Table of Contents

Summary of Contents for SMC Networks AFJ20-D Series

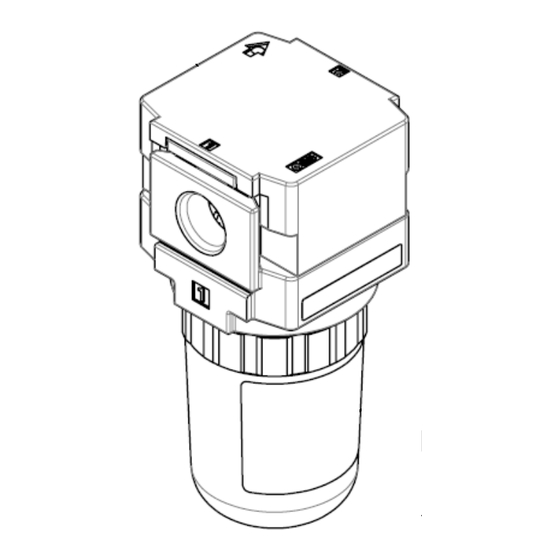

- Page 1 Doc. No. DOC1061738 PRODUCT NAME VACUUM FILTER MODEL / Series / Product Number AFJ20-(F,N)01~(F,N)02(B)-(5,40,80)-(S,T)(-6,R,Z)-D AFJ30-(F,N)02~(F,N)03(B)-(5,40,80)-(S,T)(-6,R,Z)-D AFJ40-(F,N)02~(F,N)04(B)-(5,40,80)-(S,T)(-6,R,Z)-D...

-

Page 2: Table Of Contents

Contents Page 1. Safety Instructions 2. Application 3. Standard Specifications 4. How to Order 5. Structural Drawing, Option and Replacement Parts 6. Bowl Assembly Specifications 7. Assembly of Optional Parts 8. Trouble Shooting 9. How to Replace the Components 13-16 9-1. -

Page 3: Safety Instructions

Safety Instructions These safety instructions are intended to prevent hazardous situations and/or equipment damage. These instructions indicate the level of potential hazard with the labels of “Caution,” “Warning” or “Danger.” They are all important notes for safety and must be followed in addition to International Standards (ISO/IEC) , and other safety regulations. - Page 4 Safety Instructions Caution We develop, design, and manufacture our products to be used for automatic control equipment, and provide them for peaceful use in manufacturing business. Use in non-manufacturing business is not covered. Products we manufacture and sell cannot be used for the purpose of transactions or certification specified in the Measurement Act.

- Page 5 Precautions for Design Warning (1) Do not use the product if no leakage is allowed due to the environment, or if the fluid is not air. (2) Polycarbonate resin is used for the external parts including the bowl. Organic solvents including thinner, acetone, alcohol and ethylene chloride;...

- Page 6 Caution (1) Do not use the product under pressure except momentary pressure (0.5 MPa or less) such as pressure release. Selection Warning (1) Grease used on the internal sliding parts and seals may flow to the outlet side. (2) Oil included in air cannot be separated. (3) If a more powerful moisture separator of moist is necessary, the vacuum drain separator AMJ series is recommended.

- Page 7 Air Source Warning (1) Use clean air. Do not use air containing chemicals, organic solvent, synthetic oil or corrosive gas as it may be cause of breakage of components or operation failure. Maintenance Warning (1) Release the pressure in the product to the atmosphere when replacing parts or removing piping. (2) Maintenance and checks should be done by following the procedure in this operation manual.

-

Page 8: Application

2. Application This product aims at eliminating drop of water and solid foreign matter in the air line for vaccum. 3. Standard Specifications Model AFJ20-D AFJ30-D AFJ40-D Port size Fluid -5 to 60 ℃ (with no freezing) Ambient and fluid temperature Proof pressure 0.5 MPa Operating pressure range... -

Page 9: How To Order

4. How to Order ❶ ❷ ❸ ❹ ❺ ❻ ❼ ❶ Symbol Description Body size ● ● ● ❷ ● ● ● Thread type ● ● ● ● ー ー ● ● ● ❸ Port size ー ● ● ー... -

Page 10: Structural Drawing, Option And Replacement Parts

5. Structural Drawing, Option and Replacement Parts Structural drawing / Option / Replacement parts AFJ30-D/AFJ40-D AFJ20-D Option Part No. Part name AFJ20-D AFJ30-D AFJ40-D Note 1) AF24P-070AS AF34P-070AS AF44P-070AS Bracket assembly Note 1) Assembly of 2 types of bracket and 2 set screws. Replacement Parts Part No. -

Page 11: Bowl Assembly Specifications

6. Bowl Assembly Specifications 6-1. Bowl assembly for AFJ20-D - Semi-standard symbol Appearance and part No. 6-2. Bowl assembly for AFJ30-D - Semi-standard symbol Appearance and part No. 6-3. Bowl assembly for AFJ40-D - Semi-standard symbol Semi-standard: - (Standard) Piping port (5) Part No. -

Page 12: Assembly Of Optional Parts

7. Assembly of Optional Parts Bracket Vacuum filter 1) Mounting of bracket A Insert bracket A from the front of the air filter so that the fingers of the bracket A hold the air filter at the groove and the bottom of the body. Groove Bottom of the body... -

Page 13: Trouble Shooting

8. Trouble Shooting Refer to the sections [9. How to Replace the Components] (P13-16) and [10.Disassembly Drawing] (P17). Trouble Page for Possible cause Countermeasure reference Category Failure As pressure drop Clog of the element. Replace the element. is large, fluid P13-16 does not flow. -

Page 14: How To Replace The Components

9. How to Replace the Components ! Warning Before replacement, make sure that no pressure remains in the product. After replacement, confirm that the product satisfies specific functions and no external leakage occurs before operating it. 9-1. Bowl Assembly Replacement Applicable Work Procedure Tool... - Page 15 Applicable Work Procedure Tool Criteria model category AFJ30-D Disassembly 1) Remove the bowl assembly from the product. AFJ40-D While the lock button is held down, rotate the bowl assembly by approx. 30 degrees so that the mating - - marks of the body and bowl assembly meet each other.

-

Page 16: Element Replacement

9-2. Element Replacement Applicable Work Procedure Tool Criteria model category AFJ20-D Disassembly 1) Remove the bowl assembly referring to the section [9-1. Bowl Assembly Replacement] (P13), then remove the snap fits (2 pcs.) of the deflector and pull - - upward to remove the element assembly. - Page 17 Applicable Work Procedure Tool Criteria model category AFJ30-D Disassembly 1) Remove the bowl assembly referring to the section [9-1. Bowl Assembly AFJ40-D Replacement] (P14). With the bowl assembly removed, rotate the deflector 90 - - degrees while holding the holding part. 2) Pull upward and remove the element assembly while holding the holding part.

-

Page 18: Disassembly Drawing

10. Disassembly Drawing AFJ20-D AFJ30-D, AFJ40-D Body Body O-ring O-ring Deflector Deflector Element Element Seal Seal For 40 μm and For 40 μm and 80 μm elements 80 μm elements Baffle Baffle Bowl seal Bowl seal Bowl assembly Bowl assembly -17-... -

Page 19: Dimensions

11. Dimensions AFJ20-D Bracket (Option) (Port size) AFJ30-D, AFJ40-D Bracket (Option) (Port size) Optional specifications Standard specifications Model Bracket mount ー AFJ20-D 79.3 1/8・1/4 AFJ30-D 104.3 1/4・3/8 136.1 AFJ40-D 1/4・3/8・1/2 -18-... - Page 20 Revision history 4-14-1, Sotokanda, Chiyoda-ku, Tokyo 101-0021 JAPAN Tel: + 81 3 5207 8249 Fax: +81 3 5298 5362 https://www.smcworld.com Note: Specifications are subject to change without prior notice and any obligation on the part of the manufacturer. © SMC Corporation All Rights Reserved...

Need help?

Do you have a question about the AFJ20-D Series and is the answer not in the manual?

Questions and answers