Table of Contents

Advertisement

Quick Links

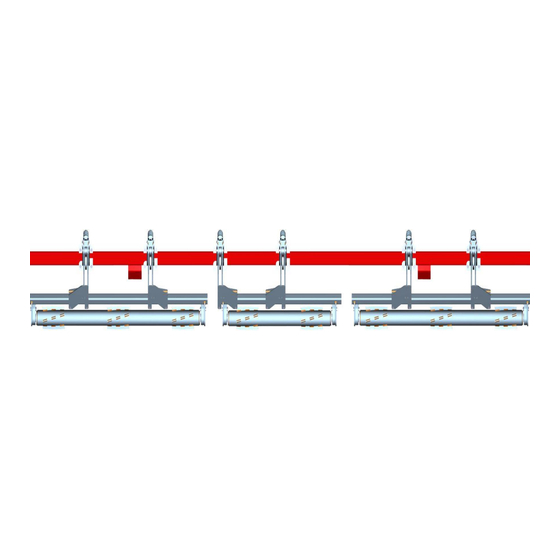

5000 SERIES STALK DEVASTATOR

5000-005B – 5000-021C, 5000-031C, 5000-037

YETTER MANUFACTURING CO.

FOUNDED 1930

Colchester, IL 62326-0358

Toll free: 800/447-5777

309/776-3222 (Fax)

Website:

www.yetterco.com

E-mail:

info@yetterco.com

CORN STALK ROLLER

*PATENTED*

OPERATOR'S MANUAL

PART IDENTIFICATION

2565-771_REV_I – 01/2024

Advertisement

Table of Contents

Summary of Contents for Yetter 5000-005B

- Page 1 5000 SERIES STALK DEVASTATOR CORN STALK ROLLER *PATENTED* OPERATOR’S MANUAL PART IDENTIFICATION 2565-771_REV_I – 01/2024 5000-005B – 5000-021C, 5000-031C, 5000-037 YETTER MANUFACTURING CO. FOUNDED 1930 Colchester, IL 62326-0358 Toll free: 800/447-5777 309/776-3222 (Fax) Website: www.yetterco.com E-mail: info@yetterco.com...

-

Page 2: Introduction / Warranty

WARRANTY Yetter Manufacturing warrants all products manufactured and sold by it against defects in material. This warranty being expressly limited to replacement at the factory of such parts or products as shall appear to be defective after inspection. -

Page 3: Safety Information

BE ALERT! YOUR SAFETY IS INVOLVED. WATCH FOR THIS SYMBOL. IT POINTS OUT IMPORTANT SAFETY PRECAUTIONS. IT MEANS “ATTENTION---BECOME ALERT!” It is your responsibility as an owner, operator, or supervisor to know and instruct everyone using this machine at the time of initial assignment and at least annually thereafter, of the proper operation, precautions, and work hazards which exist in the operation of the machine in accordance with OSHA regulations. - Page 4 PLEASE READ, VERY IMPORTANT SECURE CORN HEADER AGAINST UNWANTED LOWERING BY APPLYING THE LOCKING MECHANISM ON THE HYDRAULIC CYLINDERS! 1. Attach head to combine, lock head to combine 2. Raise the head off the ground and engage safety stop on the feeder house cylinder. 3.

-

Page 5: Table Of Contents

SAFETY INFORMATION…………………………………………..3 – 4 TABLE OF CONTENTS…………………………………..……...….....5 OPERATION………………………………………………………………..6 TORQUE / TOOLS REQUIRED……………………..…………..7 INSTALLATION / PARTS IDENTIFICATON 5000-005B (CNH 3206/3406/NH98D).………….. 8 - 9 5000-006C (CNH 3208/3408/NH98D)..…..10 - 11 5000-007D (DRAGO 630)………..…..…………..……12 - 13 5000-009C (CNH 2206/NH96C/996)..…..14 – 15 5000-010C (CNH 2208/2408/NH96C/996)..16 – 17 5000-013B (CNH 1063)……………………..…..18 –... -

Page 6: Operation

USE THE 5000-455 TO CHECK CORN HEAD ANGLE: Put the combine on a level surface. Lower the Corn head to your normal working head height. Place the magnetic protractor on the stripper plate to get the angle. Adjust the feeder house as needed, fore or aft, to achieve 23 –... -

Page 7: Torque / Tools Required

All hardware used on the 5000 Devastator is Grade 5 unless otherwise noted. Grade 5 cap screws are marked with three radial lines on the head. If hardware must be replaced, be sure to replace it with hardware of equal size, strength and thread type. Refer to the torque values chart when tightening hardware. -

Page 8: 5000-005B (Cnh 3206/3406/Nh98D)

5000-005B ASSEMBLY INSTRUCTIONS / PART ID CASEIH 3206, 3406 NH98D 6 ROW Step 1: Install 1) 5000-215 single mount to the frame between rows 1 & 2 and 5 & 6. Install 1) 5000-216 double mount between rows 3 & 4. Use 4) 5/8” X 6” bolts, 2) mount straps, & 4) 5/8” lock hex nuts to fasten the mounts to the corn head frame. - Page 9 5000-005B ASSEMBLY INSTRUCTIONS / PART ID CASEIH 3206, 3406 NH98D 6 ROW ITEM PART # DESCRIPTION 2502-325 5/8–11 X 3 CAP SCREW GRADE 5 2502-352 5/8-11 X 6 CAP SCREW GRADE 8 2502-353 ½-13 X 2.5 CAP SCREW GRADE 8 2502-365 ½-13 X 3.75 CAP SCREW GRADE 5...

-

Page 10: 5000-006C (Cnh 3208/3408/Nh98D)

5000-006C ASSEMBLY INSTRUCTIONS / PART ID CASEIH 3208, 3408 NH98D 8 ROW Install 1) 5000-215 single mount to the frame between rows 1 & 2, 2 & 3, 4 & 5, 5 & 6, 6 & 7, and 7 & 8. Use 4) 5/8” X 6” Step 1: bolts, 2) mount straps, &... - Page 11 5000-006C ASSEMBLY INSTRUCTIONS / PART ID CASEIH 3208, 3408 NH98D 8 ROW ITEM PART # DESCRIPTION 2502-325 5/8–11 X 3 CAP SCREW GRADE 5 2502-352 5/8-11 X 6 CAP SCREW GRADE 8 2502-353 ½-13 X 2.5 CAP SCREW GRADE 8 2502-365 ½-13 X 3.75 CAP SCREW GRADE 5 2505-345...

-

Page 12: 5000-007D (Drago 630)

5000-007D ASSEMBLY INSTRUCTIONS / PART ID DRAGO 630 Step 1: Attach the 5000-218 Drago mount brackets to the frame using 2) 5/8” X 3” bolts & 2) 5000-340 clamp blocks for the bottom set of holes & 2) ½” X 2 bolts, 2) 5000-339 mount plate washers, & 2) ½” hex flange lock nuts for the top set of holes. Mounting brackets should be located between rows 1 &... - Page 13 5000-007D ASSEMBLY INSTRUCTIONS / PART ID DRAGO 630 ITEM PART # DESCRIPTION 2502-325 5/8–11 X 3 CAP SCREW GRADE 5 2502-351 ½-13 X 2 CAP SCREW GRADE 5 2502-353 ½-13 X 2.5 CAP SCREW GRADE 8 2502-365 ½-13 X 3.75 CAP SCREW GRADE 5 2510-121 5/8 SHOULDER BOLT THREAD ½-13 2520-361...

-

Page 14: 5000-009C (Cnh 2206/Nh96C/996)

5000-009C ASSEMBLY INSTRUCTIONS / PART ID CASEIH 2206, 2406 NH98C/996 6 ROW Step 1: Install each 5000-224 single mount to the corn head frame using 4) 5/8” X 6” bolts, 2) 5000-341 mount straps, & 4) 5/8” lock nuts per mount. Mounting bracket locations will be between rows 1 & 2, 3 & 4, 4 & 5, & 5 & 6. Install the 5000-323 lock up pin in the storage location &... - Page 15 5000-009C ASSEMBLY INSTRUCTIONS / PART ID CASEIH 2206, 2406 NH98C/996 6 ROW ITEM PART # DESCRIPTION 2502-294 ½–13 X 1.5 CAP SCREW GRADE 5 2502-314 ½–13 X 2.25 CAP SCREW GRADE 5 2502-325 5/8–11 X 3 CAP SCREW GRADE 5 2502-352 5/8-11 X 6 CAP SCREW GRADE 8 2502-353...

-

Page 16: 5000-010C (Cnh 2208/2408/Nh96C/996)

5000-010C ASSEMBLY INSTRUCTIONS / PART ID CASEIH 2208, 2408 NH96C, 98C, 996 8 ROW Step 1: Install each 5000-224 single mount to the corn head frame using 4) 5/8” X 6” bolts, 2) 5000-341 mount straps, & 4) 5/8” lock nuts per mount. Mounting bracket locations will be between rows 1 & 2, 2 & 3, 4 & 5, 5 & 6, 6 & 7, & 7 & 8. Step 2: Install 1) 5000-223 support strap on each mount. - Page 17 5000-010C ASSEMBLY INSTRUCTIONS / PART ID CASEIH 2208, 2408 NH96C, 98C, 996 8 ROW ITEM PART # DESCRIPTION 2502-294 ½–13 X 1.5 CAP SCREW GRADE 5 2502-314 ½–13 X 2.25 CAP SCREW GRADE 5 2502-325 5/8–11 X 3 CAP SCREW GRADE 5 2502-352 5/8-11 X 6 CAP SCREW GRADE 8 2502-353...

-

Page 18: 5000-013B (Cnh 1063)

5000-013B ASSEMBLY INSTRUCTIONS / PART ID CASEIH 1063 6 ROW Step 1: Install each 5000-202 single mount & 5000-201 double mount to the corn head frame, using 4) 5/8” X 6” bolts, 2) 5000- 319 mount straps, & 4) 5/8” lock nuts per mount. Single mount locations will be between rows 1 & 2 and 5 & 6. The double mount will be located between rows 3 &... - Page 19 5000-013B ASSEMBLY INSTRUCTIONS / PART ID CASEIH 1063 6 ROW ITEM PART # DESCRIPTION 2502-325 5/8–11 X 3 CAP SCREW GRADE 5 2502-352 5/8-11 X 6 CAP SCREW GRADE 8 2502-353 ½-13 X 2.5 CAP SCREW GRADE 8 2502-365 ½-13 X 3.75 CAP SCREW GRADE 5 2505-345 ½-13 X 2 CARRIAGE BOLT GRADE 5 2510-121...

-

Page 20: 5000-014C (Cnh 1083)

5000-014C ASSEMBLY INSTRUCTIONS / PART ID CASEIH 1083 8 ROW Step 1: Install each 5000-202 single mount & 5000-201 double mount to the corn head frame, using 4) 5/8” X 6” bolts, 2) 5000- 319 mount straps, & 4) 5/8” lock nuts per mount. Single mount locations will be between rows 1 & 2, 2 & 3, 6 & 7, and 7 & 8. The double mount will be located between rows 4 &... - Page 21 5000-014C ASSEMBLY INSTRUCTIONS / PART ID CASEIH 1083 8 ROW ITEM PART # DESCRIPTION 2502-325 5/8–11 X 3 CAP SCREW GRADE 5 2502-352 5/8-11 X 6 CAP SCREW GRADE 8 2502-353 ½-13 X 2.5 CAP SCREW GRADE 8 2502-365 ½-13 X 3.75 CAP SCREW GRADE 5 2505-345 ½-13 X 2 CARRIAGE BOLT GRADE 5 2510-121...

-

Page 22: 5000-015C (Geringhoff 8 Row)

PLATE ADJUSTMENT WILL NEED MOVED. APPROXIMATELY 1FT OF HYD. HOSE WILL NEED ADDED TO REACH THE CYLINDER’S NEW LOCATION. CALL YETTER FOR MORE INFO, 1-800-447-5777, & ASK FOR SERVICE DEPARTMENT! Step 2: Install 1) 5000-318 pivot bushing in each single mount. Attach 1) 5000-256 LH over bearing arm to the single mount between rows 2 &... - Page 23 5000-015C ASSEMBLY INSTRUCTIONS / PART ID GERINGHOFF 8 ROW ITEM PART # DESCRIPTION 2502-325 5/8–11 X 3 CAP SCREW GRADE 5 2502-353 ½-13 X 2.5 CAP SCREW GRADE 8 2502-365 ½-13 X 3.75 CAP SCREW GRADE 5 2502-393 5/8-11 X 2.5 CAP SCREW GRADE 5 2502-396 5/8-11 X 7 CAP SCREW GRADE 8 2510-121...

-

Page 24: 5000-016C (Geringhoff 12 Row)

PLATE ADJUSTMENT WILL NEED MOVED. APPROXIMATELY 1FT OF HYD. HOSE WILL NEED ADDED TO REACH THE CYLINDER’S NEW LOCATION. CALL YETTER FOR MORE INFO, 1-800-447-5777, & ASK FOR SERVICE DEPARTMENT! Step 2: Install 1) 5000-318 pivot bushing in each single mount. Attach 1) 5000-256 LH over bearing arm to the single mount between rows 2 &... - Page 25 5000-016C ASSEMBLY INSTRUCTIONS / PART ID GERINGHOFF 12 ROW ITEM PART # DESCRIPTION 2502-325 5/8–11 X 3 CAP SCREW GRADE 5 2502-353 ½-13 X 2.5 CAP SCREW GRADE 8 2502-365 ½-13 X 3.75 CAP SCREW GRADE 5 2502-393 5/8-11 X 2.5 CAP SCREW GRADE 5 2502-396 5/8-11 X 7 CAP SCREW GRADE 8 2510-121...

-

Page 26: 5000-017D (Drago 830)

5000-017D ASSEMBLY INSTRUCTIONS / PART ID DRAGO 830 ROW Step 1: Attach each 5000-218 Drago mount brackets to the frame using 2) 5/8” X 3” bolts & 2) 5000-340 clamp blocks for the bottom set of holes & 2) ½” X 2 bolts, 2) 5000-339 mount plate washers, & 2) ½” hex flange lock nuts for the top set of holes. Mounting brackets should be located between rows 1 &... - Page 27 5000-017C ASSEMBLY INSTRUCTIONS / PART ID DRAGO 830 ROW ITEM PART # DESCRIPTION 2502-325 5/8–11 X 3 CAP SCREW GRADE 5 2502-351 ½-13 X 2 CAP SCREW GRADE 5 2502-353 ½-13 X 2.5 CAP SCREW GRADE 8 2502-365 ½-13 X 3.75 CAP SCREW GRADE 5 2510-121 5/8 SHOULDER BOLT THREAD ½-13 2520-361...

-

Page 28: 5000-018D (Drago 1230)

5000-018D ASSEMBLY INSTRUCTIONS / PART ID DRAGO 1230 ROW Step 1: Attach each 5000-218 Drago mount brackets to the frame using 2) 5/8” X 3” bolts & 2) 5000-340 clamp blocks for the bottom set of holes & 2) ½” X 2” bolts, 2) 5000-339 mount plate washers, & 2) ½” hex flange lock nuts for the top set of holes. Mounting brackets should be located between rows 1 &... - Page 29 5000-018D ASSEMBLY INSTRUCTIONS / PART ID DRAGO 1230 ROW ITEM PART # DESCRIPTION 2502-325 5/8–11 X 3 CAP SCREW GRADE 5 2502-351 ½-13 X 2 CAP SCREW GRADE 5 2502-353 ½-13 X 2.5 CAP SCREW GRADE 8 2502-365 ½-13 X 3.75 CAP SCREW GRADE 5 2510-121 5/8 SHOULDER BOLT THREAD ½-13 2520-361...

-

Page 30: 5000-019C (Cnh 2412/3412Nh98C/996)

5000-019C ASSEMBLY INSTRUCTIONS / PART ID CASEIH 2412, 3412 12 ROW Step 1: Install each 5000-224 single mount to the corn head frame using 4) 5/8” X 6” bolts, 2) 5000-341 mount straps, & 4) 5/8” lock nuts per mount. Substitute 1) 2570-131 5/8” – 11 X 4” X 8” U-Bolt for 1 mount strap & 2 5/8” X 6” bolts on each single mount between rows 1 &... - Page 31 5000-019C ASSEMBLY INSTRUCTIONS / PART ID CASEIH 2412, 3412 12 ROW ITEM PART # DESCRIPTION 2502-294 ½–13 X 1.5 CAP SCREW GRADE 5 2502-314 ½–13 X 2.25 CAP SCREW GRADE 5 2502-325 5/8–11 X 3 CAP SCREW GRADE 5 2502-352 5/8-11 X 6 CAP SCREW GRADE 8 2502-353 ½-13 X 2.5 CAP SCREW GRADE 8...

-

Page 32: 5000-021C (Gerninghoff 6-Row)

PLATE ADJUSTMENT WILL NEED MOVED. APPROXIMATELY 1FT OF HYD. HOSE WILL NEED ADDED TO REACH THE CYLINDER’S NEW LOCATION. CALL YETTER FOR MORE INFO, 1-800-447-5777, & ASK FOR SERVICE DEPARTMENT! Step 2: Install 1) 5000-318 pivot bushing in each single mount. Attach 1) 5000-256 LH over bearing arm to the single mount between rows 2 &... - Page 33 5000-021C ASSEMBLY INSTRUCTIONS / PART ID GERINGHOFF 6 ROW ITEM PART # DESCRIPTION 2502-325 5/8–11 X 3 CAP SCREW GRADE 5 2502-353 ½-13 X 2.5 CAP SCREW GRADE 8 2502-365 ½-13 X 3.75 CAP SCREW GRADE 5 2502-393 5/8-11 X 2.5 CAP SCREW GRADE 5 2502-396 5/8-11 X 7 CAP SCREW GRADE 8 2510-121...

-

Page 34: 5000-031C (Fantini 8 Row)

5000-031C ASSEMBLY INSTRUCTIONS / PART ID FANTINI 8 ROW Step 1: Attach each 5000-258 mount bracket to the frame using 4) 5/8” X 7” bolts, 2) 5000-386 mount straps, 4) 5/8” flat washers (underneath mount plate), & 4) 5/8” lock hex nuts. Mounting brackets should be located between rows 1 & 2, 2 & 3, 3 & 4, 5 & 6, 6 &... - Page 35 5000-031C ASSEMBLY INSTRUCTIONS / PART ID FANTINI 8 ROW ITEM PART # DESCRIPTION 2502-325 5/8–11 X 3 CAP SCREW GRADE 5 2502-353 ½-13 X 2.5 CAP SCREW GRADE 8 2502-365 ½-13 X 3.75 CAP SCREW GRADE 5 2502-396 5/8-11 X 7 CAP SCREW GRADE 8 2510-121 5/8 SHOULDER BOLT THREAD ½-13 2520-362...

-

Page 36: 5000-037 (8 Row Folding Geringhoff)

PLATE ADJUSTMENT WILL NEED MOVED. APPROXIMATELY 1FT OF HYD. HOSE WILL NEED ADDED TO REACH THE CYLINDER’S NEW LOCATION. CALL YETTER FOR MORE INFO, 1-800-447-5777, & ASK FOR SERVICE DEPARTMENT! Step 2: Install 2) 5000-318 pivot bushing in each double mount. Attach 1) 5000-256 LH over bearing arm to the left side of each double mount. - Page 37 5000-037 ASSEMBLY INSTRUCTIONS / PART ID GERINGHOFF 8 ROW FOLDING ITEM PART # DESCRIPTION 2502-322 5/8-11 X 2 CAP SCREW GRADE 8 2502-325 5/8–11 X 3 CAP SCREW GRADE 5 2502-353 ½-13 X 2.5 CAP SCREW GRADE 8 2502-365 ½-13 X 3.75 CAP SCREW GRADE 5 2502-396 5/8-11 X 7 CAP SCREW GRADE 8 2510-121...

-

Page 38: Geringhoff Hydr. Cylinder Relocation

GERINGHOFF HYDRAULIC CYLINDER RELOCATION ON SOME GERINGHOFF MODELS, THE HYDRAULIC CYLINDER(S) AND SPRING TENSION MECHANISM FOR THE DECK PLATE ADJUSTMENT WILL NEED RELOCATED TO ALLOW CLEARANCE FOR THE MOUNT BRACKET IN THAT LOCATION. FOLLOW THE STEPS BELOW. OLD LOCATION (INTERFERENCE) HARDWARE TO REMOVE REPOSITIONING THE CLAMPS NEW LOCATION REASSEMBLED... -

Page 39: Troubleshooting

TROUBLESHOOTING ISSUE CAUSE CORRECTIVE ACTION 1. Adjust head angle to 23 – 25 degrees (see page 37) Residue Plugging 1. Incorrect Head Angle 2. Roller Mount Tube 2. Make sure the Bearing Support Tab is on the backside incorrectly installed of the Roller Arm Mount Tube 3. - Page 40 2565-771_REV_I 01/2024...

Need help?

Do you have a question about the 5000-005B and is the answer not in the manual?

Questions and answers