ZIEHL-ABEGG FE2owlet-ECQ Ex Assembly Instructions Manual

Motor size u

Hide thumbs

Also See for FE2owlet-ECQ Ex:

- Assembly instructions manual (19 pages) ,

- Assembly instructions manual (24 pages)

Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for ZIEHL-ABEGG FE2owlet-ECQ Ex

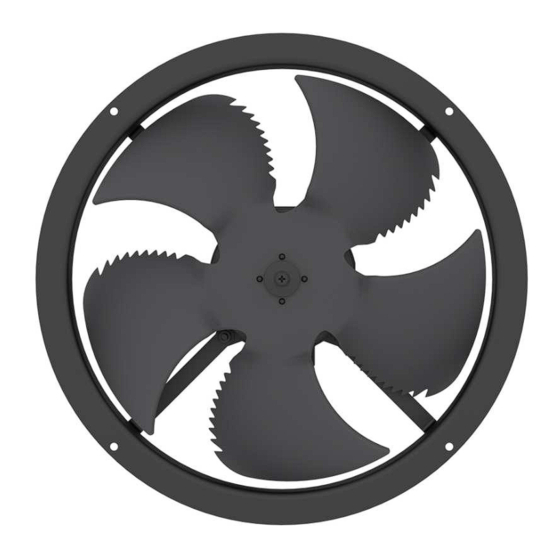

- Page 1 FE2owlet-ECQ Ex Motor size U Explosion-proof design for use in zone 2 (category 3) explosive atmospheres Assembly instructions Keep for reference! VENTILATOR-Typenschild einkleben! L-BAL-F072-GB 2022/30 Index 001 Part.-No. 00703699-GB...

-

Page 2: Table Of Contents

Assembly instructions FE2owlet-ECQ Ex Content General notes ............. - Page 3 Assembly instructions FE2owlet-ECQ Ex Service work ............. .

-

Page 4: General Notes

We do not accept any liability for possible errors or omissions in the information contained in data, illustrations or drawings provided. ZIEHL-ABEGG SE is not liable for damage due to misuse, incorrect use, improper use or as a consequence of unauthorized repairs or modifications. -

Page 5: Safety

-are considered part of intended use. • To consider is also the documentation of attached components. The following application limits apply to ZIEHL-ABEGG fans suitable for use in potentially explosive atmospheres: – maximum pumped medium temperature in the range from -30...+50 °C –... -

Page 6: Improper Use / Reasonably Foreseeable Misuse

Assembly instructions FE2owlet-ECQ Ex Safety 2.3.2 Improper use / reasonably foreseeable misuse • Operation in or with an explosion protection zone for which the fan is unsuitable because of its category, e.g. operation of a gas explosion proof fan in a dust explosive area. -

Page 7: Requirements Placed On The Personnel / Due Diligence

Use only genuine spare parts / genuine wearing parts / genuine accessories from ZIEHL-ABEGG.Th- ese parts were specifically designed for the device. There is no guarantee that parts from non-original sources are designed and manufactured in correspondence with load and safety requirements. -

Page 8: Operator's Obligation Of Diligence

3.1.1 Explosion protection zone The fans FE2owlet-ECQ Ex are only intended for the conveyance of air or zone 2 explosive atmospheres. The conveyance of solid matter, solids content, and dust/air mixtures is not permitted. 3.1.2... -

Page 9: Functional Description

Assembly instructions FE2owlet-ECQ Ex Product overview Functional description ECQ motors from ZIEHL-ABEGG are highly efficient, electronically commuted motors (EC) with an integrated controller. They are designed exclusively for driving axial fans. The motors are designed for continuous operation (S1-operation) and are thermally protected. -

Page 10: Transport, Storage

Assembly instructions FE2owlet-ECQ Ex Product overview Transport, storage Attention! • Use the original packaging materials when transporting the device. • Do not transport the fan by the connecting cable! • Avoid shocks and impacts to the device during the transport. -

Page 11: Mounting

Assembly instructions FE2owlet-ECQ Ex Mounting 4 Mounting General notes Attention! • Check the fan for damage, e.g. cracks, dents or damage to the electric cables, before assembly. Start-up is not allowed in the case of transport damage! • Mounting is only to be undertaken by trained service personnel. The system manufacturer or the machine builder and/or the user is responsible that the inherent installation and security information are harmonized with the valid standard and guidelines (EN ISO12100 / 13857). -

Page 12: Dimensions Motor

Assembly instructions FE2owlet-ECQ Ex Mounting Dimensions motor 03060-NN04 17.11.2021 Information The 7 holes in the motor's plastic housing (for self-tapping screws Ø 4.2) are designed for one-time use. Mounting fans design A and E To attach the fan unit, use screws with a property class of 4.8 as per EN ISO 4014 and provide with suitable thread lockers. -

Page 13: Connection Cable & Junction Box

Assembly instructions FE2owlet-ECQ Ex Mounting Fans design E 4x90° A minimum head gap “A” of 2 mm in all installation positions, but espe- cially in installation position H (hori- zontal motor shaft), is necessary. In- stallation surfaces must be level. -

Page 14: Electrical Installation

Appropriate explosion-proof junction boxes with tested cable and line inlets are available in our ZIEHL-ABEGG parts lists. Allowed medium temperature see intended use. Information Refer to the connection diagram enclosed or attached to the product, which must be available at the operating location. -

Page 15: Connection Of The Motor

Assembly instructions FE2owlet-ECQ Ex Electrical installation Connection of the motor Danger due to electric current • The mains voltage must comply with the EN 50160 quality characteristics and the defined standard voltages in IEC 60038! • Connect the motor only to electrical circuits that can be disconnected with an all-pole isolating switch. -

Page 16: Commissioning

3. Check the system for resonances. If they lead to unacceptably high vibrations on the fan, the system must not be started up. 4. Fans from ZIEHL-ABEGG SE are delivered balanced in accordance with DIN ISO 21940-11 for the appropriate fan category in accordance with ISO 14694. Check the fan for mechanical vibrations after installation. -

Page 17: Trouble Shooting

Assembly instructions FE2owlet-ECQ Ex Trouble shooting 7 Trouble shooting Code of behaviour in the event of faults In the event of faults, which represent a danger to people, installation or environment, the motor " must be switched off. " Search for the cause of the error. -

Page 18: Cleaning

Repair, e.g. by welding or gluing is prohibited! • Bolted-on or pressed on impellers and/or wings may only be replaced by authorised ZIEHL-ABEGG SE staff. The manufacturer shall not be liable for damage caused through improper repair work. • Regular inspection and possibly cleaning is necessary to prevent imbalance and blockage of the drain holes (if available)due to ingress of dirt. -

Page 19: Enclosure

Assembly instructions FE2owlet-ECQ Ex Enclosure 9 Enclosure Technical data Line voltage* 1 ~ 230 V, 50/60 Hz (see rating plate) 1 ~ 120 V, 50/60 Hz Power consumption (P1) max. 34 W Speed step 3 / 2 / 1 see rating plate Maximal line fuse Max. -

Page 20: Ec Declaration Of Incorporation

Assembly instructions FE2owlet-ECQ Ex Enclosure EC Declaration of Incorporation - Translation - (english) ZA87-GB 2022/17 Index 012 as defined by the EC Machinery Directive 2006/42/EC, Annex II B The design of the partly completed machine: Axial fan DN.., FA.., FB.., FC.., FE.., FF.., FG.., FH.., FL.., FN.., FP.., FS.., FT.., FV.., VN.., VR.., ZC.., ZF.., ZG.., ZN..Centrifugal fan ER.., GR.., HR.., RA.., RD.., RE.., RF.., RG.., RH.., RK.., RM.., RR..,... - Page 21 Assembly instructions FE2owlet-ECQ Ex Enclosure Start-up of this incomplete machine is prohibited until it is ensured that the machine in which it has been installed complies with the provisions of the EC Machinery Directive. Künzelsau, 27.04.2022 (Location, date of issue)

- Page 22 Assembly instructions FE2owlet-ECQ Ex Enclosure EU declaration of conformity - Translation - (english) ZA97ex-GB 2022/20 Index 002 Manufacturer: ZIEHL-ABEGG SE Heinz-Ziehl-Straße 74653 Künzelsau Germany The manufacturer is solely responsible for issuance of the declaration of conformity. The products: • Internal rotor motors MI060-4QN.05.N1, MI060-4QN.05.N2, MI060-4QN.05.N3, MI060-4QN.05.N4 as group IIA electrical operating equipment for zone 2 explosive areas, type of protection "ec"...

- Page 23 Assembly instructions FE2owlet-ECQ Ex Enclosure The following persons are authorized to compile the technical documents, address see above. Künzelsau, 19.05.2022 (Location, date of issue) ZIEHL-ABEGG SE ZIEHL-ABEGG SE Moritz Krämer Ralf Oesselke Director Product Development Director Projects & Series Development...

-

Page 24: Manufacturer

If you have any questions about how to use our products or if you are planning special applications, please contact: ZIEHL-ABEGG SE Heinz-Ziehl-Straße D-74653 Künzelsau Phone 07940/16-0 Fax 07940/16-300 info@ziehl-abegg.de Service address Please refer to the homepage at www.ziehl-abegg.com for a list of our subsidiaries worldwide. L-BAL-F072-GB 2022/30 Index 001 Part.-No. 00703699-GB 24/24...

Need help?

Do you have a question about the FE2owlet-ECQ Ex and is the answer not in the manual?

Questions and answers