JUMO IMAGO 500 Operating Manual

Multi-channel process and program controller

Hide thumbs

Also See for IMAGO 500:

- Operating manual (92 pages) ,

- Manual (13 pages) ,

- Interface description (40 pages)

Subscribe to Our Youtube Channel

Summary of Contents for JUMO IMAGO 500

- Page 1 All manuals and user guides at all-guides.com JUMO IMAGO 500 Multi-channel Process and Program Controller Operating Manual 70359000T90Z001K000 V2.01/EN/00403546...

- Page 2 All manuals and user guides at all-guides.com Please read these Operating Manual before starting up the instrument. Keep these operating manual in a place which is accessible to all users at all times. These operating manual are valid from software version 162.03.05. Please assist us to improve these operating manual, where necessary.

-

Page 3: Table Of Contents

All manuals and user guides at all-guides.com Contents Introduction Description ....................5 Typographical conventions ................. 6 Identifying the instrument version Type designation ..................7 Accessories ....................8 Nameplate ..................... 9 Mounting Location and climatic conditions .............. 11 Dimensions ....................11 Fitting ...................... - Page 4 All manuals and user guides at all-guides.com Contents Parameterization Configuration Analog inputs ....................41 Controller ....................46 Generator ....................49 Limit comparators ..................53 Outputs ......................56 Logic functions ................... 58 Math and logic module ................63 C-level control .................... 65 7.8.1 C-level control example ................

-

Page 5: Introduction

All manuals and user guides at all-guides.com 1 Introduction 1.1 Description Type 703590 is a process and program controller with up to eight controller channels or four program channels. The instrument is built to the format 144 mm × 130 mm for a standard 92 mm × 92 mm panel cut-out and a mounting depth of 170 mm. -

Page 6: Typographical Conventions

All manuals and user guides at all-guides.com 1 Introduction 1.2 Typographical conventions Warning Danger This symbol is used when there may be danger to signs personnel if the instructions are ignored or not followed correctly! Caution This symbol is used when there may be damage to equipment or data if the instructions are ignored or not followed correctly! Caution... -

Page 7: Identifying The Instrument Version

All manuals and user guides at all-guides.com 2 Identifying the instrument version 2.1 Type designation Basic type 703590 Type 703590: Process snd program controller Basic type extensions No. of controller and program channels 2 controller channels with max. 2 program channels 4 controller channels with max. -

Page 8: Accessories

All manuals and user guides at all-guides.com 2 Identifying the instrument version 2.2 Accessories External relay One of the RS422/485 interfaces is required to module operate one or two external relay modules 142 143 242 243 342 343 3 2 3 3 442 443 (L+) (L-) (external relay or logic outputs). -

Page 9: Nameplate

All manuals and user guides at all-guides.com 2 Identifying the instrument version PC evaluation PCC+PCA (software) software ® under Windows XP, Vista, 7 (32-bit and 64-bit) 2.3 Nameplate Position The nameplate is glued onto the instrument. Contents It carries important infomation, for instance: Description Designation Example... - Page 10 All manuals and user guides at all-guides.com 2 Identifying the instrument version...

-

Page 11: Mounting

All manuals and user guides at all-guides.com 3 Mounting 3.1 Location and climatic conditions The conditions at the location must meet the requirements specified in the Technical Data. The ambient temperature at the location can be -5 to +50 °C, with a relative humidity of not more than 75 %. -

Page 12: Fitting

All manuals and user guides at all-guides.com 3 Mounting 3.3 Fitting h From the back, fit the seal that is supplied onto the instrument. h Insert the instrument from the front into the panel cut-out. h From behind the panel, slide the mounting brackets into the guides on the sides of the housing. -

Page 13: Electrical Connection

All manuals and user guides at all-guides.com 4 Electrical connection 4.1 Installation notes • The choice of cable, the installation and the electrical connection must con- form to the requirements of VDE 0100 “Regulations on the Installation of Power Circuits with Nominal Voltages below 1000 V” or the appropriate local regulations. -

Page 14: Electrical Isolation

All manuals and user guides at all-guides.com 4 Electrical connection • Since the instrument is short-circuit proof only to a limited extent, an exter- nal fusing and a switch-off facility must be provided. Depending on the sup- ply voltage, the following values apply to the external fusing: AC/DC 20 to 53 V, 48 to 63 Hz fuse 4 A slow (only for operation in SELV or PELV current circuits) -

Page 15: Connection Diagram

All manuals and user guides at all-guides.com 4 Electrical connection 4.3 Connection diagram OUT 1 / IN 5 OUT 2 / IN 6 OUT 3 / IN 7 The electrical connection must only be carried out by qualified personnel. COM 1 29-32 OUT 4 / IN 8 OUT 5... - Page 16 All manuals and user guides at all-guides.com 4 Electrical connection Outputs (slots: OUT1to 6) 1 analog 1 logic output 1 solid-state relay 2 logic outputs 1 changeover 2 make output 0/22 V * 1 A / 230 V 0/14 V Ö...

-

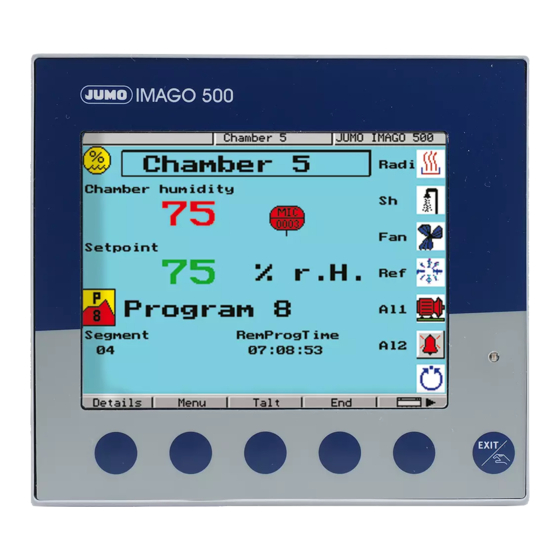

Page 17: Operation

All manuals and user guides at all-guides.com 5 Operation 5.1 Operation: General 5.1.1 Displays and controls Front view (10) EXIT Displays and No. Meaning controls Status line with time, date, name of screen template and instrument name. Color screen (screen templates can be configured) Factory setting for fixed-setpoint controller: process value, setpoint, output level (bar graph). - Page 18 All manuals and user guides at all-guides.com 5 Operation Symbols in Symbol Bedeutung display Info Alarm is present Alarm messages must be acknowledged (see explanation for “screen operating loop”) Automatic mode/Program is running Manual (“Hand”) operating mode Enables setpoint and control contact definition in the case of a program controller.

-

Page 19: Overview Of Operation

All manuals and user guides at all-guides.com 5 Operation 5.1.2 Overview of operation Custom picture 2 Custom picture 1 Recording Collective picture 2 Collective picture 1 Channel 8 Channel 1 v Chapter 7.9 “Display” Event list Service mode Device info Configuration level Parameter level Operating level... - Page 20 All manuals and user guides at all-guides.com 5 Operation Screen The operating loop contains the screen templates for a maximum of four con- operating loop troller channels, the collective picture of all the active controller channels, the recording function as well as two freely definable screen templates. The screen templates can be individually switched into display.

- Page 21 All manuals and user guides at all-guides.com 5 Operation Menu Event list Service mode Device info Configuration level Parameter level Operating level User level EXIT User level With the help of this screen template, the user can compile parameters that have to be frequently altered, through the setup program.

-

Page 22: Entering Values And Selecting Settings

All manuals and user guides at all-guides.com 5 Operation 5.1.3 Entering values and selecting settings Entering values Parameters can be altered in a number of screen templates. h Select parameter h Increase parameter value with h Decrease parameter value with The longer the key is pressed the faster the value changes. -

Page 23: Setpoint Input

All manuals and user guides at all-guides.com 5 Operation 5.1.4 Setpoint input Configuration Each controller channel has four setpoints which can be switched by logic sig- in controller nals. Setpoints for the controller are defined as shown below. Exception: configuration of a program controller with external setpoint input. -

Page 24: Recording

All manuals and user guides at all-guides.com 5 Operation 5.1.5 Recording Screen The recording function can be used to show the traces of up to four analog template signals and the switching actions of up to three logic signals. Momentary values Graphical representation Scaling of the of up to four analog signals... -

Page 25: Operation: Controller

All manuals and user guides at all-guides.com 5 Operation h Zoom in /zoom out of trace with h Return to the scroll functions with h Quit history with EXIT 5.2 Operation: Controller If the instrument has been configured as a fixed-setpoint controller, the follow- ing actions can be performed in automatic/manual mode: 5.2.1 Altering the setpoint The active setpoint of a controller channel can be altered in the corresponding... -

Page 26: Manual Mode

All manuals and user guides at all-guides.com 5 Operation 5.2.2 Manual mode Altering the The control loop of the controller channel that is displayed can be interrupted output by switching to manual mode. h Switch to manual mode with EXIT (hold key down for at least 2 sec!) (the symbol for manual mode appears in the operating mode display) h Alter the output with... -

Page 27: Program Editor

All manuals and user guides at all-guides.com 5 Operation 5.3.1 Program editor h Call up with Input template Edit program h Select program using the cursor keys h Select program channel using the cursor keys Number of program channel Program number and name Number of Entry mode program... - Page 28 All manuals and user guides at all-guides.com 5 Operation General 50 programs with up to 99 segments each can be programmed; a total of 1000 segments can be implemented. Programs are created by programming setpoints and segment times, segment by segment. Furthermore, the states of the control contacts 1 to 16 and the active parameter set can be defined for each segment.

- Page 29 All manuals and user guides at all-guides.com 5 Operation Tolerance band To monitor the process value, a tolerance band can be applied around the set- point profile for each segment. If the upper or lower limit is infringed, a tolerance band signal is generated, which is internally processed or produced via an output.

-

Page 30: Starting The Program

All manuals and user guides at all-guides.com 5 Operation Entering repeat A group of segments that are arranged in sequence can be repeated up to 99 cycles times or repeated endlessly (input: -1). The repeat cycles are programmed in the last segment of the group. Example: S02 to S04 are to be repeated once. - Page 31 All manuals and user guides at all-guides.com 5 Operation Starting the A program can be started at a specific point of time. There are two program with configurable options: time input 1. Start at a specified date and time 2. Start with a specified start delay in hours, minutes and seconds. v Chapter 7.3 “Generator”...

-

Page 32: Overview Of Operation

All manuals and user guides at all-guides.com 5 Operation 5.3.3 Overview of operation The diagram below provides an overview of the different operating modes and operating options of a program controller. Many operating options can also be implemented via the logic functions. Contr. - Page 33 All manuals and user guides at all-guides.com 5 Operation Temporary Temporary alterations are alterations to the current program in the program alterations editor. They are not stored in the program memory, i.e. alterations will be lost after a fresh start. In the case of alterations concerning the current segment, the setpoint se- quence is automatically adapted.

-

Page 34: Shifting The Program Profile

All manuals and user guides at all-guides.com 5 Operation 5.3.4 Shifting the program profile The function “External setpoint with correction” can be used to shift the pro- gram profile upwards or downwards. External setpoint The external setpoint is defined via an analog signal. v Chapter 7.2 “Controller”... -

Page 35: Parameterization

All manuals and user guides at all-guides.com 6 Parameterization General Two parameters sets can be stored for each controller channel. The parameter sets can be switched via the logic function, for example. Access code Factory-set code: 0001 The access code can be modified via the setup program. Parameter level Controller 1 (2 to 8) Parameter set 1 (2) - Page 36 All manuals and user guides at all-guides.com 6 Parameterization Controller structure 2 Controller P, I, PD, PI, PID PID The parameters refer to the second controller output for structure 2 a 3-state controller. Proportional 0to9999 digits 0 digits band Derivative time 0 to 9999 sec 80 sec Reset time...

- Page 37 All manuals and user guides at all-guides.com 7 Configuration General The following applies to the representation of parameters and functions at the configuration level: The parameter is not displayed or cannot be selected if • the instrument features do not permit the function assigned to the parame- ter.

- Page 38 All manuals and user guides at all-guides.com 7 Configuration Analog selector Y cascade C1 Standardized output with cascade control for controller 1 Y cascade C8 Standardized output with cascade control for controller 8 Setpoint 1 C1 Setpoint 1 for controller 1 Setpoint 4 C1 Setpoint 4 for controller 1 Setpoint 1 C2...

- Page 39 All manuals and user guides at all-guides.com 7 Configuration Analog selector RemSegT PCh1 Remaining segment time for program channel 1 (in seconds) RemSegT PCh4 Remaining segment time for program channel 4 (in seconds) Seg. Time PCh1 Segment time for program channel 1 (in seconds) Seg.

- Page 40 All manuals and user guides at all-guides.com 7 Configuration Binary selector Binary logic value any binary logic value (from address) Program end Program end signal Ramp end 1 Ramp end signal for controller 1 Ramp end 8 Ramp end signal for controller 8 Tolerance band Signal on going above/below tolerance band Manual mode C1...

-

Page 41: Configuration Analog Inputs

All manuals and user guides at all-guides.com 7 Configuration 7.1 Analog inputs Depending on the instrument version, up to eight analog inputs are available. Configuration The analog inputs are numbered in sequence (IN 1 to 8) according to their slot Analog inputs assignment. - Page 42 All manuals and user guides at all-guides.com 7 Configuration Analog input 1 (2 to 8) Value/selection Description Linearization Linear For customized linearization (e.g. “customized 1”) a maximum of 20 knee-points can be implemented, or a 5th Pt100 order polynominal function programmed (only with setup Pt100 JIS program).

- Page 43 All manuals and user guides at all-guides.com 7 Configuration Analog input 1 (2 to 8) Value/selection Description Range start -1999 to +9999 The instrument will change over earlier to the response defined for overrange/underrange if the range is restricted. Range end -1999 to +9999 Example: Range: Pt100 -200 to +850 °C.

- Page 44 All manuals and user guides at all-guides.com 7 Configuration Customized A signal is processed electronically (conversion, linearization …) to produce a recalibration measured value via the analog inputs of the controller. This measured value enters into the computations of the controller and can be visualized on the displays (measured value = displayed value).

- Page 45 All manuals and user guides at all-guides.com 7 Configuration Procedure Apply two measurement points ((1), (3)), one after another, to the controller; they should be as far apart as possible. At these measurement points, enter the required display value (start value, end value) in the controller.

-

Page 46: Controller

All manuals and user guides at all-guides.com 7 Configuration 7.2 Controller The following are set here: controller type, input variables of the controller, the Configuration setpoint limits, conditions for manual mode and the presettings for self-optimi- Analog inputs zation of the eight controller channels. Controller Generator Limit comparators... - Page 47 All manuals and user guides at all-guides.com 7 Configuration Controller 1 (2 to 8) Configuration Value/selection Description Dead band 0 to 100 The output movement is suppressed within the dead band; e. g. with noisy signals. The dead band is only effective for controller structures with an I-component.

- Page 48 All manuals and user guides at all-guides.com 7 Configuration Controller 1 (2 to 8) Inputs Value/selection Description Output feedback (Analog selector) Defines the source for output feedback. Switched off Output feedback must be configured in the case of a continuous controller with integral actuator driver! Additive (Analog selector) Defines the source for the additive disturbance.

-

Page 49: Generator

All manuals and user guides at all-guides.com 7 Configuration 7.3 Generator The basic function of the instrument is defined here. The instrument with all Configuration the available controller channels can be operated as fixed-setpoint controller, Analog inputs program controller or program generator. Controller Generator Furthermore, ramp functions (fixed-setpoint controller) can be activated for the... - Page 50 All manuals and user guides at all-guides.com 7 Configuration The ramp function can be stopped and canceled via the logic functions. v Chapter 7.6 “Logic functions” Ramp Ramp controller 1 (2 to 8) Value/selection Description Function Inactive Defines whether the ramp function is to be activated for the corresponding controller channel.

- Page 51 All manuals and user guides at all-guides.com 7 Configuration Program Value/selection Description Response to power Prog.canceled Response of the program run on a power failure failure Continue Standstill Program canceled: Program run canceled; instrument switches to basic status. Continue X% Continue PV Continue: The program continues from the point at which it was...

- Page 52 All manuals and user guides at all-guides.com 7 Configuration Program Value/selection Description Start at time Starts the program after an adjustable start delay, or at a time that can be defined (start with time). Setting the clock: v Chapter 7.11 “Device data” Program end time -1 to 0 to 9999 sec Duration of program end signal...

-

Page 53: Limit Comparators

All manuals and user guides at all-guides.com 7 Configuration 7.4 Limit comparators Limit comparators (limit monitors, limit contacts) can be used to monitor an input variable (limit comparator process value) against a fixed limit or another Configuration variable (limit comparator setpoint). When a limit is exceeded, a signal can be Analog inputs output or an internal controller function initiated. - Page 54 All manuals and user guides at all-guides.com 7 Configuration Limit comparator 1 (2to16) Value/selection Value/selection LK function no funct. Limit comparator function LK type 1 LK type 8 Limit value -1999 to 0 to +9999 Limit value to be monitored Switching 0 to 1 to 9999 Switching differential...

- Page 55 All manuals and user guides at all-guides.com 7 Configuration Absolute At the time of alteration, the limit comparator acts in accordance with its func- tion. Relative The limit comparator is in the OFF status. An alteration of the limit value or the (limit comparator) setpoint could cause the limit comparator to switch ON.

-

Page 56: Outputs

All manuals and user guides at all-guides.com 7 Configuration 7.5 Outputs Configuration of the instrument outputs are subdivided into analog outputs Configuration (max. 6) and logic outputs (max. 12). Display and numbering of the outputs de- Analog inputs pends on the assignment of the output slots OUT 1 to 6. Controller Generator Limit comparators... - Page 57 All manuals and user guides at all-guides.com 7 Configuration Analog outputs Analog output 1 (2 to 6) Value/selection Description Zero point -1999 to 0 to +9999 A physical output signal is assigned to the value range of an output variable. End value -1999 to 100 to +9999 Example:...

-

Page 58: Logic Functions

All manuals and user guides at all-guides.com 7 Configuration 7.6 Logic functions Functions are assigned here to the logic signals of the logic inputs, limit Configuration comparators and logic functions (formula). Analog inputs Controller In addition, the functions for control contacts, tolerance band signal and pro- Generator gram end signal are defined for program controllers/generators. - Page 59 All manuals and user guides at all-guides.com 7 Configuration Combined The functions are implemented through logic functions the combination of up to four control variables. Any control variable can be selected. The states Z1 to Z4 are assigned to the control variables in descending order of the control variables (see list on the right).

- Page 60 All manuals and user guides at all-guides.com 7 Configuration Program selection Program Z6 Z5 Z4 Z3 Z2 Z1 Program 1 Program 2 Program 3 Program 4 Program 64 0 = contact open /OFF 1 = contact closed /ON Multifunctional Logic functions can cover several func- logic functions tions simultaneously.

- Page 61 All manuals and user guides at all-guides.com 7 Configuration Logic input 1 (2 to 6) Limit comparator 1 (2 to 16) Logic 1 (2 to 16) Control contact 1 (2 to 16) Tolerance band signal Program end signal Ramp end signal 1 (2 to 8) Timer 1 (2 to 4) Value/selection Description...

- Page 62 All manuals and user guides at all-guides.com 7 Configuration Logic input 1 (2 to 6) Limit comparator 1 (2 to 16) Logic 1 (2 to 16) Control contact 1 (2 to 16) Tolerance band signal Program end signal Ramp end signal 1 (2 to 8) Timer 1 (2 to 4) Value/selection Description...

-

Page 63: Math And Logic Module

All manuals and user guides at all-guides.com 7 Configuration 7.7 Math and logic module Special controller types (differential, ratio, humidity, C-level controller) or Configuration mathematical formulae and logical combinations are configured here. Analog inputs Controller C-level control and math/logic formulae (math and logic module) are extras. Generator The results of the calculations can be called up, under the variables “Math X”... - Page 64 All manuals and user guides at all-guides.com 7 Configuration Ratio Control is always based on variable a. control The math module forms the ratio of the measurements of a and b (a/b) and produces the setpoint for the controller. The ratio is made available as a value, via the function “Math X”, and can be displayed.

-

Page 65: C-Level Control

All manuals and user guides at all-guides.com 7 Configuration 7.8 C-level control C-level control is used for the control of carbon in the atmosphere of a gas Configuration coking furnace. The C-level is determined through the oxygen measurement Analog inputs with a zirconium dioxide sensor and measurement of the sensor temperature. -

Page 66: C-Level Control Example

All manuals and user guides at all-guides.com 7 Configuration Value/selection Description Sensor voltage (Analog selector) Source for the voltage signal of the zirconium dioxide sensor Switched off Sensor (Analog selector) Source for the temperature signal of the zirconium dioxide temperature sensor Switched off CO measurement... -

Page 67: Display

All manuals and user guides at all-guides.com 7 Configuration 7.9 Display The time-dependent screen saving is defined here. In addition, time-out and Configuration the sequence of the different screen templates can be defined. The Analog inputs representations on the controller pictures 1 to 8 and on the collective picture Controller can be adapted to suit individual requirements. - Page 68 All manuals and user guides at all-guides.com 7 Configuration Value/selection Description Operating loop The screen templates that are to appear in the screen operating loop can be selected. Controller pic. 1 Visible as a factory setting: Controller pic. 8 - Controller pic. 1 Collective pic.

- Page 69 All manuals and user guides at all-guides.com 7 Configuration Collective picture Controller 1 (2 to 8) Value/selection Description Value column 1 (Analog selector) Display: Ramp end C1 Decimal point XXXX. column 1 Controller 1 Value column 2 (Analog selector) Controller 2 Setpoint C1 Controller 3 Controller 4...

-

Page 70: Interfaces

All manuals and user guides at all-guides.com 7 Configuration 7.10 Interfaces The interface parameters for the standard RS422/485 interface (MODbus 1) Configuration and an optional RS422/485 (MODbus 2) or PROFIBUS-DP interface have to Analog inputs be configured in order to communicate with PCs, bus systems and peripheral Controller devices. -

Page 71: Device Data

All manuals and user guides at all-guides.com 7 Configuration 7.11 Device data Basic settings such as supply frequency or temperature unit are made here. Configuration Analog inputs Controller Generator Limit comparators Outputs Logic functions Math / Logic C-level Display Interfaces Device data Recording Timers... -

Page 72: Recording

All manuals and user guides at all-guides.com 7 Configuration 7.12 Recording The recording function permits the visualization of up to four analog and three Configuration logic signals. The signal sources are defined here. Analog inputs Controller The ring memory contains a total of 43200 measurement points. The maxi- Generator mum recording time depends on the storage rate that was set and the number Limit comparators... -

Page 73: Timers

All manuals and user guides at all-guides.com 7 Configuration 7.13 Timers Timers are used for time-dependent control. The timer signal (timer 1 to 4) in- Configuration dicates whether the timer is active. The signal can be output via the logic out- Analog inputs puts or processed internally. - Page 74 All manuals and user guides at all-guides.com 7 Configuration...

-

Page 75: Optimization

All manuals and user guides at all-guides.com 8 Optimization 8.1 Self-optimization Oscillation Self-optimization SO establishes the optimum controller parameters for PID or method PI controllers. Depending on the controller type, the following controller parameters can be defined: Reset time (Tn), derivative time (Tv), proportional band (Xp), cycle time (Cy), filter time constant (dF) The controller selects one of two procedures (a or b), depending on the size of the control deviation:... - Page 76 All manuals and user guides at all-guides.com 8 Optimization With output type “solid-state”, the cycle time during optimization is reduced to 8 x the sampling time. With the “relay” output type, care has to be taken that the process value is not influenced by the switching cycle time, since otherwise optimization cannot be completed successfully.

- Page 77 All manuals and user guides at all-guides.com 8 Optimization Start of self-optimization during operation Starting self- Start at the operating level optimization h Select the controller channel in Operating level Self-optimization Controller number 1to8 h Start self-optimization for the selected controller channel with Status “Active”...

-

Page 78: Check Of The Optimization

All manuals and user guides at all-guides.com 8 Optimization h Switch the “Status” parameter at the operating level to “inactive” or press Canceling self- optimization again 8.2 Check of the optimization The optimum adaptation of the controller to the process can be checked by recording the start-up phase with the control loop closed. -

Page 79: Retrofitting Of Modules

All manuals and user guides at all-guides.com 9 Retrofitting of modules The following steps are necessary for retrofitting modules: Safety notes Only qualified personnel are permitted to retrofit modules. For safety reasons, care must be taken that the back panel and the fixing screws are correctly reassembled and mounted after the alterations. - Page 80 All manuals and user guides at all-guides.com 9 Retrofitting of modules h Pull off the pluggable connector Removing the back panel from h Loosen screws (do not remove (1) and (2)!) the housing OUT 1 / IN 5 OUT 2 / IN 6 OUT 3 / IN 7 COM 1 29-32...

- Page 81 All manuals and user guides at all-guides.com 9 Retrofitting of modules h Remove dummy module or existing module by using a screwdriver, for Retrofitting of modules example h Push module into the vacant slot until the pluggable connector snaps into place h Hook the back panel into the slots provided on the top edge and close it.

- Page 82 All manuals and user guides at all-guides.com 9 Retrofitting of modules...

-

Page 83: Appendix

All manuals and user guides at all-guides.com 10 Appendix 10.1 Technical data Thermocouple input Designation Measurement range Meas. accuracy Ambient temperature error Fe-Con L -200 to +900 °C 0.25 % 100 ppm / °C Fe-Con J EN 60584 -200 to +1200 °C 0.25 % 100 ppm / °C... - Page 84 All manuals and user guides at all-guides.com 10 Appendix Logic inputs Floating contacts Measurement circuit monitoring In the event of a fault, the outputs move to a defined (configurable) status. Sensor Overrange / Probe or lead short-circuit Probe or lead break underrange Thermocouple •...

- Page 85 All manuals and user guides at all-guides.com 10 Appendix Electrical data Supply voltage (switchmode PSU) AC 110 to 240 V +10/-15 % 48 to 63 Hz AC/DC 20 to 30 V 48 to 63 Hz (only for operation in SELV or PELV current circuits) Electrical safety to EN 61010, Part 1 overvoltage category III, pollution degree 2...

- Page 86 All manuals and user guides at all-guides.com 10 Appendix...

-

Page 87: Index

All manuals and user guides at all-guides.com 11 Index Dimensions 11 Display 67 Access code 35 Display end 43 Accessories 8 Acknowledgement 54 Action 54 Actuator time 35 End value Alarm 62 for analog signals 57 Alteration Event list 21 of the segment time for the current segment 33 External relay module 8 of the setpoint during the current segment 33... - Page 88 All manuals and user guides at all-guides.com 11 Index self-optimization 48 Module Sampling time 71 identification 79 Screen operating loop 20 retrofitting 79 Screen saving 67 Selectors 37 Self-optimization 48 Sensor temperature 66 OFF time 57 Setpoint ON time 57 alteration 25 Operating level 21 external 47...

- Page 89 All manuals and user guides at all-guides.com...

- Page 90 All manuals and user guides at all-guides.com...

- Page 91 All manuals and user guides at all-guides.com...

- Page 92 All manuals and user guides at all-guides.com JUMO GmbH & Co. KG JUMO Instrument Co. Ltd. JUMO Process Control, Inc. Street address: JUMO House 6733 Myers Road Moritz-Juchheim-Straße 1 Temple Bank, Riverway East Syracuse, NY 13057, USA 36039 Fulda, Germany...

Need help?

Do you have a question about the IMAGO 500 and is the answer not in the manual?

Questions and answers