Table of Contents

Advertisement

Quick Links

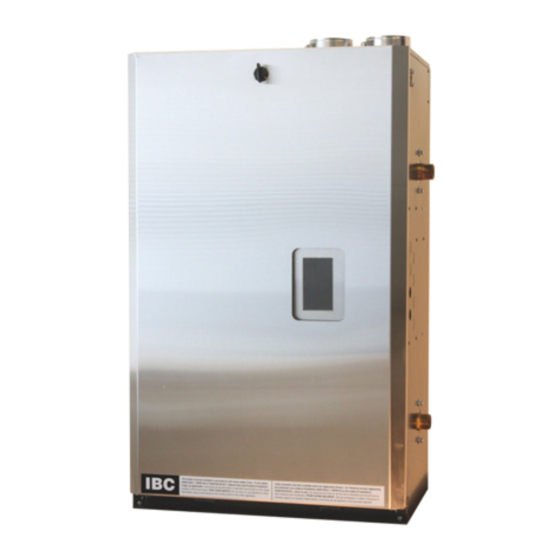

MODULATING GAS BOILER

WARNING: If the information in this manual is not followed exactly, a fire or

explosion may result causing property damage, personal injury, or loss of life.

Do not store or use gasoline or other flammable vapours and liquids or other

combustible materials in the vicinity of this or any other appliance.

WHAT TO DO IF YOU SMELL GAS:

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone in your building.

• Immediately call your gas supplier from a nearby phone. Follow the gas

supplier's instructions.

• If you cannot reach your gas supplier, call the fire department.

Installation and service must be performed by a qualified installer, service

agency or the gas supplier.

This Manual is also available in French - contact IBC or visit our web site www.ibcboiler.com

SL 28-160

(Natural Gas or Propane)

www.ibcboiler.com

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for IBC SL 28-160

- Page 1 • If you cannot reach your gas supplier, call the fire department. Installation and service must be performed by a qualified installer, service agency or the gas supplier. This Manual is also available in French - contact IBC or visit our web site www.ibcboiler.com www.ibcboiler.com...

- Page 2 † boilers are shipped with 30 psig pressure relief valve NOTE Points out installation, Supplied with the boiler - The IBC boiler is shipped with an accessory parts kit maintenance and operation consisting of the following items: details that will result in •...

-

Page 3: Table Of Contents

IBC BOILER CONTROLLER ........ - Page 4 SL 28-160 MODULATING GAS BOILER The Installer must carefully read this manual to ensure that all installation details can be adhered to. Special attention is to be paid to clearances and access, vent travel and termination, gas supply, condensate removal and combustion air supply.

-

Page 5: Installation

2-1/4” x 4” Water Outlet 1” NPT-M Water Inlet 1” NPT-M Knock-outs (8) 1/2” Gas Inlet 1/2” NPT-F Condensate Outlet 3/4” Hose Table 1: Connections Figure 1a: Dimensions / Connections for SL 28-160 Figure 1b: Dimensions / Connections for SL 28-160 INSTALLATION... -

Page 6: Code Requirements

SL 28-160 MODULATING GAS BOILER CODE REQUIREMENTS The SL 28-160 model was tested to and certified under CSA 4.9-2014 / ANSI Z21.13-2014. Installation must conform to local codes, or in the absence of these, with the latest editions of CAN/CGA B149.1 and the Canadian Electrical Code Part 1 CSA C22.2 No. 1. In the US, installations must conform to the current National Fuel Gas Code ANSI Z223.1 and the National Electrical Code ANSI/NFPA 70. -

Page 7: Exhaust Venting And Air Intake

SL 28-160 MODULATING GAS BOILER contaminants; combustion air should be drawn from a CLEAN source (e.g. WARNING outdoors) and the boiler should be isolated from interior dust sources. Exposed water piping and associated components DISTANCE FROM RECOMMENDED DISTANCE FOR (relief valves, circulators, etc.) - Page 8 SL 28-160 MODULATING GAS BOILER All venting must be installed in accordance with the requirements of the WARNING jurisdiction having authority: in Canada, Part 8, Venting Systems of the B149.1- 10 Code and any other local building codes are to be followed. In the USA Venting, condensate the National Fuel Gas Code, ANSI 223.1, latest edition, prevails.

- Page 9 (e.g. boiler room, attic and/or chase). EXHAUST VENT MATERIAL – USA IBC strongly recommends that only CPVC or PPs vent component systems approved under UL1738 (Standard for Venting Systems for Gas Burning Appliances, Categories II, III and IV), ULC-S636 Standard for Type BH Gas Venting Systems, or stainless steel Type BH venting systems* are to be used, but many local jurisdictions in the USA still allow the use of PVC (Sch.

- Page 10 CPVC or PPs (Rigid Single Wall) piping is the standard venting option; with this, the SL 28-160 boiler, for example, can be sited up to 35 equivalent feet from the vent termination using 2” or up to 170’ using 3”. The actual vent travel allowance is reduced for fittings in accordance with Table 3.

- Page 11 Some local jurisdictions require a minimum initial length of pipe be exposed or accessible for inspection. • Pipe clearances - no IBC requirements, but best practice allows a minimum 1/4” open gap around the pipe to prevent binding and expansion noise; follow local codes.

- Page 12 3’ apart (the closest intake and exhaust pipes shall be 36” - or more - apart). Use the same 24” (minimum) vertical separation for 2 pipe option. For alternate group terminations, contact the IBC Factory for written guidance. • Roof Top Concentric Termination Kits are approved for use with this boiler model.

- Page 13 Clearance under veranda, porch, deck or balcony: - 12” (0.3m) IBC strongly Figure 6: Prohibited installation recommends a minimum of 24” with the SL 28-160 to avoid damage to the structure. Note: Prohibited unless fully open on a minimum of two sides below the floor.

- Page 14 SL 28-160 MODULATING GAS BOILER CAUTION Vent termination clearances in this section are code minimum, or IBC recommended minimum requirements, and may be inadequate for your installation. Building envelope details must be examined carefully, and ingress of moisture into building structures is to be avoided.

- Page 15 The Stainless Sidewall Terminal (SST), 2 inch IBC part number 180-148 (sold Users must be advised to separately included with IBC kit P-256 ) or 3 inch IBC part number 180-149 check side wall vent and (sold separately included with IBC kit P-257 ), are the only direct vent sidewall air intake terminations on terminals approved for use with the this IBC boiler model.

- Page 16 SL 28-160 MODULATING GAS BOILER Figure 12: Allowed SST installation orientations Figure 13: Pipes extend completely through the wall (Vertical orientation shown). Figure 14: Minimum separation for multiple vent installation, vertical orientation Figure 15: Minimum separations for multiple vent installation, horizontal orientation...

- Page 17 SL 28-160 MODULATING GAS BOILER 1.4.7 “Direct Vent” Combustion Air Intake Piping There are two basic methods of supplying combustion air to an IBC boiler. The direct vent option uses piping from the outside to supply combustion air directly to the boiler’s combustion air connection.

- Page 18 SL 28-160 MODULATING GAS BOILER For the inlet air – Schedule 40 PVC, CPVC, ABS or PPs piping of any type is WARNING permitted. Use same diameter as Vent pipe. When using Indoor It is not permitted to add to the exhaust length by transfer of unused...

- Page 19 SL 28-160 MODULATING GAS BOILER 1.4.9 Combustion Air Filtration If combustion air contamination from ingested particulate matter may be a concern in any installation, an optional air intake filter may be installed. IBC supplied air intake filters have a known pressure drop and fouling factor and should be used as a component of the combustion air system according to the allowable intake length in Table 4.

-

Page 20: Condensate Removal

SL 28-160 MODULATING GAS BOILER CONDENSATE REMOVAL IBC’s specified vent configuration promotes the safe drainage of moisture from WARNING the boiler and exhaust venting without flowing liquids back through the heat exchanger (as done by some other condensing boilers). Fill trap with water before Reliable system operation requires (1) proper design and installation of exhaust boiler is first fired to prevent venting to allow condensate to run back to the drain/trap;... - Page 21 SL 28-160 MODULATING GAS BOILER 1.5.3 Condensate Trap Assembly - cleaning procedure Turn off the power to the boiler and allow it to cool down. Remove the trap from the boiler (reverse the installation procedure above). Remove the Trap Cleanout Assembly (H), from the Trap Body and clean and flush the debris out.

- Page 22 SL 28-160 MODULATING GAS BOILER Figure 20: Condensate trap disassembly for cleaning Figure 21: Condensate trap drainage WARNING If condensates are to be discharged into building drain piping materials that are subject to corrosion, a neutralization package must be used.

-

Page 23: Water Piping

In short – IBC has built a boiler that will allow you to pipe the system the way you prefer, rather than try and dictate your piping practices from boiler to radiator. - Page 24 SL 28-160 MODULATING GAS BOILER The SL modulating series boilers are designed for use within a closed loop, forced circulation, low pressure system. A 30 psi pressure relief valve (3/4” NPT) is supplied for field installation at one of the locations shown in the following illustrations. Relief valve discharge piping must terminate between 6” (15cm) and WARNING 12” (30cm) above the floor or per local Code.

- Page 25 For best results, use a Primary: Secondary piping system, with a pumped boiler refrigerated air circulation loop using 1-1/4” piping for the SL 28-160. Heat exchanger head is only 0.5’ at 5 must be equipped with USgpm and approximately 4’ at 16 USgpm.

- Page 26 SL 28-160 MODULATING GAS BOILER The SL Series modulating boilers are designed to supply four different heating WARNING loads with temperatures within the range 34°F to 185°F - to meet four separately piped loads. Use closely spaced tees to connect each pumped “load” (e.g. DHW,...

- Page 27 SL 28-160 MODULATING GAS BOILER NOTE The piping drawings in this manual are simple schematic guides to a successful installation. There are many necessary components not shown, and details such as thermal traps are left out so the drawings have greater clarity.

- Page 28 SL 28-160 MODULATING GAS BOILER Figure 29: Basic Primary/Secondary piping with hydraulic separator concept Figure 30: Primary/Secondary with Indirect Domestic Hot Water 1-24 INSTALLATION AND OPERATION INSTRUCTIONS...

- Page 29 SL 28-160 MODULATING GAS BOILER Propylene glycol solution is commonly used in a closed loop where freeze protection is required. Its density is lower than that of water, resulting in lower thermal performance at a given flow and pressure. As a rule of thumb, a 50%:50% solution of propylene glycol and water will require an increased system circulation rate (gpm up 10%), and system head (up 20%) to provide performance equivalent to straight water.

- Page 30 SL 28-160 MODULATING GAS BOILER The use of the multi-temperature modulating system is optimized when the need to shutdown the boiler is reduced or eliminated during the transitional period. System design enhancements: (a) keep a relatively low thermal mass in the primary loop, and (b) incorporate a 3-way mixing valve on the “cool”...

- Page 31 (available at www.ibcboiler. MULTIPLE BOILER PIPING - BENEFITS AND INSTALLATION RULES com or from your IBC Multiple IBC boilers can be installed in a single heating system to provide Representative). redundancy, increased output, and greater heating plant turn-down capabilities. Primary/Secondary piping must be employed, and each boiler must be installed with its own pump as illustrated below.

-

Page 32: Gas Piping

SL 28-160 MODULATING GAS BOILER 1.7 GAS PIPING The boiler should have an inlet gas pressure of at least 5.0" w.c. for natural gas WARNING or propane. For either fuel, the inlet pressure shall be no greater than 14.0" w.c. -

Page 33: Electrical Connections

SL 28-160 MODULATING GAS BOILER ELECTRICAL CONNECTIONS All Electrical wiring to the boiler (including grounding) must conform to local electrical codes and/or National Electrical Code, ANS/NFPA No. 70 – latest edition, or The Canadian Electrical Code, C22.1 - Part 1. - Page 34 Sensors connected to any sensor input contacts must be of NTC NOTE: stealing thermostats. See the Thermister - type with a resistance of 10,000 ohms at 25°C and β = 3892. We do Wiring Diagram for details. not recommend using 3rd party supplied sensors. Compatible water temperature sensors and outdoor sensors can be supplied by your IBC distributor. 1-30 INSTALLATION AND OPERATION INSTRUCTIONS...

- Page 35 SL 28-160 MODULATING GAS BOILER 1.8.6 Thermostat Heat Anticipator IBC “Therm.” contacts draw no power, so an anticipator setting for the thermostat is not applicable with the SL modulating series boilers. In the case of a single temperature / heat load where zone valves are used to manage individual thermostatically controlled zones, each room thermostat’s heat anticipator should...

- Page 36 SL 28-160 MODULATING GAS BOILER THIS PAGE INTENTIONALLY LEFT BLANK 1-32 INSTALLATION AND OPERATION INSTRUCTIONS...

-

Page 37: Ibc Boiler Controller

Load Combining – simultaneous operation of 2 similar water temperature loads • The control can manage and/or operate in a network of up to 24 IBC VFC or SL boilers Some of the new features available in the touch screen control include: •... -

Page 38: Control Interface

SL 28-160 MODULATING GAS BOILER Operational and historical data may be accessed at any time using the System Status and Load Profiles sections of the control. Error logs are available in the Diagnostics section and the controller is capable of recording any or all errors since original power-up complete with the date and time of the error. -

Page 39: Startup And Commissioning

SL 28-160 MODULATING GAS BOILER STARTUP AND COMMISSIONING 3.1 LIGHTING AND SHUTTING DOWN THE BOILER clockwise open close STARTUP AND COMMISSIONING... -

Page 40: Prior To Start-Up

COMMISSIONING The SL 28-160 modulating boiler is factory calibrated to operate with natural gas (or propane if so ordered) at sea level. The Low Fire (Zero Offset) valve adjustment cap has been factory sealed using paint-seal compound. This cap must not be tampered with. - Page 41 SL 28-160 MODULATING GAS BOILER Turn OFF the gas supply to the boiler. With a small (1/8" or 3 mm) flat screwdriver, open the inlet gas supply pressure test port by turning its center-screw 1 full turn counterclockwise. Attach a manometer to the pressure test port and turn on gas to appliance. Static manometer reading should be ideally 7”...

-

Page 42: Fuel Conversion

SL 28-160 MODULATING GAS BOILER FUEL CONVERSION WARNING The SL 28-160 modulating boiler is factory fire-tested to operate with natural gas, or propane as ordered. The rating plate will be marked to indicate which fuel the Check the rating plate of particular boiler has been set up with. Firing a boiler with a fuel other than what is... - Page 43 SL 28-160 MODULATING GAS BOILER 3.4.1 Gaining access to combustion chamber, burner NOTE removal instructions The safety warning regarding Remove fan and gas valve assembly. See “Fan and gas valve removal burner refractory on page instructions” on page 4-6 of this manual.

- Page 44 SL 28-160 MODULATING GAS BOILER THIS PAGE INTENTIONALLY LEFT BLANK INSTALLATION AND OPERATION INSTRUCTIONS...

-

Page 45: Maintenance

SL 28-160 MODULATING GAS BOILER MAINTENANCE BOILER MAINTENANCE 4.1.1 General Care CAUTION • Keep combustible materials and flammable liquids and vapours away from the The owner is responsible for boiler. general care of the boiler. • Keep vent terminals clear of obstructions (snow, dirt, etc.). Improper maintenance of the boiler may result in a hazardous condition. - Page 46 SL 28-160 MODULATING GAS BOILER 4.1.6 Heat Exchanger CAUTION During annual inspection (with the burner removed), examine the heat exchanger The heat exchanger has a small for signs of contamination and clean if necessary. In areas of poor gas quality, amount of combustion chamber there may be a buildup of black plaque (typically sulfur).

- Page 47 SL 28-160 MODULATING GAS BOILER 4.1.12 Boiler Treatment WARNING • Check consistency of any boiler treatment used, for appropriate mixture. Do not use automotive-type Chemical inhibitors are consumed over time, lowering their density. ethylene or other types of • Verify proper operation after servicing.

-

Page 48: Geography & Components

SL 28-160 MODULATING GAS BOILER GEOGRAPHY & COMPONENTS NOTE Vent stack piping and air intake riser have been removed in some of these photos for clarity Fan housing Removing front cover Gas valve Fan motor Removing top service cover Ignition module... - Page 49 SL 28-160 MODULATING GAS BOILER Vent temperature sensor bracket Removing vent stack test port plug Combustion air intake riser Water pressure sensor Water temperature high limit switch Removing combustion air intake riser Upper vessel high limit switch Ignition electrode/flame sensor...

- Page 50 SL 28-160 MODULATING GAS BOILER 4.2.1 Fan and gas valve removal instructions Turn off electric power and gas supply to the boiler. Ensure boiler cools down to ambient temperature. Do not drain the boiler unless freezing conditions are expected during this procedure.

-

Page 51: Troubleshooting

SL 28-160 MODULATING GAS BOILER 5.0 TROUBLESHOOTING The troubleshooting section is divided into 3 sections: NOTE 5.1 Preliminary Checks This boiler is equipped with a 5.2 Electronic Components blocked vent shutoff system, which closes the gas supply 5.3 Troubleshooting Guide... -

Page 52: Electronic Components

SL 28-160 MODULATING GAS BOILER ELECTRONIC COMPONENTS This section details the method for troubleshooting the non-standard electronic components on the boiler including the electronic differential air pressure sensor and the temperature sensors. 5.2.1 Temperature Sensors The resistance of the temperature sensors varies inversely with temperature. To... - Page 53 Air Pressure Sensor tubing not correctly attached. If the Differential Air Pressure Sensor replacement is required, Ensure the replacement sensor is marked for use on the SL 28-160 model boiler. Use of any other differential air pressure sensor is forbidden.

- Page 54 SL 28-160 MODULATING GAS BOILER 5.2.5 Hi-Limit Switches (water and UVHL) Check resistance between leads. If resistance is very low, temperature should be acceptable. If resistance is very high, temperature should be out of bounds. A simple means of checking whether a high limit switch is open is by measuring the AC voltage across the device.

-

Page 55: Troubleshooting Guide

SL 28-160 MODULATING GAS BOILER 5.3 TROUBLESHOOTING GUIDE 5.3.1 Using Control Module Errors Displayed The bottom line of the Touch Screen is reserved for displaying the boilers error status. The boiler status bar will normally be Green but can change colour to Yellow or Red. - Page 56 SL 28-160 MODULATING GAS BOILER SYMPTOM DIAGNOSIS REMEDY MAXIMUM IGNITION TRIALS No spark when igniting. Check that igniter lead is secure at the control ERROR Igniter probe/flame module and at the probe. sensor disconnected. Touch Screen Message: Manual gas shutoff is Check for gas flow. Open manual gas shutoff...

- Page 57 SL 28-160 MODULATING GAS BOILER SYMPTOM DIAGNOSIS REMEDY • TEMPERATURE SENSOR Current outlet Check water flow. ERROR temperature exceeds operating limit. Touch Screen Message: • Defective or Check wiring to temperature sensor and Error - Max. Inlet/Outlet Sensor disconnected control module. Temp. Exceeded. -> Check temperature sensor.

- Page 58 SL 28-160 MODULATING GAS BOILER 5.3.3 Cycling Problems SYMPTOM DIAGNOSIS REMEDY RAPID CYCLING Improper values Check load maximum temps are above target entered via keypad. temps, by 1/2 of the selected boiler differential. Ensure boiler differential is OK (16-30°F is...

- Page 59 SL 28-160 MODULATING GAS BOILER 5.3.4 Temperature Problems SYMPTOM DIAGNOSIS REMEDY LOW HEAT Operating increase temperature target. temperature too low. Priority parameters Review load configuration parameters. or load configuration improperly set up. Unit undersized. Refer to Load Calculation vs. Boiler Output. Air trapped within Bleed system as required.

- Page 60 SL 28-160 MODULATING GAS BOILER 5.3.5 Miscellaneous SYMPTOM DIAGNOSIS REMEDY FUMES AND HIGH HUMIDITY Improperly installed Refer to installation/operation instructions condensate trap Leak in vent piping Inspect using soap solution Flue gas leak within boiler Visually inspect all mechanical connections...

-

Page 61: Diagrams

SL 28-160 MODULATING GAS BOILER 6.0 DIAGRAMS 6.1 - PARTS DIAGRAMS 6.2 - WIRING DIAGRAMS 6.3 - SEQUENCE OF OPERATION DIAGRAMS... - Page 62 SL 28-160 MODULATING GAS BOILER 6.1 PARTS DIAGRAMS SL 28-160 Modulating Boiler - Parts assembly Diagram 6.1-1: Boiler assembly parts INSTALLATION AND OPERATION INSTRUCTIONS...

- Page 63 SL 28-160 MODULATING GAS BOILER ITEM NO. PART NO. DESCRIPTION 240-066 BLOWER 240-065 GAS VALVE, VENTURI 250-498 GAS INLET FITTING 190-111 GAS LINE 240-002 IGNITOR 250-050 IGNITOR GASKET 250-593 BLOWER TO H.Ex. GASKET 250-057 VIEWPORT HOLDER 250-060 VIEWPORT GASKET, TOP...

- Page 64 SL 28-160 MODULATING GAS BOILER 6.2 WIRING DIAGRAMS Diagram 6.2-1: Ladder wiring diagram INSTALLATION AND OPERATION INSTRUCTIONS...

- Page 65 SL 28-160 MODULATING GAS BOILER INTERNAL WIRING DIAGRAM Better Boilers brown Combustion Valve blue blue 5 x plug blue blue orange green orange Transformer blue blue brown black Vent High black Limit black orange Switch Upper Vessel yellow High Limit...

- Page 66 SL 28-160 MODULATING GAS BOILER 6.3 SEQUENCE OF OPERATION Diagram 6.3: Sequence of operation diagram INSTALLATION AND OPERATION INSTRUCTIONS...

- Page 67 INSTALLATION & COMMISSIONING REPORT Boiler Details: Model Number _____________________ Serial Number ______________________________________________ Date of Installation ______________ Address of installation __________________________________________ _____________________________________________________________________________________________ User contact information _______________________________________________________________________ Installer Information Company ___________________________________________________________________ Address ______________________________________________________________________________________ Phone/Fax/E mail ____________________________________________________________________________ Fuel Natural Gas Propane Gas Supply Pressure (high fire) _______ Inches w.c. Measured Rate of Input (high fire) ____________ Btu/hr Installation instructions have been followed and completed (Section 1 of Installation and Operating Instructions).

- Page 68 INSTALLER SET-UP Load Definition - Load #1 _______________________________________________________________________ Load Configuration - Load #1 _____________________________________________________________________________________________ Load Definition - Load #2 _______________________________________________________________________ Load Configuration - Load #2 _____________________________________________________________________________________________ Load Definition - Load #3 _______________________________________________________________________ Load Configuration - Load #3 _____________________________________________________________________________________________ Load Definition - Load #4 _______________________________________________________________________ Load Configuration - Load #4 _____________________________________________________________________________________________...

- Page 69 SERVICE RECORD DATE LICENSED CONTRACTOR DESCRIPTION OF WORK DONE...

- Page 70 NOTES...

- Page 71 NOTES...

- Page 72 • This boiler is part of a modular or multiple boiler system having a total input 300,000 BTU/hr or greater. • This boiler is equipped with a tankless coil (not applicable to IBC’s SL boilers). US installers should contact IBC for any further information required.

- Page 73 REVISION HISTORY R1 (JULY 2014) Initial release R2 (MAY 2015) Address update R3 (FEBRUARY 2016) Added Stainless Sidewall Terminal direct venting details and Z-DENS PPs appliance adapter information.

- Page 74 IBC Technologies Inc. 8015 North Fraser Way Burnaby, BC Canada V5J 5M8 Tel: 604.877.0277 Fax: 604.877.0295 www.ibcboiler.com 120-200E-A-R3 February 2016 © IBC Technologies Inc. 2016...

Need help?

Do you have a question about the SL 28-160 and is the answer not in the manual?

Questions and answers