Subscribe to Our Youtube Channel

Summary of Contents for BioLAB BLVR-101

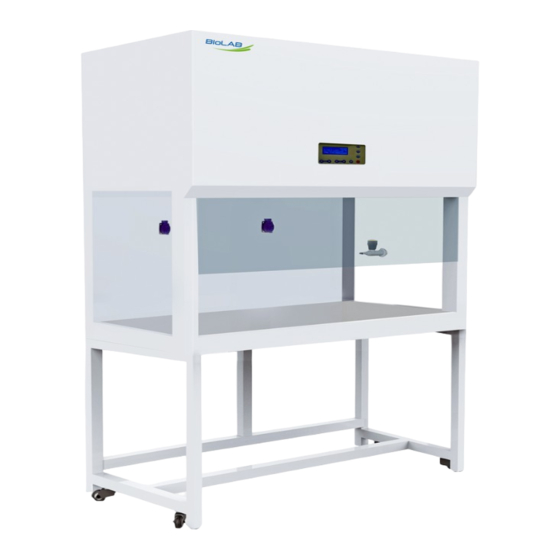

- Page 1 Operation Manual BLVR-101/102 Vertical Laminar Flow Cabinet Thank you for Choosing Biolab products. Please read the “Operating Instructions” and “Warranty” before operating this unit to assure proper operation.

- Page 2 Disclaimer Biolab shall not be liable for any equipment failure or damage, or for any direct or indirect damage that may occur during the use of the equipment. 1.Malfunction or damage due to violation of the instructions, precautions, and intended use of this manual.

- Page 3 Vertical Laminar Flow Cabinet BLVR-101/102 Index 1.Unpacking, Installation and Debugging..................04 2. User Instructions..........................11 3. Trouble Shooting and Solution......................22 www.biolabscientific.com...

- Page 4 Vertical Laminar Flow Cabinet BLVR-101/102 Unpacking, Installation and Debugging Please firstly check if packing box is in good condition. If the packing box is damaged, please take photos. Unpacking Choose proper tools and unpacking method as shown in the below picture.

- Page 5 Vertical Laminar Flow Cabinet BLVR-101/102 Picture 2 The following diagram demonstrates quick unpacking procedures (Picture 3). Remove the screws as shown in the below diagram, then remove the wooden sheet to left of the wooden box. www.biolabscientific.com...

- Page 6 Vertical Laminar Flow Cabinet BLVR-101/102 1.2 Accessories Checking Refer to the packing list and check the accessories. BLVR-101 Packing list Items Quantity Position Main body 1unit Wood package Base stand 1set Paper package(Behind the cabinet) UV Lamp(T6 30W) Gas Tap SAN-3102...

- Page 7 Vertical Laminar Flow Cabinet BLVR-101/102 BLVR-102 Packing list Items Quantity Position Main body 1unit Wood package Base stand 1set Paper package(Behind the cabinet) UV Lamp(T6 30W) Gas Tap SAN-3102 Power Cord Fuse (10A) Hexagon socket head cap screws Bags(Behind the cabinet)

- Page 8 Vertical Laminar Flow Cabinet BLVR-101/102 Atmospheric pressure range: 70KPa 106KPa ~ Electrical parameters: Adequate power supply to the laminar flow cabinet(See 2.1.4 Technical Parameters) Power supply need to be grounded; (Judging method: test the live wire and the neutral wire of the socket with multimeter. The voltage between live and ground should equal to the voltage of local electrical grid, and the voltage between neutral and ground should equal to 0.

- Page 9 Vertical Laminar Flow Cabinet BLVR-101/102 Removing Hexagon cylinder head bolt on both side lateral brace and T frame, the bottom of T frame, assemble referring to the picture, fasten the screw and Cap nut on the both side of base stand.

- Page 10 Vertical Laminar Flow Cabinet BLVR-101/102 First, keep the main body above the base stand. (picture 5), then align the bolt of base stand. Mounting holes of the Main body at both sides, using Hexagon head bolt M10*55, flat washer 10, Spring washer 10 insert through base stand and the side panel and make them stable.

- Page 11 Vertical Laminar Flow Cabinet BLVR-101/102 h. After the above steps, move cabinet to the right cabinet position slightly, remove the power cord, check the power cord is intact. See picture 7. 1.5 Inspection after Installation First, make sure the voltage and frequency to be same as nameplate showing,...

- Page 12 Vertical Laminar Flow Cabinet BLVR-101/102 2.1.2 Works / airflow mode protection area Picture 8 2.1.3 Protected objects Laminar flow cabinet is to protect the experimental material, to create a local high cleanliness air environment, the main role is to ensure the accuracy of the operating area of the experiment, but for the environment and operators can’t...

- Page 13 99.999%efficiency at 0.3μm Noise <65dB Notes: Biolab reserves the right to make changes in future product design, without reservation and without notification to its users. 1) Vibration amplitude The net vibration amplitude between frequency 10Hz and 10KHz is no more than 5μm(rms).

- Page 14 Vertical Laminar Flow Cabinet BLVR-101/102 2) Air filtration system Air filtration system is the core system of laminar flow cabinet. It consists of blower and HEPA filter system. The main function of air filtration system is to transfer filtered air to work area, ensure airflow velocity, and keep Class 100 cleanness of work area.

- Page 15 Vertical Laminar Flow Cabinet BLVR-101/102 Picture 10 1.Blower 2.Fluorescent lamp 3.UV lamp 4.Power 5.Socket 6.Glass window up 7.Glass window down 8. Air volume decreases 9.Air volume increase a. Gear display Working wind speed can be known by gear display. b. Soft touch button The main operation of the device can be carried out by touching button.

- Page 16 Vertical Laminar Flow Cabinet BLVR-101/102 : To control socket power status. : Press Down button, glass window will fall down. Each time you press, the buzzer will sound; hold down this key, the glass door will continue to decline; release the button, the glass door will stop declining.

- Page 17 Vertical Laminar Flow Cabinet BLVR-101/102 (1) Please make sure the total load of sockets should be ≤ 500W; (2) Waterproof socket is waterproof only when the front cover is down. When the front cover is opened, the socket can not be considered waterproof socket.

- Page 18 Vertical Laminar Flow Cabinet BLVR-101/102 reaches the maximum point, the speed requirements can’t be met then please contact Biolab service department to get a new one. The used filter should be processed as medical waste. (7 ) Please do NOT remove or loose the screws of those parts. To contact service personnel for special technical requirements.

- Page 19 Vertical Laminar Flow Cabinet BLVR-101/102 entire surface with a dry cotton cloth or towel rapidly. For the contaminated or dirty work surface and sump, use 70% rubbing alcohol or other disinfectant to wipe. Disinfectants used for wiping should not damage the 304 stainless steel.

- Page 20 Vertical Laminar Flow Cabinet BLVR-101/102 Storage period shall not exceed one year. Safety cabinet stored for more than one year needs to be unpacked and checked before selling and using. Only the tested and qualified safety cabinet could be sold.

-

Page 21: Control Panel

Vertical Laminar Flow Cabinet BLVR-101/102 BT-08 Control panel LCD control panel BT-09 1723*640*5mm Front window glass BT-10 Side window glass 1 575*540.5*5mm(has hole) BT-11 Side window glass 2 575*540.5*5mm BT-12 Single wall gas tap SAN-3102 yel l ow green Φ1.0 (... -

Page 22: Trouble Shooting And Solution

Vertical Laminar Flow Cabinet BLVR-101/102 Trouble Shooting and Solution 3.1 Trouble Shooting Please confirm that the power is well connected, the cord is in good condition(without any damage) and the power lock is unlocked before trouble shooting the following problems. - Page 23 Risk caused by failing to follow those instructions would be responsible by user. (2) Please contact Biolab technical department if a failure could not be traced or solved. Do NOT repair the equipment without a qualified electrician.

- Page 24 Vertical Laminar Flow Cabinet BLVR-101/102 Take out the fuse tube base with a flat screwdriver. Then can replace and check the fuse. Picture 13 3.3 Replace fluorescent light When the fluorescent light needs to be changed, turn off the power. Then remove the LED stand, unplug the right side, After replacing a new LED stand, inserted into the inclined slot.

- Page 25 Vertical Laminar Flow Cabinet BLVR-101/102 3.4 Replace the UV lamp The UV lamp tube should change regularly, such as every 600 hours. For replacing the lamp tube, turn off the power and disconnect the plug. Rotate the tube for 90° to remove it and then install a new UV lamp tube by rotating in reverse direction.

- Page 26 1) Warranty is 12 months from EX-factory date (excluding consumable accessories: UV lamp, fluorescent lamp and fuse). 2) Biolab would not be liable for any repair of damage caused by improper operation. 3) If the warranty has been expired, Biolab would still responsible for repair with relative charges.

- Page 27 Vertical Laminar Flow Cabinet BLVR-101/102 BIOLAB SCIENTIFIC LTD. 3660 Midland Avenue, Suite 300, Toronto, Ontario M1V 0B8 Canada Email: contact@biolabscientific.com Tel: +1 707 533 1445 Website: www.biolabscientific.com www.biolabscientific.com...

Need help?

Do you have a question about the BLVR-101 and is the answer not in the manual?

Questions and answers