Advertisement

Quick Links

Installation

Packing List

•

•

•

IS

T H

•

E

S ID

U P

215-1296 Rev. E EN 10-09-010

© 2012 Bradley

Page 1 of 5

10/1/2012

Read this entire installation manual to ensure proper installation.

When finished with the installation, file this manual with the owner or

maintenance department. Compliance and conformity to local codes and

ordinances is the responsibility of the installer.

Hot limit screw is set in the maximum temperature position. Failure to

adjust properly may result in serious scalding. This valve may not protect

from scalding if there is a failure of other temperature-controlling devices

elsewhere in the plumbing system. Excessive heat may cause damage to

internal parts.

Separate parts from packaging and make sure all parts are accounted for

before discarding packaging material. If any parts are missing, do not begin

installation until you obtain the missing parts.

Make sure that all water supply lines have been flushed and then

completely turned off before beginning installation. Debris in supply lines

can cause valves to malfunction.

Product warranties may be found under "Products" on our web site at

www.bradleycorp.com.

Installation

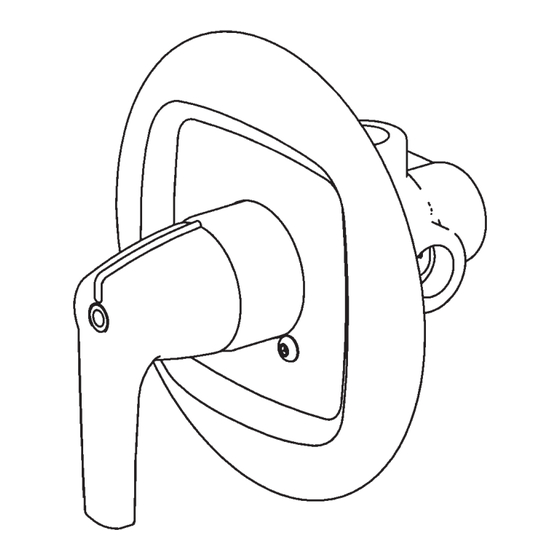

S59-2006

Bradley Thermostatic Mixing

Valve for Individual Showers

Table of Contents

Supplies Required. . . . . . . . . . . . . . . . . 2

Installation Instructions . . . . . . . . . . . . . . 2

Valve Adjustments. . . . . . . . . . . . . . . . . 3

Inlet Connections: 1/2" NPT

Outlet Connections: 1/2" NPT

Temperature Range: 90 – 110°F

Maximum Pressure: 125 PSIG

IMPORTANT!

P.O. Box 309, Menomonee Falls, WI USA 53052-0309

PHONE 800.BRADLEY (800.272.3539) FAX 262.251.5817

bradleycorp.com

Advertisement

Subscribe to Our Youtube Channel

Summary of Contents for Bradley S59-2006

- Page 1 Product warranties may be found under “Products” on our web site at www.bradleycorp.com. 215-1296 Rev. E EN 10-09-010 P.O. Box 309, Menomonee Falls, WI USA 53052-0309 © 2012 Bradley PHONE 800.BRADLEY (800.272.3539) FAX 262.251.5817 Page 1 of 5 10/1/2012 bradleycorp.com...

- Page 2 • Rough-in 1/2" NPT hot and cold water supply piping (supplied by installer) as shown below. • For finished wall, make a 4-1/2" hole in the wall where the shower handle is desired. Bradley • 215-1296 Rev. E; EN 10-09-010 10/1/2012...

- Page 3 1/4" The included foam rim seal may be applied to the back of the escutcheon 1/4" from the outer edge, with the seam at the bottom. 1/4" Bradley • 215-1296 Rev. E; EN 10-09-010 10/1/2012...

- Page 4 Do not remove the seat. The components may be brushed with a small wire brush to remove debris. If the optional stop/check valves need to be replaced, contact your Bradley representative and ask for Stop/Check Valve (part number S27-292). Temperature The stop and check sections of the valve do not Clean Stop and Check Valves as described above.

-

Page 5: Parts Breakdown

Qty. Description Stem Screw Seal O-Ring O-Ring Seal O-Ring O-Ring Spring Thermostat Kit S65-201 Seal Screw Piston Item Qty. Description O-Ring Screw Spring Thermostat O-Ring Plate Retainer O-Ring O-Ring Nut, Hex Retaining Ring Bradley • 215-1296 Rev. E; EN 10-09-010 10/1/2012...

Need help?

Do you have a question about the S59-2006 and is the answer not in the manual?

Questions and answers