Display window PIN . 5. Enter password "1967" and tap field Confirm . Display from service area 6.

-

Page 41: Importing Additional Content

Software 7.3 Importing additional content Description Description The additional content includes the following files: • Pictures for AutoChef • Help information • Sound files Import of additional content (sounds, videos, graphics, help texts). Import is absolutely essential after the operating panel has been replaced. INFORMATION Preparing the USB stick Prerequisite USB stick. -

Page 42: Importing The Manufacturer's Cookbook

Software 7. Tap the "Import additional contents" field. 8. Tap the "OK" field. The data is imported. Finally, a confirmation appears on the touchscreen. 9. Tap the "OK" field. 7.4 Importing the manufacturer's cookbook Preparing the USB stick Create the folder "Cooking_CODG2" on the USB stick. Copy the update file to the "Cooking_CODG2"... -

Page 43: 8 Trade Show Mode

Trade show mode 8 Trade show mode 8.1 Description Trade show mode allows appliance operation for demonstration purposes. 8.2 Opening the unit functions Connecting the unit Tap the "Unit functions" field. Display of Appliance functions menu. 8.3 Switching the trade show mode on/off Description Trade show mode allows appliance operation for demonstration purposes. -

Page 44: 9 Electronics

Electronics 9 Electronics 9.1 Block diagram for the control 24V AC 208V AC 24V DC +1-T1 +1-A3 24V DC +1-A1 +1-E3 +1-A2 24V DC 208 AC +1-M10 +1-T10 U/V/W 24V AC 208V AC 24V DC +2-T1 +2-A3 24V DC +2-A1 +2-E3 +2-A2 24V DC... -

Page 45: Control Board

Electronics 9.2 Control board Layout Service-instructions... -

Page 46: Configuration

Electronics Configuration Connector X1 Description Input 24 V DC for lighting Output 24 V DC for lighting Control board I/O voltage supply (24 V AC) Connector X5 CAN bus line to the motor M10 Connector X7 MMI communication Connector X8 Digital key contains device-specific information. Connector X9 (24V DC) Description 24 V DC supply for operating panel (MMI) - Page 47 Electronics Connector X17 (208V AC) Description Output K8, lift magnet M8 N for lift magnet M8 Connector X23 Description Output to upper or lower unit. "Unit On" message , 24 V DC Input from upper or lower unit. "Unit On" feedback, 24 V DC Connector X24 B1 core temperature sensor Connector X25 B2 cooking chamber sensor...

-

Page 48: Safety Overview

Electronics 9.3 Safety overview F4.1 6,25A 208V AC 24V DC 630mA F4 6,25A A1-F3 208V AC 3,15A A1-F5 208V AC 3,15A A1-F2 24V DC 3,15A Legend Control board Operating panel Lighting circuit board Thermal switch 85°C (185 °F) Cooking chamber STL LED illumination WaveClean pump Siphon pump... -

Page 49: 10 Error Messages

Error messages 10 Error messages 10.1 Symbols for errors For some errors, an additional symbol appears in the title bar. If the exact error is not known, switch the unit off and then back on. In the event of an error, the exact error will appear in the display. Display on the left Description touchscreen... -

Page 50: Emergency Operation

Error messages 10.2 Emergency operation Description In order to allows limited use in case of error, the appliance has various emergency programs. Emergency operation is activated automatically and displayed. After elimination of the error indicated, the controller switches back into regular operation automatically. A reset is not necessary. -

Page 51: Temperature Sensor Area

Error messages 10.3 Temperature sensor area Cooking chamber sensor defective (694, 695) Check contacting from cooking chamber sensor to control board A1 X25. Error eliminated? Remove existing cooking chamber sensor from the control board A1 X25 and plug in new cooking chamber sensor. -

Page 52: Core Temperature Sensor Defective (699, 700)

Error messages Core temperature sensor defective (699, 700) Is the wire or the test prod damaged physically? Remove existing core temperature sensor from the control board A1, X24 and plug in new core temperature sensor. Error eliminated? Replace control board. Replace core temperature sensor. -

Page 53: Water Vapor Sensor Defective (710)

Error messages Water vapor sensor defective (710) Description Switching to emergency operation takes place automatically. The software controls steam elimination. This results in higher water consumption. Naming on the circuit diagram Troubleshooting Unlatch and open the operating panel. Check contacting on control board A1, X27. Remove existing water vapor sensor from the control board A1, X27 and plug in new water vapor sensor. -

Page 54: Risk Of Frost (Tmp_Id72)

Error messages Risk of frost (TMP_ID72) Increase the room temperature and switch on unit again. Change location of the unit. Service-instructions... -

Page 55: Excess Temperature In The Cooking Chamber (Id18, Id73)

Error messages Excess temperature in the cooking chamber (ID18, ID73) Description The measured temperature in the cooking chamber is outside the allowable range of more than 320°C. The unit is no longer operational until the cooking chamber cools down. The measurement is taken by the cooking chamber sensor, core temperature sensor and the moisture sensor. -

Page 56: Motor Area

Error messages 10.4 Motor area Warning: electric shock! Danger of death! DANGER When working on the power board, make sure that energized parts are ex- posed. Work on these components during operation and up to 3 minutes after enabling is not allows. Even if the motor is stopped and the appliance is de-en- ergized, the connection terminals and components can conducted dangerous voltage! Overview... -

Page 57: Fan Defective Or Temperature Limiter Triggered (702)

Error messages Fan defective or temperature limiter triggered (702) Description The control board A1 does not receive any response via the CAN bus cable from motor power board T10. There is an fault in the fan area. Troubleshooting Nature and source of the hazard INFORMATION Perform software update. - Page 58 Error messages Does the fault message appear only after a longer period of operation or at high temperatures? Switch unit on and measure voltage at main Via the thermal switch B0 the unit switches off the contactor Q1, terminals A1 and A2. Is voltage main contactor Q1 at 85 C°...

- Page 59 Error messages Continued from previous page Does the error appear only sporadically? Measure input voltage to motor control. Are 208 V Replace motor control unit. Check whether the fault present and the green LED on the motor control unit still appears. lit? Replace fan motor.

-

Page 60: Fan Defective. Cooking Program Was Cancelled (701)

Error messages Fan defective. Cooking program was cancelled (701) Description The control board A1 does not receive any response via the CAN bus cable from power board T10. Troubleshooting FAN_ID6: Motor overtemperature Description The error message was introduced with software version 3.3.17. The temperature from the motor is monitored via an integrated thermal switch (bimetal). -

Page 61: Fan_Id23: Fan Error: Attempt To Restart

Error messages FAN_ID23: Fan error: Attempt to restart Overview a Fuse F1 6.3 A b Power board c Connector S300. Motor power d Connector S100. Power supply supply circuit board e Connector S500. CAN connection f Connector S501. Input for to control circuit board temperature switch from motor Description... - Page 62 Error messages Troubleshooting Warning: electric shock! Danger of death! DANGER When working on the power board, make sure that energized parts are ex- posed. Work on these components during operation and up to 3 minutes after enabling is not allows. Even if the motor is stopped and the appliance is de-en- ergized, the connection terminals and components can conducted dangerous voltage! Switch off unit and restart.

-

Page 63: Fan_Id27: Motor System Error

Error messages FAN_ID27: Motor system error Description The error message is generated when the control board receives a too low or no speed from the motor control. After unit restart via "ON/ OFF" the error is reset. A new query is made at the start of the cooking program. -

Page 64: Water Area

Error messages 10.5 Water area Water pressure too low (709) Overview a Pressure switch c Water supply pipe in the cooking chamber b Sieve Troubleshooting The water pressure at the water connection must be at least 2 bar. Service-instructions... -

Page 65: Water Pressure During Waveclean Too Low

Error messages Soft water connection attached and water valve at site open? Connect water supply or open water valve. Is the fault message displayed continuously? Check sieve on the water connection for soiling. To Check the on-site water pressure while observing do this, remove the on-site water connection to the nearby water consumers. -

Page 66: Electronics / Control Area

Error messages Troubleshooting Ensure customer-supplied water supply on the soft water connection of unit. The supply pressure on the water connection must be at least 2 bar. If the fault occurs sporadically, check the on-site water pressure while observing nearby water consumers. 10.6 Electronics / control area Failure to access external EEPROM (SOF_ID12) Description... -

Page 67: 5008: No New Version Found

Error messages 5008: No new version found Description The following causes generate the message: USB stick not recognized or not present Required content not present on the USB stick or saved incorrectly. The software version on the unit is newer than that on the USB stick. Troubleshooting Check content and structure of the USB stick. -

Page 68: 5010: The Application Could Not Be Started. Restore Configuration Backup

Error messages Disconnect CAN bus cable between control board and motor. Then restart the unit. Does the error still appear? Disconnect the communication line between the Replace CAN bus cable. Check whether the fault still operating unit and the control board. Check whether appears. -

Page 69: 5027: The Application Could Not Be Started. Perform A Software Update

Error messages Troubleshooting Confirm message. An automatic restore starts. Next, update the software. If the error continues to appear, the operating panel needs to be replaced. With software version 1.78 (10/2018) or higher, a restore is possible by means of a rescue tool. Contact the manufacturer in this regard. -

Page 70: The Operating Unit Battery Is Empty (1478)

Error messages The operating unit battery is empty (1478) Description The date and time are lost after the unit is switched on or they reset. HACCP and log data are no longer saved in a form that can be evaluated. Replacement requires disassembly of the operating unit. -

Page 71: Door Is Open - Cooking Program Was Stopped

Error messages Door is open - cooking program was stopped Description During fault-free operation, this message appears if the cooking chamber door is opened during an active cooking program. If the message is displayed with a closed cooking chamber door, there is an error on the reed contact switch or door magnet. -

Page 72: 11 Circuit Diagram 3Pe Ac 208-240V

Circuit diagram 3PE AC 208-240V 11 Circuit diagram 3PE AC 208-240V Service-instructions... - Page 73 +2-A1:X5 /7.6 +2-M10 +2-A1:X10:1 /5.3 -XL2-PE:PE /2.3 S300 S100 -Q4.2:3 /3.6 -Q4.2:1 /3.5 +2-A3:X2:1 /5.8 -X30:5 /8.3 +24V +2-A1:X10:5 /5.1 +2-Q1:A2 /5.1 -XL2.1 +1-A1:X5 /6.6 CAN+1-M10 +1-A1:X10:1 /4.3 S300 S100 -Q4.1:3 /3.4 -Q4.1:1 /3.4 +1-A3:X2:1 /4.8 -X30:3 /8.3 +24V +1-Q1:A2 /4.1 +1-A1:X10:5 /4.1...

- Page 74 fast slow +2-Q1:24 /2.7 +2-Q1:14 /2.7 +1-Q1:24 /2.3 +1-Q1:14 /2.3 +2-A1:X32:4 /5.1 +2-A1:X32:3 /5.1 +2-A1:X32:2 /5.1 +2-A1:X32:1 /5.1 +1-A1:X32:4 /4.1 +1-A1:X32:3 /4.1 +1-A1:X32:2 /4.1 +1-A1:X32:1 /4.1...

- Page 75 -X30:4 /8.3 +1-T1:- /2.2 -K2:A1 /3.4 -Q4.1:2 /3.4 +2-A1:X23:2 /7.1 +2-A1:X23:1 /7.1 +1-F4:2 /2.3...

- Page 76 -X30:6 /8.3 +2-T1:- /2.7 +1-A1:x13:2 /4.5 -Q4.1:2 /3.5 +1-A1:X23:2 /6.1 +1-A1:X23:1 /6.1 +2-F4:2 /2.8...

- Page 77 -X31:3 /8.5 yellow -X31:2 /8.4 brown -X31:1 /8.4 white 3,15AT -X30:1 /8.2 white -X30:2 /8.3 brown Motor CAN+1-M10 /2.4 Probe Drain Wrasen Probe Cabinet Garraum Probe Coretemp. Kerntemp. +2-A1:x16:2 /5.5 +2-A1:X16:1 /5.5...

- Page 78 -X31:7 /8.5 green -X31:6 /8.5 pink -X31:5 /8.5 grey 3,15AT -X30:7 /8.3 white -X30:8 /8.3 brown Motor /2.8 +2-M10 Probe Drain Wrasen Probe Cabinet Garraum Probe Coretemp. Kerntemp. +1-A1:x16:2 /4.5 +1-A1:X16:1 /4.5...

- Page 79 TERM CAN1 CAN1 CAN1 TERM CAN1 I²C I²C +2-A1:X7:4 /7.7 green +2-A1:X7:2 /7.7 pink +2-A1:X7:1 /7.7 grey +1-A1:X7:4 /6.7 yellow +1-A1:X7:2 /6.7 brown +1-A1:X7:1 /6.7 white +2-A1:X9:1 /7.6 yellow +2-A1:X9:2 /7.6 green +2-A3:X2:3 /5.8 brown +2-T1:+24V /2.6 white +1-A3:X2:3 /4.8 +1-T1:+24V /2.2 blue...

- Page 82 Henny Penny Corporation P.O.Box 60 Eaton, OH 45320 Phone +1 937 456-8400 Fax +1 937 456-8402 *FM06-078B* Toll free in USA Phone +1 937 417-8417 Henny Penny Corp., Eaton, Ohio 45320, Revised 9/6/2023 Fax +1 937 417-8434 www.hennypenny.com...

Need help?

Do you have a question about the SpaceSaver Plus Team and is the answer not in the manual?

Questions and answers