Table of Contents

Advertisement

Quick Links

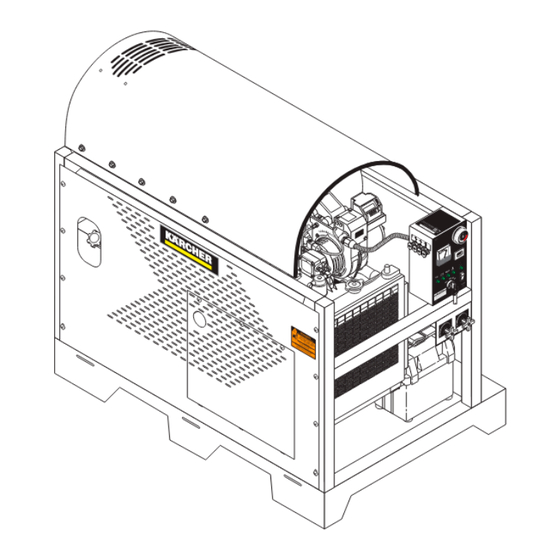

Kubota Skid Diesel

Register

your product

www.kaercher.com/welcome

W A

PR

EC

AU

R N

CI

EX

ÓN

IN

BE

PO

/ AV

G

8.9

LT S

SE

ER

TIS

32-

D PU

SE

965

.0

KE

EP

CA

LL

ME

PO

CL

N CA

EY

NT

NO

LE

AS

EA

R WH

US

S AN

SE

AC

PU

Y CO

IS

OP

ILE

E IN

DE

S CO

ER

ED

RR

ER

MA

JU

D

NE

QU

E SI

EN

CA

EA

S EX

AT

ING

CH

INE

RY

PA

S S'A

PE

UV

UR

RO

MÀ

US

RY

PP

EN

IES

QU

INA

AR

PU

ES

RO

CH

T CA

OU

ES

DA

ÑO

TA

ER

LO

US

ER

PO

UL

TÁ

S

RS

QU

DE

IES

FU

NC

E L'A

S BL

EX

ION

AN

PP

AR

ES

PO

SÉ

DO

EIL

SU

RE

ES

EST

S

EN

OP

ÉR

ATI

ON

98014960-1

G L S T

O N

O FF

.0

427

9.8

01-

IO

N

R

UT

RA

TO

CA

GE

NE

erat

or

e

AD

ona

l gen

resi

stiv

ER

LO

opti

0 wat

ts

deta

ils.

T OV

d with

100

ual

for

DO

s equ

NO

ippe

exce

ed

Man

Unit

uld

not

Ser

vice

sho

. See

load

English

02

®

9.801-496.0-AF

12/14/22

Advertisement

Table of Contents

Summary of Contents for Kärcher HDS 30/22 DE Cage

- Page 1 Kubota Skid Diesel English G L S T O FF erat l gen resi stiv opti 0 wat deta ils. T OV d with s equ ippe exce Unit vice . See load ÓN / AV LT S D PU N CA R WH S AN...

- Page 2 MODEL # ORDER # HDS 30/22 DE Cage 1.110-601.0 HDS 37/22 DE Cage 1.110-602.0...

-

Page 3: Table Of Contents

CONTENTS Introduction & Important Safety Information Component Identifi cation Assembly Instructions Operating Instructions Detergents & General Washing Techniques Shutting Down & Clean-Up Storage Troubleshooting 12-15 Maintenance, Service, & Schedule 16-19 Preventative Maintance Karcher Kubota Skid 30/22 Burner Assembly Exploded Views & Parts List 22-23 Karcher Kubota Skid 30/22 Burner Assembly Exploded Views &... -

Page 4: Introduction & Important Safety Information

INTRODUCTION & IMPORTANT SAFETY INFORMATION WARNING: This machine exceeds Thank you for purchasing this Pressure Washer. WARNING 85 db appropriate ear protection We reserve the right to make changes at any time must be worn. without incurring any obligation. Owner/User Responsibility: The owner and/or user must have an understanding of the manufacturer’s operating instructions and warnings EAR PROTECTION... - Page 5 IMPORTANT SAFETY INFORMATION In an overfi lling situation, additional precautions are 15. Be certain all quick coupler fi ttings are secured necessary to ensure that the situation is handled before using pressure washer. in a safe manner. WARNING: High pressure devel- WARNING WARNING: Risk of injury.

- Page 6 IMPORTANT SAFETY INFORMATION 21. Do not allow acids, caustic or abrasive fl uids to pass through the pump. 22. Never run pump dry or leave spray gun closed longer than 1-2 minutes. 23. Machines with shut-off spray gun should not be operated with the spray gun in the off position for extensive periods of time as this may cause dam- age to the pump.

-

Page 7: Component Identification

COMPONENT IDENTIFICATION Rupture Disk Water Inlet Pump and Unloader Valve High Pressure Nozzles Volt Wand Thermostat Meter G L S T al gen isti h opt ails T OV 0 wa l for e Ma Steam Valve (optional) Detergent Valve (optional) C IÓ... -

Page 8: Assembly Instructions

ASSEMBLY INSTRUCTIONS Discharge Nipple Trigger Wand Water Inlet High Pressure Safety Latch Garden Hose Hose Collar 98014960-5 98014960-4 98014960-3 STEP 1: Attach a 5/8" water supply STEP 2: Attach high pressure hose STEP 3: Attach variable pressure hose to inlet connector. Minimum to discharge nipple using quick cou- control wand to spray gun using fl... -

Page 9: Operating Instructions

OPERATING INSTRUCTIONS Engine Switch G L S T G L S T 7. 0 7. 0 1- 42 1- 42 9. 80 9. 80 G EN G EN ra to ra to ge ne ge ne tiv e tiv e na l na l re sis... -

Page 10: Detergents & General Washing Techniques

DETERGENTS & GENERAL WASHING TECHNIQUES WARNING: Some de ter gents WARNING CLEANING TIPS may be harm ful if in haled or in gest ed, caus ing severe nau- Pre-rinse clean ing surface with fresh water. Place de- sea, fainting or poi son ing. The ter gent suc tion tube di rect ly into clean ing so lu tion and harm ful el e ments may cause ap ply to sur face at low pressure (for best re sults, limit... -

Page 11: Shutting Down & Clean-Up

SHUTTING DOWN AND CLEAN-UP G L S T -4 27 Burner isti ails h op T OV al for Switch t exc e Se Engine -4 27 Switch isti h op ails T OV al for t exc e Se 98014960-22 98014960-21 98014960-23... -

Page 12: Troubleshooting

TROUBLESHOOTING PROBLEM POSSIBLE CAUSE SOLUTION Faulty pressure gauge Install new gauge. OPERATING Insuffi cient water supply Use larger supply hose; clean fi lter at water inlet. PRESSURE Old, worn or incorrect spray Match nozzle number to machine and/or replace nozzle with new nozzle. - Page 13 TROUBLESHOOTING PROBLEM POSSIBLE CAUSE SOLUTION BURNER Flex coupling slipping on fuel pump Replace if needed. WILL shaft or burner motor shaft NOT LIGHT On-Off switch defective Check for electrical current reaching (continued burner assembly with burner switch on. from previous Heavy sooting on coil and burner Clean as required.

- Page 14 TROUBLESHOOTING PROBLEM POSSIBLE CAUSE SOLUTION LOW WATER Improper fuel or water in fuel Replace with clean and proper fuel. TEMPERATURE Low fuel pressure Increase fuel pressure. Weak fuel pump Check fuel pump pressure. Replace pump if needed. Fuel fi lter partially clogged Replace as needed.

- Page 15 TROUBLESHOOTING PROBLEM POSSIBLE CAUSE SOLUTION OIL DRIPPING Oil seal worn Check and replace if necessary. EXCESSIVE VIBRATION Irregular functioning of the valves Check and replace if necessary. IN DELIVERY LINE DETERGENT Air leak Tighten all clamps. Check detergent NOT DRAWING lines for holes.

-

Page 16: Maintenance, Service, & Schedule

MAINTENANCE & SERVICE Check List: the anti-freeze mixture through the machine. If com- pressed air is available, an air fi tting can be screwed 1. Check to see that water pump is properly into the fl oat tank by removing the fl oat tank strainer lubricated. - Page 17 MAINTENANCE & SERVICE JP5 or JP8 must be approved on an application Removal of Soot and Heating Coil: basis and is not recommended for broad range In the heating process, fuel residue in the form of soot commercial applications. deposits may develop between the heating coil pipe and block air fl...

- Page 18 MAINTENANCE & SERVICE baseline factory-supplied nozzle for operating in such- To adjust, start machine and turn burner ON. Loosen temperature extremes if performance is not meeting two locking screws found on the air band and close air needs with air band and fuel pressure settings alone. band until black smoke appears from burner exhaust vent.

- Page 19 MAINTENANCE & SERVICE Coil Removal: Removal of coil because of freeze breakage, or to clean soot from it can be done quickly and easily. 1. Disconnect hose from pump to inlet side of the coil. 2. Carefully disconnect the thermostat sensor making sure you do not crimp the capillary tube.

-

Page 20: Preventative Maintance

PREVENTATIVE MAINTENANCE MAINTENANCE SCHEDULE Inspect Daily Engine Oil SAE 10W-30 Change Every 100 hours or 15W-40 Filter Every 200 hours Inspect Every 50 hours or monthly Air Cleaner Clean Every 3 months Battery Level Check monthly Engine Fuel Filter 300 hours or 6 months Clean Fuel Tank(s) Annually Replace Fuel Lines... - Page 21 NOTES Karcher Kubota Diesel Dealer Manual • 9.801-496.0 - AF...

-

Page 22: Exploded Views & Parts List

KARCHER KUBOTA SKID 30/22 BURNER ASSEMBLY EXPLODED VIEW 98014960-26 From Unloader Karcher Kubota Diesel Dealer Manual • 9.801-496.0 - AF... - Page 23 KARCHER KUBOTA SKID 30/22 BURNER ASSEMBLY PARTS LIST ITEM PART NO. DESCRIPTION NPT ST Male ITEM PART NO. DESCRIPTION 8.757-205.0 Hose Barb, 1/4" Barb X 1/4" M-NPTF, 90° 8.912-220.0 Insulation Retainer Plate 8.709-158.0 Filter, Fuel/H20 Separator 1 8.912-449.0 Wrap, Bottom, 24" 8.757-199.0 Hose Barb, 1/4"...

-

Page 24: Exploded Views & Parts List

KARCHER KUBOTA SKID 30/22 EXPLODED VIEW Reversed Views of Labels 19 - Inlet to Engine 12 - Return from Engine 40 - Return Steam from Burner Valve Kit (optional) 20 - Inlet to Burner Float Tank W/Detergent Valve Kit (optional) Detail See ÓN N IN... - Page 25 KARCHER KUBOTA SKID 30/22 EXPLODED VIEW Unloader Assembly See Pump Assembly 98014960-28 Detail See Engine Assembly Karcher Kubota Diesel Dealer Manual • 9.801-496.0 - AF...

- Page 26 KARCHER KUBOTA SKID 30/22 PARTS LIST ITEM PART NO. DESCRIPTION ITEM PART NO. DESCRIPTION 9.802-071.0 Trim, 750 B2 X 1/16", Black 48" Bushing, See Specifi cations Pages 40-41 9.802-082.0 Cap, Fuel Belt, See Specifi cations Pages 40-41 8.706-600.0 Battery Box, Large Belt, See Specifi...

- Page 27 KARCHER KUBOTA SKID 30/22 PARTS LIST ITEM PART NO. DESCRIPTION 9.803-845.0 Bolt, 1/2" x 5", NC 9.802-800.0 Washer, 1/2" Flat 9.802-785.0 Nut, 8/32" 9.802-779.0 Nut, 3/8", ESNA, NC 8.758-329.0 Label, Warning Exposed Pulleys 9.802-776.0 Nut, 5/16 8.726-103.0 Screw, 1/4" x 1/2" Whiz 8.725-319.0 Nut, 7/16"...

-

Page 28: Burner Assembly Exploded Views & Parts List

KARCHER KUBOTA SKID 37/22 BURNER ASSEMBLY EXPLODED VIEW 9814960-31 From Unloader Karcher Kubota Diesel Dealer Manual • 9.801-496.0 - AF... - Page 29 KARCHER KUBOTA SKID 37/22 BURNER ASSEMBLY EXPLODED VIEW PARTS LIST ITEM PART NO. DESCRIPTION ITEM PART NO. DESCRIPTION 8.757-205.0 Hose Barb, 1/4" Barb x 1/4" 9.802-517.0 Connector, 1/2" L/T, 90° M-NPTF, 90° ▲ Con duit, Flexo 8.716-011.0 8.725-306.0 Fuel Filter Separator Unit 1/2"...

-

Page 30: Exploded Views & Parts List

KARCHER KUBOTA SKID 37/22 EXPLODED VIEW Reversed Views of Labels 77 - Inlet to Engine 70 - Return from Burner 12 - Return Steam from Engine Valve Kit (optional) 70 - Inlet to Burner Float Tank W/Detergent Valve Kit (optional) Detail See ÓN / AV... - Page 31 KARCHER KUBOTA SKID 37/22 EXPLODED VIEW Unloader Assembly See Pump Assembly 98014960-30 Detail See Engine Assembly Karcher Kubota Diesel Dealer Manual • 9.801-496.0 - AF...

- Page 32 KARCHER KUBOTA SKID 37/22 EXPLODED VIEW PARTS LIST ITEM PART NO. DESCRIPTION ITEM PART NO. DESCRIPTION 9.802-071.0 Trim, 750 B2 X 1/16", Belt, See Specifi cations Pages 40-41 Black 48" 8.757-257.0 Tee, Street 1/2" 9.802-082.0 Cap, 18 Fuel 8.757-639.0 TB2400 Generator 8.706-600.0 Battery Box, Large 9.803-541.0...

- Page 33 KARCHER KUBOTA SKID 37/22 EXPLODED VIEW PARTS LIST ITEM PART NO. DESCRIPTION 8.758-329.0 Label, Warning Exposed Pulleys 9.802-254.0 Fuel Line, 1/4" 54" 8.726-103.0 Screw, 1/4" x 5/8" Whiz 8.758-334.0 Label, Hot Water Outlet 8.718-988.0 Washer, 7/16" 8.758-341.0 Label, Diesel Black On Yellow 8.725-319.0 Nut, 7/16"...

-

Page 34: Control Panel Exploded View & Parts List

CONTROL PANEL EXPLODED VIEW G L S T 7 .0 -4 2 9 .8 ra to e n e a l g is ti re s il s . p ti tt s e ta w it a l fo ip p e q u x c e... - Page 35 CONTROL PANEL PARTS LIST ITEM PART NO. DESCRIPTION 8.712-378.0 Nozzle, SAQCMEG, 0009, Red (30/22) 8.712-379.0 Nozzle, SAQCMEG, 1509, Yellow (30/22) 8.712-380.0 Nozzle, SAQCMEG, 2509, Green (30/22) 8.712-381.0 Nozzle, SAQCMEG, 4009, White (30/22) 8.707-760.0 Nozzle, 0011, (37/22) 8.707-761.0 Nozzle,1511, (37/22) 8.707-762.0 Nozzle, SAQCMEG, 2511, (37/22) 8.707-763.0...

-

Page 36: Pump Assembly Exploded Views & Parts List

PUMP ASSEMBLY EXPLODED VIEW & PARTS LIST 98014960-35 PUMP ASSEMBLY PARTS LIST ITEM PART NO. DESCRIPTION ITEM PART NO. DESCRIPTION 9.802-744.0 Bolt, 10mm x 20mm 9.802-126.0 Plug, 1/2" JIC Flare, HH Zinc 8.920-596.0 Pump, Karcher, KX1036L.2 8.757-262.0 Elbow, 1/2" 45° SAE X 3/8" 37/22 M-NPTF, Brass 8.920-594.0... -

Page 37: Unloader Assembly Exploded View & Parts List

UNLOADER ASSEMBLY EXPLODED VIEW & PARTS LIST 98014960-36 UNLOADER PARTS LIST ITEM PART NO. DESCRIPTION ITEM PART NO. DESCRIPTION 9.802-869.0 Block, Unloader, 1/2 x 1/2 8.757-660.0 Plug Counter Sunk Brass 8.757-510.0 Elbow, 3/4"-16 SAE, 1/2"NPTF (M), Steel 8.757-627.0 Pump Protector 1/2 190° 8.757-654.0 Elbow Street Steel NPTF 8.933-006.0... -

Page 38: Engine Assembly Exploded View & Parts List

ENGINE ASSEMBLY 22 23 98014960-33 ENGINE ASSEMBLY PARTS LIST ITEM PART NO. DESCRIPTION ITEM PART NO. DESCRIPTION 8.753-177.0 Engine, Kubota 9.802-781.0 Nut, 3/8" NC, Whiz Loc D11050-E3B 9.802-126.0 Plug, 1/2" Flare 8.753-183.0 Muffl er, Silencer, Hapco 9.802-151.0 Swivel, 1/2" Barb x 1/2" Kubota D1105 JIC, Fem/Brass 8.753-178.0... -

Page 39: Hose & Spray Gun Assembly Exploded View & Parts List

EXPLODED VIEW - HOSE & SPRAY GUN ASSEMBLY 8, 9 High Pressure HOSE & SPRAY GUN ASSEMBLY PARTS LIST ITEM PART NO. DESCRIPTION ITEM PART NO. DESCRIPTION 9.802-166.0 Coupler, 3/8" Female 8.707-761.0 Nozzle, MEG 1511, Yellow 37/22 ▲ Quick Coupler O-Ring, 9.802-100.0 8.707-762.0 Nozzle, MEG 2511,... - Page 40 WAYNE EH OIL-FIRED BURNER Karcher Kubota Diesel Dealer Manual • 9.801-496.0 - AF...

- Page 41 WAYNE EH OIL-FIRED BURNER REPLACEMENT PARTS ITEM PART NO. DESCRIPTION 8.700-770.0 MOTOR, 1/4 120VAC 13121 MOTOR CORD COVER 8.756-438.0 BURNER FAN 8.700-735.0 BURNER HOUSING -PAINTED 8.700-802.0 IGNITOR, E, 120VAC 8.757-055.0 HONEYWELL R7284P (POTTED) 13392 SLOT COVER PLATE 8.700-732.0 BAND, AIR BURNER INNER EHA/SR 8.700-729.0 AIR BAND 8 HOLE...

-

Page 42: Parts Specifications

PARTS SPECIFICATIONS PUMP ENGINE Hi-Pres Pump Pump Pump Pulley Bushing Pump Belt Engine Model Nozzle Model # Part # Pulley Part # Bushing Part # Belt (Qty) Part # Engine Part # 30/22 3200 KX-9536\L 8.920-594.0 3BK80H 8.715-618.0 25mm 8.802-403.0 BX37 (3) 8.715-698.0 Kubota D1105... - Page 43 PARTS SPECIFICATIONS ENGINE GENERATOR Engine Pulley Engine Bushing Generator Pulley Generator Bushing Generator Belt Model Pulley Part # Bushing Part # Pulley Part # Bushing Part # Belt (Qty) Part # 30/22 4840SD 8.715-623.0 SDx1-7/16 8.753-182.0 BK32 9.802-377.0 7/8" 8.715-663.0 BX22 (1) 9.802-412.0 37/22...

-

Page 44: Kx.2 Pump Exploded View And Parts List

KX.2 SERIES PUMP EXPLODED VIEW 8.920-594.0 KX 9536L 8.920-596.0 KX 1036L TORQUE SPECS ITEM # FT. LBS. KX.2 SERIES PUMP EXPLODED VIEW PARTS LIST ITEM PART NO. DESCRIPTION ITEM PART NO. DESCRIPTION 8.752-825.0 Crankcase 9.802-926.0 Brass Plug 1/2 See Kit Below Plunger Oil Seal See Kit Below Valve Seat... - Page 45 KX.2 SERIES PUMP PARTS LIST (CONT) ITEM PART NO. DESCRIPTION 9.803-181.0 Bearing Housing 8.752-841.0 Plunger Bolt 8.752-820.0 Bonded Seal 8.752-847.0 Plunger, 22mm 8.752-823.0 Copper Spacer 8.752-842.0 Plunger Rod 8.752-822.0 Connecting Rod Pin 9.803-157.0 Connecting Rod 9.802-889.0 Spring Washer 9.802-937.0 Connecting Rod Screw 9.803-194.0 O-Ring Ø2.62 x 152.07 8.752-826.0...

-

Page 46: Beckett Cf800 Burner Exploded View & Parts List

BECKETT CF800 BURNER ASSEMBLY EXPLODED VIEW 8.717-102.0 BURNER ASSEMBLY EXPLODED VIEW PARTS LIST ITEM PART NO. DESCRIPTION 8.718-216.0 Nozzle Line Assy (ATC CF60KHS) Includes Air Tube, Head, Nozzle Gun Assy. 8.717-367.0 Nozzle, 4.5 80B (SLX10) 8.717-832.0 Fuel Pump, B2YA-8916 8.701-088.0 Motor, 1/3 HP 120V (21341) 9.802-667.0 Fuel Line, 8"... - Page 48 THANK YOU! MERCI! GRACIAS! DANKE! Register your product and benefit from many advantages. Enregistrez votre produit et bénéficiez de nombreux avantages. Registre su producto y aproveche de muchas ventajas. Registrieren Sie Ihr Prudukt und Sie von vielen Vorteilen. www.kaercher.com/welcome Rate your product and tell us your opinion. Évaluez votre produit et donnez-nous votre opinion.

Need help?

Do you have a question about the HDS 30/22 DE Cage and is the answer not in the manual?

Questions and answers