Summary of Contents for SMC Networks AFF75A-20

- Page 1 Doc. No.FGX-OM-P003-D PRODUCT NAME Main Line Filter MODEL / Series / Product Number AFF75A-20 / AFF75A-20X13 AFF125A-30 / AFF125A-30X13 AFF150A-40 / AFF150A-40X13 AFF220A-40 / AFF220A-40X13...

-

Page 2: Table Of Contents

Contents Safety Instructions 1. Operating Precaution 2. Construction 3. Specifications 1) How to Order 2) Specifications 4. Installation / Piping 1) Installation 2) Piping 5. Maintenance 1) Daily maintenance 2) Element or Gasket replacement 2-1. The replacement interval for the Element or the Gasket 2-2. -

Page 3: Safety Instructions

Safety Instructions These safety instructions are intended to prevent hazardous situations and/or equipment damage. These instructions indicate the level of potential hazard with the labels of “Caution,” “Warning” or “Danger.” They are all important notes for safety and must be followed in addition to International Standards (ISO/IEC) , and other safety regulations. - Page 4 Safety Instructions Caution We develop, design, and manufacture our products to be used for automatic control equipment, and provide them for peaceful use in manufacturing industries. Use in non-manufacturing industries is not covered. Products we manufacture and sell cannot be used for the purpose of transactions or certification specified in the Measurement Act.

-

Page 5: Operating Precaution

1.Operating Precaution Selection / Design Selection / Design 3. Operate within the specified operating pressure Warning range. 1. Confirm the specifications. Damage, failure, or malfunction may occur if the mist This product is designed only for use in compressed Separator is operated above the maximum operating air systems (including vacuum). - Page 6 Maintenance Maintenance 4. Gasket replacement Warning Replace the gasket immediately when the time for its Replacement has arrived. 1. Perform maintenance inspection according to the <The replacement interval for the Gasket> procedures indicated in this manual. The replacement interval for the gasket is when after If handled improperly, malfunction and damage of one year of operation or when degradation or air machinery or equipment may occur.

-

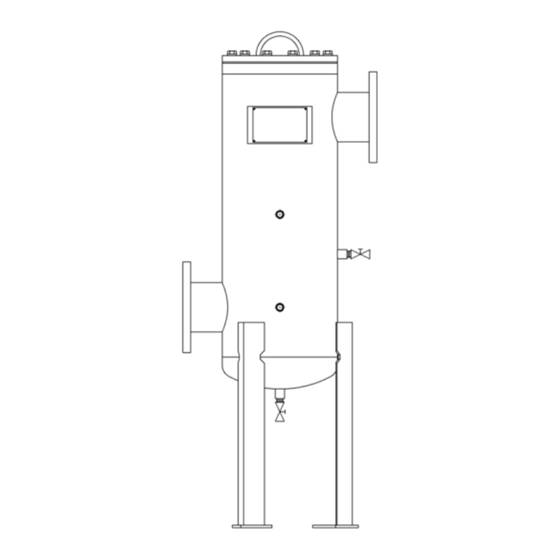

Page 7: Construction

2.Construction Name plate Pressure gauge port Drain port of downstream side of downstream Side (Port to discharge separated water, or oil content, etc, in element.) Drain port of upstream side Pressure gauge port (Port to discharge removed of Upstream Side water inside case) Fig. -

Page 8: Specifications P7

3. Specifications 1)How to Order AFF 75A - 20 D X13 Filtration rating of ELEMENT Standard size Symbol Filtration rating (Applicable compressor) 3 μm Symbol Compressor output 0.3 μm 75kW Accessory 125A 110 to 125kW 150A 150kW Symbol Description - 220A 180 to 220kW Auto drain (Metal bowl type) -

Page 9: Installation / Piping P8

4.Installation / Piping 1)Installation Install this product and fix the feet to the ground firmly using foundation bolt, etc. Warning The weight of this product is 50kg or more. Transfer and install this product with a crane, etc, to prevent a drop and a fall . Caution When installing and piping the products, allow access for maintenance. -

Page 10: Maintenance P9

5.Maintenance 1) Daily maintenance 1. Open the drain valve and discharge the drain at least once a day. Comfirm that the auto drain operates in the case of type with auto drain. 2. Confirm that air leakage do not occur. Caution Failure to discharge the drain will allow the accumulated drain to flow over to the outlet side. - Page 11 【Mounting of the element】 Element 1. Insert the new element vertically from the top of housing and fit the internal bore of element to the outside of hollow frame. Caution Confirm that the internal bore of element are fitted to the outside of hollow frame. If handled improperly, it could lower its performance or may damage an element.

- Page 12 Revision history 1st edition : April 2012 Revision : July 2012 Revision : December 2014 Revision : January 2020 Revision : March 2024 Tel: + 81 3 5207 8249 Fax: +81 3 5298 5362 https://www.smcworld.com Note: Specifications are subject to change without prior notice and any obligation on the part of the manufacturer. ©...

Need help?

Do you have a question about the AFF75A-20 and is the answer not in the manual?

Questions and answers