AAON VCCX2 Technical Manual

Hide thumbs

Also See for VCCX2:

- Technical manual (116 pages) ,

- Technical manual (140 pages) ,

- Technical manual (134 pages)

Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for AAON VCCX2

- Page 1 VCCX2 Controller Technical Guide ASM01698 Software SS1088...

- Page 2 Exhaust Damper to VCC-X EM1 Wiring Rev. Q, March 24, 2021 Updated RSMZ Trendlog tables, updated labels, miscellaneous minor edits Updated BACnet points to latest VCCX2 software, updated Appendix A figures, various cosmetic Rev. R, May 26, 2021 updates Added information regarding Paragon Air Flow. Edited BACnet table. Corrected errata. Updated Rev.

-

Page 3: Table Of Contents

START-UP AND COMMISSIONING ....................... 23 Powering Up and Configuration ..........................23 INPUTS AND OUTPUTS ..........................24 VCCX2 Controller and EM1 Module Inputs/Outputs Maps ................... 24 VCCX2 Controller Inputs/Outputs Descriptions ....................26 VCC-X EM1 Expansion Module Inputs/Outputs Descriptions ................28 User Configurable Relay Outputs ......................... 29 SEQUENCE OF OPERATIONS ........................ - Page 4 Analog Values ............................... 80 Binary Inputs ................................. 86 Enumerated Fields ..............................90 Bitfields ................................. 91 BACnet Protocol Implementation Conformance Statement - VCCX2 v1.90 and previous ........93 BACnet Protocol Implementation Conformance Statement - VCCX2 v2.00 and on ..........94 VCCX2 Controller Technical Guide...

-

Page 5: Table Of Figures

Typical Networked Single Loop System Layout Figure 22: ....................63 Typical Networked Multiple Loop System Layout Figure 23: ....................64 LCD Display and Navigation Keys Figure 24: ........................65 VCCX2 BACnet Connection to MS/TP Network Figure 25: ....................71 VCCX2 Controller Technical Guide... -

Page 6: Table Of Tables

RSMZ Module VFD Status Trend Log Table 17: ........................53 VCCX2 Trend Log Bit Strings Table 18: ..........................55 VCCX2 Trend Log Bit Strings (continued) Table 19: ......................56 0-5V Temperature Sensor - Voltage and Resistance for Type III Sensors Table 20: .............59... -

Page 7: Overview

It also has an on-board BACnet port for connection • Indoor air quality economizer reset to an MS/TP network. The VCCX2 contains a 2 x 8 LCD character display and four buttons that allow for status and alarm display, •... -

Page 8: Applications

Application assumes unit has return air to allow for unoccupied operations with outdoor air damper closed. Dehumidification mode utilizes the outdoor air dewpoint and resets the coil temperature based off the supply air dewpoint. VCCX2 Controller Technical Guide... -

Page 9: Part Number Cross Reference

ASM01688 / ASM01689 Standard Room Sensor - Plain or W/ Override ASM02227 / ASM01638 Standard Room Sensor - with Setpoint Adjust or Setpoint Adjust and Override ASM01642 / ASM01643 Strap-On Temperature Sensor Kit ASM01624 Suction Pressure Transducer ASM02222 VCCX2 Controller Technical Guide... - Page 10 OVERVIEW Part Number Cross Reference PART NUMBER CROSS REFERENCE System Manager TS-L (Touch Screen - Limited Access) ASM01900 USB-Link 2 Kit ASM02244 VCCX2 Controller Technical Guide...

-

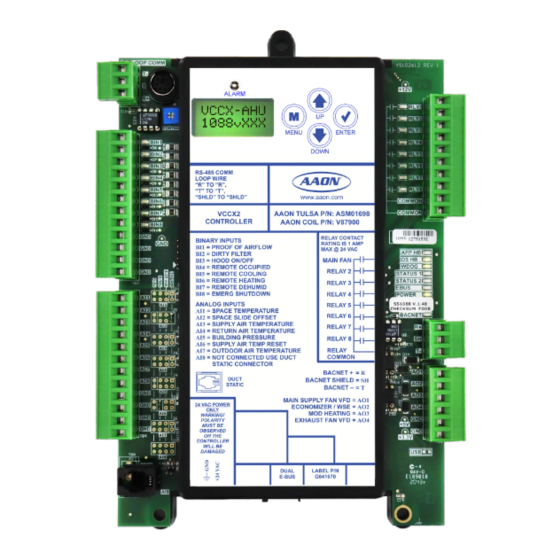

Page 11: Vccx2 Controller Components

OVERVIEW VCCX2 Controller Components Figure 1: VCCX2 Controller Components VCCX2 Controller Technical Guide... -

Page 12: Dimensions

DIMENSIONS VCCX2 Controller 6.04 2.75 0.213 8.38 7.95 4.10 Note: All Dimensions are in inches. 0.70 Note: Depth is 1.50 inches. Figure 2: VCCX2 Controller Dimensions VCCX2 Controller Technical Guide... -

Page 13: Vcc-X Em1 Expansion Module

OR THE CONTROLLER CONNECT G040660 CONNECT WILL BE DAMAGED 1002 OPTIONS 1002 0.20 ADDRESS .01uF 0.62 2.05 4.10 Note: All Dimensions are in inches. Note: Depth is 1.50 inches. Figure 3: VCC-X EM1 Expansion Module Dimensions VCCX2 Controller Technical Guide... -

Page 14: 12 Relay E-Bus Module

R211 RELAY R213 TB10 EXPANSION BOARD YS102324 REV 2 24VAC 1002 0.20 POWER COMM .1uF 0.71 2.05 4.10 Note: All Dimensions are in inches. Note: Depth is 1.50 inches. Figure 4: 12 Relay E-BUS Module Dimensions VCCX2 Controller Technical Guide... -

Page 15: Wiring

• When communication wiring is to be used to connect The VCCX2 Controller is housed in a plastic enclosure. It is VCCX2 Controllers together or to connect to other designed to be mounted by using the three mounting holes in the communication devices, all wiring must be plenum-rated, enclosure base. -

Page 16: Vccx2 Controller

Connect FRP Tubing to High Pressure Port (bottom tube) and route to Static Pressure Pickup Probe located in unit discharge. Plug into VCCX2 Leave port marked “LO” open to atmosphere. Controller’s Duct Static Port Figure 5: VCCX2 Controller Input Wiring VCCX2 Controller Technical Guide... -

Page 17: Figure 6: Vccx2 Controller Output Wiring

WIRING VCCX2 Controller Outputs NOTE: All Relay Outputs are normally open and rated for 24 VAC power only. 1 amp maximum load Waterside Economizer V alve Figure 6: VCCX2 Controller Output Wiring VCCX2 Controller Technical Guide... -

Page 18: Vcc-X Em1 Expansion Module

WIRING VCC-X EM1 Expansion Module The VCC-X EM1 Expansion Module connects to the VCCX2 It is very important to be certain that all wiring Controller with an E-BUS cable and adds an additional five analog WARNING: is correct as shown in the wiring diagram inputs, five analog outputs, three binary inputs, and five configurable below. -

Page 19: Figure 9: Vcc-X Em1 Exhaust Duct Static Pressure And Economizer Actuator Feedback Wiring

Belimo Actuator wiring shown. Consult factory for other manufacturer wiring instructions. (by others) Connect to Set jumper to 0-10 V Expansion Module(s) (when used) Figure 9: VCC-X EM1 Exhaust Duct Static Pressure and Economizer Actuator Feedback Wiring VCCX2 Controller Technical Guide... -

Page 20: Figure 10: Vcc-X Em1 Expansion Module Output Wiring

24 VAC POWER ONLY WARNING! POLARITY MUST BE OBSERVED E-BUS LABEL P/N: E-BUS OR THE CONTROLLER CONNECT G040660 CONNECT WILL BE DAMAGED (for Return Plenum Pressure Control Applications) Figure 10: VCC-X EM1 Expansion Module Output Wiring VCCX2 Controller Technical Guide... -

Page 21: 12 Relay E-Bus Expansion Module

12 Relay E-BUS Expansion Module E-BUS cable connects to VCCX2 Controller E-BUS cable connects to the next Expansion Board Figure 11: 12 Relay E-BUS Expansion Module Wiring VCCX2 Controller Technical Guide... -

Page 22: Airflow Station

WIRING Airflow Station The E-BUS Adapter Board attaches to the VCCX2 Controller with The Airflow Station’s baud rate needs to be set to 19,200 in order an E-BUS cable. The Adapter Board is used for connecting the to communicate with the VCCX2 Controller (excludes Paragon EBTRON, GreenTrol, or Paragon Airflow Measurement Digital MTSE). -

Page 23: Start-Up And Commissioning

VCCX2 sizing for each controller. Each VCCX2 Controller requires 15 VA Controller in the order that follows: of power delivered to it at 24 VAC. Use separate transformers for each device (preferred) or power several devices from a common Configure the controller for the application. -

Page 24: Inputs And Outputs

Table 5: VCCX2 Controller Relay Outputs Dirty Filter The following E-BUS sensors and modules are available to connect Hood On/Off to the VCCX2 Controller via E-BUS ports or E-BUS Expansion Remote Forced Occupied Modules: Remote Forced Cooling • E-BUS Digital Room Sensor - LCD Display - Temp Only... -

Page 25: Table 6: Vcc-X Em1 Expansion Module Analog Inputs

INPUTS AND OUTPUTS VCCX2 Controller and EM1 Module Inputs/Outputs Maps EM1 Expansion Module Inputs ANALOG INPUTS (AI) INPUT NAME Entering Water Temperature Sensor Mixed Air Temperature sensor SIG1 Return Air Plenum Pressure (0-5V) SIG2 Economizer Damper Midway Switch (5VDC) SIG3... -

Page 26: Vccx2 Controller Inputs/Outputs Descriptions

BI3 - Hood On/Off Input This sensor is only required if configuring the VCCX2 Controller When this wet contact input closes (hood on), the VCCX2 Controller for building pressure control. Building pressure control can be switches from indoor air control to outdoor air control. This is accomplished by using one of two main control methods. - Page 27 The controller remains active and can initiate alarm relays. For reverse acting building pressure control using the NOTE: outdoor air damper or supply fan VFD, the VCCX2 The binary inputs require wet contacts (24 VAC only) NOTE: Controller uses the outputs specific to those devices.

-

Page 28: Vcc-X Em1 Expansion Module Inputs/Outputs Descriptions

This static pressure reading is used to control the output These relays are configurable by the user. See Table 10, page 29 signal (AO4 on the VCCX2 Controller) supplied to the exhaust fan VFD. Binary Inputs BI1 - Return/Exhaust Proof of Flow... -

Page 29: User Configurable Relay Outputs

If configured, this relay will energize anytime the space sensor push-button override is active. Alarm Active If configured, this relay will energize anytime a VCCX2 alarm is active. A1 Comp Run Status Will enable when the RSM A1 compressor activates. -

Page 30: Sequence Of Operations

Space Temperature Typical selection for CAV recirculating units. • Broadcast week schedule from GPC-XP The VCCX2 Controller can be forced into the Occupied Mode by Return Air Temperature Optional selection for CAV recirculating units. inputting a forced schedule from any operator interface. - Page 31 When the remote forced occupied signal is removed, the controller will revert to the Unoccupied Mode of operation, or if an internal VCCX2 schedule is also being used, it will revert to the current scheduled mode. Setting the internal week schedule to “0” will cause the controller to only look for the remote forced occupied signal for occupied/ unoccupied commands.

-

Page 32: Modes Of Operation

Cooling with the Refrigerant System Modules the active Supply Air Cooling Setpoint. The modulating cooling On units with digital or VFD compressors, the VCCX2 Controller proportional window is used to determine the signal to the chilled will utilize one or more RSMs. Units with only fixed staged water valve and is user adjustable. - Page 33 VCCX2 controller is wired to the direct fire controller to adjust (adjustable) before it is allowed to energize, and successive stages the amount of heat it puts out. The VCCX2 uses the same modulating are subject to a heating stage up delay (adjustable).

- Page 34 Damage to the unit could occur since the outdoor air damper remains default of 0%, the controller will not initiate this protection sequence. closed in the Unoccupied Mode. This operation works during emergency shutdown. VCCX2 Controller Technical Guide...

- Page 35 Dehumidification Operation on Chilled Water Units If the unit is equipped with a MHGRV-X, during Dehumidification it For chilled water units, the VCCX2 Controller will open the chilled will modulate the reheat valve to maintain the supply air temperature water valve to a fixed 100% position to provide full moisture at the active Supply Air Temperature Setpoint.

- Page 36 Heat Pump Standard Defrost Operation If using the VCCX2 Controller with an installed defrost coil When the SAT rises above the SAT setpoint the MHGRV will temperature switch, a defrost cycle is available.

- Page 37 SEQUENCE OF OPERATIONS Modes of Operation Heat Pump Adaptive Defrost Operation When the VCCX2 Controller is configured for Morning Warm-Up The adaptive defrost operation adjusts the time interval (adaptive and switches to the Occupied Mode of Operation (not Override or defrost timer) in between Defrost Mode cycles.

- Page 38 If utilizing the Title 24 economizer option, an economizer feedback signal (0-10 VDC) can be wired into the VCC-X EM1 Expansion Module for status monitoring. Several Title 24 alarm conditions can also be displayed. VCCX2 Controller Technical Guide...

- Page 39 The digital sensors each need to be configured with unique addresses (#1 -10) and have an LCD display for this operation. In A remote contact control option can be configured on the VCCX2 this arrangement, only the sensor at address #1 can utilize the slide Controller to initiate the HVAC Modes of operation.

- Page 40 Outdoor Air Temperature Sensor connected directly to the established by the configured Low and High Supply Air Temperature VCCX2 Controller) will be used as the temperature that locks out Setpoints. compressors during heat pump heating mode. See the PREHEAT-X Module Technical Guide for more details.

- Page 41 In order to maintain a constant cubic feet per minute through the unless close observation reveals that the supply fan or bypass damper supply air ducts on a mixed air constant air unit, the VCCX2 can is hunting and not maintaining a stable pressure reading.

- Page 42 This is done to prevent any damage to either the return or Outdoor Air Damper exhaust damper assemblies. If this option is configured, the VCCX2 will use the user-adjustable economizer/outdoor air damper output signal (AO2 – Economizer Control Signal) to maintain the Building Pressure Setpoint.

- Page 43 The air being exhausted is controlled by a separate control system hours. This is accomplished by simply configuring Night Setback that sends the VCCX2 a 0-10 VDC signal on analog input 6 based Temperature Setpoints (anything other than the default 30ºF) on a on its exhaust demand.

- Page 44 Space Heating High and a Space Heating Low If there is no demand, the VCCX2 switches to Vent Mode. If the Reset Source Setpoint. outdoor air temperature is greater than the Hood On HVAC Cooling...

- Page 45 In this operation, if night setback operation will be initiated by the Sump Heater Enable Temperature Setpoint. The sump heater a Space Sensor connected to the VCCX2 Controller, then the relay deactivates once the sump temperature rises 10ºF above the...

- Page 46 The sump and condenser valves are open. drain enable relay can be disabled in one of two ways: 1. Cycle power to the VCCX2 when the sump temp is above For waterside economizer bypass wiring, please see NOTE: the Sump Drain Enable Setpoint or the RSMD Technical Guide.

-

Page 47: Alarms

CO control. Relief Pressure Sensor This alarm occurs if the VCCX2 is receiving the value from a Broadcast or BACnet and the value is out of an acceptable range. Airflow Alarms •... - Page 48 A 24 VAC wet contact input is available to be used when a normally closed smoke Detector, Firestat, or other shutdown condition occurs. If this contact opens, it will initiate shutdown of the VCCX2 and will generate an alarm condition. If an Occupied relay is configured, it will remain energized.

-

Page 49: Figure 16: Prism 2 Direct Fire Alarms Screen

Expansion Boards If the controller is configured to have any of the below expansion boards (Modules), but the VCCX2 controller does not detect that board, then the applicable alarm will occur. If the board is properly detected after the unit has alarmed, the alarm will be cleared. -

Page 50: Figure 17: Prism 2 Compressor Alarms Screen

In the Prism 2 Alarm Menu, Click OK on Compressor Alarms and the following detail screen will appear: Refer to the individual RSM Technical Guides for more details. Figure 18: Prism 2 EVAP Module Alarms Screen Figure 17: Prism 2 Compressor Alarms Screen VCCX2 Controller Technical Guide... -

Page 51: Trend Logs

AlrmGrp5 (Bit String)* Refrigeration Module Alarms Table 12: RSMZ Module Trend Log Binary Inputs Status Bin IN (Bit String)* Relays Status of VCCX2 and EM1 Main Rly (Bit String)* Relays Status of 12 Relay Expansion Exp Rly (Bit String)* Module * Bit String and Enumeration Value information and interpretation is explained in the paragraphs and tables at the end of this section. -

Page 52: Table 13: Rsmv/Rsmd Module Trend Logs

A2 Discharge Temperature 1DisChg2 (ºF) Relay Status 1Relay1 (Bit String)* * Bit String and Enumerated Value information and interpretation is explained in the paragraphs and tables at the end of this section. Table 13: RSMV/RSMD Module Trend Logs VCCX2 Controller Technical Guide... -

Page 53: Table 15: Rsmz Module Comp Status Trend Log

1 = Timer 5RSMAlrms Compressor2_NotRunning Exceeded 6RSMAlrms LowSuperheat Table 17: RSMZ Module VFD Status Trend Log HighDischargeTemperature DMQ_NoDetect ModBusSlaveCommTO LowSuctionComp2Off 1024 TripHighDiscPSI_Comp2 2048 HighSuperheat 4096 HighEvapTemp 8192 EmergencyShutdown Table 16: RSMZ Module RSM Alarm Trend Log VCCX2 Controller Technical Guide... - Page 54 The tables on the following pages provide the bits, values and to decode the VCCX2 trend log items that are indicated as being descriptions for the various points on the VCCX2 Controller and bit string values.

-

Page 55: Table 18: Vccx2 Trend Log Bit Strings

VCCX2 Relay #7 Configurable VCCX2 Relay #8 Configurable EM1 Relay #1 Configurable EM1 Relay #2 Configurable 1024 EM1 Relay #3 Configurable 2048 EM1 Relay #4 Configurable 4096 EM1 Relay #5 Configurable Table 18: VCCX2 Trend Log Bit Strings VCCX2 Controller Technical Guide... -

Page 56: Table 19: Vccx2 Trend Log Bit Strings (Continued)

Defrost Mode Relay 1 Active Relay 2 Active RSMV/RSMD 1Relay1 Relay 3 Active 2Relay2 Relay 4 Active 3Relay3 Relay 5 Active 4Relay4 Unloader 1 Active Unloader 2 Active Table 19: VCCX2 Trend Log Bit Strings (continued) VCCX2 Controller Technical Guide... -

Page 57: Troubleshooting

This green LED lights up when the proof of flow contact is BI1 - closed. The VCCX2 Controller is equipped with LEDs that can be used to verify operation and perform troubleshooting. There are LEDs This green LED lights up when the dirty filter switch is closed. -

Page 58: Figure 19: Vccx2 Controller Led Locations

BINARY INPUT LEDs APPLICATION HB LED OPERATING SYSTEM HB LED STATUS 1 & 2 LEDs E-BUS LED POWER LED BACNET LED Figure 19: VCCX2 Controller LED Locations RELAY OUTPUT TERMINALS YS102482 REV1 4992 1002 10uF www.aaon.com STATIC PRESSURE 1002 EXHAUST DUCT... -

Page 59: Temperature Sensor Testing

1.246 12191 2.746 57.2 3015 1.159 20.6 11906 2.717 2743 1.077 21.1 11652 2.691 62.7 2502 1.001 21.7 11379 2.661 65.6 2288 0.931 Table 20: 0-5V Temperature Sensor - Voltage and Resistance for Type III Sensors VCCX2 Controller Technical Guide... -

Page 60: Pressure Sensor Testing

GND terminal and the “+” (plus) lead on the right side of the Place the “-” (minus) lead on terminal labeled GND and the “+” resistor labeled R85. Be sure to replace the jumper after checking. lead on terminal AI5 on the VCCX2 Controller. DUCT STATIC PRESSURE SENSOR BUILDING PRESSURE SENSOR... -

Page 61: Appendix A: System Configuration

Networked System For a networked single loop system, a range of one to 59 VCCX2 Controllers sharing information, connect the controllers together using AAON communications wire or 18-gauge, two-conductor, twisted pair with shield wire (Belden #82760 or equivalent). -

Page 62: Stand-Alone System Layout

APPENDIX A: SYSTEM CONFIGURATION Stand-Alone System Layout Figure 21: Typical Stand-Alone System Layout VCCX2 Controller Technical Guide... -

Page 63: Networked System Single Loop Layout

18-30 VAC 18-30 VAC 18-30 VAC transformer sizing. (10 VA) (10 VA) (10 VA) (10 VA) (10 VA) Connect to next VAV/Zone BACnet Controller ® on local loop Figure 22: Typical Networked Single Loop System Layout VCCX2 Controller Technical Guide... -

Page 64: Networked System Multiple Loop Layouts

1002 1002 1002 Connect to MiniLink PD 5 Loop 3 YS102398 REV 3 PIC32 MLPD transformer sizing. MADE IN USA ADDRESS POWER Line oltage 18-30 VAC (6 VA) Figure 23: Typical Networked Multiple Loop System Layout VCCX2 Controller Technical Guide... -

Page 65: Appendix B: Lcd Screens

The <MENU> key cancels editing when in Edit Mode. The screen you were editing will return to its original value and the underscore will disappear. A second press of the <MENU> key will return you to the Main Menu. Table 24: Editing Key Functions VCCX2 Controller Technical Guide... -

Page 66: Main Screens Map

0.0 % XX.X vdc MSTPBaud SA Temp See the following pages for detailed descriptions of NOTE: XXXXX XX.X° the options for each menu. EBUS RA Temp XX Speed XX.X° OA Temp XX.X° 0.0 % CO2Level X ppm VCCX2 Controller Technical Guide... -

Page 67: Screen Descriptions

Used to override relay and analog outputs. Override Air Balance screens that can be used by air Balance balance to set min and max fan speeds. Factory This screen is for AAON factory use only. Testing Table 25: Main Screens VCCX2 Controller Technical Guide... -

Page 68: Table 27: Settings Screens

RA Temp Return air temperature. XX.X° OA Temp Outdoor air temperature. XX.X° OA RH Outdoor air humidity. 0.00% - 100%. X.X % CO2Level Carbon dioxide level. 0.00 ppm to 5000 ppm. X ppm Table 28: Status Screens VCCX2 Controller Technical Guide... -

Page 69: Table 29: Alarms Screens

RELAY Relay run time exceeded alarm RUNTIME ECONO Title 24 Economizer alarms FAILURE RET FAN Return/Exhaust fan proving alarm FAILURE DIR FIRE Direct fire heat alarm ALARM Fan Array Controller alarm ALARM Table 29: Alarms Screens VCCX2 Controller Technical Guide... -

Page 70: Table 30: Output Override Screens

Maximum fan voltage. 0.0 to 10.0 VDC. Press the 10.0 VDC <UP> and <DOWN> buttons to change the value. RELAY #1 VCCX2 controller relays 1-8. Press the <UP> Default is 10.0. AUTO button to change the value. Default is AUTO. -

Page 71: Appendix C: Bacnet Guide

1. All wiring to be in accordance with local and national electrical codes and specifications. 2. All communication wiring to be 18-gauge minimum, two-conductor, twisted pair with shield. Use Belden #82760 or equivalent. Figure 25: VCCX2 BACnet Connection to MS/TP Network VCCX2 Controller Technical Guide... -

Page 72: Analog Inputs

Return Air Bypass Modulating Cooling Position AI: 34 Current percentage of the Modulating Chilled Water Signal Modulating Heat Position AI: 35 Current percentage of the Modulating Heating signal (Hot Water or SCR heat) Objects labeled AI are read-only. VCCX2 Controller Technical Guide... - Page 73 B1 Compressor Signal AI: 69 Current Compressor B1 Modulating Cooling Signal B2 Compressor Signal AI: 70 Current Compressor B2 Modulating Cooling Signal B1 Condenser Signal AI: 71 Current B1 Condenser Signal Objects labeled AI are read-only. VCCX2 Controller Technical Guide...

- Page 74 Current Compressor C1 Suction Line Temperature (Heat (Heat Pump) Pump) C2 Condenser Suction Temp AI: 107 Current Compressor C2 Suction Line Temperature (Heat (Heat Pump) Pump) C1 Superheat Temperature AI: 108 Current Compressor C1 Superheat Temperature Objects labeled AI are read-only. VCCX2 Controller Technical Guide...

- Page 75 D1 Discharge Temperature AI: 141 Current Compressor D1 Discharge Temperature D2 Discharge Temperature AI: 142 Current Compressor D2 Discharge Temperature D1 Leaving Water Temp AI: 143 Current D1 Leaving Water Temperature for WSHP Objects labeled AI are read-only. VCCX2 Controller Technical Guide...

- Page 76 See RSMZ Faults Bits on page 91. RSMZ 2 Lockouts AI: 182 Current RSMZ 2 Lockouts See RSMZ Lockouts Bits on page 91. RSMZ 3 Condenser Fan AI: 183 Current RSMZ 3 condenser fan signal Objects labeled AI are read-only. VCCX2 Controller Technical Guide...

- Page 77 Current RSMZ 5 Warnings See RSMZ Warnings Bits on page 91. RSMZ 5 Comp VFD Alarms 1 AI: 225 Current RSMZ 5 Comp VFD Alarms 1 See RSMZ Alarms 1 Bits on page 92. Objects labeled AI are read-only. VCCX2 Controller Technical Guide...

- Page 78 Current Subcooling Module 2 Sub Cool 1 reading SUB 2 Sub Cool 2 AI: 266 Current Subcooling Module 2 Sub Cool 2 reading SUB 2 Sub Cool 3 AI: 267 Current Subcooling Module 2 Sub Cool 3 reading Objects labeled AI are read-only. VCCX2 Controller Technical Guide...

- Page 79 Space Dew Point AI: 285 Current value of the calculated Space Dew Point. Return Dew Point AI: 286 Current value of the calculated Return Dew Point. Objects labeled AI are read-only. VCCX2 Controller Technical Guide...

-

Page 80: Analog Values

Warm-Up Mode activates if the Return Target Temperature) Air is below this temperature by one degree Objects labeled AV are read/write. The only sensor values that can be written to are AV points 72, 73, and 76 through 79. VCCX2 Controller Technical Guide... - Page 81 Temperature at which the Low Ambient Relay activates in -30°F (-34.4°C) 70°F (21.1°C) Setpoint the Occupied or Unoccupied Mode Objects labeled AV are read/write. The only sensor values that can be written to are AV points 72, 73, and 76 through 79. VCCX2 Controller Technical Guide...

- Page 82 Min Damper Position is proportionally reset between the configured Min Damper Position and the Max Position in High CO2. Objects labeled AV are read/write. The only sensor values that can be written to are AV points 72, 73, and 76 through 79. VCCX2 Controller Technical Guide...

- Page 83 Dehumidification. During Coil Temp Reset, this is the lowest Space RH value that corresponds to the High Coil Temp Setpoint. If the VCCX2 is configured for indoor dewpoint control, this point displays Dew Point instead of Humidity. Indoor Humidity Setpoint High...

- Page 84 This must be an infrequent event, so the default is 15 minutes. Objects labeled AV are read/write. The only sensor values that can be written to are AV points 72, 73, and 76 through 79. VCCX2 Controller Technical Guide...

- Page 85 BMS wants them disabled. Supply Air Dew Point Setpoint AV: 99 When the VCCX2 is configured for DX-DOAS control it modulates the compressors to try to maintain the Supply Air Dew Point Setpoint during dehumidification mode. Objects labeled AV are read/write. The only sensor values that can be written to are AV points 72, 73, and 76 through 79.

-

Page 86: Binary Inputs

BI: 36 Occurs when the Controlling Sensor Temperature rises above the Cooling Mode Enable Setpoint plus the Control Mode High Alarm Offset. Applies only to Space or Return Air Temperature controlled units. Objects labeled BI are read-only. VCCX2 Controller Technical Guide... - Page 87 BI: 76 Status of MHGRV Controller A1 Compressor Enable BI: 77 Current Status of Enable Signal to Compressor A1 A2 Compressor Enable BI: 78 Current Status of Enable Signal to Compressor A2 Objects labeled BI are read-only. VCCX2 Controller Technical Guide...

- Page 88 Emergency Shutdown Input on Module D Refrigerant Module 4 Relay 1 BI: 120 Current Status of Compressor 1 Enable Relay Refrigerant Module 4 Relay 2 BI: 121 Current Status of Compressor 2 Enable Relay Objects labeled BI are read-only. VCCX2 Controller Technical Guide...

- Page 89 Heat Enable signal is removed and direct fire heating is locked out. Direct Fire Setpoint Override BI: 149 Indicates the max calculated heat rise is limiting the Supply Air Setpoint to a lower value. Objects labeled BI are read-only. VCCX2 Controller Technical Guide...

-

Page 90: Enumerated Fields

VCCX HVAC MODE STATUS = ENUMERATED ITEM ENUM Vent Mode Cooling Mode Heating Mode Vent RH Mode Cooling RH Mode Heating RH Mode Warm Up Mode Purge Mode Defrost Mode Cool Down Mode Table 34: VCCX Mode Status = Enumerated VCCX2 Controller Technical Guide... -

Page 91: Bitfields

0=Voltage Okay; 16384 Emergency Shutdown Exceeded 1=Voltage Exceeded Table 36: RSMZ Faults Status Bit Strings Torque 16384 0=Torque Okay; Exceeded 1=Torque Exceeded Timer 32768 0=Timer Okay; Exceeded 1=Timer Exceeded Table 38: RSMZ Drive Status Bit Strings VCCX2 Controller Technical Guide... -

Page 92: Table 39: Rsmz Module Vfd1 Alarm Trend Log

24 V Supply Low Mains Failure 1.8V Supply Low 1024 Brake Resistor 2048 Brake IGBT 4096 Option Change 8192 Drive Initialized 16384 Safe Stop 32768 Mech brake low Table 40: RSMZ Module VFD2 Alarm Trend Log VCCX2 Controller Technical Guide... -

Page 93: Bacnet Protocol Implementation Conformance Statement - Vccx2 V1.90 And Previous

APPENDIX C: BACNET GUIDE BACnet Protocol Implementation Conformance Statement - VCCX2 v1.90 and previous BACnet Protocol Implementation Conformance Statement Date: December 2017 Vendor: AAON, Inc. Product: VCCX2 Controller Product Model Number: ASM01698 Product Version: 1.13 Product Description: HVAC Unit Controller... -

Page 94: Bacnet Protocol Implementation Conformance Statement - Vccx2 V2.00 And On

APPENDIX C: BACNET GUIDE BACnet Protocol Implementation Conformance Statement - VCCX2 v2.00 and on BACnet® Protocol Implementation Conformance Statement Date: January 2023 Vendor: AAON Inc. Product: VCCX2 Controller Product Model Number: ASM01698 Product Version: FW v1.28 Product Description: HVAC Unit Controller... - Page 95 PARTS: For replacement parts, please contact your local AAON Representative. 2425 So. Yukon Ave • Tulsa, OK • 74107-2728 Ph: (918) 583-2266 • Fax: (918) 583-6094 AAON P/N G115820, Rev. V Created in the USA • © February 2024 AAON All Rights Reserved...

Need help?

Do you have a question about the VCCX2 and is the answer not in the manual?

Questions and answers