Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Kärcher Trailer HDS Series

- Page 1 Trailer HDS Series Operator’s Manual Hot Water - Diesel Heated MODELS: HDS 3.5/40 GE MT 1.103-844.0 HDS 3.5/4.0 Ge VMT 1.110-118.0 To locate your local K rcher Commercial ä Pressure Washer Dealer nearest you, visit www.karchercommercial.com 9.807-942-0-C 04/14/23...

-

Page 2: Machine Data Label

Machine Data Label Model Number: _____________________________________________ Serial Number: ______________________________________________ Date of Purchase: ____________________________________________ The model and serial numbers will be found on a decal attached to the pressure washer. Record both serial number and date of purchase. PATENT PENDING Introduction Thank you for purchasing this Pressure Washer. -

Page 3: Table Of Contents

Table of Contents Machine Data Label ......2 Posi-lube Lubrication Procedure ....27 Troubleshooting . -

Page 4: Safety

Safety Important Safety Information WARNING: Risk of fire — Do not add fuel when the product is WARNING WARNING: To reduce the risk of operating or still hot. WARNING injury, read operating instruc- AVERTISSEMENT: Risque tions carefully before using. d'incendie-Ne pas ajouter de AVERTISSEMENT: Pour réduire le carburant pendant que la risque de blessures, lire attentive-... - Page 5 Safety WARNING: This machine exceeds WARNING: Grip cleaning wand 85 dB. Appropriate ear protection securely with both hands WARNING WARNING must be worn. before starting. Failure to do this could result in injury from a Cette machine AVERTISSEMENT: whipping wand. excède 85 dB et une protection de l'ouïe appropriée doit être portée AVERTISSEMENT: Agripper la...

- Page 6 Safety Reporting Safety Defects DANGER: Risk of asphyxiation. Use this product only in a well DANGER If you believe that your trailer has a defect which could ventilated area. cause a crash or could cause injury or death, you DANGER: Risque d'asphyxie: should immediately inform the National Highway Traffic Utiliser ce produit uniquement Safety Administration (NHTSA) in addition to notifying...

-

Page 7: Important Trailer Safety Information

Important Trailer Safety Information Referencing the Utility Trailer in this • The maximum weight the trailer is designed to carry. Manual • Gross vehicle weight rating of the trailer. All references to the trailer or component parts to either • Gross axle weight rating of the trailer. -

Page 8: Maintaining Proper Tire Pressure

Important Trailer Safety Information Maintaining Proper Tire Pressure Never Tow the Trailer Before Checking • Coupler and latch assembly show no signs of Locate the recommended tire pressure on the trailer's wear or damage. tire information placard or owner's manual. •... -

Page 9: Tow Vehicles

Important Trailer Safety Information Tow Vehicles Hitch Coupler Troubleshooting WARNING: Serious injury or property damage can If the coupler becomes damaged it must be repaired or result if the total weight of your loaded trailer exceeds replaced before towing. When the coupler is placed on the the capacity of the hitch and/or your tow vehicle. -

Page 10: Safety Chains

Important Trailer Safety Information Safety Chains The safety chains on your trailer are an added insurance that it will not become detached from the tow Listed in the chart below are the different class sizes of vehicle. All safety chains are provided with an added safety chains and the rated load each chain must be clasp to keep them from becoming accidentally capable of withstanding. -

Page 11: Tongue Weight

Important Trailer Safety Information The tire label will list the tire size that was installed on TIRE AND LOADING INFORMATION the trailer as original equipment when it was sold to RENSEIGNEMENTS SUR LES PNEUS ET LE CHARGEMENT you, the consumer. It also lists the maximum carrying The weight of cargo should never exceed XXXX kg or XXXX lbs capacity of the trailer. -

Page 12: Caster Operations

Important Trailer Safety Information Caster Operations This trailer has a caster for manual transporting while using the pressure washer and to keep the trailer tongue off the ground when not trailering. WARNING: The caster must be in the up position when trailering the unit. -

Page 13: Trailer Brake Operations

Important Trailer Safety Information Trailer Brake Operations WARNING: To avoid injury, the trailer brake must be set when operating the pressure washer or when not in use. AVERTISSEMENT: Pour éviter les blessures, le frein de la remorque doit être serré lors de l'utilisa- tion du nettoyeur haute pression ou lorsqu'il n'est pas utilisé. -

Page 14: What To Check And How To Check

What to Check And How To Check Tire Pressure Tires Proper air pressure for your tires is printed on the Before mounting tires onto wheels make certain that sidewall. Check pressure while tires are cold. Do not the rim size and contour is approved for the tire as raise or lower pressure to meet load. -

Page 15: Operations

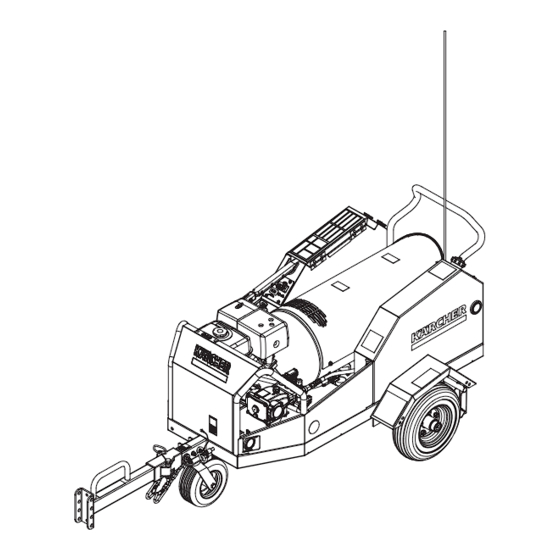

Operations Trailer Component Identification Hose and Wand Storage Diesel Tank Gasoline Tank Discharge Manifold and Safety Relief Valve VIN Plate Hitch Channel Pump & Unloader Valve Control Panel Thermostat Chemical Injector (Optional) Nozzle Quick Coupler Trigger Wand Spray Gun Battery Box High Pressure Outlet Water Inlet... -

Page 16: Accessory Assembly Instructions

Operations Accessory Assembly Instructions Handle Installation Safety Rod installation Handle Washer Bolt Align the 4 holes in the handle with the holes in the back plate, install the fasteners and washers supplied. (See Hose Box and Fuel Tank pages for fastener part Slide the rod through both holes in the tabs. -

Page 17: Assembly Instructions

Operations Assembly Instructions Safety High Pressure Inlet Latch Hose Connector Detergent Injector Discharge (Option) Nipple Detergent Hose STEP 1: Attach a 5/8" garden hose STEP 2: Attach high pressure hose STEP 3: Attach wand to spray gun to inlet connector. Minimum flow to discharge nipple using quick using teflon tape on threads to should be 5 gpm. -

Page 18: Installation

Operations Installation Placement Place machine in a convenient location providing Do not locate near any combustible material. Keep all ample support, draining and room for maintenance. flammable material at least 20 feet away. This machine is intended for outdoor use. Machine Allow enough space for servicing the machine. -

Page 19: Operating Instructions

Operations Operating Instructions Engine Switch Valve Choke STEP 1: Turn water on. STEP 2: Grip spray gun handle STEP 3: Turn the engine key securely and pull trigger. switch to the on position till the engine starts. STEP 4: For hot water, turn thermostat to desired temperature and turn burner switch to the on position. -

Page 20: Detergents & General Operating Techniques

Operations Detergents & General Thermal Pump Protection Operating Techniques If you run the engine on your pressure washer for 3-5 minutes without pressing the trigger on the spray gun, WARNING: Some detergents may circulating water in the pump can reach high tempera- be harmful if inhaled or ingested, WARNING tures. -

Page 21: Shutting Down And Clean-Up

Operations Rinsing I t will take a few seconds for the detergent to clear. Apply safety latch to spray gun. Remove black soap nozzle from the quick coupler. Select and install the desired high pressure nozzle. NOTE: You can also stop detergent from flowing by simply removing detergent siphon tube from bottle. -

Page 22: Storage

Operations Storage 5. Do not allow high pressure hose to become kinked. 6. Store the machine and accessories in a room CAUTION: Always store your pressure washer in a which does not reach freezing temperatures. location where the temperature will not fall below 32°F (0°C). -

Page 23: Maintenance

Maintenance Preventative Maintenance Maintenance And Service 1. Use clean fuel — kerosene, No. 1 home heating Unloader Valves fuel or diesel fuel. Clean or replace fuel filter every 100 hours of operation. Avoid water contaminated Unloader valves trap pressure in the line when a shut- fuel as it will seize up the fuel pump. -

Page 24: Fuel

Maintenance Deliming Coils With A Pressure Washer ATTENTION : Une inspection périodique est recom- mandée pour s'assurer que l'électrovanne de Periodic flushing of coils is recommended. carburant fonctionne correctement. Cela peut être fait en faisant fonctionner la machine et en vérifiant 1. -

Page 25: Electrode Setting

Operations Electrode Setting temperatures will make for a thicker flow and less fine a fuel spray while hotter temperatures will make for a thinner flow a more fine spray with the same nozzle. Consider alternate nozzle configurations from the baseline factory-supplied nozzle for operating in such temperature extremes if performance is not meeting needs with air band and fuel pressure settings alone. -

Page 26: Hub Inspection Removal-Replacement And Adjustments

Maintenance Hub Inspection Removal- D. Bearing Adjustment Replacement And Adjustments Feel and Drag Method A. Removal of Hub Tighten slotted nut until hub drags slightly whe rotated. (Rotating the hub while tightening the nut seats the 1. Remove wheel bearing.) Loosen the slotted nut 1/6 turn (1 hex) to align 2. -

Page 27: Posi-Lube Lubrication Procedure

Maintenance Torque Wrench Method Make sure nut is loose. Tighten nut with torque wrench to an initial torque of 50 ft. lbs. Loosen nut from initial torque and fingertighten. Insert new cotter pin through nut and spindle. If equipped with Posi-Lube, reset tang. If necessary loosen, never tighten, nut to align slot with the hole in the spindle. -

Page 28: Troubleshooting

Maintenance Troubleshooting PROBLEM POSSIBLE CAUSE SOLUTION Faulty pressure gauge Install new gauge. Use larger garden hose; clean filter washer at water Insufficient water supply inlet. Match nozzle number to machine and/or replace Old, worn or incorrect spray nozzle with new nozzle. LOW OPERATING Check plumbing system for leaks. - Page 29 Maintenance PROBLEM POSSIBLE CAUSE SOLUTION Improper fuel or water in fuel Drain fuel tank and replace with proper fuel. Low fuel pressure Increase fuel pressure. Check fuel pump temperature. Replace Weak fuel pump pump if needed. LOW WATER TEMPERATURE Fuel filter partially clogged Replace as needed.

-

Page 30: Maintenance Schedule

Maintenance Pressure Washer Preventive Maintenance This pressure washer was produced with the best available materials and quality craftsmanship. However, you as the owner have certain responsibilities for the correct care of the equipment. Attention to regular preventative main- tenance procedures will assist in preserving the performance of your equipment. Contact your Pressure Washers dealer for maintenance. -

Page 31: Trailer Maintenance

Operations Trailer Maintenance Trailer Maintenance Schedule 12 Months 6 Months or Item Function Required 3 Months or 3,000 Miles or 12,000 6,000 Miles Miles Check for abnormal wear and Hub/Drum scoring Wheel Bearings & Inspect for corrosion or wear; Cups clean and repack Inspect for leakage;... - Page 32 #9.807-942.0 - Printed in U.S.A. or Mexico...

Need help?

Do you have a question about the Trailer HDS Series and is the answer not in the manual?

Questions and answers