Advertisement

Quick Links

New & Reconditioned Equipment & Parts - www.southeasternequipment.net

OPERATOR'S MANUAL

HDS 2.0/10 E

HDS 1.9/15 E

HDS 3.5/20 E

To locate your local Kärcher Commercial Pressure Washer Dealer nearest you,

MODEL

Cage

d

Cage

d

Cage

a

visit www.karchercommercial.com

ORDER #

1.575-511.0

1.575-512.0

1.575-513.0

9.800-191.0

Advertisement

Summary of Contents for Kärcher 1.575-511.0

- Page 1 New & Reconditioned Equipment & Parts - www.southeasternequipment.net OPERATOR’S MANUAL MODEL ORDER # HDS 2.0/10 E Cage 1.575-511.0 HDS 1.9/15 E Cage 1.575-512.0 HDS 3.5/20 E Cage 1.575-513.0 To locate your local Kärcher Commercial Pressure Washer Dealer nearest you, visit www.karchercommercial.com...

-

Page 2: Table Of Contents

New & Reconditioned Equipment & Parts - www.southeasternequipment.net CONTENTS Introduction and Safety Information Component Identification Operating Instructions Preventative Maintenance and Service 9-11 Exploded Views 12-13 Exploded Views Parts List 14-15 Control Panel Exploded View and Parts List 16-18 Hose & Spray Gun Assembly and Parts List Downstream Injector Assembly and Parts List UU1 Unloader Exploded View and Parts List Pump Exploded View and Parts List... - Page 3 New & Reconditioned Equipment & Parts - www.southeasternequipment.net INTRODUCTION & IMPORTANT SAFETY INFORMATION DANGER: Improper connection of the equipment- Thank you for purchasing this Pressure Washer. grounding conductor can result in a risk of elec- We reserve the right to make changes at any time trocution.

- Page 4 New & Reconditioned Equipment & Parts - www.southeasternequipment.net IMPORTANT SAFETY INFORMATION WARNING: High pressure devel- 10. Keep operating area clear of all persons. WARNING oped by these machines will WARNING: High pressure spray WARNING cause personal injury or equip- can cause paint chips or other ment damage.

- Page 5 New & Reconditioned Equipment & Parts - www.southeasternequipment.net IMPORTANT SAFETY INFORMATION INSTALLATION Place machine in a convenient location providing ample support, draining and room for maintenance. This machine is intended for indoor use. Machine must be stored indoors when not in use. Location: The location should protect the machine from damag- ing environmental conditions, such as wind, rain, and...

-

Page 6: Component Identification

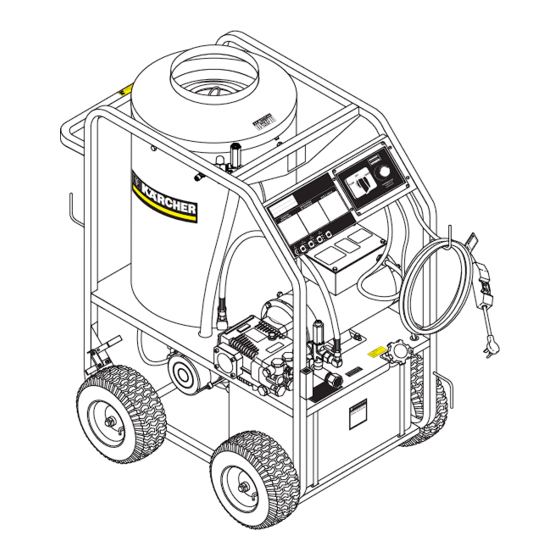

New & Reconditioned Equipment & Parts - www.southeasternequipment.net COMPONENT IDENTIFICATION C AU T I O N H O T WAT E R : Must use insulated spray gun and wand. Nozzle ON - OFF Switch Hour Meter Adjustable Thermostat Downstream Detergent Injector GFCI... -

Page 7: Operating Instructions

New & Reconditioned Equipment & Parts - www.southeasternequipment.net OPERATING INSTRUCTIONS Electrical: 5. Insert quick coupler onto discharge nipple and secure by pushing quick coupler collar forward. This machine, when installed, must be electrically grounded in accordance to local codes. Check for 6. - Page 8 New & Reconditioned Equipment & Parts - www.southeasternequipment.net OPERATING INSTRUCTIONS 4. Place detergent pick-up tube into container of HOW TO USE THE detergent solution. DETERGENT INJECTOR 5. Turn pressure control handle counterclockwise on the variable pressure wand. This lowers the pres- WARNING: Some detergents sure by directing the water flow through the soap WARNING...

-

Page 9: Preventative Maintenance And Service

New & Reconditioned Equipment & Parts - www.southeasternequipment.net PREVENTATIVE MAINTENANCE AND SERVICE solution of anti-freeze/water into a 5 gallon bucket. PREVENTATIVE MAINTENANCE Place a short section of garden hose into bucket and connect it to machine. Elevate bucket and turn pump on 1. - Page 10 New & Reconditioned Equipment & Parts - www.southeasternequipment.net PREVENTATIVE MAINTENANCE AND SERVICE Burner Nozzle: the soot on the coil must be washed off after coil has been removed using the following steps: Keep the tip free of surface deposits by wiping it with a clean, solvent-saturated cloth, being careful not to plug 1.

- Page 11 New & Reconditioned Equipment & Parts - www.southeasternequipment.net PREVENTATIVE MAINTENANCE AND SERVICE NOTE: When changing fuel pump, a by-pass plug must Air Band be installed in return line port or fuel pump will not prime. Karcher Clear Fire Oil Burner Burner Air Adjustment: The oil burner on this machine is preset for operation at altitudes below 1000 feet.

- Page 12 New & Reconditioned Equipment & Parts - www.southeasternequipment.net EXPLODED VIEW - LEFT (Reversed View of Labels) (Reversed View of Label) Detail See Control Panel Illus. To Fuel Tank Fuel Tank 9.800-191.0 • Rev. 01/18...

- Page 13 New & Reconditioned Equipment & Parts - www.southeasternequipment.net EXPLODED VIEW - RIGHT 28,29 Enlarged D EP O SI TI VO R ES R EP O SI C IO View Overload Button 9.800-191.0 • Rev 01/18...

-

Page 14: Exploded Views Parts List

New & Reconditioned Equipment & Parts - www.southeasternequipment.net EXPLODED VIEWS PARTS LIST ITEM PART NO. DESCRIPTION ITEM PART NO. DESCRIPTION 9.802-782.0 Collar, 5/8" Bore Shaft 9.802-526.0 Locknut, 3/4" 8465 (513.0) 8.754-435.0 Wheel & Pu Tire Assy, 12" 8.754-696.0 Unloader, VBT Banjo 1/2M 3/8M, 3000PSI Steel Rim 9.175-018.0... - Page 15 New & Reconditioned Equipment & Parts - www.southeasternequipment.net EXPLODED VIEWS PARTS LIST ITEM PART NO. DESCRIPTION ITEM PART NO. DESCRIPTION 8.756-181.0 Burner, MSR 3.75 8.706-827.0 Elbow, 1/4" Street, 120V 1T 120V S Brass 8.756-709.0 Burner, MSR, 230V 1T 230V S (For models HDS 3.5/20 EA) 8.754-953.0 Fuel Nozzle, 1.75 X 90AZ...

-

Page 16: Control Panel Exploded View And Parts List

New & Reconditioned Equipment & Parts - www.southeasternequipment.net CONTROL PANEL EXPLODED VIEW Thermostat To Burner Motor To Power Pressure Source Switch To Motor CONTROL PANEL EXPLODED VIEW PARTS LIST ITEM PART NO. DESCRIPTION ITEM PART NO. DESCRIPTION 8.750-094.0 Thermostat, 150C/302F 9.802-514.0 Strain Relief, STRT LQ TITE 2 9.802-449.0... -

Page 17: Hose & Spray Gun Assembly And Parts List

New & Reconditioned Equipment & Parts - www.southeasternequipment.net HOSE AND SPRAY GUN EXPLODED VIEW HOSE AND SPRAY GUN PARTS LIST ITEM PART NO. DESCRIPTION ITEM PART NO. DESCRIPTION 9.802-287.0 Nozzle SAQMEG 0003, 9.802-166.0 Coupler, 3/8" Female Red (512.0) 9.802-100.0 s Quick Coupler O-Ring LG 1 9.802-288.0 Nozzle, SAQMEG 1503, 8.925-130.0... - Page 18 New & Reconditioned Equipment & Parts - www.southeasternequipment.net DOWNSTREAM INJECTOR EXPLODED VIEW DOWNSTREAM INJECTOR PARTS LIST ITEM PART NO. DESCRIPTION 9.802-215.0 Injector, Detergent, Non-Adjust #2 (511.0, 512.0) 9.802-216.0 Injector, Detergent, Non-Adjust #3 (513.0) 6.390-126.0 Clamp, Hose, UNI .46 - .54 9.802-251.0 Tube, 1/4"...

- Page 19 New & Reconditioned Equipment & Parts - www.southeasternequipment.net VBT UNLOADER EXPLODED VIEW 8.754-696.0 UNLOADER, VBT BANJO 1/2M 3/8M, 3000PSI (SPARE) VBT UNLOADER EXPLODED VIEW PARTS LIST ITEM PART # DESCRIPTION KIT QTY ITEM PART # DESCRIPTION KIT QTY 9.803-914.0 Seal Washer 1/2) 8.754-929.0 Stem 8.754-937.0 Bypass Manifold 9.803-912.0 Backup Ring...

- Page 20 New & Reconditioned Equipment & Parts - www.southeasternequipment.net KF SERIES PUMP EXPLODED VIEW 8.923-791.0 KF 2030S TORQUE SPECS Item # Ft.-lbs KF SERIES PUMP PARTS LIST PART NO. DESCRIPTION ITEM PART NO. DESCRIPTION 8.754-841.0 Crankcase 8.754-850.0 Washer, Lock 8.754-846.0 O-ring Ø1.78 X 72.75 9.803-198.0 Washer, Copper G3/8 See Kits Below Plunger Oil Seal...

- Page 21 New & Reconditioned Equipment & Parts - www.southeasternequipment.net KF SERIES PUMP PARTS LIST ITEM PART NO. DESCRIPTION 8.754-855.0 Bolt, Plunger 8.754-092.0 Spacer, Copper 8.754-848.0 Plunger, 16mm 9.803-962.0 Spacer, Copper 8.754-827.0 Plunger Rod 9.803-965.0 Connecting Rod Pin 9.803-966.0 Connecting Rod 8.933-020.0 Screw, Connecting Rod 8.754-847.0 O-ring Ø2.62 X 111.62...

- Page 22 New & Reconditioned Equipment & Parts - www.southeasternequipment.net KF SERIES PUMP EXPLODED VIEW 8.923-794.0 KF5330F TORQUE SPECS Item # Ft.-lbs KF SERIES PUMP EXPLODED VIEW PARTS LIST ITEM PART NO. DESCRIPTION ITEM PART NO. DESCRIPTION 8.754-841.0 Crankcase 8.754-850.0 Washer, Lock 8.754-846.0 O-ring Ø1.78 X 72.75 9.803-198.0...

- Page 23 New & Reconditioned Equipment & Parts - www.southeasternequipment.net KF SERIES PUMP EXPLODED VIEW PARTS LIST ITEM PART NO. DESCRIPTION 39* 8.754-855.0 Bolt, Plunger 40* 8.754-092.0 Spacer, Copper 8.754-849.0 Plunger, 14mm 9.803-962.0 Spacer, Copper 8.754-827.0 Plunger Rod 9.803-965.0 Connecting Rod Pin 9.803-966.0 Connecting Rod 8.933-020.0...

- Page 24 New & Reconditioned Equipment & Parts - www.southeasternequipment.net BURNER ASSEMBLY EXPLODED VIEW 1/4" Above nozzle center 1/8"min 5/32" max Gap 1/8" AC 3/16" DC Nozzle-to- 1-3/8" tip spacing Cone distances and electrode gaps checked with burner gage (8.922-740.0), sold separately. BURNER ASSEMBLY EXPLODED VIEW PARTS LIST ITEM PART NO.

- Page 25 New & Reconditioned Equipment & Parts - www.southeasternequipment.net WAYNE BURNER EXPLODED VIEW Replacement Parts For best performance specify genuine WAYNE replacement parts 9.800-191.0 • Rev 01/18...

- Page 26 New & Reconditioned Equipment & Parts - www.southeasternequipment.net WAYNE BURNER PART LIST Replacement Parts For best performance specify genuine WAYNE replacement parts ITEM PART NO. DESCRIPTION 101397-001 Tube/Hous-101392-001/ 5A/3.5"/3"I 101295-002 Ignitor- D W/M Plate 120V 100990-001 Spring, Contact 8.756-740.0 Junction Box, MSR, Black Body 8.700-707.0 Air Band Inner "M"...

- Page 27 New & Reconditioned Equipment & Parts - www.southeasternequipment.net Replacement Parts for model HDS 3.5/20 EA For best performance specify genuine KNA replacement parts 9.800-191.0 • Rev 01/18...

- Page 28 New & Reconditioned Equipment & Parts - www.southeasternequipment.net Replacement Parts for model HDS 3.5/20 EA For best performance specify genuine KNA replacement parts ITEM PART NO. DESCRIPTION 101396-001 Tube/Hous-21922-001/6A/3.75"/.88"I 101391-002 Ignitor-D W/M Plate 230V 100990-001 Spring,Contact 21319-003 J-Box,3X4 (No Knockouts) 20601-002 Band, Air Inner-Mod M 20602-002...

-

Page 29: Troubleshooting

New & Reconditioned Equipment & Parts - www.southeasternequipment.net TROUBLESHOOTING PROBLEM POSSIBLE CAUSE SOLUTION LOW OPERATING Faulty pressure gauge Install new gauge. PRESSURE Insufficient water supply Use larger garden hose; clean filter washer at water inlet. Old, worn or incorrect spray nozzle Match nozzle number to machine and/or replace with new nozzle. -

Page 30: Maintenance Schedule

New & Reconditioned Equipment & Parts - www.southeasternequipment.net MAINTENANCE SCHEDULE PREVENTATIVE MAINTENANCE This pressure washer was produced with the best available materials and quality craftsmanship. However, you as the owner have certain responsibilities for the correct care of the equipment. Attention to regular preventative maintenance procedures will assist in preserving the performance of your equipment. - Page 31 New & Reconditioned Equipment & Parts - www.southeasternequipment.net Phone: 888-805-9852 LIMITED NEW PRODUCT WARRANTY—COMMERCIAL Fax: 800-248-8409 www.karchercommercial.com PRESSURE WASHERS WHAT THIS WARRANTY COVERS All Kärcher commercial pressure washers are warranted by Kärcher to the original purchaser to be free from defects in materials and workmanship under normal use, for the periods specified below.

- Page 32 New & Reconditioned Equipment & Parts - www.southeasternequipment.net www.karchercommercial.com Form # 9.800-191.0 • Revised 01/18 • Printed in U.S.A. or Mexico...

Need help?

Do you have a question about the 1.575-511.0 and is the answer not in the manual?

Questions and answers