Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Brooks Marathon Express

- Page 1 Marathon Express™ User Manual Part Number 605914 Rev. B...

- Page 2 Marathon Express Part Number: 605914 Rev. B Brooks Automation, Inc. Information provided within this document is subject to change without notice, and although believed to be accurate, Brooks Automation, Inc. assumes no responsibility for any errors, omissions, or inaccuracies. ABF™, AcuLigner™, Advan Tag™, Align™, AutoTeach™, ATR™, AXM™, Basic Blue™, BiSymmetrik™, CenterSmart™, Crate to Operate™, CrossingConnect™, DARTS™, E nerta™, e-RMA™, e-Spares™, e- Volution™, F alcon™, FastRegen™, FIXLOAD™, FrogLeg™, Independent Twin Linear Exchange™, InLigner™, Interface™, I soport™, ITLX™, Jet™, Jet Engine™, LEAP™, LowProfile™, M2 Nano™, PASIV™, PowerPak™, PerformanceBlue™, Plate Auditor™, PowerPak™, PowerTools™, PuroMaxx™, QuadraFly™, Radius™, Radient™, Radient Express™, Reliance™, Reliance ATR™, RetroEase™, SCARA™, SmartPM™, SPOTLevel™, Sprint™, Synetics™, The New Pathway to Productivity™, Time Optimized Trajectory™, Time Optimal Trajectory™, Time Optimized Path™, TopCooler™, TopLigner™, Ultimate Blue™, VAC-407™, VacuTran™, VersaPort™, and WaferEngine™ are trademarks of Brooks Automation, Inc. AcuTran®, A syst®, Crossing Automation®, Fusion®, GOLDLink®, Guardian®, H elix®, L eapfrog®, MagnaTran®, ...

- Page 3 Chelmsford, MA 01824 U.S.A. For Technical Support: Location Contact Number Website +1-800-447-5007 (Toll Free) North America +1-978-262-2900 (Local) +49 800 000 9347 (Toll Free Germany) Europe +49 364 176 9999 6 (Has Toll) +81 120-255-390 (Toll Free) Japan +81 45-330-9005 (Local) http://www.brooks.com/ China +86 21-5131-7066 +886 080-003-5556 (Toll Free) Taiwan +886 3-5525258 (Local) Korea 1800-5116 (Toll Free) +65 1-800-4-276657 (Toll Free) Singapore +65 6309 0701 (Local) Contact Technical Publications directly: Technical.Publications@brooks.com Accelerating Innovation Copyright © 2023, Brooks Automation, Inc.

- Page 4 Zhangjiang Hi-Tech Malaysia Brooks Automation Ltd. (Germany) GmbH Park P udong, Shanghai ...

- Page 5 Brooks Automation Part Number: 605914 Rev. B Revision History Revision Date Action Author EC146354 6/29/2023 Initial release. K. Forscher Added AC Power Distribution information to the EC146805 7/13/2023 K. Forscher Operational Interfaces and Operation chapters. Copyright © 2023, Brooks Automation, Inc.

-

Page 6: Table Of Contents

Mechanical Specifications Electrical Specifications Chamber Heating and Cooling Facilities Specifications Communications Specifications Center of Gravity and Floor Loading Site Requirements for Moving the Marathon Express Process Module Space Allocation Service and Exclusion Zones 2. Safety Regulatory Compliance and Declaration of Incorporation Explanation of Hazards and Alerts Safety Text Safety Icons Signal Words and Color Alert Example General Safety Considerations Illustration of Hazard Locations Safety and Identification Labels Illustration of Hazard Locations Interlocks Lockout/Tagout Mechanical Hazards Lid Lockout/Tagout Procedure Electrical Hazards Disconnect Devices Laser Hazards Thermal Hazards Vacuum Hazards Ergonomics Hazards Tip Hazard Environmental Information Noise Emission Vibration Copyright © 2023, Brooks Automation, Inc. - Page 7 Installation Procedure Procedure Category Required Tools and Equipment Remove Protective Packaging Removing Shipping Brackets Installing the Vacuum Cassette Elevators Installing the Marathon Express Mounting the Process Modules to the MX System Intermodule Connections Facilities Connections Electrical EMO Circuit Communications Connections Power-up Sequence 4. Subsystems System Overview Transport Chamber Transport Chamber Lid Assembly Lid Operation Frame Assembly Power Distribution AC Power Distribution Circuit Protection Vacuum Systems Pumping System Chamber Isolation Valves Venting System Vacuum Measurement System Gauges Vacuum System Control Pneumatic System Gas System Water System Transport Chamber Heating System Copyright © 2023, Brooks Automation, Inc.

- Page 8 Material Presence Sensors MagnaTran 7 or LEAP Vacuum Robot Control/Display Module Vacuum Load Locks 5. Operational Interfaces Heater Power Supply Remote AC Power Distribution Power Connections AC Power Distribution Cable 6. Operation Theory of Operation Station Coordinate System Marathon Express Frames of Reference Robot’s Frame of Reference Aligner’s Frame of Reference System Operation Overview Determining Material Locations Pick and Place Commands Material Presence Sensing Wafer Mapping Radial Motion Sensors Controls and Indicators AC Power Distribution Heater Power Supply Temperature Controller Ethernet to Serial Gateway Module Ethernet Switch Module Safety Interlocks Lid Open Emergency Off (EMO) Circuit Lid Lifter Operation Raising the Lid Lowering the Lid Control/Display Module (CDM) Operation Copyright © 2023, Brooks Automation, Inc.

- Page 9 Wafer Cooling System Pneumatic (Air Distribution) System Gas Facilities Operation Controls and Indicators TopCooler Operation TopLigner Vacuum Aligner Operation Vacuum System Operation Initial Conditions Chamber Bakeout Start-up Exchange Wafers in the Load Locks Shut down from high vacuum Vent Transport Chamber Vent Load Locks Venting the Chambers - Profiled Vent Start-up Normal Running 7. Command Reference 8. System Alignment Overview Procedure Category Required Tools and Test Equipment Alignment Strategy Alignment Overview Alignment Process Level the VCE Platforms Level the Process Modules and Dock to the Marathon Express Adjust the Robot’s End Effectors System Preparation Initializing the Vacuum Cassette Elevators Initializing the TopLigner Initializing the TopCooler Initiating the CDM Opening the Chamber Lid Copyright © 2023, Brooks Automation, Inc.

- Page 10 Adjust the Load Lock Platform Set the Load Lock T and R Coordinates Align the Load Lock’s SPS Teach the Robot the Integral Wafer Buffer Station Procedure Teach the Robot the Process Modules Procedure Teaching Pan ’B’ on a Dual End-Effector Arm Set Fine-Tuning the Station Assignment Using the Aligner as a True Position Reference Using Physical Location as a True Position Reference System Alignment Check-out Alignment Procedure 9. Maintenance and Repair Preventative Maintenance Parts Pad Cleaning Procedure Maintenance Procedure Cleaning Procedure Maintenance Procedure TopCooler Cool Chuck Cleaning Maintenance Procedure O-Ring Removal/Replacement/Cleaning Maintenance Procedure Verifying Flatness of Robot’s End Effector Measurement Procedure Adjusting the Robot’s End Effector(s) Adjustment Procedure Repair Philosophy Repair Procedures Wafer Change-Over Procedure Maintenance Procedure Removing/Replacing Viewports Lid Replacement Copyright © 2023, Brooks Automation, Inc.

- Page 11 Brooks Automation Part Number: 605914 Rev. B Lid Lifter Replacement Vacuum Robot, Arm, or End Effector Replacement Pad Removal/Replacement Heater Cartridge Replacement TopCooler Poppet Open/Close Sensor Adjustment TopLigner Support Pin Replacement Isolation Valve Replacement 10. Troubleshooting Initial Troubleshooting Interlocks Material Transport TopLigner Vacuum Aligner Pressure/Indicator Switch Vacuum System 11. Field Replaceable Units Marathon Express 12. Appendices Appendix A: Contact Brooks Automation Technical Support Appendix B: Factory Default Settings Default Robot Settings Default VCE 6 Drive Settings Default TopLigner Vacuum Aligner Settings Appendix C: Station Identification Appendix D: Document Abbreviations Appendix E: Consumables Appendix F: Packing and Shipping Instructions Packing Procedure Appendix G: Material Safety Information Copyright © 2023, Brooks Automation, Inc.

-

Page 12: Introduction

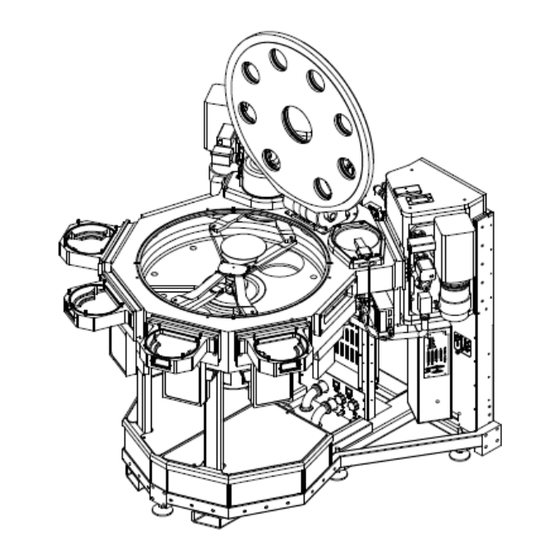

1. Introduction Marathon Express System Overview Part Number: 605914 Rev. B 1. Introduction This Introduction provides a brief overview of the Brooks Automation Marathon Express™ Cluster Tool Integration Platform highlighting its features, components, operation, and specifications. Additionally, the chapter organization and a description of each chapter’s contents is presented, and notation conventions are explained. This Marathon Express is intended for use by industrial customers and should be serviced only by Brooks or Brooks trained representatives. The service manuals and related materials are provided in English at no charge and are intended for use by experienced technicians. It is the responsibility of the user to obtain and assure the accuracy of any needed translations of manuals. If you require assistance please contact Brooks service department. Contact information can be found at www.brooks.com. System Overview The Brooks Automation Marathon Express (MX) Cluster Tool Integration Platform transfers 100 mm to 200 mm wafers or 100 mm to 150 mm square substrates from a Vacuum Cassette Elevator Load Lock into a Vacuum Back End for access to multiple Process Modules for multi-step processing without leaving the vacuum environment. The MX system provides SEMI-standard compatible process module and material carrier interface systems, with a full set of options, to meet factory interface requirements. The Brooks Automation MX system is designed for use in a vacuum transport cluster tool system. The full Marathon Express system includes the cluster tool platform that accommodates up to 6 Process Modules, two vacuum cassette elevators, and a vacuum robot. Figure 1-1 shows a Marathon Express Cluster Tool with all Brooks Automation components. Copyright © 2023, Brooks Automation, Inc. -

Page 13: Options

Brooks Automation 1. Introduction Part Number: 605914 Rev. B System Overview Figure 1-1: Brooks Automation Marathon Express The SEMI S2 and CE regulatory compliant Marathon Express Cluster Tool Integration Platform offers integral support for all system structures. The integrated frame architecture of the MX system supports standard OEM SEMI roll up style process modules with standard interfacing to frame and facet and MESC bolt on style process chambers. Options TopCooler (wafer cool module) VX Aligner (vacuum aligner) Complete slot valve/process module/robot hardware interlocking depending on System Integration Level Subsystems The Marathon Express is made up of several functional subsystems designed for ease of use, maintenance, and repair. These subsystems are modular in design to allow ease of maintenance and to minimize Mean Time To Repair (MTTR). The individual modules that make up the MX system are described briefly below and in detail in "Subsystems". Marathon Express™ Vacuum Transport System The Brooks Automation Marathon Express Vacuum Back End is a multifaceted Cluster Tool Integration Platform utilizing proven Brooks components such as the VCE vacuum cassette elevator and MagnaTran LEAP vacuum robot. Copyright © 2023, Brooks Automation, Inc. - Page 14 VCE 6 Vacuum Cassette Elevator The Brooks Automation VCE allows SEMI standard H-bar wafer cassettes to be introduced into, and removed from, the high-vacuum environment of the Transport Module without disturbing that vacuum environment. The VCE consists of a wafer cassette elevating mechanism housed in an aluminum vacuum load lock chamber. The elevator raises or lowers a cassette so that individual slots are aligned with the system Material Transport Plane for wafer transport by the vacuum robot. See the VCE User Manual for more information on the VCE. See the robot manual for more information on the robot. Vacuum Aligners TThe vacuum aligners accept randomly-oriented wafers and rotates them while scanning for fiducial location and eccentricity. Using the eccentricity information provided the robot can then pick up the wafer using an offset to center the wafer on the end effector. Wafer Cool Station The Brooks Automation TopCooler is designed to cool wafers in SEMI-standard 100 mm through 200 mm sizes prior to further processing or reinsertion into a cassette. The cooling cycle involves discharging a fixed quantity of gas into the closed cool chamber, which provides conductive heat transfer between the gas and a chill plate to cool the wafer. Controls The Marathon Express is available with several different control configurations. These configuration are described briefly below and in detail in "Electrical System" on page 97. Configuration The configuration of the Marathon Express is determined by the user and is based on the Basic Configuration needed and the System Integration Level required. Basic Configuration The Basic Configuration of the Marathon Express is determined by thewafer size and the number of Process Modules (PMs) accommodated. System Integration Level The System Integration Level is determined by the user’s requirements for system integration and controls and is available in Levels as described below. This manual provides complete coverage for the hardware used in all integration levels of the Marathon Express and the software used through the Level 2.5 integrated systems. Copyright © 2023, Brooks Automation, Inc.

-

Page 15: Supplementary And Related Documentation

Level 2.5 - Marathon Express with Electrical Integration This level of integration provides complete Electrical Integration, including Controls Wiring and System Power. This system includes all components, integration, and testing for a complete Controls solution. Level 2.5 provides a complete component set including all cabling and complete Power Distribution as detailed below. All Level 2 items Connector panel with internal wiring and power distribution Supplementary and Related Documentation This user manual provides documentation for operation and maintenance of the Brooks Automation Marathon Express Cluster Tool Integration Platform. While this document covers specific information and adjustments for the Marathon Express, there may be information in other manuals which affect the settings or operating mode of the MX system and the attached components. The Marathon Express is set to system specifications and acceptance tested at Brooks Automation. Before adjusting or changing settings on a Marathon Express, consult the following documentation: Brooks Automation robot manuals Brooks Automation VCE U ser Manual OEM Components Manuals (supplied with this manual) Process Module User Manual Process Module Controller User Manual Transport Controller User Manual Copyright © 2023, Brooks Automation, Inc. -

Page 16: Manual Notation

Supplementary and Related Docu- Part Number: 605914 Rev. B mentation NOTE: All documents cited should be the latest revision. This manual is intended to provide information about a wide variety of Marathon Express configurations and options. It may contain references to items not installed on a specific system. The commands for controlling the robots and other components used in the Marathon Express are defined in their user manuals. This user manual may refer the reader to these manuals for additional information. This manual contains, as addendums and attachments, customized documents for a specific build of the Marathon Express. These documents are provided to allow service personnel to identify specific parts within the system and aid in maintenance and troubleshooting. This manual and all addendums and attachments are not controlled. Changes may have been made or additional documents or drawings added to the system documentation at any time. To identify the current revisions or to obtain a current set of drawings and documents, contact Brooks Automation Customer Support. Manual Notation This manual uses a standard notation system to provide consistent descriptions of all items and functions associated with all Brooks Automation devices. These standards include; hardware notation, software notation, and descriptive warnings. These notation standards identify tasks to be performed by the user during a service, installation, or operation procedure, or as a specific input to the Marathon Express. In applications where “should” or “shall” is used, conformance to this application is required. Where “may”, “suggested”, or “preferred” is used, conformance is not required. Copyright © 2023, Brooks Automation, Inc. -

Page 17: Specifications

NOTE: These dimensions are for standard MX system Range of Motion configurations, dimensions can vary for customized configurations Maximum Noise Level 55 dB (A) 900 mm at VCE platform (SEMI standard) Transport Plane 1100 mm (43.31 in) per SEMI E21 at Process Module side (3.78 mm (0.15 in) above slot centerline) 100 mm 25 mm Material Sizes (wafers) 150 mm 200 mm with or without notched fiducial per SEMI M1 100 mm square Material Sizes (substrates) 125 mm square 150 mm square 400g maximum with BiSymmetrik arms Material Weight 200g maximum with Leapfrog arms 6 mm maximum with BiSymmetrik arms Material Thickness 3 mm maximum with Leapfrog arms Material Transparency 0 to 96% MX 800: Approximately 117.7 liters (7,184 in3) Vacuum Chamber Volume (typical values MX 700: Approximately 117.1 liters (7,150 in3) shown, can vary based on configuration): MX 600: Approximately 69.0 liters (4,212 in3) VCE 6: Approximately 50.0 liters (3,051 in3) (each) Copyright © 2023, Brooks Automation, Inc. -

Page 18: Environmental Specifications

Alignment time: 4.8 sec (wafer) 9 - 13.8 sec (square substrate) Thermal Transfer Gas: Argon, Nitrogen (factory) optional Wafer Cooler Module Gas Delivery Pressure: 20 psi max Gas Consumption: 2 cc/cycle at regulator pressure Integral Wafer Buffer Station Capacity: 4 wafers at 5.5 mm (0.22 in) pitch Capacity: 4 wafers at 6.0 mm (0.236 in) pitch Buffer Station Volume: Approximately 4.5 liters (276 in Mounting: Facet mount with slot valve and atmospheric door Small Volume Lock Volume: Approximately 12.0 liters (732 in Environmental Specifications ISO 14644-1 Class ISO 6 or better cleanroom ambient. Table 1-2: Environmental Specifications Specification Value Operating: 20° C to 30° C (68° F to 86° F) Temperature Shipping: -25° C to 55° C (-13° F to 131° F), up to 65° C (149° F) for 24 hrs. max Storage: -25° C to 55° C (-13° F to 131° F), up to 65° C (149° F) for 24 hrs. max Humidity 30% to 55% (relative, non-condensing) Standard lighting provided in the cleanroom environment where the Marathon Express is Lighting installed is sufficient for proper operation. Maintenance may require a user-supplied service light (i.e., flashlight). Copyright © 2023, Brooks Automation, Inc. -

Page 19: Mechanical Specifications

Stainless Steel, Cold Rolled Steel, Baked Powder Coated Epoxy, 7740 Pyrex®, 7056 (Atmosphere) Glass, Viton®, Lexan® 6061 T6 Aluminum, 5080R Aluminum, 316 Stainless Steel, AM350 Stainless Steel, Sintered Exposed Materials Nickel, Electroless Nickel Plate, 7740 Pyrex, 7056 Glass, BK7 Glass, Teflon®, Viton, (Vacuum) Kalrez®, Tinned Copper Wire, Quartz (TopCooler option) 100 mm, 125 mm, 150 mm, and 200 mm Cassette Type SEMI standard cassettes 25 or 26 wafer cassette configurations At VCE interface panel As specified by user At Marathon Express Vacuum Transport System ISO 160 Port for High Vacuum Pump ISO 200 Port for High Vacuum Pump Vacuum Ports KF 50 Port for Venting KF 40 Port for Rough Pump KF 25 Port for Material Sensor (x facet number) KF 25 Port for Vacuum Gauging (x 2) KF 16 Port for Vacuum Gauging (x 2) 1/4 inch VCR fitting at Nitrogen Facilities Connection Nitrogen Port To support venting capacity, a minimum of a 3/8 inch O.D. line is required with a reducer to connect to the 1/4 inch VCR fitting. Argon Port 1/4 inch VCR fitting at TopCooler Facilities Connection Pneumatic Port 10 mm Quick Connect Water 1/2 inch OD tubing, Swagelok interface Copyright © 2023, Brooks Automation, Inc. -

Page 20: Electrical Specifications

Adjustable feet to meet WTP Leveling Provision -0.4/+1.0 inch range Rolling Provision 3 casters, removable Lifting Provision Built-in fork tubes, one-side access Hold-down Pro- User supplied and installed brackets visions Electrical Specifications Overvoltage Category Table 1-4 describes electrical overvoltage categories. Brooks Automation has designed the Marathon Express as an Overvoltage Category II device. Table 1-4: Overvoltage Category Category Description Signal level (special equipment or parts of equipment, telecommunications, etc.) with smaller tran- Category I sient overvoltages than Overvoltage Category II. Local level (appliances, portable equipment, etc.) with smaller transient overvoltages than Over- Category II voltage Category III. Distribution level (fixed installation, building wiring, etc.) with smaller transient overvoltages than Category III Overvoltage Category IV. Category IV Primary supply level (overhead lines, cable systems, etc.). Copyright © 2023, Brooks Automation, Inc. -

Page 21: Chamber Heating And Cooling

120° C to 40° C in 2 hours (with water cooling option) (for base system as supplied by Cool-down Time Brooks Automation only, does not include any user attached modules) Facilities Specifications Table 1-6: Facilities Specifications Specification Value Typical configurations require the following supply of clean, dry (unfiltered), oil free air: Pneumatic 90 psig ±10 psig at 50 slm nominal, 200 slm maximum Typical configurations require the following supply of clean, dry nitrogen: Nitrogen <1 ppm contamination 40 psig ±5 psig at 100 slm nominal, 300 slm maximum Configurations using a facet mounted TopCooler may require the following supply of clean, dry argon: Argon <1 ppm contamination 20 psig -5/+0 psig at 10 sccm Typical configurations require the following differential vacuum supply (input to vacuum Vacuum, Backing aligner seals) 635 mm Hg at 50 cc/sec (25 in Hg at 3.05 ci/sec) Pumping speed, 900 lpm (32 cfm) minimum Vacuum, Rough Ultimate pressure, < 23 mTorr Pumping speed, 900 lpm (32 cfm) minimum Vacuum, Foreline Ultimate pressure, < 23 mTorr Copyright © 2023, Brooks Automation, Inc. - Page 22 UL489/IEC60947-2 compliant branch circuit breaker (circuit breaker supplied with Gen 5 EN system ACPD is 5,000 AIC). Electrical System Europe, Korea, Israel: 220 - 240V AC @ 50/60 Hz, single phase (phase to neutral), 8 A, based on configuration and operating mode. Inrush current < 38 A max for 1/2 to 1 cycle Overvoltage Category II The system must be installed on the load side of a user-supplied 10,000 AIC rated, UL489/IEC60947-2 compliant branch circuit breaker (circuit breaker supplied with Gen 5 EN system ACPD is 5,000 AIC). Three phase star (Y) connection: 50/60 Hz (Europe, Korea, Israel) 220 VAC @ 9.45 A per phase, total power 5.7 kVA 230 VAC @ 9.88 A per phase, total power 6.2 kVA 240 VAC @ 10.31 A per phase, total power 6.8 kVA Heater Power Supply incorporates a 10,000 AIC rated, UL489/IEC60947-2 compliant, branch curcuit breaker. Electrical Heater Delta connection: 50/60 Hz (Japan, USA) 200 VAC @ 15.58 A per phase, total power 5.7 kVA 208 VAC @ 16.85 A per phase, total power 6.2 kVA Heater Power Supply incorporates a 10,000 AIC rated, UL489/IEC60947-2 compliant, branch curcuit breaker. Copyright © 2023, Brooks Automation, Inc.

- Page 23 Specifications Specification Value Facilities chilled water must be supplied for cool modules and some pumps. Supply Pressure: 50 psig nominal, 70 psig maximum 30 psig minimum delta p between inlet and outlet 40 psig if equipped with turbo pumps (or manufacturers listed cooling requirements) 20 psi min is required to avoid boiling chamber cooling water during the system cartridge heater 120° C bake out Flow Rate: 15 l/m (4 gpm) Filtration: 200 um (0.5 mm Filter pre-installed) Temperature: 15° C ± 5° C (59° F ± 9° F) Water Acidity: 6.0 to 8.0 Ph Conductivity: 2000 μmhos/cm Dissolved Solids: < 75 ppm as calcium carbonate Corrosion Inhibitor: 300 - 600 ppm nitrite borate, 450 - 900 ppm sodium nitrite Organics, Intermittent Chlorination or Biocide application as required Open Systems: based on visual inspection (Do Not use algicides containing ethyl alcohol as it may degrade any seals it contacts) Organics, Closed Systems: Standard filter test count < 100 Exhaust Sufficient to support return from air lines and exhaust from vacuum pumps Water Return Sufficient to handle water flow. Nominal 20 psi, 70 psi max. Copyright © 2023, Brooks Automation, Inc.

-

Page 24: Communications Specifications

1. Introduction Marathon Express Specifications Part Number: 605914 Rev. B Figure 1-2: Marathon Express Space Requirements Table 1-7: Space Specifications Model Width Depth Height Width 1416.1 mm (55.75 1462.3 mm (57.57 1442.5 mm (56.79 MX 600 900.0 kg (1984 lb) 1416.1 mm (55.75 1442.7 mm (56.80 1442.5 mm (56.79 1014.0 kg (2236 MX 700 1431.8 mm (56.37 1479.3 mm (58.24 1444.0 mm (56.85 1451.5 kg (3200 ... -

Page 25: Center Of Gravity And Floor Loading

Brooks Automation 1. Introduction Part Number: 605914 Rev. B Specifications Center of Gravity and Floor Loading Center Of Gravity and Floor Loading information for the Marathon Express varies based on the configuration of the Transport Chamber and the options installed on the system. For the Center of Gravity and Floor Loading of the specific system refer to the Mechanical Layout Drawing supplied with this manual. Overturning Moment: 800 ft.lbs. applied at any PM facet PM Weight Supported: 100 kg (220.5 lb) maximum per PM Site Requirements for Moving the Marathon Express Various locations within the site where the Marathon Express will be installed must meet the following minimum requirements to ensure proper handling of the MX system: Door Openings: The Marathon Express has been designed to fit through standard door openings. People: A minimum of four people are required for moving the Mara thon Express within the facility. Floor: The Marathon Express system has been designed to roll easily across smooth interior floors only. The floor where the Marathon Express will be installed must be capable of supporting the weight of the MX system as shown in Table 1-7. The weight information provided is maximum weight, including VCEs, ... - Page 26 Marathon Express Specifications Part Number: 605914 Rev. B Figure 1-3: Example of Service and Exclusion Zones - Horizontal (See Interface Drawing) Figure 1-4: Example of Service and Exclusion Zones - Vertical (See Interface Drawing) Copyright © 2023, Brooks Automation, Inc.

-

Page 27: Safety

2. Safety Part Number: 605914 Rev. B 2. Safety Read the Safety Chapter Failure to review the Safety chapter and follow the safety warnings can result in death or serious injury. All personnel involved with the operation or maintenance of this product must read and understand the information in this safety chapter. Follow all applicable safety codes of the facility as well as national and international safety codes. Know the facility safety procedures, safety equipment, and contact information. Read and understand each procedure before performing it. It is the responsibility of each person working on this product to know the applicable regulatory safety codes as well as the facility safety procedures, safety equipment, and contact information. This chapter describes safety guidelines for the Brooks Automation Marathon Express. All personnel involved in the operation or maintenance of the Marathon Express system should be familiar with the safety precautions outlined in this chapter. The Brooks Automation Technical Support Group notifies users of record if additional safety-related upgrades or new hazards associated with the Marathon Express are identified. Copyright © 2023, Brooks Automation, Inc. -

Page 28: Regulatory Compliance And Declaration Of Incorporation

2. Safety Marathon Express Regulatory Compliance and Declaration of Part Number: 605914 Rev. B Incorporation Regulatory Compliance and Declaration of Incorporation The Marathon Express meets the applicable requirements of the European Union’s Machinery Directive 2006/42/EC as a partially completed machine. In accordance with the Directive, Brooks Automation has issued a Declaration of Incorporation and the Marathon Express does not have a CE mark affixed. The Marathon Express meets the applicable requirements of SEMI Guidelines. In addition to this section, other sections may include regulatory information. Copyright © 2023, Brooks Automation, Inc. -

Page 29: Explanation Of Hazards And Alerts

Danger signal word is white on a red background with an iconic exclamation point inside a yellow triangle with black border. Warning indicates a hazardous situation which, if not avoided, could result in death or serious injury. Warning signal word is black on an orange background with an iconic exclamation point inside a yellow triangle with black border. Caution indicates a hazardous situation or unsafe practice which, if not avoided, may result in minor or moderate personal injury. Caution signal word is black on a yellow background with an iconic exclamation point inside a yellow triangle with black border. Indicates a situation or unsafe practice which, if not avoided, may result in equipment damage. Notice signal word is white on blue background with no icon. Copyright © 2023, Brooks Automation, Inc. -

Page 30: Alert Example

2. Safety Marathon Express Explanation of Hazards and Alerts Part Number: 605914 Rev. B Alert Example The following is an example of a Warning hazard alert. Figure 2-1: Components of a Safety Alert Number Description How to Avoid the Hazard Source of Hazard and Severity General Alert Icon Signal Word Type of Hazard Hazard Symbol(s) Copyright © 2023, Brooks Automation, Inc. -

Page 31: General Safety Considerations

Emergency Off (EMO) This device is not equipped with an EMO disconnect device. Using this product without an Emergency Off (EMO) circuit may cause death or personal injury. The integrator and user are responsible for installation of the EMO disconnect device that complies with the mandated safety codes. Personnel servicing this product are responsible for disconnecting power as specified by the facility Lockout/Tagout procedures. Unauthorized Service Personal injury or damage to equipment may result if this product is operated or serviced by unauthorized personnel. Only qualified personnel are allowed to transport, assemble, operate, or maintain the Product. Properly qualified personnel are those who have received certified training and have the proper qualifications for their jobs. Training and Unauthorized Service Personal injury or damage to equipment may result if this product is operated or serviced by untrained or unauthorized personnel. Only qualified personnel who have received certified training and have the proper qualifications for their jobs are allowed to transport, assemble, operate, or maintain the product. Copyright © 2023, Brooks Automation, Inc. - Page 32 Wear protective eyewear when setting up or testing the system. Seismic Restraint The use of this product in an earthquake prone environment may cause equipment damage or personal injury. The user is responsible for determining whether the product is used in an earthquake prone environment and installing the appropriate seismic restraints in accordance with local regulations. Inappropriate Use Use of this product in a manner or for purposes other than for what it is intended may cause equipment damage or personal injury. Only use the product for its intended application. Do not modify this product beyond its original design. Always operate this product with the covers in place. Damaged Components The use of this product when components or cables appear to be damaged may cause equipment malfunction or personal injury. Do not use this product if components or cables appear to be damaged. Place the product in a location where it will not get damaged. Route cables and tubing so that they do not become damaged and do not present a personal safety hazard. Copyright © 2023, Brooks Automation, Inc.

-

Page 33: Illustration Of Hazard Locations

Brooks Automation 2. Safety Part Number: 605914 Rev. B Illustration of Hazard Locations It is the responsibility of each person working on this product to know the applicable regulatory safety codes as well as the facility safety procedures, safety equipment, and contact information. Please follow all facility and local wiring regulations before operating or servicing the product. Illustration of Hazard Locations Figure 2-2: Location of Hazardous Points Copyright © 2023, Brooks Automation, Inc. -

Page 34: Safety And Identification Labels

Table 2-1: Safety Labels placed on Product Caution Label - Heavy Object P/N: 70025562 Qty: Varies by configuration Location: On the top of the Chamber Lid Hazard Type: Heavy Object Possible injuries: Muscle strain or back injury How to avoid the hazard: Use proper lifting techniques when moving Warning Label - Moving parts P/N: 104162 Qty: Varies by configuration Location: On the sides of the Lid Lifter Hazard Type: Moving Parts Present Possible injuries: Serious injury to hands or fingers. How to avoid the hazard: Keep hands away from moving parts, disconnect and lockout power before servicing Caution Label - Hot Surfaces P/N: 144444 Qty: Varies by configuration Location: On Chamber Hazard Type: Hot Surfaces (Heater option only) Possible injuries: Burn How to avoid the hazard: Ensure all surfaces are cool before touching Copyright © 2023, Brooks Automation, Inc. - Page 35 Brooks Automation 2. Safety Part Number: 605914 Rev. B Safety and Identification Labels Warning Label - Impact hazard P/N: 130432 Qty: 1 Location: On the Lid Lifter Hazard Type:Impact Hazard Possible injuries: Serious injury or death How to avoid the hazard: Secure lid and follow lockout/tagout procedures before servicing Product Information Label P/N: 209930 Qty: 1 Location: On the Chamber and Frame Seismic Tie Down Point Label P/N: 130165 Qty: 3 Location: On the Frame Copyright © 2023, Brooks Automation, Inc.

-

Page 36: Illustration Of Hazard Locations

Safety and Identification Labels Part Number: 605914 Rev. B Illustration of Hazard Locations Figure 2-3: Label Locations on the MX System Table 2-2: Labels Used on the ACPDU Warning Label - Shock Hazard P/N: 130166 Qty: 1 Location: On the front of the AC Power Dis- tribution Unit Hazard Type: Hazardous voltage Possible injuries: Electric shock or burn How to avoid the hazard: Do not service while the ACPDU is energized Copyright © 2023, Brooks Automation, Inc. - Page 37 Safety and Identification Labels Warning Label - Power Requirements P/N: 119221 Qty: 1 Location: On the top of the AC Power Dis- tribution Unit Hazard Type: Hazardous voltage Possible injuries: Electric shock or burn How to avoid the hazard: Do not connect incor- rect power to ACPDU Label - Protective Earth Ground P/N: 106413 Qty: 1 Location: On the bottom of the AC Power Dis- tribution Unit next to the Ground Terminal Label - Do Not Use P/N: 70060555 Qty: A/R Location: On all unused AC Outlets on the ACPDU Product Information Label P/N: 002-5271-01 Qty: 2 Location: On the side of the AC Power Dis- tribution Unit Label - Field Replaceable Unit P/N: 130165 Qty: 1 Location: On the top of the AC Power Dis- tribution Unit Copyright © 2023, Brooks Automation, Inc.

- Page 38 Part Number: 605914 Rev. B Figure 2-4: Label Locations on the ACPDU Table 2-3: Labels Used on the Safety Hub Warning Label - Hazardous Voltage P/N: 70020026 Qty: 1 Location: On the top of the Safety Node Hazard Type: Hazardous voltage Possible injuries: Electric shock or burn How to avoid the hazard: Do not service while the Load Lock Node is energized Caution Label - Heavy Object P/N: 70025562 Qty: 1 Location: On the top of the Safety Node Hazard Type: Heavy Object Possible injuries: Muscle strain or back injury How to avoid the hazard: Use proper lifting techniques when moving Copyright © 2023, Brooks Automation, Inc.

- Page 39 Product Information Label P/N: 002-5271-01 Qty: 2 Location: On the rear of the Safety Node Label - Field Replaceable Unit P/N: 130165 Qty: 1 Location: On the top of the Safety Node Figure 2-5: Label Locations on the Safety Hub Table 2-4: Labels Used on the Robot Power Supply Warning Label - Hazardous Voltage P/N: 70022616 Qty: 1 Location: On the top of the Robot Power Sup- Hazard Type: Hazardous voltage Possible injuries: Electric shock or burn How to avoid the hazard: Do not service while the Robot Power Supply is energized Copyright © 2023, Brooks Automation, Inc.

-

Page 40: Interlocks

Marathon Express Interlocks Part Number: 605914 Rev. B Label - Field Replaceable Unit P/N: 130165 Qty: 1 Location: On the side of the Robot Power Sup- Figure 2-6: Label Locations on the Robot Power Supply Interlocks Safety interlocking capabilities exist for user safety and operational interlocks exist to protect the Marathon Express and the material moving through it. Refer to"Safety Interlocks" on page 121 for detailed operation. Refer to the controls manual for more information on safety interlocks. Safety Interlocks Overriding the safety interlocks could cause personal injury or death. Always use the safety interlocks. The following Safety Interlocks may exist on the Marathon Express: Lid Open - refer to "Raising the Lid" on page 123. Copyright © 2023, Brooks Automation, Inc. -

Page 41: Lockout/Tagout

Brooks Automation 2. Safety Part Number: 605914 Rev. B Interlocks Lockout/Tagout Per standard industry practices, lockout/tagout procedures must be followed when service or maintenance is performed on the Marathon Express system to prevent personal injury or equipment damage. Local or company procedures must also be followed; but where no procedures exist, follow the guidelines below. If a service lock or tag is installed, DO NOT remove the tag or engage the circuit breaker without proper authorization. Lockout / Tagout Working with energized equipment may cause sudden movement or electrical shock and may result in death or serious injury. All power to the Marathon Express must be disconnected per the facilities Lockout/Tagout procedure before servicing. All energy must be removed from the equipment per the facility’s Lockout/Tagout procedure before servicing. If local procedures are not available, follow the procedure for Lockout/Tagout in OSHA Standard 29CFR 1910.147. Copyright © 2023, Brooks Automation, Inc. -

Page 42: Mechanical Hazards

Automatic Movement / Crush hazard Whenever power is applied to the Marathon Express, the possibility exists of automatic movement that can cause serious injury or death. These components include: Robot Aligner Cool Module Poppet Load Lock Module(s) (AutoDoor, Arm, Platform) Atmospheric Doors Vacuum Slot Valves Isolation Valves Pumps Moving mechanisms do not have obstruction sensors and can cause serious personal injury or death. Do not operate the Marathon Express without the protective covers in place and all safety interlocks enabled. Do not operate the robot without the protective covers in place. Do not operate the Vacuum Slot Valves or Atmospheric Doors when the chamber lid is open. Copyright © 2023, Brooks Automation, Inc. -

Page 43: Lid Lockout/Tagout Procedure

Brooks Automation 2. Safety Part Number: 605914 Rev. B Mechanical Hazards Lid Lockout/Tagout Procedure Whenever the lid for the Transport Chamber is open the lockout/tagout device must installed to ensure it cannot be closed. Crush Hazard / Pinch Point The chamber lid can weigh up to 49.2 kg (108.4 lb). Personal injury could result in the squeezing or compression of head or arms when performing any service inside of the chamber during the lid is raised. Precautions should be taken when performing any service inside of the chamber when a lid is raised. Do not lean inside, or place hands or arms into the chamber unless the lid is in the full upright position. Personnel should not place their head or arms into the chamber without verifying plunger in lid lifter is fully engaged in open position in case of lifter failure. The only two acceptable positions for the lid are fully lowered, or fully raised (90°). Copyright © 2023, Brooks Automation, Inc. - Page 44 Mechanical Hazards Part Number: 605914 Rev. B Step Action Once the lid is in the fully open (90°) position insert the Lid Stop Block Foot between the lid and the chamber and centered against the Lid Lifter as shown in Figure 2-7 (adjust the position of the lid to greater than 90° if required). Figure 2-7: Installing Lid Lockout/Tagout Device Insert the Lid Stop Block against the lid between the arms of the Lid Lifter and slide it down until it engages the Lid Stop Block Foot as shown in Figure 2-7. Ensure that the Block is fully seated (adjust the position of the lid if necessary). Install a lock through the hole provided on the Lid Stop Block. Attach a tag to the lock describing the reason for the lockout/tagout. The tag on the lock must have the following information: Date of maintenance/service action Names of the persons performing the service procedure Short description of the service/maintenance action Signatures of the service supervisor and production supervisor Once the service procedure is complete remove the lock, the Lid Stop Block, and the Lid Stop Block Foot. As soon as the lockout/tagout device is removed, close and secure the lid. Copyright © 2023, Brooks Automation, Inc.

-

Page 45: Electrical Hazards

Maximum power consumption for the Marathon Express during normal operation is 200 - 240 VAC at 8 Amps and for the Marathon Express Heating System during bake-out operations is 200 - 240 VAC at 17 Amps. Improper handling of the power source or connecting devices may induce electrical shock or burn resulting in serious injury or death or cause an equipment fire. All power to Marathon Express must be disconnected per the facility’s lockout/tagout procedure before servicing to prevent the risk of electrical shock. Approximately 1000 watts (240 volts @ 4.2 A) is present at each heating element Approximately 108 VAC is present at the connection to any Hot Cathode Ion Gauges during operation. Always provide the Marathon Express system with the proper electrical code compliant connections. Working with energized equipment may cause electrical shock and may result in death or serious injury. All energy must be removed from the equipment per the facility’s Lockout/Tagout procedure before servicing. Follow the Lockout/Tagout procedures specified by the local facility. If local procedures are not available, follow the procedure for Lockout/Tagout in OSHA Standard 29CFR 1910.147. Refer the units specifications for the actual system power requirements and use appropriate precautions. Copyright © 2023, Brooks Automation, Inc. -

Page 46: Disconnect Devices

2. Safety Marathon Express Laser Hazards Part Number: 605914 Rev. B Disconnect Devices The integrator and end user are responsible for the Marathon Express system’s main disconnect device, ensuring that it is readily accessible and complies with the correct electric codes. The main user installed disconnect device must meet, or exceed, the minimum AIC rating specified by SEMI S2. Personnel servicing the Marathon Express system and any equipment connected to it are responsible for the status of the system’s main disconnect device as specified by the facilities’ lockout/ tagout procedure. Before disconnecting main power to the Marathon Express, ensure all circuit breakers on the Marathon Express system and any related equipment are in the OFF position. Damage to internal components may result if circuit breakers are left in the ON position. Laser Hazards The Brooks Automation Marathon Express uses low power laser light for mapping of wafers and to ensure all wafers are properly seated in the cassette in the VCE. These lasers produce low power invisible infrared light. They are Class II laser diodes. These lasers are Class I as implemented because they are not visible during normal operation. The proper precautions for operating and servicing lasers must be observed. Any precautions specified within the facility where the Marathon Express is being used must also be observed. Copyright © 2023, Brooks Automation, Inc. -

Page 47: Thermal Hazards

Brooks Automation 2. Safety Part Number: 605914 Rev. B Thermal Hazards Figure 2-8: Laser Locations Laser Radiation Laser radiation may cause serious eye injury. Know the power and hazard level of all lasers. Avoid exposure to laser hazards. Do not look directly at or into the laser beam (no matter what Class of laser). Follow any posted laser warnings or labels. Do not attempt to service, repair, or remove the protective housing of the laser device. Thermal Hazards Heating elements may exist on the Marathon Express vacuum transport chamber. Be aware of hot surfaces on the transport chamber during servicing and operation. Brooks recommends placing barriers around the Marathon Express system while bake-out is in process to ensure facility personnel do not come into contact with any hot surfaces. Copyright © 2023, Brooks Automation, Inc. -

Page 48: Vacuum Hazards

Part Number: 605914 Rev. B Extreme Temperature Surfaces heated during system bake-out can reach temperatures of 121° C (250° F), which could cause burns when in contact with skin. Once system heating has been started, all personnel must keep away from the system to avoid possible burn injury due to high temperatures. Allow time for the Marathon Express to cool before servicing or operating and before performing maintenance involving volatile chemicals. Vacuum Hazards The Brooks Automation Marathon Express is designed for use as an atmospheric vacuum equipment transport system. Vacuum pumps are used within the vacuum side of the Marathon Express system to provide a high vacuum environment. These vacuum pumps may be exposed to hazardous chemicals left on the material after processing. All vacuum supplied to the Marathon Express must be disconnected as outlined in the facility’s lockout/tagout procedures before servicing, or injury may result from the automatic operation of the equipment. If no such procedures exist, follow the guidelines provided in "Laser Hazards" on page Whenever any vacuum pump exhaust is vented, the facility’s environmental procedures must be followed regarding the venting of gases. Implosion Hazard Implosion may result from equipment damage, which could result in personal injury or death. Opening an unequalized vacuum slot valve or atmospheric door may result in severe damage to the equipment or Marathon Express in process or cause personal injury. It is essential that a complete inspection of the equipment be performed prior to use. Copyright © 2023, Brooks Automation, Inc. - Page 49 Brooks Automation 2. Safety Part Number: 605914 Rev. B Vacuum Hazards The standard vacuum safety measures for the application in which the Marathon Express is being used should be applied. Explosion Hazard The vacuum back end of the Brooks Automation Marathon Express is designed specifically for vacuum. Internal pressures should never exceed normal atmospheric pressure, as damage to the system or personal injury due to unexpected popping of the Pressure Relief Valve could result. It is essential that a complete inspection of the equipment be performed prior to use. Copyright © 2023, Brooks Automation, Inc.

-

Page 50: Ergonomics Hazards

Marathon Express Ergonomics Hazards Part Number: 605914 Rev. B Ergonomics Hazards Heavy Object The Marathon Express can weigh as much as 1451.5 kg (3200 lb). The Vacuum Cassette Elevator modules of the Marathon Express weigh at least 111 kg (245 lb) without the vacuum pump attached. Failure to take the proper precautions before moving any of these items could result in personal injury. Do not attempt to lift these Marathon Express and VCE modules without a forklift or a hoist. Tip Hazard Tip Hazard The Vacuum Casette Elevator may tip and fall when they are not attached to the Marathon Express which may cause serious injury or death. Do not attempt to move the Vacuum Casette Elevator without the use of a fork lift or a hoist. Moving it without a hoist could cause a tip hazard. Move on smooth floors only. The Slot Valves and Atmospheric Doors may drift to an indeterminate position if pneumatic pressure is lost. Copyright © 2023, Brooks Automation, Inc. -

Page 51: Environmental Information

Environmental Information Noise Emission The Brooks Automation Marathon Express provides no direct noise hazard during operation. When operating normally the Maximum Sound Pressure is NC55 (does not include pumps) and causes no hazardous conditions. Vibration The Brooks Automation Marathon Express provides no direct vibration hazard during operation. Any vibrations produced during normal operation are minimal and cause no hazardous conditions. Refrigerant Gasses Refrigerant Gas A qualified refrigeration technician is required to remove the refrigerant from this product. When working with refrigerant gases, flow all facility and local regulatory and environmental procedures regarding the storage, handling, and disposal of the gases. Refer to Safety Data Sheets, SDS, for the refrigerant. Recycling and Hazardous Materials The Brooks Automation Marathon Express contains, or uses for maintenance, the following items that may require special handling for disposal or recycling. Lithium Batteries A Lithium Battery is located on the Processor Board within the robot to maintain data when power is removed. A Lithium Battery is located on the Aligner Controller Board to maintain data when power is removed. A Lithium Battery is located on the optional T5X Processor Board to maintain data when power is removed. Copyright © 2023, Brooks Automation, Inc. - Page 52 Marathon Express Environmental Information Part Number: 605914 Rev. B Lithium Battery Disposal A lithium battery is located on the controller, Processor Board, and optional T5X Processor Board. If any of the these is being removed or replaced, it must be handled following all Federal, State, Local, and Facility’s procedures for the disposal of hazardous material. Lead Acid Battery A Lead-Acid Battery is located on the optional MAG 7 PowerPak to provide power for robot shut- down when system power is removed. If this battery is being removed or replaced it must be handled in the following manner: Lead Acid Battery Disposal A Lead-Acid battery is located on the optional MAG 7 PowerPak. If it is being removed or replaced, it must be handled following all Federal, State, Local, and Facility’s procedures for the disposal of hazardous material. IPA Wipes Used During Maintenance IPA Wipes are used in maintenance. Approximately 20 wipes required per cleaning, each containing approximately 3 mL of 10% IPA / 90% DI Water solution (6 mL IPA total). Follow all facility and government regulations regarding recycling and disposal when discarding Marathon Express components that have been replaced. Copyright © 2023, Brooks Automation, Inc.

-

Page 53: Material Safety Information

Part Number: 605914 Rev. B Material Safety Information Material Safety Information Hazardous materials may be present during the operation or maintenance of the Marathon Express. Table 2-5 identifies the materials that are contained or shipped with the MX system. Read and understand the Material Safety Data Sheet (MSDS) for each material. These sheets provide crucial information pertaining to the hazardous materials used in the Marathon Express system. The facility where the Marathon Express is to be used is responsible for the maintenance and distribution of each MSDS. Ensure that there is a copy in each workplace for all hazardous materials involved in the operation and maintenance of the Marathon Express system. Other gases, cleaners, and lubricants may be recommended for use with the Marathon Express. Obtain the MSDS for these materials from the supplier. Table 2-5: Hazardous Material Used in the Marathon Express Material Description Location in MX System Krytox® LVP White, waxy grease Lubrication within vacuum chambers, if required Copyright © 2023, Brooks Automation, Inc. -

Page 54: Installation

Site Requirements Part Number: 605914 Rev. B 3. Installation The Brooks Automation Marathon Express has been designed for quick and easy mounting to the user’s Process Modules. This chapter provides complete installation procedures for the Brooks Automation Marathon Express including: unpacking, assembly, initial setup, and initial check-out. Site Requirements Before the Brooks Automation Marathon Express installed, the site where the MX system will be located must be properly prepared. This preparation includes ensuring that the proper facilities, including electrical and communications connections, are available and are properly prepared for connection to the Marathon Express. Floor Space and Loading The site for the Marathon Express must meet the minimum space requirements specified in "Mechanical Specifications" on page 19 and Figure 1-3 and "Example of Service and Exclusion Zones - Vertical ( See Interface Drawing)" on page 26 to ensure proper clearance for installation, operation, and servicing of the MX system. Note that the dimensions given are for the MX system only. It is the user’s responsibility to ensure adequate space around the Process Modules for operation and service based on their needs. All drawings within this manual are generic and may not reflect specific builds of the Marathon Express. To obtain a complete and current set of drawings and documents contact Brooks. See Contact Us for more information. Copyright © 2023, Brooks Automation, Inc. -

Page 55: Environmental

Unpacking and Inspection The Brooks Automation Marathon Express is shipped in separate packages which are individually sealed to maintain cleanroom conformance. Unpack each crate carefully following the steps provided in "Unpacking Instructions"; inspect and verify the contents against the checklist provided on the front page of the AT. Report any damage immediately to the shipper and to Brooks Automation. One set of shipping documents will be attached to the outside of the main shipping crate for easy access. An additional set of the same documents will be attached to the equipment inside the shipping crate. NOTE: The number and contents of the shipping crates will depend on the items purchased. Refer to the AT for the exact contents. Table 3-1, below, is provided for reference only. Table 3-1: Packing Checklist Reference Package Typical Contents Marathon Chamber mounted on frame with wheels with installed options that may include: the robot, Express VCE l oad locks, custom end effector, aligner , etc. Copyright © 2023, Brooks Automation, Inc. - Page 56 Electronics Controller Computer Pump controllers, etc. Copy of ATP (Certificate of Performance Testing) Connector for power cable Installation System cables Mounting Hardware User Manuals When the Marathon Express is being prepared for shipping, the outer bag is cleaned and a foil bag is placed around each module of the MX system. The foil bag is then sealed and evacuated and the system is bolted to the crate bottom before the crate is closed and bolted together. Tip indicators, shock indicators, and moisture indicators are attached to each crate. Heavy Object The Marathon Express can weigh as much as 1451.5 kg (3200 lb). The Vacuum Cassette Elevator modules of the Marathon Express weigh at least 111 kg (245 lb) without the vacuum pump attached. Failure to take the proper precautions before moving any of these items could result in personal injury. Do not attempt to lift these Marathon Express and VCE modules without a forklift or a hoist. Copyright © 2023, Brooks Automation, Inc.

- Page 57 Tip Hazard Tip hazard exists when moving the Marathon Express. Ensure that all the force exerted on the Marathon Express modules when moving them is below the center of the gravity. Failure to take the proper precautions before moving any module, especially while moving it out of the shipping crate, could result in personal injury. Do not attempt to move the Marathon Express without the use of a fork lift or a hoist. Personal Protective Equipment Failure to take proper precautions when installing the Marathon Express may cause injury to the eye. Use safety glasses when installing or maintaining the Marathon Express. When rolling the Marathon Express o n its casters, place hands on the dummy process modules or on the process module blankoffs. Gauges and sensors are located in other areas of the MX system and could be damaged if pushed against. NOTE: Save the shipping crates for possible future use. If any of the modules of the Marathon Express are returned to Brooks for service or shipped to another location, the original shipping crates must be used. If the original crates have become lost or damaged, contact Brooks Automation for replacements. Refer to Appendix F: "Packing and Shipping Instructions" on page 224. The Brooks Automation Marathon Express was assembled and bagged in plastic in a cleanroom environment. To ensure the cleanliness of the MX system, unbag it only in a cleanroom depack environment. Copyright © 2023, Brooks Automation, Inc.

-

Page 58: Procedure Category

Part Number: 605914 Rev. B Procedure Category Type 1 Procedure: Equipment is fully de-energized. Required Tools and Equipment Fork truck or appropriate lift with bumper stops Open end wrenches, adjustable or size 19 mm, 3/4 in, and 1 1/8 in Metric hex wrenches Unpacking Instructions Step Action Upon receiving the crate, inspect the indicators for disturbance. Also, visually verify crate is not dam- aged. Inform freight carrier and Brooks Automation of any inspection discrepancy. Remove the cover of each shipping crate. Inspect and verify contents. The Marathon Express Acceptance Test (ATP) is included in the shipment and is a permanent record of the system as it was manufactured by Brooks Automation. In addition to providing information about serial number, model number, and robot station assignments, it also provides critical data. Make copies of the form and keep a copy close to the system. Should maintenance be required, data from the ATP may be needed. Remove the crate walls of the Transport Chamber. Unbolt the caster brackets from the pallet floor (3 places). NOTE: Save the shipping crate for possible future use. If the Marathon Express is returned to Brooks for service or shipped to another location, the original shipping crate and brackets must be used. Copyright © 2023, Brooks Automation, Inc. - Page 59 Part Number: 605914 Rev. B Unpacking and Inspection Step Action Using the fork lift, pick the Transport Chamber up only enough to clear the shipping skid. The fork lift channels are located below the VCE as shown in Figure 3-1. NOTE: The Marathon Express system must be lifted from the Load Lock side only. Bumper stops must be present on the fork lift to prevent the lift from contacting the frame. Figure 3-1: Fork Lift Channel Locations Slide out the shipping skid and lower the MX system jacking casters as shown in Figure 3-1 by turning the threaded rods clockwise. Gradually transfer the weight of the system from the fork-lift channels to the casters. Remove the fork lift. NOTE: The individual modules of the Marathon Express are top heavy and it may tip and fall which may cause serious injury or death. Do not attempt to move the Marathon Express without the use of a forklift or a hoist. Move on smooth floors only. Cut open and remove the foil bag the MX system is shipped in and roll the system into the Depack area. NOTE: Inspect the travel route of the Marathon Express system to ensure that it is level and clear of all debris and obstacles. Cover dips, thresholds, or any uneven floor transitions with plates. Move the contents of all other crates into the Depack area. Copyright © 2023, Brooks Automation, Inc.

-

Page 60: Installation Procedure

NOTE: Recycle all packaging materials. Carefully inspect the Marathon Express for signs of damage that may have occurred during shipping. Roll the system into the cleanroom and position it at its final location. NOTE: When pushing the Marathon Express on its casters, place hands on the dummy process modules or on the process module blankoffs. Gauges and sensors are located in other areas of the Marathon Express and could be damaged if pushed against. Remove all inner bags and any additional wrapping. Carefully inspect the MX system and all additional items for signs of damage that may have occurred during shipping. Inform the freight carrier and Brooks Automation of any inspection discrepancy. Procedures for re-packaging the Marathon Express are provided in Appendix F: " Packing and Shipping Instructions" on page 224. Installation Procedure The Marathon Express is typically supplied in one of several standard configurations and arrives as a set of modules ready to install. Heavy Object The Marathon Express weighs at least 900.0 kg (1984 lb) and can weigh as much as 1451.5 kg (3200 lb). The Vacuum Cassette Elevator modules of the Marathon Express weigh at least 111 kg (245 lb) without the vacuum pump attached. Failure to take the proper precautions before moving any of these items could result in personal injury. Do not attempt to lift these Marathon Express and VCE modules without a forklift or a hoist. Copyright © 2023, Brooks Automation, Inc. -

Page 61: Procedure Category

Do not attempt to move the VCE without the use of a fork lift or a hoist. Move on smooth floors only. Personal Protective Equipment Failure to take proper precautions when installing the Marathon Express may cause injury to the eye. Safety glasses and steel toe shoes should be worn at all times when installing the Marathon Express. Procedure Category Type 1 Procedure: Equipment is fully de-energized. Required Tools and Equipment The following tools and materials are required during the installation of the Marathon Express: Metric Hex Wrenches Standard Hex Wrenches Scale (ruler) I-beam Level Bubble Level 1/2 inch Bolt (or Threaded Rod), Qty 3, for MX system tie-down Copyright © 2023, Brooks Automation, Inc. -

Page 62: Remove Protective Packaging

Remove Protective Packaging The modules of the Marathon Express are shipped with their internal components (robot, aligner, etc.) covered in protective packaging. This packaging must be removed before installation can be started. Marathon Express Module Remove protective wrapping from any loose cable ends or connectors. VCE Module(s) Remove protective wrapping from any loose cable ends or connectors. Rack Mountable Equipment Remove protective wrapping from any loose cable ends or connectors. Removing Shipping Brackets The modules of the Marathon Express are shipped with shipping brackets attached to them, which protect their moving parts and provide ease of movement of the modules. These shipping brackets must be removed before the MX system may be installed or used. NOTE: Save the shipping brackets for possible future use. If any of the modules of the Marathon Express are returned to Brooks for service or shipped to another location, the original shipping brackets must be used. Refer to Appendix F: " Packing and Shipping Instructions" on page 224. Marathon Express Vacuum Back End The robot arms are secured in place for protection during shipment. These shipping brackets must be removed before attempting to operate the robot. Step Action Remove all mounting bolts securing the lid to the chamber. Raise the lid from the top of the vacuum chamber by turning the wheel on the lid lifter. Refer to the "Lid Lockout/Tagout Procedure" on page 43. Copyright © 2023, Brooks Automation, Inc. -

Page 63: Installing The Vacuum Cassette Elevators

Action Unscrew the arm shipping brackets. Remove the brackets and save for future use. If the Marathon Express Vacuum Back End is shipped, the brackets must be replaced before shipping. Lower the lid and secure all mounting bolts. VCE Module(s) The door and the cassette platform of each VCE are secured in place for protection during shipment. These shipping brackets must be removed before attempting to operate the VCEs. Refer to the VCE User Manual for detailed instructions on removing the shipping brackets. Step Action Remove the brackets securing the door to the frame of the VCE. Remove the bracket securing the cassette elevator platform to the back wall of the VCE chamber. Installing the Vacuum Cassette Elevators The VCE 6 Load Locks are typically mounted at the factory and not removed for shipping. Installing the Marathon Express The Marathon Express must be positioned within the facility to ensure proper handoff between the facility wafer carriers and the Vacuum Cassette Elevators. Once the MX system is positioned it must be leveled and the Material Transport Plane must be adjusted to the proper height. After these preliminary adjustments are complete the MX system may be bolted to the floor using the tie-down points provided. Leveling the Marathon Express and Setting the Material Transport Plane Adjustable feet are provided on the frame of the Marathon Express. These feet are used to support the Marathon Express Vacuum Back End and VCEs, to set the Material Transport Plane (MTP), and to compensate for an uneven floor. Copyright © 2023, Brooks Automation, Inc. - Page 64 3. Installation Marathon Express Installation Procedure Part Number: 605914 Rev. B Do not raise the non-supporting feet more than 1 mm from the floor to ensure that the system is not allowed to “twist” as this could damage any components connected to the system and could cause a potentially unsafe operating environment. Step Action Lower the leveling feet, shown in Figure 3-2, until the feet are fully supporting the module’s weight. Figure 3-2: Lowering the Leveling Feet Raise the wheels and remove the casters. Retain the casters for future use. NOTE: The casters must be saved for future use in moving the Marathon Express. Copyright © 2023, Brooks Automation, Inc.

- Page 65 Brooks Automation 3. Installation Part Number: 605914 Rev. B Installation Procedure Step Action The Material Transport Plane (MTP) can be established at the SEMI MESC height of 1100 mm (43.31 in) per SEMI E21 by setting the distance from the scribe mark on the side of the chamber to the floor at 1100 mm as shown in Figure 3-3. Alternately, set the center of a material transfer slot to the floor at 1090.5 mm, which will set the MTP at 1100.0 mm. Figure 3-3: Setting the Material Transport Plane Level the MX system using an I-beam level placed along the chamber by adjusting each foot as necessary. NOTE: When adjusting the height of the transport chamber or leveling the chamber, ensure that it is not allowed to “twist”. This could damage the chamber or frame. Verify the WTP height from the floor to the center of each vacuum facet alignment pin. Copyright © 2023, Brooks Automation, Inc.

-

Page 66: Mounting The Process Modules To The Mx System

Part Number: 605914 Rev. B Installing the Tie-down Brackets Seismic brackets must be provided to secure the Marathon Express to the floor to eliminate movement and for earthquake protection. The caster brackets must be removed from the system and the system secured with angle brackets (not supplied) using the tapped holes in the side of the frame as shown in Figure 3-4. NOTE: Seismic hold-down for facilities requiring earthquake protection are the responsibility of the user. Figure 3-4: Seismic Bracket Mounting Step Action Locate the Seismic Brackets at the points the casters were attached to the frame as shown in Figure 3- Position the brackets so that the seismic mounting holes are against the floor. Replace the four bolts and washers to secure the bracket to the frame. Install one M12 or equivalent size bolt (not supplied) through the bracket and into the floor. Verify the WTP height from the floor to the center of each vacuum facet alignment pin. Mounting the Process Modules to the MX System Any components that will be mounted to the Marathon Express Transport Chamber are assumed to conform with SEMI MESC standards. Copyright © 2023, Brooks Automation, Inc. -

Page 67: Intermodule Connections

NOTE: It may be convenient to mount these components after initial installation and testing. Step Action Remove the blankoffs from the vacuum facets of the Marathon Express Vacuum Back End. Adjust the Process Module so that its Material Transport Plane is at 1100 mm (refer to the Process Module’s User Manual). Ensure that the Process Module remains level while making any adjustments to the height. Mate the Process Module to the vacuum facet of the Marathon Express by inserting the pins on the Process Module into the holes on the Vacuum Slot Valve of the facet. NOTE: It may be necessary to re-adjust the height of the module(s) to align them to the Transport Chamber. If a height re-adjustment is required, take care to ensure that the module remains level. Once the Process Module is mated, clamp the flanges of the Process Module and the Slot Valve together using the ISO clamps provided. Intermodule Connections The standard configuration of the Marathon Express does not require any connections be made between the Marathon Express Vacuum Transport System and the VCE modules during installation. Most cables in the Marathon Express are shipped from the factory already connected to the tool. However, individual subsystems such as any rack mountable components must be connected during installation. See Figure 1-1 on page 13 for all Brooks components in the MX system. Wiring, vacuum, and vent system diagrams for the specific system configuration are supplied with this manual. Refer to these diagrams while installing the system to verify correct connections. The configuration of the Marathon Express will determine which components may be included with the system. Use the following instructions as a reference for step order only. Some connections may have been installed at the factory, in this case only verification of the connection is required. Rack Mountable Brooks Automation Component Connections Ensure all connections are routed such that they will not be damaged and that they do not present a hazard to personnel. Copyright © 2023, Brooks Automation, Inc. - Page 68 DIG 1 OUTPUTS FROM 0 TO 15 to I/O Distribution Hub J8 DIG 1 OUTPUTS FROM 16 TO 31 to I/O Distribution Hub J19 DIG 2 OUTPUTS (Optional) to I/O Distribution Hub J10 Network connection to Serial Communications Module J1 NOTE: If any of the above options are not installed, the protective caps should be placed over the exposed connector. From the DC Power Supply to the Main DC Harness P.DC.LF located in the lower facilities. From the Heater Power Supply (Optional), Main Heater cable P.HP from Heater Power Supply to Main Heater Harness J.HH.LF Rack Mountable Vacuum Communication Connections Step Action From Water Pump Controller to Transport Chamber Water Pump REMOTE From Cryo Pump Controller to Transport Chamber Cryopump From Turbo Pump Controller to Turbo Pump B-Lock From Turbo Pump Controller to Turbo Pump A-Lock From Turbo Pump Controller to Turbo Pump Transport Chamber From optional Turbo Pump Controller to second Turbo Pump Transport Chamber NOTE: Do not connect facilities power at this time. Facilities power will be connected after all other connections have been made. Copyright © 2023, Brooks Automation, Inc.

-

Page 69: Facilities Connections

Load Lock Node P11 to I/O Distribution Hub J17 for A-Lock, J12 for B-Lock Load Lock Node J12 to Pneumatic Manifold P1 Connect pneumatic lines from Load Lock: Refer to the Pneumatic, Vacuum, and Vent Diagrams supplied with this manual for color and termination of all lines. Process Module Connections Step Action From the Process Modules to (J5) Facet Node PM interface. NOTE: If a process module WILL NOT be connected to a Facet Node, a jumper connector labeled PDP (supplied with the system) at the J5 connector must be installed. Facilities Connections The standard configuration of the Marathon Express requires compressed air, nitrogen (vent gas), vacuum, exhaust, electrical power, communications connections, and optionally cooling water, water return, and argon (cool gas). Refer to the "Facilities Specifications" on page 21 for detailed descriptions of the required user-supplied facilities. All Marathon Express Cluster Tool Integration Platforms come with the required connectors to facilitate interfacing the system, along with connectors for the vacuum sources. The MX system is supplied with Facilities and Interface Panels located as shown in Figure 3-5, and Figure 3-6. All the connectors on the facilities interfaces are labeled for easy identification. Copyright © 2023, Brooks Automation, Inc. - Page 70 Marathon Express Installation Procedure Part Number: 605914 Rev. B Lockout / Tagout Working with energized equipment may cause sudden movement or electrical shock and may result in death or serious injury. All energy must be removed from the equipment per the facility’s Lockout/Tagout procedure before servicing. If local procedures are not available, follow the procedure for Lockout/Tagout in OSHA Standard 29CFR 1910.147. Personal Protective Equipment This product contains heavy objects that may cause personal injury. Use safety shoes and head protection when installing or maintaining the product. Wear protective eyewear when setting up or testing the system. Copyright © 2023, Brooks Automation, Inc.

- Page 71 Brooks Automation 3. Installation Part Number: 605914 Rev. B Installation Procedure Figure 3-5: Marathon Express Interface Locations Copyright © 2023, Brooks Automation, Inc.

- Page 72 3. Installation Marathon Express Installation Procedure Part Number: 605914 Rev. B Figure 3-6: Marathon Express Interface Locations (continued) Copyright © 2023, Brooks Automation, Inc.

- Page 73 Brooks Automation 3. Installation Part Number: 605914 Rev. B Installation Procedure Figure 3-7: Marathon Express Interface Locations Copyright © 2023, Brooks Automation, Inc.

-

Page 74: Electrical

3. Installation Marathon Express Installation Procedure Part Number: 605914 Rev. B Figure 3-8: Marathon Express Interface Locations (continued) Electrical Electrical power is connected to the Marathon Express for operation of the robot, elevators, sensors, and other subsystems. A 200 - 240 VAC electrical connection is provided on the Marathon Express for AC power from the facility. Refer to "Facilities Specifications" on page 21 for electrical requirements. Ensure that the electrical connection is for the appropriate voltage. Electrical Shock Turn on the electrical supply before connecting the facilities to the Marathon Express can cause personal injury or death. Do not turn on the electrical supply from the facility until all connections to the Marathon Express and all installation procedures have been completed. Copyright © 2023, Brooks Automation, Inc. -

Page 75: Emo Circuit

3. Installation Part Number: 605914 Rev. B Installation Procedure EMO Circuit Step Action The EMO circuit is the responsibility of the user. An optional EMO button may be supplied with the sys- tem for the user’s convenience. Once the EMO circuit is wired and tested, remove the Warning label from the optional EMO button. Pneumatic Air is connected to the Marathon Express for operation of the Vacuum Cassette Elevators, Slot Valves, Atmospheric Doors, and optional TopCooler. Quick connect air ports are provided on the Marathon Express system’s Pneumatic Facilities Panel. Refer to "Facilities Specifications" on page 21 for pneumatic requirements. Ensure that the pneumatic connection is for the appropriate pressure. Do not turn on the pneumatic supply until all connections to the Marathon Express a nd all installation procedures have been completed. Figure 3-9: Pneumatic and Water Connections Copyright © 2023, Brooks Automation, Inc. - Page 76 3. Installation Marathon Express Installation Procedure Part Number: 605914 Rev. B Step Action Connect the compressed air line from the facility to the 10 mm quick connect air connection on the Marathon Express system’s Pneumatic Facilities Panel. Nitrogen Nitrogen is connected to the Marathon Express for venting the Vacuum Cassette Elevators and the Marathon Express Vacuum Back End and, depending on the configuration, nitrogen may be used as the thermal transfer gas in the TopCooler. A 1/4 inch VCR connection is provided on the MX system on the Gas Facilities Panel. Refer to "Facilities Specifications" on page 21 for nitrogen gas requirements. Ensure that the nitrogen connection is for the appropriate pressure. Do not turn on the nitrogen supply until all connections to the Marathon Express and all installation procedures have been completed. Figure 3-10: Gas and Vacuum Connections Step Action Connect the nitrogen line from the facility to the nitrogen connection on the MX system as shown in Fig- ure 3-5 on page 71. Copyright © 2023, Brooks Automation, Inc.

- Page 77 Part Number: 605914 Rev. B Installation Procedure Argon Argon may be connected to the Marathon Express in the optional TopCooler. A 1/4 inch VCR connection may be provided on the MX system on the Gas Facilities Panel, or it may be provided on the TopCooler. Refer to "Facilities Specifications" on page 21 for argon gas requirements. Ensure that the argon connection is for the appropriate pressure. Do not turn on the argon supply until all connections to the Marathon Express and all installation procedures have been completed. Step Action Connect the argon line from the facility to the argon connection on the MX system’s TopCooler as shown in Figure 3-6. Vacuum An appropriate user supplied vacuum system must be connected to the Marathon Express Vacuum Back End to provide the desired pump-down times for the vacuum chambers. Refer to "Facilities Specifications" on page 21 for vacuum requirements and Figure 3-5. Depending upon the configuration of the Marathon Express, differential vacuum may need to be supplied to various seals including the TopLigner vacuum aligner and the Vacuum Cassette Elevators for proper operation of these units. If differential vacuum is required it is taken directly off of the roughing vacuum line, no user connection is required. Do not turn on the vacuum connection until all connections to the Marathon Express and all installation pro- cedures have been completed. Step Action Connect the facility’s rough-vacuum system to the Marathon Express. Copyright © 2023, Brooks Automation, Inc.

-

Page 78: Communications Connections