Osburn OB01700 Owner's Manual

Hide thumbs

Also See for OB01700:

- Installation and operation manual (64 pages) ,

- Installation and operation manual (64 pages)

Table of Contents

Advertisement

Quick Links

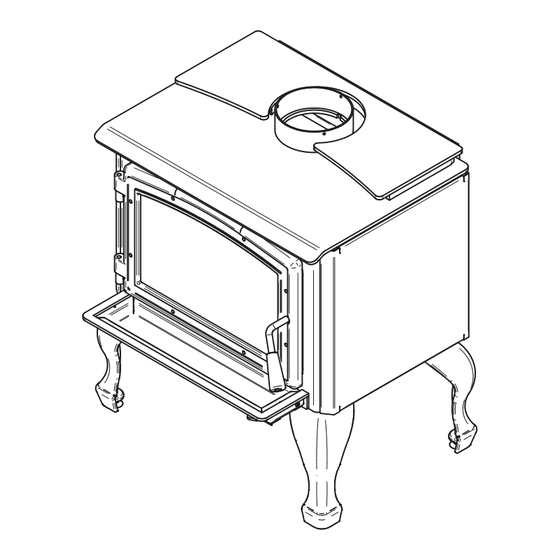

OSBURN 1700

(OB01700 model)

CONTACT LOCAL BUILDING OR FIRE OFFICIALS ABOUT RESTRICTIONS AND INSTALLATION INSPECTION REQUIREMENTS

IN LOCAL AREA.

READ THIS ENTIRE MANUAL BEFORE INSTALLATION AND USE OF THIS WOOD STOVE. FAILURE TO FOLLOW THESE

INSTRUCTIONS COULD RESULT IN PROPERTY DAMAGE, BODILY INJURY OR EVEN DEATH.

READ AND KEEP THIS MANUAL FOR REFERENCE

Printed in Canada

Wood Stove

Owner's Manual

Part 2 of 2

INSTALLATION AND OPERATION

US Environmental Protection Agency

phase II certified wood stove compliant

with 2020 cord wood standard

Safety tested according to CAN/ULC

S627, UL 1482 and UL 737 standards

by an accredited laboratory.

REQUIREMENTS

MOBILE

HOME

45982_IA

2023-07-27

Advertisement

Table of Contents

Summary of Contents for Osburn OB01700

- Page 1 Owner's Manual Part 2 of 2 INSTALLATION AND OPERATION OSBURN 1700 REQUIREMENTS (OB01700 model) US Environmental Protection Agency phase II certified wood stove compliant with 2020 cord wood standard Safety tested according to CAN/ULC S627, UL 1482 and UL 737 standards by an accredited laboratory.

- Page 2 If it can not be provided, the warranty period will be determined by the date of manufacture of the product. It is also highly recommended to register the warranty online at https://www.osburn-mfg.com/en/warranty/warranty-registration/ Registering the warranty will help to quickly find the information needed on the unit.

-

Page 3: Table Of Contents

6.10 Mobile Home Installation ....................39 7. Maintenance/Parts Replacement ..................40 7.1 Replacement ........................40 7.2 Gasket ..........................41 7.3 Door ..........................41 8. Exploded Diagram and Parts List ..................44 OSBURN LIMITED LIFETIME WARRANTY ................47 Installation and Operation Requirements - Osburn 1700 Page 3... -

Page 4: Certification Plate

1. CERTIFICATION PLATE Page 4 Installation and Operation Requirements - Osburn 1700... -

Page 5: General Information

This appliance is officially tested and certified by an independent agency. Tested and certified in compliance with CFR 40 part 60, subpart AAA, section 60.534(a)(1(ii) and ASTM E3053-17. Based on EPA letter dated November 1, 2022. Carbon monoxide. Installation and Operation Requirements - Osburn 1700 Page 5... -

Page 6: Specifications

CAN/CSA- Z240 MH standard. Tested and certified in compliance with CFR 40 part 60, subpart AAA, section 60.534(a)(1(ii) and ASTM E3053-17. Based on EPA letter dated November 1, 2022 Page 6 Installation and Operation Requirements - Osburn 1700... -

Page 7: Dimensions

19 1/4" 490mm 17 1/2" 444mm 10 7/8" 276mm 9 3/8" 239mm 15 3/4" 399mm 24 1/2" 622mm 25 7/8" 658mm 17 7/8" Figure 2: Front View Figure 3: Side View 454mm Installation and Operation Requirements - Osburn 1700 Page 7... - Page 8 19 1/4" 490mm 17 1/2" 444mm 10 7/8" 276mm 9 3/8" 239mm 15 3/4" 399mm 24 1/2" 622mm 25" 635mm 17 5/8" Figure 5: Front View Figure 6: Side View 449mm Page 8 Installation and Operation Requirements - Osburn 1700...

- Page 9 19 1/4" 490mm 17 1/2" 444mm 10 7/8" 276mm 9 3/8" 240mm 15 3/4" 399mm 22 1/2" 572mm 23 3/8" 595mm 14 7/8" 376mm Figure 8: Front View Figure 9: Side View Installation and Operation Requirements - Osburn 1700 Page 9...

- Page 10 17 1/4" 438mm Figure 10: Door Opening 3/16" 5/16" 19 5/8" 11 7/8" 498mm 301mm 13 1/2" 343mm Figure 11: Front View - Combustion Chamber Figure 12: Side View - Combustion Chamber Page 10 Installation and Operation Requirements - Osburn 1700...

- Page 11 The front (3rd) piece should stand off on the steel andirons by approximately 1-2 inches. The 2 other pieces should be added on top of the first Installation and Operation Requirements - Osburn 1700 Page 11...

- Page 12 4 inches cross section dimensions approximately) on top. To make sure combustion is equal, put the smallest piece on top of the first three, at the back of the firebox (see Figure 15 for an example of low burn load). Page 12 Installation and Operation Requirements - Osburn 1700...

- Page 13 For optimal medium fire load, use medium to large size fuel pieces (between 4- and 5.5-inches cross section dimensions approximately) on the bottom and use small to medium size fuel pieces (2.5 to 4 inches cross section dimensions approximately) on top. To make sure combustion is Installation and Operation Requirements - Osburn 1700 Page 13...

- Page 14 4 and 15 minutes after the loading period. Before closing further, make sure the flame intensity is increasing or stable. Turn ON the blower at maximum speed. Page 14 Installation and Operation Requirements - Osburn 1700...

-

Page 15: Clearances To Combustible Material

14 ¾" (375 mm) 14 ¾" (375 mm) The pipe distances listed in this table refer to the distances obtained when the stove is installed in accordance with the appliance clearances above mentioned. Installation and Operation Requirements - Osburn 1700 Page 15... - Page 16 48" Flush 48" 36" 122 cm 92 cm Figure 25: Clearances - Top Figure 26: Clearances - Corner 84" 213 cm Figure 27: Clearances - Side Page 16 Installation and Operation Requirements - Osburn 1700...

- Page 17 6" from combustible materials must be used. Only in this case, the same clearances as a certified double wall pipe connector can be used. The pipe distances listed in this table refer to the distances obtained when the stove is installed in accordance with the appliance clearances above mentioned. Installation and Operation Requirements - Osburn 1700 Page 17...

- Page 18 21 ¾" (552 mm) 21 ¾" (552 mm) The pipe distances listed in this table refer to the distances obtained when the stove is installed in accordance with the appliance clearances above mentioned. Page 18 Installation and Operation Requirements - Osburn 1700...

- Page 19 The pipe distances listed in this table refer to the distances obtained when the stove is installed in accordance with the appliance clearances above mentioned. Installation and Operation Requirements - Osburn 1700 Page 19...

- Page 20 20 ¾" (527 mm) 20 ¾" (527 mm) The pipe distances listed in this table refer to the distances obtained when the stove is installed in accordance with the appliance clearances above mentioned. Page 20 Installation and Operation Requirements - Osburn 1700...

- Page 21 122 cm 92 cm Les distances de tuyau listées dans ce tableau se réfèrent aux distances obtenues lorsque le poêle est installé en accord avec les dégagements de l’appareil mentionnés ci-dessus. Installation and Operation Requirements - Osburn 1700 Page 21...

-

Page 22: Floor Protection

The floor protection at the back of the stove is limited to the stove’s required clearance if such clearance is smaller than 8 inches (203 mm). Only required under the horizontal section (Ho) of the connector. Must exceed each side of the connector by at least 2 inches (51 mm). Page 22 Installation and Operation Requirements - Osburn 1700... -

Page 23: Reducing Wall And Ceiling Clearances Safely

Mounting hardware must not be located closer than 8" (200 mm) from the vertical centre line of the appliance. G) Edge clearance for ceiling shields to side and back walls: 3" (75 mm) Shield extension beyond each side of the appliance: 18" (450 mm) Installation and Operation Requirements - Osburn 1700 Page 23... - Page 24 Figure 29: Heat shield clearances Figure 30: Heat shield clearances Figure 31: Heat shield clearances Figure 32: Heat shield clearances Page 24 Installation and Operation Requirements - Osburn 1700...

- Page 25 Brick, with a minimum of 24 gauge (0.61 mm) sheet metal backing, spaced out at least 1" (25 mm)* by non-combustible spacers 12" (305 mm) * In Canada this space can be ⅞" (21 mm) Installation and Operation Requirements - Osburn 1700 Page 25...

-

Page 26: Installation Of Options On Your Product

Remove the door, the firebricks, and the ash plug from the stove, if desired. Put the stove on its back. Remove and dispose of the two freight supports (D). Keep the nuts (C) and washers (B) for step 4. Page 26 Installation and Operation Requirements - Osburn 1700... - Page 27 Install the legs (E) on the legs supports (F). Secure with the washers (G) and nuts (H) supplied with the leg assembly. With the nuts (C) and washers (B) removed in step 2, secure both leg assemblies to the stove. Installation and Operation Requirements - Osburn 1700 Page 27...

- Page 28 See step 1. The baffle and the bricks must be put back in the right place after the final positioning of the stove. Page 28 Installation and Operation Requirements - Osburn 1700...

-

Page 29: Pedestal Installation

Remove the door, the firebricks and the ash plug from the stove, if desired. Put the stove on its back. Remove and dispose of the two freight supports (D). Keep the nuts (C) and washers (B) for step 3. Installation and Operation Requirements - Osburn 1700 Page 29... - Page 30 See step 1. The baffle and the bricks must be put back in the right place after the final positioning of the stove. Page 30 Installation and Operation Requirements - Osburn 1700...

-

Page 31: Door Overlay Installation

Position the overlay (A) on the door frame and secure it in place from behind using the nuts (B). To ease the installation, do not tighten the nuts until they are all installed. Note: It is not necessary to remove the glass to install the overlay. Installation and Operation Requirements - Osburn 1700 Page 31... -

Page 32: Decorative Panels

Decorative Panels To remove the decorative panel (A), remove the screws (B) and push forward on the panel to unhook it from the bracket (C). Page 32 Installation and Operation Requirements - Osburn 1700... -

Page 33: Optional Fresh Air Intake Kit Installation

(HVAC type, must meet ULC S110 or UL 181 class 0 or class 1) (B), sold separately. Refer to air intake kit installation instructions for more details. Installation with legs Installation with pedestal Installation and Operation Requirements - Osburn 1700 Page 33... -

Page 34: Optional Fire Screen Installation

Lift the fire screen upwards and push the bottom part towards the stove then let the fire screen rest on the bottom of the door opening. Warning: Never leave the stove unattended while in use with the fire screen. Page 34 Installation and Operation Requirements - Osburn 1700... -

Page 35: Optional Blower And Thermodisc Installation

Ensure that the blower’s power cord is not in contact with any surface of the stove to prevent electrical shock or fire damage. Do not run the power cord beneath the stove. Installation and Operation Requirements - Osburn 1700 Page 35... -

Page 36: Log Retainers Installation

Log Retainers Installation Page 36 Installation and Operation Requirements - Osburn 1700... -

Page 37: Air Tubes And Baffle Installation

Put the baffle in place. Repeat steps 1 and 2 for the three other tubes. To remove the tubes use the above steps in reverse order. Installation and Operation Requirements - Osburn 1700 Page 37... - Page 38 Note that secondary air tubes (B) can be replaced without removing the baffle board (A) and that all tubes are not necessarely identical (look at the part number on the tube). Page 38 Installation and Operation Requirements - Osburn 1700...

-

Page 39: Mobile Home Installation

For a stove on legs, install a plate (L) on each leg and screw it in place with the proper hardware (M). For a stove on a pedestal, remove the plugs (N) and screw the base on the floor with the proper hardware (O). Installation and Operation Requirements - Osburn 1700 Page 39... -

Page 40: Maintenance/Parts Replacement

Reinstall the glass, being careful to centre the glass in the door and not to over-tightening the retaining screw. The two main causes of broken door glass are uneven placement in the door and over-tightening the retaining screws. Page 40 Installation and Operation Requirements - Osburn 1700... -

Page 41: Gasket

Remove the split pin by pulling and turning it using pliers. Turn the handle one counterclockwise turn to increase pressure. Reinstall the split pin with a small hammer. Figure 33: Removing the split pin Figure 34: Installing the split pin Installation and Operation Requirements - Osburn 1700 Page 41... - Page 42 Using a flat screwdriver, turn the adjustable hinge rods in the direction shown to adjust the doors. Tighten all door hinge pressure screws when they are at the desired positions. Configurations 1-2-3-4-5-6, show in which direction these act on the adjustment of the door. Page 42 Installation and Operation Requirements - Osburn 1700...

- Page 43 Leave about ½" long of the gasket when cutting and press the end into the groove. Tuck any loose fibers under the gasket and into the silicone. Close the door. Do not use the stove for 24 hours. Installation and Operation Requirements - Osburn 1700 Page 43...

-

Page 44: Exploded Diagram And Parts List

8. Exploded Diagram and Parts List Page 44 Installation and Operation Requirements - Osburn 1700... - Page 45 30050 LEVELING BOLT 3/8-16 X 1 1/2" 30100 BLACK HEX NUT 1/4 - 20 (NON-OILED) 30185 17/64" AA TYPE WASHER BLACK 30025 1/4-20 X 1/2" PAN-HEAD QUADREX BLACK SCREW PL70631 FACEPLATE Installation and Operation Requirements - Osburn 1700 Page 45...

- Page 46 CROSSFLOW BLOWER SINGLE CAGE 130 CFM 115V-60Hz-56W 44028 CERAMIC THERMODISC F110-20F SE45982 OSBURN 1700 INSTRUCTIONS MANUAL KIT AC05959 METALLIC BLACK STOVE PAINT - 342 g (12oz) AEROSOL PL75747 1.7 SERIES SECONDARY AIR TUBE Page 46 Installation and Operation Requirements - Osburn 1700...

-

Page 47: Osburn Limited Lifetime Warranty

Labour cost and repair work to the account of the manufacturer are based on a predetermined rate schedule and must not exceed the wholesale price of the replacement part. Shall your unit or a components be defective, contact immediately your OSBURN dealer. To accelerate processing of your warranty claim, make sure to have on hand the following information when calling:... - Page 48 Resale is strictly prohibited. The manufacturer may update St-Augustin-de-Desmaures (Québec) Canada this document from time to time and cannot be responsible G3A 2H3 for problems, injuries, or damages arising out of the use 1-877-356-6663 of information contained in any document obtained from www.osburn-mfg.com/en unauthorized sources. tech@sbi-international.com...

Need help?

Do you have a question about the OB01700 and is the answer not in the manual?

Questions and answers