State Water Heaters 301 Series Instruction Manual

Hide thumbs

Also See for 301 Series:

- Installation and operating manual (60 pages) ,

- Service handbook (54 pages) ,

- Instruction manual (80 pages)

Table of Contents

Advertisement

www.statewaterheaters.com

500 Tennessee Waltz Parkway

Ashland City, TN 37015

Technical Support 800-365-0024

Parts 800-821-2017

WARNING: If the information in these

instructions is not followed exactly, a fire

or explosion may result causing property

damage, personal injury or death.

Do not store or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any other appliance.

WHAT TO DO IF YOU SMELL GAS:

•

Do not try to light any appliance.

•

Do not touch any electrical switch; do

not use any phone in your building.

•

Immediately call your gas supplier

from a neighbor's phone. Follow the

gas supplier's instructions.

•

If you cannot reach your gas supplier,

call the fire department.

Installation and service must be

performed by a qualified installer,

service agency or the gas supplier.

Thank you for buying this energy efficient water heater.

We appreciate your confidence in our products.

KEEP THIS MANUAL IN THE POCKET ON HEATER FOR FUTURE REFERENCE

WHENEVER MAINTENANCE ADJUSTMENT OR SERVICE IS REQUIRED.

PRINTED 0418

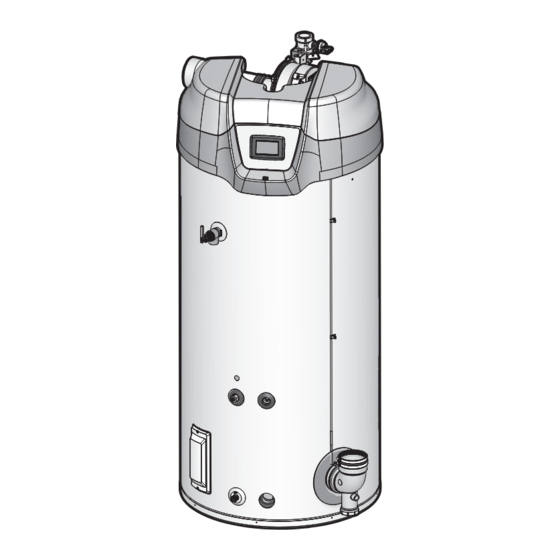

COMMERCIAL GAS WATER HEATERS

Instruction Manual

SUF 60120 THRU SUF 100250

SERIES 300 & 301

INSTALLATION - OPERATION - SERVICE

- MAINTENANCE - LIMITED WARRANTY

Read and understand this instruction

manual and the safety messages

herein before installing, operating or

servicing this water heater.

Failure to follow these instructions and

safety messages could result in death

or serious injury.

This manual must remain with the

water heater.

•

For Your Safety

AN ODORANT IS ADDED TO THE GAS USED

BY THIS WATER HEATER.

100303964 2000540702 (Rev. D)

MODELS

•

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for State Water Heaters 301 Series

- Page 1 Instruction Manual COMMERCIAL GAS WATER HEATERS MODELS SUF 60120 THRU SUF 100250 SERIES 300 & 301 INSTALLATION - OPERATION - SERVICE - MAINTENANCE - LIMITED WARRANTY www.statewaterheaters.com 500 Tennessee Waltz Parkway Ashland City, TN 37015 Technical Support 800-365-0024 Parts 800-821-2017 WARNING: If the information in these instructions is not followed exactly, a fire or explosion may result causing property...

-

Page 2: Table Of Contents

TABLE OF CONTENTS GENERAL SAFETY INFORMATION ......4 AL29-4C ® Vent Installations ......... 29 Precautions ..............4 Common Direct Venting Requirements ......29 Grounding Instructions ..........4 Concentric Termination Installation Preparation ... 30 Hydrogen Gas Flammable ......... 4 Concentric Termination Installation ......31 Low-Profile Vent Termination installation ...... - Page 3 SAFE INSTALLATION, USE, AND SERVICE The proper installation, use, and servicing of this water heater is extremely important to your safety and the safety of others. Many safety-related messages and instructions have been provided in this manual and on your own water heater to warn you and others of a potential injury hazard.

-

Page 4: General Safety Information

GENERAL SAFETY INFORMATION PRECAUTIONS HYDROGEN GAS FLAMMABLE DO NOT USE THIS WATER HEATER IF ANY PART HAS BEEN EXPOSED TO FLOODING OR WATER DAMAGE. Immediately call a qualified service agency to inspect the water heater and to make a determination on what steps should be taken next. If the unit is exposed to the following, do not operate heater until Explosion Hazard all corrective steps have been made by a qualified service agency. - Page 5 GENERAL SAFETY INFORMATION Fire or Explosion Hazard Fire Hazard For continued protection against Do not store or use gasoline or other flammable vapors and risk of fire: liquids in the vicinity of this or any other appliance. Do not install water heater on Avoid all ignition sources if you smell gas.

-

Page 6: Introduction

INTRODUCTION manual. These diagrams will serve to provide the in- Thank You for purchasing this water heater. Properly installed and maintained, it should give you years of trouble free service. staller with a reference. It is essential that all venting, water piping, gas piping and wiring be installed as ABBREVIATIONS USED shown. -

Page 7: Basic Operation

FEATURES AND COMPONENTS BASIC OPERATION MODULATION The water heaters covered in this manual have a helical The water heaters covered by this manual are capable of modulating their firing rate. The combustion blower is controlled coil shaped heat exchanger that is submerged in the stor- by the Central Control Board (CCB). -

Page 8: Components- Top View (All Models)

FEATURES AND COMPONENTS COMPONENTS- TOP VIEW (ALL MODELS) 8. Supply gas line connection. See the requirements for gas supply systems in (page 13). Gas Supply Systems IMPORTANT. The Enable/Disable switch listed in this manual is 9. Low Gas Pressure switch. Normally open contacts that close NOT an "on/off"... -

Page 9: Side Views

LEFT SIDE RIGHT SIDE Figure 4. Left-Side and Right-Side Components SIDE VIEWS 13. Supply gas line connection. See (page 1. Cleanout access panel, covers water heater cleanout opening Gas Supply Systems 13). and ASME plate where applicable. 14. Low Gas Pressure switch, see item 9 in 2. -

Page 10: Installation Considerations

INSTALLATION CONSIDERATIONS ROUGH-IN DIMENSIONS SUPPLY GAS CONNECTION INTAKE AIR CONNECTION 3 INCH PVC WATER OUTLET HEIGHT T & P VALVE FRONT BACK 3/4” NPT RECIRCULATION RETURN LOWER VENT TEMPERATURE CONNECTION PROBE 3 INCH (exhaust elbow) CLEANOUT 1 1/2” NPT WATER 3/4”... -

Page 11: Locating The Water Heater

Table 3. Storage Capacities Table 2. Fuel Type/Connection Size by Model † MODEL SERIES NATURAL GAS PROPANE GAS MODEL U. S. GALLONS LITERS SUF 60120 300/301 3/4 "NPT 3/4 "NPT SUF 60120 SUF 100150 300/301 3/4 "NPT 3/4 "NPT SUF 100150 SUF 100199 3/4 "NPT 3/4 "NPT... -

Page 12: Optional Direct Vent Terminations

CIRCULATION PUMPS Flammable items, pressurized containers or any other potential fire hazardous articles must never be placed on or adjacent to A circulating pump is used when a system requires a circulating the water heater. loop or there is a storage tank used in conjunction with the water heater. -

Page 13: Installation Requirements

INSTALLATION REQUIREMENTS GAS SUPPLY SYSTEMS 4. After installing the positive lock-up gas pressure regulator(s) an initial nominal supply pressure setting of 7.0” W.C. while the Low pressure building gas supply systems are defined as those water heater is operating is recommended and will generally systems that cannot under any circumstances exceed 14”... -

Page 14: Mixing Valves

MIXING VALVES Water heated to a temperature which will satisfy clothes washing, HOT WATER dish washing, and other sanitizing needs can scald and cause OUTLET permanent injury upon contact. Short repeated heating cycles caused by small hot water uses can cause temperatures at the 12”... -

Page 15: Temperature-Pressure Relief Valve

TEMPERATURE-PRESSURE RELIEF VALVE CAUTION Water Damage Hazard Explosion Hazard • Temperature-Pressure Relief Valve discharge Temperature-Pressure Relief Valve pipe must terminate at adequate drain. must comply with ANSI Z21.22- CSA 4.4 and ASME code. Properly sized temperature- T&P Valve Discharge Pipe Requirements pressure relief valve must be •... -

Page 16: Condensate Drain

CONDENSATE DRAIN Note: Lower PH levels are acidic. Do not connect a metal drain line, such as copper, to the water heater for this The water heaters covered in this manual are condensing reason. See (page 39). Condensate Drain Installation appliances and require a building drain to be located in close proximity to allow the condensate to drain safely. -

Page 17: Air Requirements

AIR REQUIREMENTS UNUSUALLY TIGHT CONSTRUCTION In unconfined spaces in buildings, infiltration may be adequate to For safe operation an adequate supply of fresh uncontaminated provide air for combustion, ventilation and dilution of flue gases. air for combustion and ventilation must be provided. However, in buildings of unusually tight construction (for example, An insufficient supply of air can cause recirculation of combustion weather stripping, heavily insulated, caulked, vapor barrier, etc.),... -

Page 18: Fresh Air Openings For Confined Spaces

FRESH AIR OPENINGS FOR CONFINED SPACES Alternatively a single permanent opening, commencing within 12 inches (300 mm) of the top of the enclosure, shall be provided. The following instructions shall be used to calculate the size, . The water heater shall have clearances of at least Figure 10 number and placement of openings providing fresh air for 1 inch (25 mm) from the sides and back and 6 inches (150 mm) - Page 19 OUTDOOR AIR THROUGH TWO VERTICAL DUCTS AIR FROM OTHER INDOOR SPACES The illustrations shown in this section of the manual are a reference for the openings that provide fresh air into confined spaces only. DO NOT refer to these illustrations for the purpose of vent installation.

-

Page 20: Installation Requirements - Commonwealth Of Massachusetts

INSTALLATION REQUIREMENTS - COMMONWEALTH OF MASSACHUSETTS COMMONWEALTH OF MASSACHUSETTS EXEMPTIONS For all side wall terminated, horizontally vented power vent, direct The following equipment is exempt from 248 CMR 5.08(2)(a)1 vent, and power direct vent gas fueled water heaters installed in through 4 every dwelling, building or structure used in whole or in part for 1. -

Page 21: Venting Installation

VENTING INSTALLATION metallic vent pipe and fittings with thermal insulation is prohibited. CATEGORY IV APPLIANCES Breathing Hazard - Carbon Monoxide Gas Category IV appliances operate with a positive vent (exhaust) • static pressure and with vent-gas temperatures low enough to Install vent system in accordance with codes. -

Page 22: Venting Requirements

during severe cold weather. To prevent the recirculation of flue branch and hose barb must not be angled any lower (towards the gases, maintain as much distance as possible between the ground) than this factory specification. Angling higher, up to a 90° intake air and vent terminations. -

Page 23: Common Direct Venting

PIPE SIZE REQUIREMENTS Table 7. PVC/CPVC Equivalent Length and The water heaters covered in this manual are certified for the Maximum Number of Elbows use of two-, three-, and four-inch pipe for the vent (exhaust) and Equivalent Vent Length Max Elbows intake air piping. -

Page 24: Direct Vent Installation

27). piping back to the water heater. 6. When installation of the termination is complete install necessary 7. The intake air and vent piping shall be supported properly piping and fittings to route the vent piping back to the water to avoid bending or failure. -

Page 25: Vertical Termination Installation

18 inches (45 cm) or less in length. VERTICAL TERMINATION INSTALLATION 1. Determine the location for the termination(s). 3” PIPE FACTORY INSTALLED FACTORY INSTALLED INTAKE AIR TEE 1/2 INCH 2. If installing only the vent (exhaust) piping in a Power Vent FITTING BRANCH configuration vertically through the roof;... - Page 26 Note: Beware of concealed wiring and piping when 2” (5 cm) MAXIMUM cutting through the roof. FACTORY SUPPLIED STANDARD TERMINATION 8. Suspend the pipe(s) through center of hole using field supplied FIELD POINTED DOWN TOWARDS metal strapping or equivalent support materials as shown in SUPPLIED THE GROUND (page 26).

-

Page 27: Sidewall Termination Installation

SIDEWALL TERMINATION INSTALLATION 24 INCHES (61 cm) MINIMUM 48 INCHES (122 cm) IN COLDER CLIMATES 1. Determine the location for the termination(s). FIELD INTAKE AIR 2. If installing only vent (exhaust) piping in a Power Vent SUPPLIED TERMINATION 90° ELBOW configuration through a sidewall;... -

Page 28: Polypropylene Installations

(page 28). 12. Place a bead of silicone caulking (field supplied) around the Figure 26 gap between the installed pipe(s) and the wall. Apply enough Note: Vent Termination – exhaust gases of this water to fill the gap between the pipe(s) and wall. heater are less than 140°F. -

Page 29: Al29-4C ® Vent Installations

Polypropylene vent systems do not use cement to connect the Note: The equivalent lengths of the AL29-4C ® elbows pipe and elbow sections. They use a push-together gasket-seal are different than those from smooth walled plastic method. Do not attempt to connect Polypropylene with sealant vents. -

Page 30: Concentric Termination Installation Preparation

CONCENTRIC TERMINATION INSTALLATION PREPARATION national codes must be maintained. 6. When installing multiple concentric terminations vertically 1. Concentric terminations must be ordered separately. All models through a roof or horizontally through a sidewall ensure the must use the four-inch concentric termination; Part Number: required clearances between terminations and groupings of 100111100 for both three-inch and four-inch vent diameters or multiple terminations are maintained. -

Page 31: Concentric Termination Installation

CONCENTRIC TERMINATION INSTALLATION 9. Return to (page 24) to complete the Direct Vent Installation installation of the intake air and vent piping between the Assemble and install the concentric termination. Refer to Figure concentric termination and the water heater. for these instructions: Figure 29 Figure 30 VENT... - Page 32 MULTIPLE CONCENTRIC TERMINATION CLEARANCES Four Concentric Terminations When installing multiple concentric terminations vertically through 1. When installing four concentric terminations through a roof or a roof or horizontally through a sidewall ensure the required through a sidewall in close proximity they may be arranged into clearances (separation) between terminations are maintained.

- Page 33 MULTIPLE CONCENTRIC TERMINATION ARRANGEMENTS The illustrations on this page show some of the installation SIDEWALL arrangements for multiple concentric terminations that are allowed. (page 32) for Multiple Concentric Termination Clearances detailed information on clearances and additional arrangement options. Note: When multiple concentric terminations are installed through a roof in the same location all termination caps must be at the same height measured from the ground.

-

Page 34: Low-Profile Vent Termination Installation

LOW-PROFILE VENT TERMINATION INSTALLATION To Heater Intake Air Connection This water heater is certified for sidewall direct venting with IPEX System 636 Low Profile Vent Kit. Follow instructions below for proper installations. From Heater Vent Pipe Connection All termination kits must be located and installed in accordance with local building code and CSA B149.1 Natural Gas and Propane 12”... -

Page 35: Venting Arrangements

VENTING ARRANGEMENTS Enlarged View of Direct Vent Air Intake Moisture Protection Figure 44. Direct Vent Vertical Figure 42. Power Vent Vertical Figure 43. Power Vent Horizontal Enlarged View of Direct Vent Air Intake Moisture Protection Enlarged View of Direct Vent Air Intake Enlarged View of Moisture Protection Direct Vent Air Intake... -

Page 36: Venting Arrangements

VENTING ARRANGEMENTS Enlarged View of Direct Vent Air Intake Moisture Protection Enlarged View of Enlarged View of Direct Vent Air Intake Direct Vent Air Intake Moisture Protection Moisture Protection Figure 48. Direct Vent Vertical Concentric Figure 49. Direct Vent Horizontal Figure 50. -

Page 37: Termination Clearances Sidewall Power Vent

TERMINATION CLEARANCES SIDEWALL POWER VENT Figure 51. Power Vent Using Room Air Vent terminal clearances for “Power Vent” installations. Power Vent configurations use room air for combustion. Canadian Canadian Type of Clearance Type of Clearance Installations Installations Installations Installations Clearance in accor- Clearance to each side Clearance in accordance with Clearance above grade,... -

Page 38: Termination Clearances Sidewall Direct Vent

TERMINATION CLEARANCES SIDEWALL DIRECT VENT Figure 52. Direct Vent Using Outside Air Vent terminal clearances for “Direct Vent” installations. Direct Vent configurations use outdoor air for combustion. Type of Clearance Canadian Installations 1 Type of Clearance US Installations Canadian Installations US Installations Clearance to each side Clearance in accordance... -

Page 39: Water Heater Installation

WATER HEATER INSTALLATION CONDENSATE DRAIN INSTALLATION INSTALLATION INSTRUCTIONS 1. Ensure the water heater’s Enable/Disable switch is in the Installation must conform with these instructions and local building “Disable” position. codes. 2. Install a 1/2 inch PVC condensate drain line between Field supplied materials required for installation include: condensate drain connection on the Exhaust/Condensate Elbow and a suitable building drain. -

Page 40: Supply Gas Line Installation

SUPPLY GAS LINE INSTALLATION GAS LINE SIZING Depending on the developed equivalent length and/or the number Contact your local gas utility company to ensure that adequate of appliances connected to a common main, the size of supply gas gas service is available and to review applicable installation codes lines may have to be increased. -

Page 41: Gas Line Leak Testing

GAS LINE CONNECTION GAS LINE LEAK TESTING 1. The water heaters covered by this manual are shipped from the Any time work is done on the gas supply system perform a leak factory with 3/4 inch supply gas connections. The supply gas test to avoid the possibility of fire or explosion. - Page 42 or connect any load (IE: relay coil) to this circuit. This POWER SUPPLY CONNECTIONS will damage the CCB circuit board and is not covered Read the requirements for the (page 13) before Power Supply under the limited warranty. See connecting power. Commercial Water (page 76).

-

Page 43: Water Line Connections

WATER LINE CONNECTIONS T&P VALVE DISCHARGE PIPE The water piping installation must conform to these instructions This water heater is provided with a properly rated/sized and and to all local and national code authority having jurisdiction. certified combination temperature - pressure (T&P) relief valve Good practice requires that all heavy piping be supported. -

Page 44: Temperature Regulation

TEMPERATURE REGULATION HIGH TEMPERATURE LIMIT CONTROL (ECO) This water heater is equipped with an ECO (energy cut out) non Table 17. Time/Temperature to Burn adjustable high temperature limit switch. The ECO is a normally Time for Permanent closed switch that opens (activates) on a rise in temperature. Burns Water Temperature Time for 1st Degree Burn... -

Page 45: Control System Operation

CONTROL SYSTEM OPERATION CONTROL SYSTEM NAVIGATION The water heaters covered in this manual are equipped with an electronic control system that regulates water temperature inside All operational information and user settings are displayed and the storage tank. Heating cycles and ignition are managed by the accessed from the UIM. - Page 46 STATUS ICONS The Status Icons are displayed on the Desktop screen and convey operational and diagnostic information. The icons are described in the table below. Table 18. Status Icons Icon Description Water temperature in the tank has fallen. Shaded area of the animated thermometer icon will rise and fall in response to water temperature in the storage tank as sensed from the Upper and Lower Temperature Probes.

- Page 47 OPERATING STATES The current operational state of the water heater is displayed on the Desktop screen as the "Status." The common operational states are described in the table below. Table 19. Operating States State Description Standby The water heater is not in an active heating cycle. IE: the Tank Temperature is at or above the Operating Set Point. Input Verification The control system is conducting a diagnostic check at the beginning of a heating cycle.

-

Page 48: User Settings & Control System Menus

USER SETTINGS & CONTROL SYSTEM MENUS When the water temperature, sensed by the control system from the two (upper and lower) Temperature Probes, reaches the Operating Set Point, the control system ends the heating TEMPERATURES MENU cycle. A heating cycle is activated again when the sensed water Operating Set Point and Differential Adjustment temperature drops below the Operating Set Point minus the The Operating Set Point is adjustable from 90°F (42°C) to 180°F... - Page 49 Temperatures Menu Description/Action Display • Differential - Adjustable user setting that changes the tank Temperatures temperature differential with a range of 2° to 20°F. The factory setting is 8°F. Operating Setpoint 120°F > • Tank Temperature - Non adjustable. Control system sensed Differential 8°F >...

- Page 50 DISPLAY SETTINGS Description/Action Display Press Display Settings from the Main Menu to enter this menu. Display Settings This menu contains adjustable display options for viewing information on the UIM’s LCD screen. Use the Slidebar to navigate Temperature Units °F > the menu.

- Page 51 CURRENT FAULT Description/Action Display Press Current Fault from the Main Menu to enter this menu. This Blocked Exhaust menu contains non adjustable operational information. Use the Slidebar to navigate the menu. 0 days 0 hr 0 min ago Error Code: A8-1201 This menu contains the current Fault or Alert error message.

- Page 52 SERVICE CONTACT INFORMATION The control system has a discrete menu that Installing contractors and/or service agents can access to enter contact information for their customers. This contact information will be displayed with all Fault and Alert messages. Table 21. Contact Information Description/Action Display From the Desktop Screen press and hold down the middle...

-

Page 53: Start Up

START UP PRIOR TO START UP 5. Connect the manometer to the supply gas pressure port on the gas valve. See (page 53) and (page 53). Figure 60 Figure 61 Installation and start up of this water heater requires abilities Note: The manometer tubing should be purged before and skills equivalent to that of a licensed tradesman in the field involved, see... -

Page 54: Lighting Operation & Labels

LIGHTING THE WATER HEATER LIGHTING OPERATION & LABELS The instruction label below is affixed to the water heaters that are covered by this manual at the factory and must be followed when lighting and operating the water heater. FOR YOUR SAFETY READ BEFORE LIGHTING WARNING: If you do not follow these instructions exactly, a fire or explosion may result causing property damage, personal injury... - Page 55 SUPPLY GAS PRESSURE ADJUSTMENT Multiple Water Heater Installations: Supply gas pressure shall be measured while the water heater is In multiple water heater installations or in installations where not firing (static pressure) AND while the water heater is firing at the installed water heater(s) share a common gas supply main full capacity (dynamic pressure).

-

Page 56: Checking The Firing Rate

CHECKING THE FIRING RATE Follow these instructions to determine the actual firing rate of the HIGH ALTITUDE INSTALLATIONS water heater: Note: The heaters covered by this manual are capable of modulating their firing rate. The firing rate should be checked with the heater operating at it's full firing rate. Fire and Explosion Hazard 1. -

Page 57: Troubleshooting

TROUBLESHOOTING SEQUENCE OF OPERATION INSTALLATION CHECKLIST Read the Sequence of Operation below before attempting to The list below represents some of the most critical installation correct any operational problems. Refer to requirements that, when overlooked, often result in operational Features and Components (page 8) for the location of various water heater components problems, down time and needless parts replacement. -

Page 58: Sequence Of Operation Flow Chart

SEQUENCE OF OPERATION FLOW CHART Sequence is shown with Enable/Disable Switch in the Enable position If tank temperature drops below Operating Set Point minus Differential setting a heating cycle is activated Control System performs diagnostic checks Control System Locks Out Normal State of all pressure switches and ECO are checked Displays Fault Msg Pressure switches and ECO are verified closed... -

Page 59: Operational Problems

OPERATIONAL PROBLEMS • Excessive equivalent lengths of intake air and/or vent (exhaust) piping installed - see (page Venting Requirements 22). • Debris clogging/blocking the intake air screen(s) - see (page 24) and (page 27). Figure 18 Figure 25 • Debris clogging/blocking the Main Burner - see Figure 2 Read and understand this instruction (page 7). -

Page 60: Fault And Alert Conditions

WATER IS TOO HOT then back on. Keep in mind; if the condition that caused the Fault has not been corrected, the control system will continue to lock out. • Operating Set Point is set too high. See Operating Set Point (page 48). - Page 61 FAULT AND ALERT MESSAGES Call the technical support phone number listed on the back cover for further technical assistance or to locate a qualified service agent in your area. Possible Causes - Check/Repair Displayed Fault/Alert Message • Using a manometer, ensure that gas supply pressure is above minimum requirement listed on heater’s data plate Ignition Failure and does not drop more than 1.5”...

- Page 62 FAULT AND ALERT MESSAGES (CONT) Call the technical support phone number listed on the back cover for further technical assistance or to locate a qualified service agent in your area. Possible Causes - Check/Repair Displayed Fault/Alert Message • If Blocked Intake error occurs before blower runs, make Blocked Air Intake sure pressure switch connections are clean and tight.

-

Page 63: Maintenance

MAINTENANCE GENERAL DRAINING AND FLUSHING Keep water heater area clear and free from combustible materials, It is recommended that the water heater storage tank be drained gasoline, and other flammable vapors and liquids. See and flushed every 6 months to reduce sediment buildup. The Locating (page 11). -

Page 64: Sediment Removal

SEDIMENT REMOVAL 5. Remove the cleanout cover from cleanout opening. 6. Remove lime, scale and/or sediment using care not to damage Waterborne impurities consist of the particles of soil and sand which the glass-lining. settle out and form a layer of sediment on the bottom of the tank. 7. -

Page 65: Vent System

Burn hazard. Explosion Hazard Hot water discharge. Temperature-Pressure Relief Valve must comply with ANSI Z21.22- Keep clear of Temperature- CSA 4.4 and ASME code. Pressure Relief Valve discharge outlet. Properly sized temperature- pressure relief valve must be installed in opening provided. To check the relief valve, lift the lever at the end of the valve Can result in overheating and several times, see... -

Page 66: Diagrams

DIAGRAMS CENTRAL CONTROL BOARD (CCB) LAYOUT Figure 66. Central Control Board Layout... -

Page 67: Wiring Diagram

WIRING DIAGRAM Figure 67. Wiring Diagram... -

Page 68: Circulation Pump Wiring Diagrams

CIRCULATION PUMP WIRING DIAGRAMS FIELD SUPPLIED TEMPERATURE CONTROL INSTALLED IN THE STORAGE TANK OR CIRCULATING LOOP RETURN LINE NOTE: USE SEPARATE 120 VAC POWER SUPPLY FOR PUMP CIRCUIT. DO NOT SHARE POWER WITH WATER HEATER AS THIS MAY CAUSE ELECTRICAL LINE NOISE AND LEAD TO ERRATIC CONTROL SYSTEM OPERATION. - Page 76 For your records, fill in the product: Serial: ___________________ Model: ___________________ U.S. Customers: State Water Heaters 500 Tennessee Waltz Parkway Ashland City, Tennessee 37015 800-365-0024 www.statewaterheaters.com...

-

Page 77: Notes

NOTES... - Page 78 NOTES...

- Page 79 NOTES...

- Page 80 500 Tennessee Waltz Parkway, Ashland City, TN 37015 Tech Support: 800-365-0024 Parts: 800-821-2017 www.statewaterheaters.com Copyright © 2018 State Water Heaters. All rights reserved.

Need help?

Do you have a question about the 301 Series and is the answer not in the manual?

Questions and answers