Summary of Contents for Daikin SV1A25AJV1B

- Page 1 Installer and user reference guide VRV 5 safety valve unit SV1A25AJV1B SV4A14AJV1B SV6A14AJV1B SV8A14AJV1B...

-

Page 2: Table Of Contents

Natural ventilation............................50 13.4.4 Ventilated enclosure ............................52 13.4.5 Overview: flowchart ............................59 13.5 Combinations of ventilated enclosure configurations....................60 13.6 Combinations of safety measures ..........................61 Installer and user reference guide SV1A25AJV1B+SV4~8A14AJV1B VRV 5 safety valve unit 4P749917-1 – 2023.09... - Page 3 Before the maintenance and service of the SV unit ...................... 117 20.2 SV unit maintenance and service label........................... 117 21 Troubleshooting 21.1 Solving problems based on error codes ......................... 118 21.1.1 Prerequisites: Troubleshooting........................118 SV1A25AJV1B+SV4~8A14AJV1B Installer and user reference guide VRV 5 safety valve unit 4P749917-1 – 2023.09...

- Page 4 Table of contents 21.1.2 Error codes: Overview ............................ 118 22 Disposal 23 Technical data 23.1 Wiring diagram................................120 24 Glossary Installer and user reference guide SV1A25AJV1B+SV4~8A14AJV1B VRV 5 safety valve unit 4P749917-1 – 2023.09...

-

Page 5: About This Document

A subset of the latest technical data is available on the regional Daikin website (publicly accessible). ▪ The full set of the latest technical data is available on the Daikin Business Portal (authentication required). 1.1 Meaning of warnings and symbols DANGER Indicates a situation that results in death or serious injury. - Page 6 Example: " 1–3 Figure title" means "Figure 3 in chapter 1". Indicates a table title or a reference to it. Example: " 1–3 Table title" means "Table 3 in chapter 1". SV1A25AJV1B+SV4~8A14AJV1B Installer and user reference guide VRV 5 safety valve unit...

-

Page 7: General Safety Precautions

WARNING Improper installation or attachment of equipment or accessories could result in electrical shock, short-circuit, leaks, fire or other damage to the equipment. ONLY use accessories, optional equipment and spare parts made or approved by Daikin unless otherwise specified. WARNING Make sure installation, testing and applied materials comply with applicable legislation (on top of the instructions described in the Daikin documentation). -

Page 8: Installation Site

Use a separate recovery system so that the unit's compressor does NOT have to operate. WARNING During tests, NEVER pressurise the product with a pressure higher than the maximum allowable pressure (as indicated on the nameplate of the unit). SV1A25AJV1B+SV4~8A14AJV1B Installer and user reference guide VRV 5 safety valve unit 4P749917-1 – 2023.09... - Page 9 Charge the liquid refrigerant as follows: Then A siphon tube is present Charge with the cylinder upright. (i.e., the cylinder is marked with "Liquid filling siphon attached") SV1A25AJV1B+SV4~8A14AJV1B Installer and user reference guide VRV 5 safety valve unit 4P749917-1 – 2023.09...

-

Page 10: Electrical

If NOT factory installed, a main switch or other means for disconnection, having a contact separation in all poles providing full disconnection under overvoltage category III condition, MUST be installed in the fixed wiring. SV1A25AJV1B+SV4~8A14AJV1B Installer and user reference guide VRV 5 safety valve unit... - Page 11 Use an appropriate screwdriver for tightening the terminal screws. A screwdriver with a small head will damage the head and make proper tightening impossible. ▪ Over-tightening the terminal screws may break them. SV1A25AJV1B+SV4~8A14AJV1B Installer and user reference guide VRV 5 safety valve unit 4P749917-1 – 2023.09...

- Page 12 ON and OFF while the product is operating, attach a reversed phase protection circuit locally. Running the product in reversed phase can break the compressor and other parts. SV1A25AJV1B+SV4~8A14AJV1B Installer and user reference guide VRV 5 safety valve unit...

-

Page 13: Specific Installer Safety Instructions

Appliance NOT accessible to the general public. Install it in a secured area, protected from easy access. This unit is suitable for installation in a commercial, light industrial, household and residential environment. SV1A25AJV1B+SV4~8A14AJV1B Installer and user reference guide VRV 5 safety valve unit 4P749917-1 – 2023.09... - Page 14 SV1A25AJV1B+SV4~8A14AJV1B Installer and user reference guide VRV 5 safety valve unit...

- Page 15 ▪ Do NOT use taped wires, extension cords, or connections from a star system. They can cause overheating, electrical shocks or fire. SV1A25AJV1B+SV4~8A14AJV1B Installer and user reference guide VRV 5 safety valve unit 4P749917-1 – 2023.09...

- Page 16 "21 Troubleshooting" [ 118]) DANGER: RISK OF ELECTROCUTION DANGER: RISK OF ELECTROCUTION Do NOT leave the unit unattended when the service cover is removed. DANGER: RISK OF BURNING/SCALDING SV1A25AJV1B+SV4~8A14AJV1B Installer and user reference guide VRV 5 safety valve unit 4P749917-1 – 2023.09...

-

Page 17: Instructions For Equipment Using R32 Refrigerant

44]. WARNING Make sure installation, servicing, maintenance and repair comply with instructions from Daikin and with applicable legislation (for example national gas regulation) and are executed ONLY by authorised persons. WARNING Refrigerant sensors of the refrigerant detection system shall only be replaced with refrigerant sensors specified by the appliance manufacturer. - Page 18 Joints made in the installation between parts of the refrigerant system shall be accessible for maintenance purposes. "13.3 To determine the required safety measures" [ 45] to check if your system meets the R32 safety requirements. SV1A25AJV1B+SV4~8A14AJV1B Installer and user reference guide VRV 5 safety valve unit 4P749917-1 – 2023.09...

-

Page 19: For The User

For the user SV1A25AJV1B+SV4~8A14AJV1B Installer and user reference guide VRV 5 safety valve unit 4P749917-1 – 2023.09... -

Page 20: User Safety Instructions

Do NOT place any objects containing water on the unit. CAUTION ▪ Do NOT place any objects or equipment on top of the unit. ▪ Do NOT sit, climb or stand on the unit. SV1A25AJV1B+SV4~8A14AJV1B Installer and user reference guide VRV 5 safety valve unit 4P749917-1 – 2023.09... -

Page 21: Instructions For Safe Operation

Always have qualified service personnel confirm that the point of leakage has been repaired or corrected before resuming operation. SV1A25AJV1B+SV4~8A14AJV1B Installer and user reference guide VRV 5 safety valve unit 4P749917-1 – 2023.09... - Page 22 Be careful with ladders when working in high places. CAUTION After a long use, check the unit stand and fitting for damage. If damaged, the unit may fall and result in injury. SV1A25AJV1B+SV4~8A14AJV1B Installer and user reference guide VRV 5 safety valve unit 4P749917-1 – 2023.09...

- Page 23 WARNING The R32 refrigerant leakage sensor must be replaced after every detection or at the end of its lifetime. ONLY authorised persons may replace the sensor. SV1A25AJV1B+SV4~8A14AJV1B Installer and user reference guide VRV 5 safety valve unit 4P749917-1 – 2023.09...

- Page 24 WARNING Make sure installation, servicing, maintenance, repair and applied materials follow the instructions from Daikin (including all documents listed in “Documentation set”) and, in addition, comply with applicable legislation and are performed by qualified persons only. In Europe and areas where IEC standards apply, EN/IEC 60335-2-40 is the applicable standard.

-

Page 25: About The System

Remote controller in supervisor mode (mandatory in some situations) h Centralised controller (optional) i Option PCB (optional) j Cool/heat changeover remote control switch (optional) Refrigerant piping SV1A25AJV1B+SV4~8A14AJV1B Installer and user reference guide VRV 5 safety valve unit 4P749917-1 – 2023.09... - Page 26 About the system Interconnection and user interface wiring Direct connection of indoor units to the outdoor unit SV1A25AJV1B+SV4~8A14AJV1B Installer and user reference guide VRV 5 safety valve unit 4P749917-1 – 2023.09...

-

Page 27: Before Operation

If your installation has a customised control system, ask your dealer for the operation that corresponds to your system. SV1A25AJV1B+SV4~8A14AJV1B Installer and user reference guide VRV 5 safety valve unit... -

Page 28: Maintenance And Service

Formula to calculate the quantity in CO equivalent tonnes: GWP value of the refrigerant × total refrigerant charge [in kg]/1000 Contact your installer for more information. SV1A25AJV1B+SV4~8A14AJV1B Installer and user reference guide VRV 5 safety valve unit 4P749917-1 – 2023.09... -

Page 29: About The Refrigerant Leakage Sensor

3 Contact your dealer immediately. For more information, see the installation manual of the outdoor unit. INFORMATION To stop the alarm of the user interface, see the reference guide of the user interface. SV1A25AJV1B+SV4~8A14AJV1B Installer and user reference guide VRV 5 safety valve unit 4P749917-1 – 2023.09... -

Page 30: Troubleshooting

(possibly listed on the warranty card). 8.1 Symptoms that are NOT system malfunctions The following symptoms are NOT system malfunctions: SV1A25AJV1B+SV4~8A14AJV1B Installer and user reference guide VRV 5 safety valve unit 4P749917-1 – 2023.09... -

Page 31: Symptom: Noise

A hissing sound originating from the 4-way valve in the outdoor unit which is heard at the start or immediately after stopping operation or defrost operation, or when switching from cooling to heating operation and vice versa. SV1A25AJV1B+SV4~8A14AJV1B Installer and user reference guide VRV 5 safety valve unit... -

Page 32: Relocation

Relocation 9 Relocation Contact your dealer to remove and reinstall the entire unit. Moving units requires technical expertise. SV1A25AJV1B+SV4~8A14AJV1B Installer and user reference guide VRV 5 safety valve unit 4P749917-1 – 2023.09... -

Page 33: Disposal

Do NOT try to dismantle the system yourself: dismantling of the system, treatment of the refrigerant, oil and other parts MUST comply with applicable legislation. Units MUST be treated at a specialised treatment facility for reuse, recycling and recovery. SV1A25AJV1B+SV4~8A14AJV1B Installer and user reference guide VRV 5 safety valve unit... -

Page 34: For The Installer

For the installer SV1A25AJV1B+SV4~8A14AJV1B Installer and user reference guide VRV 5 safety valve unit 4P749917-1 – 2023.09... -

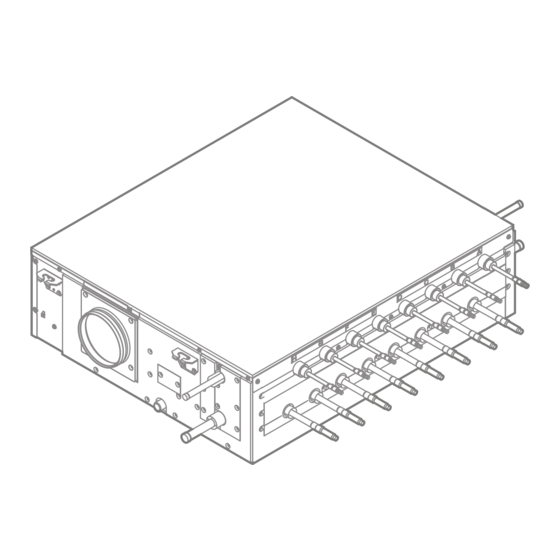

Page 35: About The Box

When you carry or manipulate the unit, never tilt it more than 70 degrees in any direction. 70°max. ▪ Optionally: As long as the SV6~8A is attached to a pallet, you can use a forklift. Move slowly when transporting the unit. SV1A25AJV1B+SV4~8A14AJV1B Installer and user reference guide VRV 5 safety valve unit 4P749917-1 – 2023.09... -

Page 36: To Unpack The Unit

After unpacking, lift the unit via the hanger brackets. Do not exert any pressure on other parts, especially not on the refrigerant piping and drain piping. 11.2 To unpack the unit For SV1~4A 1 Cut and remove the straps. SV1A25AJV1B+SV4~8A14AJV1B Installer and user reference guide VRV 5 safety valve unit 4P749917-1 – 2023.09... - Page 37 About the box 2 Remove the box parts as indicated in the picture. For SV6~8A 1 Cut and remove the inner straps. SV1A25AJV1B+SV4~8A14AJV1B Installer and user reference guide VRV 5 safety valve unit 4P749917-1 – 2023.09...

- Page 38 About the box 2 Remove the pallet. 3 Cut and remove the outer straps. 4 Remove the box parts as indicated in the picture. SV1A25AJV1B+SV4~8A14AJV1B Installer and user reference guide VRV 5 safety valve unit 4P749917-1 – 2023.09...

-

Page 39: To Remove The Accessories

Sealing material (large) g Sealing material (small) h Sealing material (thin sheet) i Insulation tube for stopper pipe Ø9.5 mm (3× for SV4A, 1× for SV1A and SV6~8A) SV1A25AJV1B+SV4~8A14AJV1B Installer and user reference guide VRV 5 safety valve unit 4P749917-1 – 2023.09... - Page 40 Gas branch expander pipe (Ø15.9 → 19.1 mm) (1× for SV1A for connection to FXMA200/250) t Gas header reducer pipe (Ø22.2 → 15.9 mm) u Gas header reducer pipe (Ø22.2 → 19.1 mm) v Gas header expander pipe (Ø22.2 → 28.6 mm) SV1A25AJV1B+SV4~8A14AJV1B Installer and user reference guide VRV 5 safety valve unit 4P749917-1 – 2023.09...

-

Page 41: About The Unit And Options

For more information, see "13 Special requirements for R32 units" [ 44]. INFORMATION The following figure is an example and may NOT completely match your system layout SV1A25AJV1B+SV4~8A14AJV1B Installer and user reference guide VRV 5 safety valve unit 4P749917-1 – 2023.09... -

Page 42: Combining Units And Options

▪ Position the ferrite core on the relay harness of the drain up kit inside the switch box of the SV unit. SV1A25AJV1B+SV4~8A14AJV1B Installer and user reference guide VRV 5 safety valve unit 4P749917-1 – 2023.09... - Page 43 Power supply of the drain up kit e Relay harness of the drain up kit f Relay connector of the drain up kit g Ferrite core SV1A25AJV1B+SV4~8A14AJV1B Installer and user reference guide VRV 5 safety valve unit 4P749917-1 – 2023.09...

-

Page 44: Special Requirements For R32 Units

For compatibility of indoor units, see the latest version of the technical data book of the outdoor unit. SV1A25AJV1B+SV4~8A14AJV1B Installer and user reference guide VRV 5 safety valve unit... -

Page 45: To Determine The Required Safety Measures

Spaces connected by only false ceilings, ductwork, or similar connections are not considered a single space. Step 3 – Use the graphs or tables below to determine the required safety measures for the SV unit. SV1A25AJV1B+SV4~8A14AJV1B Installer and user reference guide VRV 5 safety valve unit 4P749917-1 – 2023.09... - Page 46 (d) External alarm OR Natural ventilation (=External alarm OR Natural ventilation) (e) Ventilated enclosure (=Ventilated enclosure) (f) Ventilated enclosure OR External alarm + natural ventilation (=Ventilated enclosure OR External alarm + natural ventilation) SV1A25AJV1B+SV4~8A14AJV1B Installer and user reference guide VRV 5 safety valve unit 4P749917-1 – 2023.09...

- Page 47 This means that the following safety measures are required: SV unit Room area Required safety measure A=50 m²≥40 m² No safety measures A=15 m²<40 m² Ventilated enclosure OR External alarm + natural ventilation SV1A25AJV1B+SV4~8A14AJV1B Installer and user reference guide VRV 5 safety valve unit 4P749917-1 – 2023.09...

-

Page 48: Overview: Flowchart

Natural ventilation Natural ventilation Note: The flowchart is an overview. Always refer to the full text mentioned in this manual for clear understanding and detailed explanation. SV1A25AJV1B+SV4~8A14AJV1B Installer and user reference guide VRV 5 safety valve unit 4P749917-1 – 2023.09... -

Page 49: Safety Measures

SV unit of the system. Note: An address number for the supervisor remote controller must be assigned to the SV unit. See "17.1 Making field settings" [ 100]. SV1A25AJV1B+SV4~8A14AJV1B Installer and user reference guide VRV 5 safety valve unit 4P749917-1 – 2023.09... -

Page 50: Natural Ventilation

Total refrigerant charge in the system [kg] Area of the room with natural ventilation [m²] Minimum room area of the space in which the SV unit is installed [m²] SV1A25AJV1B+SV4~8A14AJV1B Installer and user reference guide VRV 5 safety valve unit... - Page 51 Note: The requirement for the upper opening can be met by false ceilings, ventilation ducts or similar arrangements that provide an airflow path between the connected rooms. SV1A25AJV1B+SV4~8A14AJV1B Installer and user reference guide VRV 5 safety valve unit 4P749917-1 – 2023.09...

-

Page 52: Ventilated Enclosure

72] for ductwork (field supply) installation and "16.5 To connect the external outputs" [ 98] to connect the extraction fan circuit (field supply) to the SV unit. SV1A25AJV1B+SV4~8A14AJV1B Installer and user reference guide VRV 5 safety valve unit 4P749917-1 – 2023.09... - Page 53 SV unit b Ductwork c Extraction fan An extraction fan must be connected to the SV unit, see "16.5 To connect the external outputs" [ 98]. SV1A25AJV1B+SV4~8A14AJV1B Installer and user reference guide VRV 5 safety valve unit 4P749917-1 – 2023.09...

- Page 54 So this airflow rate is above the required 18.8 m³/h and the pressure inside the SV unit is within the range of 20~350 Pa below the pressure of the surroundings. We use this 115 m³/h airflow rate for further calculations. SV1A25AJV1B+SV4~8A14AJV1B Installer and user reference guide VRV 5 safety valve unit...

- Page 55 Select a fan with the required flow of 115 m³/h and a total pressure rise of 114.3 Pa. Note: For ease of installation, we recommend to use in-line duct fans. SV1A25AJV1B+SV4~8A14AJV1B Installer and user reference guide VRV 5 safety valve unit...

- Page 56 (in the cluster) of each outdoor unit system. Example a SV unit belonging to outdoor unit A b SV unit belonging to outdoor unit B c Extraction fan output terminal – NOT connected SV1A25AJV1B+SV4~8A14AJV1B Installer and user reference guide VRV 5 safety valve unit 4P749917-1 – 2023.09...

- Page 57 "16.5 To connect the external outputs" [ 98]). It is not allowed to have SV units in the same series cluster that belong to different outdoor unit systems. Example SV1A25AJV1B+SV4~8A14AJV1B Installer and user reference guide VRV 5 safety valve unit 4P749917-1 – 2023.09...

- Page 58 Before SV unit operation, it is required to perform a test run that simulates a refrigerant leak. See "18.3 SV unit test run" [ 110] for more details. SV1A25AJV1B+SV4~8A14AJV1B Installer and user reference guide VRV 5 safety valve unit 4P749917-1 – 2023.09...

-

Page 59: Overview: Flowchart

Installation SV unit(s) is completed Note: The flowchart is an overview. Always refer to the full text mentioned in this manual for clear understanding and detailed explanation. SV1A25AJV1B+SV4~8A14AJV1B Installer and user reference guide VRV 5 safety valve unit 4P749917-1 – 2023.09... -

Page 60: Combinations Of Ventilated Enclosure Configurations

It is not allowed to combine parallel and series configurations within the same cluster. a SV unit b Extraction fan A Parallel configuration B Series configuration NOT allowed SV1A25AJV1B+SV4~8A14AJV1B Installer and user reference guide VRV 5 safety valve unit 4P749917-1 – 2023.09... -

Page 61: Combinations Of Safety Measures

SV units (d) with external alarm safety measure Code Description Value [2-0] Cluster indication 0 (default): disable [2-4] Safety measures 1 (default): enable [2-7] Ventilated enclosure 0: disable SV1A25AJV1B+SV4~8A14AJV1B Installer and user reference guide VRV 5 safety valve unit 4P749917-1 – 2023.09... - Page 62 Before SV unit operation, it is required to perform a test run that simulates a refrigerant leak. See "18.3 SV unit test run" [ 110] for more details. SV1A25AJV1B+SV4~8A14AJV1B Installer and user reference guide VRV 5 safety valve unit 4P749917-1 – 2023.09...

-

Page 63: Unit Installation

This unit is suitable for installation in a commercial, industrial, household and residential environment. INFORMATION The sound pressure level is less than 70 dBA. SV1A25AJV1B+SV4~8A14AJV1B Installer and user reference guide VRV 5 safety valve unit 4P749917-1 – 2023.09... - Page 64 SV unit and the indoor unit, or to keep more length between the SV unit and the indoor unit. >5 m a SV unit SV1A25AJV1B+SV4~8A14AJV1B Installer and user reference guide VRV 5 safety valve unit 4P749917-1 – 2023.09...

- Page 65 ≥ 485 c ≥ 485 b ≥ 720 [mm] ≥5 (≥49.5) ≥100 A≥1800 f: 875 f: 450 [mm] A Minimum distance to the floor a Switch box SV1A25AJV1B+SV4~8A14AJV1B Installer and user reference guide VRV 5 safety valve unit 4P749917-1 – 2023.09...

-

Page 66: Possible Configurations

A Ceiling opening size: 800 mm (SV1~4A) 1200 mm (SV6~8A) 14.2 Possible configurations Refrigerant piping A Refrigerant piping connected to left side only B Refrigerant piping connected to right side only SV1A25AJV1B+SV4~8A14AJV1B Installer and user reference guide VRV 5 safety valve unit 4P749917-1 – 2023.09... - Page 67 "14.5.3 To switch the air in- and outlet side" [ 74]. INFORMATION Some options may require additional service space. Sees the installation manual of the used option before installation. SV1A25AJV1B+SV4~8A14AJV1B Installer and user reference guide VRV 5 safety valve unit 4P749917-1 – 2023.09...

-

Page 68: Opening And Closing The Unit

1 Install 4 M8 or M10 suspension bolts into the ceiling slab. Respect the following distances: a Suspension bolt pitch (length): 513 mm SV1A25AJV1B+SV4~8A14AJV1B Installer and user reference guide VRV 5 safety valve unit 4P749917-1 – 2023.09... - Page 69 NOTICE If the unit is installed at a bigger angle than allowed, water may drip from the unit. a Level b Water-filled vinyl tube SV1A25AJV1B+SV4~8A14AJV1B Installer and user reference guide VRV 5 safety valve unit 4P749917-1 – 2023.09...

-

Page 70: To Connect The Drain Piping

(accessory) will not be forced outwards when applied. c Metal clamp (accessory) 4 Check if the water drains correctly. ▪ Open the inspection hole by removing the inspection hole cover. SV1A25AJV1B+SV4~8A14AJV1B Installer and user reference guide VRV 5 safety valve unit 4P749917-1 – 2023.09... -

Page 71: To Install The Drain Piping

Drain piping (field supply) 14.4.3 To install the drain piping 1 Install the drain piping with hanging bars as shown in the illustration. 1~1.5 m a Hanging bar SV1A25AJV1B+SV4~8A14AJV1B Installer and user reference guide VRV 5 safety valve unit 4P749917-1 – 2023.09... -

Page 72: Installing The Ventilation Ducting

▪ Make sure the connections to the unit or any other connections in the system do not leak air. 3 Insulate the ducting with field supply thermal insulation and with the accessory sealing material (against condensation drops). SV1A25AJV1B+SV4~8A14AJV1B Installer and user reference guide VRV 5 safety valve unit 4P749917-1 – 2023.09... -

Page 73: To Install The Duct Closing Plate

"13.3 To determine the required safety measures" [ 45]. 1 Remove the duct connection. Do not not throw away the screws. 4× SV1A25AJV1B+SV4~8A14AJV1B Installer and user reference guide VRV 5 safety valve unit 4P749917-1 – 2023.09... -

Page 74: To Switch The Air In- And Outlet Side

5 Lift the switch box, pull it forward and lower it. To remove the damper 1 Remove the leftmost wire fixing plate. It holds the damper wire in place. SV1A25AJV1B+SV4~8A14AJV1B Installer and user reference guide VRV 5 safety valve unit... - Page 75 ▪ Carefully guide the wires from the inside to the outside through the small hole in the unit's metal plate. Take care not to damage the connector and the earth wire connection. SV1A25AJV1B+SV4~8A14AJV1B Installer and user reference guide VRV 5 safety valve unit...

- Page 76 ▪ Pull the wires through until the foam insulation fits properly in the small hole in the unit's metal plate. This makes the connection airtight. ▪ Attach the damper with four screws. SV1A25AJV1B+SV4~8A14AJV1B Installer and user reference guide VRV 5 safety valve unit...

- Page 77 New insulation (accessory) ▪ Position the wires as far down as possible in the opening on top of which the wire fixing plate will be installed. SV1A25AJV1B+SV4~8A14AJV1B Installer and user reference guide VRV 5 safety valve unit 4P749917-1 – 2023.09...

- Page 78 ▪ Leave 20 cm of wire between the fixation on the pipe and the entry into the switch box in order to be able to put back the switch box. ▪ Bundle the damper wire if needed. SV1A SV4A SV6A SV1A25AJV1B+SV4~8A14AJV1B Installer and user reference guide VRV 5 safety valve unit 4P749917-1 – 2023.09...

- Page 79 2 Install and tighten the four screws. It is not required to tighten the M8 bolts again. 4× ≤ 3.2 N•m 3 Close the SV unit. See "14.3.2 To close the unit" [ 68]. SV1A25AJV1B+SV4~8A14AJV1B Installer and user reference guide VRV 5 safety valve unit 4P749917-1 – 2023.09...

-

Page 80: Piping Installation

Connecting the refrigerant piping............................15.3.1 To connect the refrigerant piping.......................... 15.3.2 To braze the pipe end ............................15.3.3 Joining branch pipe ports............................15.4 To insulate the refrigerant piping............................SV1A25AJV1B+SV4~8A14AJV1B Installer and user reference guide VRV 5 safety valve unit 4P749917-1 – 2023.09... -

Page 81: Installation Limitations

Maximum capacity index of connectable indoor units — per branch if two branches are combined (e) Maximum capacity index of indoor units connected to SV units in refrigerant flow-through (c) SV1A25AJV1B+SV4~8A14AJV1B Installer and user reference guide VRV 5 safety valve unit 4P749917-1 – 2023.09... -

Page 82: Piping Installation Limitation

MUST be connected. In case none of the first four ports are connected, the 7- segment display will show ' 0× 1× 2× 3× 4× Model Branch pipe port SV6A ≥1 port MUST be connected free use SV8A free use SV1A25AJV1B+SV4~8A14AJV1B Installer and user reference guide VRV 5 safety valve unit 4P749917-1 – 2023.09... -

Page 83: Preparing Refrigerant Piping

120°C ▪ Insulation thickness: Ambient temperature Humidity Minimum thickness ≤30°C 75% to 80% RH 15 mm >30°C ≥80% RH 20 mm SV1A25AJV1B+SV4~8A14AJV1B Installer and user reference guide VRV 5 safety valve unit 4P749917-1 – 2023.09... -

Page 84: Connecting The Refrigerant Piping

▪ Gas pipe: 22.2 mm 2 If necessary, cut the branch pipes as indicated in the illustration below. The diameters of the branch pipes of the SV unit are indicated in the illustration. SV1A25AJV1B+SV4~8A14AJV1B Installer and user reference guide VRV 5 safety valve unit... -

Page 85: To Braze The Pipe End

Taping d Manual valve e Pressure-reducing valve f Nitrogen ▪ Do NOT use anti-oxidants when brazing pipe joints. Residue can clog pipes and break equipment. SV1A25AJV1B+SV4~8A14AJV1B Installer and user reference guide VRV 5 safety valve unit 4P749917-1 – 2023.09... -

Page 86: Joining Branch Pipe Ports

Always use tape (field supply) to prevent air gaps in the seam between the insulation tubes. SV1A25AJV1B+SV4~8A14AJV1B Installer and user reference guide VRV 5 safety valve unit... - Page 87 SV unit. 2 Attach an extra layer of insulation tube (f) to level out the thickness. 3 Apply tape (b) to close the seam. SV1A25AJV1B+SV4~8A14AJV1B Installer and user reference guide VRV 5 safety valve unit 4P749917-1 – 2023.09...

-

Page 88: Electrical Installation

ALWAYS use multicore cable for power supply cables. WARNING Use an all-pole disconnection type breaker with at least 3 mm between the contact point gaps that provides full disconnection under overvoltage category III. SV1A25AJV1B+SV4~8A14AJV1B Installer and user reference guide VRV 5 safety valve unit 4P749917-1 – 2023.09... -

Page 89: Specifications Of Standard Wiring Components

220-240 V Phase Frequency 50 Hz Wire size Must comply with national wiring regulation. 3-core cable Wire size based on the rated current, but not less than 0.5 mm². SV1A25AJV1B+SV4~8A14AJV1B Installer and user reference guide VRV 5 safety valve unit 4P749917-1 – 2023.09... - Page 90 If the total interconnection wiring exceeds these limits, communication errors might occur. Up to 16 branches are possible for unit-unit cabling. No secondary branching are allowed after any interconnection wire branching. SV1A25AJV1B+SV4~8A14AJV1B Installer and user reference guide VRV 5 safety valve unit...

-

Page 91: Guidelines When Connecting The Electrical Wiring

2 Install a round crimp-style terminal on the end of the wire. Place the round crimp-style terminal on the wire up to the covered part and fasten the terminal with the appropriate tool. SV1A25AJV1B+SV4~8A14AJV1B Installer and user reference guide VRV 5 safety valve unit... - Page 92 Screw c Spring washer d Flat washer e Coupling washer f Sheet metal Tightening torques Terminal Wiring Screw size Tightening torque (N•m) Power supply wiring 1.32~1.62 SV1A25AJV1B+SV4~8A14AJV1B Installer and user reference guide VRV 5 safety valve unit 4P749917-1 – 2023.09...

-

Page 93: To Connect The Electrical Wiring

SV units, where each time the terminals F1/F2 (SV unit) on terminal block X2M on the n SV unit are connected to the terminals F1/F2 (Outdoor unit) on terminal block X2M on the (n+1) SV unit. SV1A25AJV1B+SV4~8A14AJV1B Installer and user reference guide VRV 5 safety valve unit 4P749917-1 – 2023.09... - Page 94 UNIT F1 F2 F1 F2 F1 F2 F1 F2 F1 F2 F1 F2 F1 F2 a SV unit 1 b SV unit 2 c Outdoor unit SV1A25AJV1B+SV4~8A14AJV1B Installer and user reference guide VRV 5 safety valve unit 4P749917-1 – 2023.09...

- Page 95 Attach the cables onto the outer cable jacket and NOT onto the wires. ▪ Do NOT strip the outer cable jacket lower than the fixation point. SV1A25AJV1B+SV4~8A14AJV1B Installer and user reference guide VRV 5 safety valve unit 4P749917-1 – 2023.09...

-

Page 96: To Finish The Electrical Wiring

Finishing tape d Interconnection cable (F1/F2) e Insulation 16.4 To set the DIP switches The DIP switches are located on the PCBs A1P, A2P (SV6~8A). SV1A25AJV1B+SV4~8A14AJV1B Installer and user reference guide VRV 5 safety valve unit 4P749917-1 – 2023.09... - Page 97 This is required for connection with e.g. FXMA200 and FXMA250. Setting when joining branch pipe ports DS2 (A1P) DS2 (A2P) SV1A SV4A SV6A SV8A Target branch pipe ports ON=joined / OFF=NOT joined (factory default) SV1A25AJV1B+SV4~8A14AJV1B Installer and user reference guide VRV 5 safety valve unit 4P749917-1 – 2023.09...

-

Page 98: To Connect The External Outputs

Do NOT use the FAN output to directly power the fan. Instead, use the output to energise a relay that controls the fan circuit. (FAN) EXAMPLE a FAN output terminal b Relay c Extraction fan power supply SV1A25AJV1B+SV4~8A14AJV1B Installer and user reference guide VRV 5 safety valve unit 4P749917-1 – 2023.09... - Page 99 SV1~8A a Power supply cable (field supply) b Output cable (FAN cable shown)(field supply) c Cable tie (accessory) SV1A25AJV1B+SV4~8A14AJV1B Installer and user reference guide VRV 5 safety valve unit 4P749917-1 – 2023.09...

-

Page 100: Configuration

17.1.2 To access the field setting components "14.3.1 To open the unit" [ 68]. 17.1.3 Field setting components Location of the 7-segment displays and push buttons: SV1A25AJV1B+SV4~8A14AJV1B Installer and user reference guide VRV 5 safety valve unit 4P749917-1 – 2023.09... -

Page 101: To Access Mode 1 Or 2

Initialisation: default situation NOTICE Turn ON the power 6 hours before operation in order to have power running to the crankcase heater and to protect the compressor. SV1A25AJV1B+SV4~8A14AJV1B Installer and user reference guide VRV 5 safety valve unit 4P749917-1 – 2023.09... -

Page 102: To Use Mode 1

Push BS2 to select the required setting. Push BS3 one time to access the selected setting's value. To quit and return to the initial Push BS1. status SV1A25AJV1B+SV4~8A14AJV1B Installer and user reference guide VRV 5 safety valve unit 4P749917-1 – 2023.09... -

Page 103: To Use Mode 2

[Mode‑Setting]=Value in this case is defined as: Mode=2; Setting=7; Value=the value we want to know/change. 1 Make sure the 7‑segment display indication is in the default situation (normal operation). SV1A25AJV1B+SV4~8A14AJV1B Installer and user reference guide VRV 5 safety valve unit 4P749917-1 – 2023.09... -

Page 104: Mode 1: Monitoring Settings

SV units belonging to different clusters need to have a different cluster number. [2-1] Description 0 (default)~63 Cluster number SV1A25AJV1B+SV4~8A14AJV1B Installer and user reference guide VRV 5 safety valve unit 4P749917-1 – 2023.09... - Page 105 Setting to confirm the completion of the commissioning check. After confirmation that the safety measures of the SV unit are working as intended, this setting must be changed to "1". SV1A25AJV1B+SV4~8A14AJV1B Installer and user reference guide VRV 5 safety valve unit...

- Page 106 A2P Main PCB 2 a Outdoor unit b SV6A unit c SV4A unit d SV8A unit e Address value for supervisor remote controller assigned to main PCB Interconnection wiring SV1A25AJV1B+SV4~8A14AJV1B Installer and user reference guide VRV 5 safety valve unit 4P749917-1 – 2023.09...

- Page 107 The table below shows an example of address values assigned: Main PCB Address value (e) SV8A SV6A SV4A [2-10] Setting to enable or disable the external alarm output during the SV unit test run. SV1A25AJV1B+SV4~8A14AJV1B Installer and user reference guide VRV 5 safety valve unit 4P749917-1 – 2023.09...

-

Page 108: Mode 2: Default Field Settings

Address value to SV unit for supervisor remote controller [2-9] Address value to SV unit for error handling [2-10] External alarm output during SV unit test run SV1A25AJV1B+SV4~8A14AJV1B Installer and user reference guide VRV 5 safety valve unit 4P749917-1 – 2023.09... -

Page 109: Commissioning

NOTICE General commissioning checklist. Next to the commissioning instructions in this chapter, a general commissioning checklist is also available on the Daikin Business Portal (authentication required). The general commissioning checklist is complementary to the instructions in this chapter and can be used as a guideline and reporting template during commissioning and hand-over to the user. -

Page 110: Unit Test Run

Note: Do not perform a SV unit test run on more than one SV unit at a time. ▪ No safety measure: all SV units with no safety measures. SV1A25AJV1B+SV4~8A14AJV1B Installer and user reference guide VRV 5 safety valve unit... -

Page 111: About Airflow Requirements

[2-21] on the outdoor unit to open the expansion valves again THEN power off the unit to conduct the SV unit test run. 18.3.2 About airflow requirements When a ventilated enclosure is required, the following requirements apply: SV1A25AJV1B+SV4~8A14AJV1B Installer and user reference guide VRV 5 safety valve unit 4P749917-1 – 2023.09... -

Page 112: About Measuring The Airflow Rate

Tip: Use the duct connection kit (EKBSDCK) and an anemometer with a funnel to conduct the entire airflow through the anemometer. ▪ Postrequisite: Remove the kit once the measurement is finished. a Vane anemometer b Duct connection kit (EKBSDCK) SV1A25AJV1B+SV4~8A14AJV1B Installer and user reference guide VRV 5 safety valve unit 4P749917-1 – 2023.09... -

Page 113: To Perform A Sv Unit Test Run

This setting confirms that the safety measures are working correctly and - in the case of ventilated enclosure – it confirms that the extraction airflow rate complies to the legal limits. SV1A25AJV1B+SV4~8A14AJV1B Installer and user reference guide VRV 5 safety valve unit... -

Page 114: Troubleshooting During A Sv Unit Test Run

Check if the sizing of the fan is appropriate. Adapt if necessary. Incorrect fan speed Check if the fan has different speed settings. Select a higher speed if necessary. SV1A25AJV1B+SV4~8A14AJV1B Installer and user reference guide VRV 5 safety valve unit 4P749917-1 – 2023.09... -

Page 115: System Test Run

7‑segment display. ▪ See the service manual for the complete list of error codes and a detailed troubleshooting guideline for each error. SV1A25AJV1B+SV4~8A14AJV1B Installer and user reference guide VRV 5 safety valve unit 4P749917-1 – 2023.09... -

Page 116: Hand-Over To The User

Explain the user how to properly operate the system and what to do in case of problems. ▪ Explain to the user only a certified installer is allowed to perform maintenance on the unit. SV1A25AJV1B+SV4~8A14AJV1B Installer and user reference guide VRV 5 safety valve unit 4P749917-1 – 2023.09... -

Page 117: Maintenance And Service

Wait for two minutes to allow the system to close the valves e Turn off the system power f Perform maintenance and servicing on the SV unit SV1A25AJV1B+SV4~8A14AJV1B Installer and user reference guide VRV 5 safety valve unit 4P749917-1 – 2023.09... -

Page 118: Troubleshooting

SV unit R32 sensor end of lifetime Malfunction of the SV unit's PCB SV unit damper malfunction Malfunction of the SV unit's electronic expansion valve SV unit power supply failure SV1A25AJV1B+SV4~8A14AJV1B Installer and user reference guide VRV 5 safety valve unit 4P749917-1 – 2023.09... -

Page 119: Disposal

Do NOT try to dismantle the system yourself: dismantling of the system, treatment of the refrigerant, oil and other parts MUST comply with applicable legislation. Units MUST be treated at a specialised treatment facility for reuse, recycling and recovery. SV1A25AJV1B+SV4~8A14AJV1B Installer and user reference guide VRV 5 safety valve unit... -

Page 120: Technical Data

A subset of the latest technical data is available on the regional Daikin website (publicly accessible). ▪ The full set of the latest technical data is available on the Daikin Business Portal (authentication required). 23.1 Wiring diagram The wiring diagram is delivered with the unit, located at the inside of the service cover. - Page 121 MR*, MRCW*, MRM*, Magnetic relay MRN* Neutral n=*, N=* Number of passes through ferrite core Functional earth Pulse-amplitude modulation PCB* Printed circuit board Power module Switching power supply SV1A25AJV1B+SV4~8A14AJV1B Installer and user reference guide VRV 5 safety valve unit 4P749917-1 – 2023.09...

- Page 122 Diode bridge, Insulated-gate bipolar transistor (IGBT) power module Wireless remote controller Terminal Terminal strip (block) Connector Electronic expansion valve coil Y*R, Y*S Reversing solenoid valve coil Ferrite core SV1A25AJV1B+SV4~8A14AJV1B Installer and user reference guide VRV 5 safety valve unit 4P749917-1 – 2023.09...

- Page 123 The factory settings of DIP switch (DS1, DS2) are as follows: Model DS1, DS2 factory settings SV1A SV4A SV6A SV8A To set the DIP switches (DS1~2) and push buttons (BS1~3), see the installation manual SV1A25AJV1B+SV4~8A14AJV1B Installer and user reference guide VRV 5 safety valve unit 4P749917-1 – 2023.09...

-

Page 124: Glossary

Optional equipment Equipment made or approved by Daikin that can be combined with the product according to the instructions in the accompanying documentation. Field supply Equipment NOT made by Daikin that can be combined with the product according to the instructions in the accompanying documentation. - Page 128 4P749917-1 2023.09 Verantwortung für Energie und Umwelt...

Need help?

Do you have a question about the SV1A25AJV1B and is the answer not in the manual?

Questions and answers