Table of Contents

Advertisement

Quick Links

OPERATOR'S MANUAL

HDS 2.8/25 P Cage

HDS 2.6/30 P Cage

HDS 3.5/30 P Cage

HDS 3.5/30 PE Cage

HDS 3.5/35 PE Cage

To locate your local Kärcher Commercial Pressure Washer Dealer nearest you,

MODEL #

visit www.karchercommercial.com

ORDER #

1.575-555.0

1.575-550.0

1.575-551.0

1.575-552.0

1.575-553.0

9.800-079.0

Advertisement

Table of Contents

Summary of Contents for Kärcher HDS 2.8/25 P Cage

- Page 1 OPERATOR’S MANUAL MODEL # ORDER # HDS 2.8/25 P Cage 1.575-555.0 HDS 2.6/30 P Cage 1.575-550.0 HDS 3.5/30 P Cage 1.575-551.0 HDS 3.5/30 PE Cage 1.575-552.0 HDS 3.5/35 PE Cage 1.575-553.0 To locate your local Kärcher Commercial Pressure Washer Dealer nearest you, visit www.karchercommercial.com...

-

Page 2: Table Of Contents

CONTENTS Introduction & Important Safety Instructions Component Identification Assembly Instructions Operating Instructions Detergents and Cleaning Tips Shut-Down and Clean Up Storage Maintenance 12-14 Troubleshooting 15-17 Maintenance & Oil Change Charts Exploded View - 555.0 Exploded View - 550.0, 551.0, 552.0, 553.0 20-21 Exploded View Parts Lists 22-25... -

Page 3: Introduction & Important Safety Instructions

INTRODUCTION & IMPORTANT SAFETY INFORMATION Thank you for purchasing this Pressure Washer. WARNING: This machine ex- WARNING We reserve the right to make changes at any time ceeds 85 db appropriate ear without incurring any obligation. protection must be worn. Owner/User Responsibility: The owner and/or user must have an understanding of the manufacturer’s operating instructions and warnings... - Page 4 IMPORTANT SAFETY INFORMATION Gasoline engines on mobile or portable equipment WARNING: Grip cleaning wand WARNING shall be refueled: securely with both hands before starting. Failure to do this could a. outdoors; result in injury from a whipping b. with the engine on the equipment stopped; wand.

- Page 5 IMPORTANT SAFETY INFORMATION WARNING: Be extremely careful WARNING when using a ladder, scaffolding or any other relatively unstable location. The cleaning area should have adequate slopes and drainage to reduce the pos- sibility of a fall due to slippery RISK OF INJURY surfaces.

-

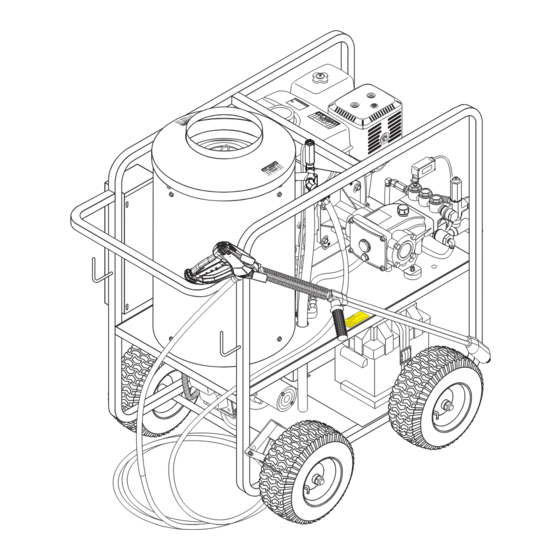

Page 6: Component Identification

COMPONENT IDENTIFICATION Gasoline Tank Discharge Detergent Nipple Injector Pressure Switch Unloader Collar Quick Water Supply Coupler Hose (not included) Pump Spray Battery Box Wand Coupler Nozzle Quick Trigger Coupler Brass Soap Variable Pressure Nozzle Control wand Control Wand Handle High Pressure Swivel Hose Connector... -

Page 7: Assembly Instructions

ASSEMBLY INSTRUCTIONS Pressure Soap Safety Nozzle Nozzle Latch Wand Coupler Spray Wand Coupler Wand Collar High Pressure Hose STEP 1: Attach the high pres- STEP 2: Pull the spring-loaded collar STEP 3: Release the coupler collar sure hose to the spray gun of the wand coupler back to insert your and push the nozzle until the collar using teflon tape on hose... -

Page 8: Operating Instructions

OPERATING INSTRUCTIONS Oil Dipstick Tank STEP 1: Check engine oil level. Oil level should be level with the bottom STEP 2: Fill gas tank with unleaded of the oil filler neck. Be sure the machine is level when checking the oil gasoline. - Page 9 OPERATING INSTRUCTIONS Throttle STEP 7: Turn the engine to "Run" position. STEP 8: Pull the starter grip. If the engine fails to start after 2 pulls, squeeze the trigger gun to release pressure and repeat step. Return starter gently. After the engine warms up enough to run smoothly, move choke to run position and throttle to fast position.

-

Page 10: Detergents And Cleaning Tips

DETERGENTS AND CLEANING TIPS THERMAL PUMP WARNING: Some detergents WARNING may be harmful if inhaled or in- PROTECTION gested, causing severe nausea, fainting or poisoning. The harm- If you run the engine on your pressure washer for 3-5 ful elements may cause property minutes without pressing the trigger on the spray gun, damage or severe injury. -

Page 11: Shut-Down And Clean Up

SHUTTING DOWN AND CLEAN-UP On-Off Switch STEP 1: Remove detergent suction STEP 2: Turn off the engine. STEP 3: Tur n off water tube from container and insert into supply. 1 gallon of fresh water.Turn variable pressure wand handle for low pres- sure or connect the black detergent nozzle. -

Page 12: Maintenance

MAINTENANCE During winter months, when temperatures drop below PREVENTATIVE MAINTENANCE 32°F, protecting your machine against freezing is neces- sary. Store the machine in a heated room. If this is not 1. Check to see that the water pump is properly lubri- possible then mix a 50/50 solution of anti-freeze/water cated. - Page 13 MAINTENANCE Use clean fuel oil that is not contaminated with water and debris. Replace fuel filter and drain tank every 100 Burner Nozzle: hours of operation. Keep the tip free of surface deposits by wiping it with a Use No. 1 or No. 2 Heating Oil (ASTM D306) only. clean, solvent-saturated cloth, being careful not to plug NEVER use gasoline in your burner tank.

- Page 14 MAINTENANCE Wayne Burner Fuel Pressure Adjustment: KNA Burner Air Adjustment To adjust fuel pressure, First install a pressure gage into the port just after the pump fuel exit. Turn the ad- Reference Numbers justing screw (located at the regulator port) clockwise to increase, and counterclockwise to decrease.

-

Page 15: Troubleshooting

TROUBLESHOOTING PROBLEM POSSIBLE CAUSE SOLUTION LOW OPERATING Water supply is insufficient Use larger supply hose; clean filter at water inlet. PRESSURE Spray nozzle is old, worn or Match the nozzle number to the machine incorrect and/or replace with new nozzle. Belt slips Tighten or replace belt;... - Page 16 TROUBLESHOOTING PROBLEM POSSIBLE CAUSE SOLUTION BURNER WILL Burner nozzle is clogged Clean as required. NOT LIGHT Thermostat has malfunctioned Test and replace if needed. (continued from previous page) Fuel solenoid has malfunctioned Test and replace if needed. MACHINE Fuel is improper or water is in fuel Drain tank and replace contaminated fuel.

- Page 17 TROUBLESHOOTING PROBLEM POSSIBLE CAUSE SOLUTION DETERGENT NOT Air is leaking Tighten all clamps. Check detergent lines for holes. DRAWING Injector head may be blocked, Clean and make sure ball and spring behind dirty or damaged detergent hose barb or injector body are working properly.

-

Page 18: Maintenance & Oil Change Charts

MAINTENANCE CHARTS PREVENTATIVE MAINTENANCE This pressure washer was produced with the best available materials and quality craftsmanship. However, you as the owner have certain responsibilities for the correct care of the equipment. Attention to regular preventative maintenance procedures will assist in preserving the performance of your equipment. Contact your dealer for maintenance. -

Page 19: Exploded View - 555.0

EXPLODED VIEW - 555.0 MODELS Reversed View Reversed View of labels of label s or tion s che s Eq tain atio 7-01 t con tion rt Fir . The 8.91 n Sta s or s.” a to t Ca “Th lifo s Tha... -

Page 20: Exploded View - 550.0, 551.0, 552.0, 553.0

EXPLODED VIEW - 550.0, 551.0, 552.0, 553.0 MODELS Reversed View of labels Detail See Control Box Illus. Reversed View of Component For Brake Honda Electric Detail See Start Only View A-A (Enlarged) pg. 21 9.800-079.0 • Rev. 01/18... - Page 21 EXPLODED VIEW - 550.0, 551.0, 552.0, 553.0 MODELS 550.0 Models Only Steam Option Steam Option 53, 69 Electric Start Model Only View A-A (Enlarged) 9.800-079.0 • Rev. 01/18...

- Page 22 EXPLODED VIEWS PARTS LIST ITEM PART NO. DESCRIPTION 8.719-913.0 Top Hat, Coil 9.800-006.0 Label, Hot/Caliente w/Arrows Warning 9.802-825.0 Clip, Retaining, U-Type 9.198-004.0 3/8 USS F/W Zinc 8.925-220.0 Spare Coil, Dura SCH 80 MTY 15" DIA 8.919-133.0 Coil Assembly (555.0) 8.919-732.0 Wrap, Outer Coil -07, Weldment (550.0, 551.0, 552.0, 553.0) 8.919-733.0 Coil, Wrap, Outer, Weldment (555.0)

- Page 23 EXPLODED VIEWS PARTS LIST ITEM PART NO. DESCRIPTION 9.802-064.0 Grommet, Rubber, Nozzle Holder 9.802-705.0 Bolt, 1/4" x 1" Carriage Burner Assy, See Burner Spec's Page 40 9.802-809.0 Nut, 5/16" Wing (552.0, 553.0) 9.802-781.0 Nut, 3/8" Flange, Whiz Loc 8.706-958.0 Hose Barb, 1/4" Barb x 1/4" Pipe, 90° (550.0, 551.0, 552.0, 553.0) 9.802-138.0 Hose Barb, 1/4"...

-

Page 24: Exploded View Parts Lists

EXPLODED VIEW PARTS LIST ITEM PART NO. DESCRIPTION 9.802-010.0 Nipple, 1/4", Hex, Steel (Steam Option) 9.802-802.0 Washer, 1/4" Flat, SAE 9.802-187.0 Valve, Flow Control w/Metering (Steam Option) 9.802-120.0 Tee, 1/4" Branch Male, Legacy Pumps (Steam Option) 8.706-803.0 Nipple, 1/4" x 2 1/2", Brass 9.802-997.0 Linkage, Brake, Black 8.725-306.0... - Page 25 EXPLODED VIEW PARTS LIST ITEM PART NO. DESCRIPTION 9.802-811.0 Washer, Fender (555.0) 9.800-018.0 Label, Tipover Hazard 9.800-049.0 Label, Cleaning Solution 9.802-807.0 Washer 3/8", SAE Flat (550.0, 551.0, 552.0, 553.0) 9.802-744.0 Bolt, 10 mm x 20 mm (551.0, 552.0, 553.0) 9.802-741.0 Bolt, 8 mm x 16 mm HEX Head (550.0) 9.802-066.0 Pad, Soft Rubber...

-

Page 26: Control Panel - 555.0 & Parts List

CONTROL PANEL EXPLODED VIEW - 555.0 MODELS 5,25 Reversed View 555.0 CONTROL PANEL PARTS LIST ITEM PART NO. DESCRIPTION 9.802-528.0 Capacitor 9.802-531.0 Regulator, Voltage, 15 Volt 9.803-036.0 Box, Electrical 9.803-121.0 Assembly, Cover, Electrical Box 8.750-094.0 Thermostat, Adjustable, 302°F 9.802-456.0 Light, Indicator, Green 12 Volt 9.802-453.0 Switch, Curvette RA901VB-B-1-V, Carling 9.802-283.0... - Page 27 555.0 CONTROL PANEL PARTS LIST ITEM PART NO. DESCRIPTION 9.802-206.0 Clamp, Hose 9.802-791.0 Nut, Cage, 10/32" x 16 Gauge 8.900-907.0 Label, Control Panel 9.802-802.0 Washer, 1/4", Flat, SAE 9.802-695.0 Nut, 10/32" Keps 9.802-771.0 Screw, 10/32" x 3/4" 9.802-759.0 Screw, 10/32" x 1/2" 9.803-048.0 Cap, Capacitor, 1.37 x 1.50 x .060 Blk, w/o Hole 9.803-840.0...

-

Page 28: Control Panel - 550.0, 551.0, 552.0, 553.0 & Parts List

CONTROL PANEL - 550.0, 551.0, 552.0, 553.0 1, 23 550.0, 551.0, 552.0, 553.0 CONTROL PANEL PARTS LIST ITEM PART NO. DESCRIPTION 8.750-094.0 Thermostat, Adjustable, 302°F 9.803-035.0 Cover, Electric Box, Black 9.802-759.0 Screw, 10/32" x 1/2" BHSOC, Black 9.802-485.0 Breaker, 1658-G41-02-P10-25A 8.750-096.0 Thermostat Dial 9.802-456.0... - Page 29 550.0, 551.0, 552.0, 553.0 CONTROL PANEL PARTS LIST ITEM PART NO. DESCRIPTION 9.802-453.0 Switch, Curvette RA901VB-B-1-V, Carling 9.802-519.0 Strain Relief, 1/2" Metal, Two Screw 9.802-514.0 Strain Relief, Small 9.803-071.0 Box, Electric, Black 9.802-788.0 Nut, 5/16" Whiz Loc Flange 9.802-530.0 Rectifier, Bridge (552.0, 553.0) 9.802-470.0 Relay, P &...

-

Page 30: Hose & Spray Gun Assembly & Parts List

HOSE & SPRAY GUN ASSEMBLY Pressure Nozzle HOSE & SPRAY GUN PARTS LIST ITEM PART NO. DESCRIPTION 9.802-166.0 Coupler, 3/8" Female 9.802-100.0 Quick Coupler O-Ring LG 8.925-130.0 Hose, 3/8" X 50' 1W 4000PSI SW/SO/CPL (All Models Except 553.0) 8.925-132.0 Hose, 3/8"... -

Page 31: Downstream Injector Assembly

DOWNSTREAM INJECTOR ASSEMBLY DOWNSTREAM INJECTOR PARTS LIST ITEM PART NO. DESCRIPTION 9.802-216.0 Injector, Detergent, Non-Adjusting #3 9.802-215.0 Injector, Detergent, Non-Adjusting #2 6.390-126.0 Clamp, Hose, UNI .46 - .54 9.802-251.0 Tube, 1/4" x 1/2", Clear Vinyl 6 ft. 9.802-160.0 Strainer, 1/4", Hose Barb 9.800-079.0 •... -

Page 32: Hose Reel Option

HOSE REEL OPTION HOSE REEL PARTS LIST ITEM PART NO. DESCRIPTION 9.802-166.0 Coupler, 3/8", Female, Brass 9.802-244.0 Hose, 3/8", 2 Wire Pressure Loop 9.802-269.0 Hose Reel, 100' Non-Pivot E-ZEE w/Pin Lock 9.802-767.0 Screw, 3/" x 3/4" HH NC, Whiz Loc 9.802-781.0 Nut, 3/8"... -

Page 33: Uu1 Unloader Exploded View And Parts List

UU1 UNLOADER EXPLODED VIEW 9.175-018.0 UU1 3500PSI, UNIVERSAL UNLOADER (SPARE) UU1 UNLOADER EXPLODED VIEW PARTS LIST ITEM PART # DESCRIPTION KIT QTY ITEM PART # DESCRIPTION KIT QTY 8.751-394.0 Piston Housing 9.149-006.0 Sliding Connector Guide Piston C, D O-Ring Backup A, D 6 x 1.45 x 1.68 Piston O-Ring Back Up... -

Page 34: Vbt Unloader Exploded View And Parts List

VBT UNLOADER EXPLODED VIEW 8.754-696.0 UNLOADER, VBT BANJO 1/2M 3/8M, 3000PSI (SPARE) VBT UNLOADER EXPLODED VIEW PARTS LIST ITEM PART # DESCRIPTION KIT QTY ITEM PART # DESCRIPTION KIT QTY 8.754-929.0 Stem 9.803-914.0 Seal Washer 1/2) 9.803-912.0 Backup Ring 8.754-937.0 Bypass Manifold 8.754-930.0 O-ring, Ø2.62 x 6.02 9.802-892.0 Outlet Connector 3/8 MPT 8.730-882.0 Stem Connector... -

Page 35: Ks.3 Pump Exploded View And Parts List

KS3540GR.3 PUMP EXPLODED VIEW 8.751-194.0 KS3540GR.3 TORQUE SPECS Item # Ft.-lbs KS3540GR.3 PUMP EXPLODED VIEW PARTS LIST ITEM PART NO. DESCRIPTION ITEM PART NO. DESCRIPTION 8.751-217.0 Crankcase 8.717-225.0 O-Ring Ø 2.62 x61.6 See Kit Below Plunger Oil Seal 9.802-914.0 Snap Ring See Kit Below O-Ring Ø1.78 x 31.47 9.803-168.0... - Page 36 KS3540GR.3 PUMP EXPLODED VIEW PARTS LIST (CONT.) ITEM PART NO. DESCRIPTION See Kit Below O-Ring Ø1.78x5.28 See Kit Below Teflon Ring 8.751-225.0 Plunger Rod 8.751-228.0 Connecting Rod Pin 9.803-158.0 Connecting Rod 9.803-218.0 Spring Washer 9.803-238.0 Connecting Rod Screw 8.933-016.0 O-Ring 2.62 x 126.67 8.751-229.0 Crankcase Cover 9.803-197.0...

- Page 37 KP3035G PUMP EXPLODED VIEW 8.923-786.0 KP3035G TORQUE SPECS Item # Ft.-lbs KP3035G1 PUMP EXPLODED VIEW PARTS LIST ITEM PART NO. DESCRIPTION ITEM PART NO. DESCRIPTION 8.754-841.0 Crankcase See Kits Below Valve Spring 8.754-846.0 O-ring Ø1.78 X 72.75 See Kits Below Valve Cage See Kits Below Plunger Oil Seal 9.802-939.0 Screw, M6 X 16...

-

Page 38: Kp 3035G Pump Exploded View And Parts List

KP3035G PUMP EXPLODED VIEW PARTS LIST (CONT) ITEM PART NO. DESCRIPTION 8.754-827.0 Plunger Rod 9.803-965.0 Connecting Rod Pin 9.803-966.0 Connecting Rod 8.933-020.0 Screw, Connecting Rod 8.754-847.0 O-ring Ø2.62 X 111.62 8.754-842.0 Cover, Crankcase 9.803-906.0 O-ring Ø1.78 X 14 9.803-202.0 Sight Glass, G3/4 * Available in kit (See below) REPAIR KIT NUMBER 8.754-860.0... -

Page 39: Lp 3035G1 Pump Exploded View And Parts List

LP3035G1 PUMP EXPLODED VIEW 8.923-759.0 LP3035G1 8.923-773.0 HP3035G1 8.923-787.0 KP3035G1 8.923-801.0 SP3035G1 TORQUE SPECS Item # Ft.-lbs LP3035G1 PUMP EXPLODED VIEW PARTS LIST ITEM PART NO. DESCRIPTION PART NO. DESCRIPTION ITEM 8.754-841.0 Crankcase 8.707-262.0 Plug, Brass G3/8 8.754-846.0 O-ring Ø1.78 X 72.75 See Kits Below Valve Seat See Kits Below Plunger Oil Seal See Kits Below Valve Plate... - Page 40 LP3035G1 PUMP EXPLODED VIEW PARTS LIST (CONT) ITEM PART NO. DESCRIPTION 9.803-244.0 Screw 9.803-217.0 Washer 9.803-216.0 Washer 8.752-824.0 Screw, M6 x 20 9.803-218.0 Washer, 6 mm 8.754-864.0 Flange, Engine 8.754-855.0 Bolt, Plunger 8.754-092.0 Spacer, Copper 8.754-849.0 Plunger, 14 mm 9.803-962.0 Spacer, Copper 8.754-827.0 Plunger Rod...

-

Page 41: Karcher Sure Fire Burner Exploded View And Parts List

Replacement Parts For best performance specify genuine KNA replacement parts 9.800-079.0 • Rev. 01/18... - Page 42 Replacement Parts For best performance specify genuine KNA replacement parts 9.800-079.0 • Rev. 01/18...

-

Page 43: Burner Specifications

WAYNE BURNER EXPLODED VIEW (HDS 2.6/30 P ONLY) Replacement Parts For best performance specify genuine WAYNE replacement parts 9.800-079.0 • Rev. 01/18... - Page 44 WAYNE BURNER PARTS LIST (HDS 2.6/30 P ONLY) Replacement Parts For best performance specify genuine WAYNE replacement parts ITEM PART NO. DESCRIPTION 101409-001 Tube/Hous-101393-001/3A/3.75"/.88"I 8.756-437.0 Pump-Combo/W Solenoid 12V/24V 550053 Fitting, Elbow 90* Street 1/8 01274-001 Tee,Street-1/8 x 1/8 Brass 14222 Connector, Male-3/16"...

- Page 45 Replacement Parts For best performance specify genuine WAYNE replacement parts 9.800-079.0 • Rev. 01/18...

- Page 46 Replacement Parts For best performance specify genuine WAYNE replacement parts ITEM PART NO. DESCRIPTION 101415-001 TUBE/HOUS-101407-001/3A/.88I 8.756-731.0 GUN ASSEMBLY, BURNER-RG/*CST/GBB2 8.756-437.0 PUMP - COMBO/W SOLENOID 12V/24V 8.700-704.0 OIL LINE ASSEMBLY 6" 13392 PLATE, SLOT COVER 14296 NUT, HEX 3/8-24 CRZC 8.700-732.0 AIR BAND INNER "E"...

- Page 47 SPECIFICATIONS BURNER SPECIFICATIONS Fuel Pump/ Fuel Pump/ Model # Burner Assy # Fuel Nozzle Transformer Burner Motor Solenoid Cord Solenoid Coil Electrode 1.575.555.0 8.918-910.0 8.754-891.0 9.802-663.0 9.802-638.0 9.802-562.0 9.802-639.0 9.802-670.0 1.575-550.0 8.756-655.0 8.756-916.0 9.107-507.0 8.700-821.0 8.756-437.0 8.756-437.0 8.756-297.0 1.575-551.0 8.756-756.0 8.756-699.0 9.107-507.0 8.756-716.0...

- Page 48 www.karchercommercial.com Form # 9.800-079.0 • Revised 01/18 • Printed in U.S.A. or Mexico...

Need help?

Do you have a question about the HDS 2.8/25 P Cage and is the answer not in the manual?

Questions and answers