Table of Contents

Advertisement

Quick Links

Model 250PR

Service/Repair Manual

TABLE OF CONTENTS

SAFETY NOTES ........................................................................................................................................... 2

INTRODUCTION AND THEORY OF OPERATION ..................................................................................... 3

HYDRAULIC SCHEMATIC ........................................................................................................................... 4

MAINTENANCE AND SERVICE .................................................................................................................. 5

TWG 250PR RECOMMENDED OILS .......................................................................................................... 6

OIL CHANGE ................................................................................................................................................ 7

DISASSEMBLY ............................................................................................................................................ 8

ASSEMBLY .................................................................................................................................................. 9

SERVICING THE BRAKE ........................................................................................................................... 10

SERVICING THE BEARING AND PINION SECTION ................................................................................ 12

SERVICING THE PLANETARY SETS ....................................................................................................... 13

TROUBLESHOOTING ................................................................................................................................ 14

TORQUE SPECIFICATIONS CHART ........................................................................................................ 15

BILL OF MATERIAL ................................................................................................................................... 16

CROSS SECTIONAL ASSEMBLY DRAWING .......................................................................................... 17

EXPLODED ASSEMBLY DRAWING ......................................................................................................... 18

INSTALLATION DRAWING........................................................................................................................ 19

SEL-0152-000

www.team-twg.com

REV 1 JUNE 2015

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Dover TWG 250PR

-

Page 1: Table Of Contents

SAFETY NOTES ............................2 INTRODUCTION AND THEORY OF OPERATION ..................3 HYDRAULIC SCHEMATIC ........................... 4 MAINTENANCE AND SERVICE ........................5 TWG 250PR RECOMMENDED OILS ......................6 OIL CHANGE ..............................7 DISASSEMBLY ............................8 ASSEMBLY ..............................9 SERVICING THE BRAKE ........................... 10 SERVICING THE BEARING AND PINION SECTION ................ -

Page 2: Safety Notes

SAFETY NOTES FAILURE TO HEED THE FOLLOWING WARNINGS MAY RESULT IN SERIOUS INJURY OR DEATH! • Operators/Technicians must be trained in the proper, safe operation of the swing-drive gearbox. • All shields and guards must be in place during operation of swing-drive gearbox. •... -

Page 3: Introduction And Theory Of Operation

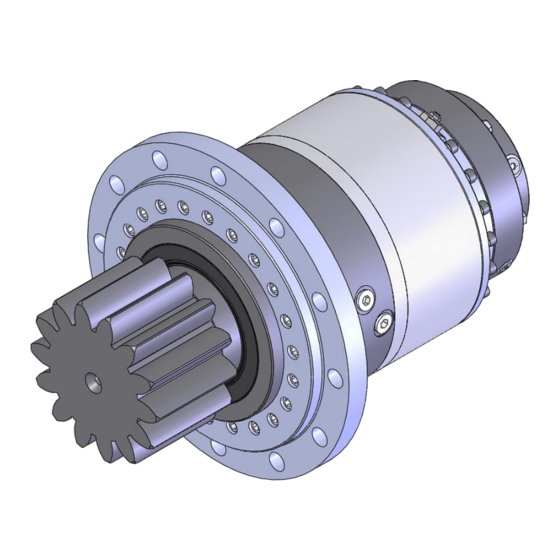

INTRODUCTION AND THEORY OF OPERATION The TWG 250PR planetary gearbox is a hydraulically driven 2-stage planetary gearbox designed to use a motor with SAE “A” 2-BOLT mount and 1.00” 6B spline shaft. This gearbox has a total ratio of 38:1. -

Page 4: Hydraulic Schematic

HYDRAULIC SCHEMATIC The TWG 250PR is equipped with a spring applied hydraulically released static “park brake” and an optional integral hydraulically applied dynamic “service brake”. The park brake on this unit should full release by pressurizing the “BR” port to 300 psi. The maximum pressure allowed into the park brake is 3,000 psi. -

Page 5: Maintenance And Service

MAINTENANCE AND SERVICE For safe and consistent operation of TWG hoists, gearboxes, and winches, a regular program of preventive maintenance is strongly recommended. Regular oil changes with the correct oil and frequency for the application and an annual inspection of the wear components will help ensure a long life for your planetary geared products. -

Page 6: Twg 250Pr Recommended Oils

TWG 250PR RECOMMENDED OILS Choose the proper gearbox and brake oil from lists below FOR STANDARD TEMP APPLICATIONS -10˚F THRU 180˚F (-23˚C THRU 82˚C) oil temp. *Gearbox oil (GL-5): API 80W/90 GL-5 (Or equivalent) Super MP 75W-90 GL-5 (Original oil in unit from factory) -

Page 7: Oil Change

OIL CHANGE Gearbox oil is drained by removing the drain plug and vent. Examine the used oil for signs of significant metal deposits and then dispose of it in a proper manner. Replace the drain plug. Fill the swing drive with the appropriate amount and type of oil and then See page 6 of this manual for the recommended oil type, amount and grade replace plug and vent. -

Page 8: Disassembly

DISASSEMBLY 1. Remove the gearbox from the crane by securing the boom, removing the 20 mounting bolts and any hydraulic hoses connecting the crane to the gearbox assembly. 2. Orient the gearbox vertical and drain the gear oil from the gearbox. See page 7 of this manual. -

Page 9: Assembly

ASSEMBLY 1. After servicing, inspecting and or repairing the Brake, Pinion Bearing and or the Planetary Gear sub-assemblies start reassembly by positioning the Bearing/Pinion section in a pinion down orientation. 2. Install new O-ring (Item 43) onto ring gear pilot on top of bearing housing (Item 1). 3. -

Page 10: Servicing The Brake

SERVICING THE BRAKE 1. Evenly remove the six bolts (Item 26) attaching the brake housing (Item 27) to the brake adapter (Item 19). Spring pressure will raise the brake housing as the bolts are loosened. Remove the brake housing from the brake adapter. 2. - Page 11 18. Carefully place brake housing assembly onto the piston ensuring to orient the motor mount bolts and all ports properly. Ensure the dowel pin (Item 34) is installed through the brake housing, brake piston and brake adapter. Tap brake housing down until it makes contact with the springs.

-

Page 12: Servicing The Bearing And Pinion Section

SERVICING THE BEARING AND PINION SECTION Remove the gearbox from the vehicle by removing the bolts in the mounting flange (Item 9). Remove the brake sub-assembly, gear sets (Items 10 and 11), and ring gear (Item 12) from unit by removing the twenty ring gear bolts and washers (Items 15 and 53). Note or mark the orientation of the brake housing in relation to the gearbox oil drain port located in the bearing housing (Item 1) for re-assembly. -

Page 13: Servicing The Planetary Sets

SERVICING THE PLANETARY SETS The TWG 250PR planetary gear sets (Items 10 and 11) are not serviceable in the field. Replace as a unit. Inspect for any damage or wear and replace if necessary. -

Page 14: Troubleshooting

TROUBLESHOOTING GEARBOX BRAKE WON’T HOLD Possible Solutions: 1. The brake discs and or stator plates are worn. Friction discs should measure no less than 0.075 inches thick and the stator plates should measure at least 0.045 inches thick and replace as necessary 2. -

Page 15: Torque Specifications Chart

TORQUE SPECIFICATIONS CHART Plated Lubricated Plated Lubricated Grade 5 Grade 5 Grade 5 Grade 8 Grade 8 Grade 8 Torque Torque Torque Torque Torque Torque Nominal Size *(Ft-Lbs) *(Ft-Lbs) *(Ft-Lbs) *(Ft-Lbs) *(Ft-Lbs) *(Ft-Lbs) ¼ ¼ 5/16 5/16 7/16 7/16 ½ ½... -

Page 16: Bill Of Material

BILL OF MATERIAL Item Part Number Description Qty./Parent 45558 HOUSING, BEARING, 250PR 45554 SHAFT, OUTPUT, PINION, 250PR 45571 BEARING, SPHERICAL 29967 BEARING, BALL 45559 SPACER, BEARING, 250PR 45572 RING, RETAINING 45573 RING, RETAINING 45553 FLANGE, MOUNTING, PLR250 4610 GEARSET, OUTPUT, 250PR 4611 GEARSET, INPUT, 38:1, 250PR 45646... -

Page 17: Cross Sectional Assembly Drawing

CROSS SECTIONAL ASSEMBLY DRAWING... -

Page 18: Exploded Assembly Drawing

EXPLODED ASSEMBLY DRAWING... -

Page 19: Installation Drawing

INSTALLATION DRAWING PO Box 1130 Jenks OK 74037-1130 USA Phone: 918-298-8300 www.dovertwg.com...

Need help?

Do you have a question about the TWG 250PR and is the answer not in the manual?

Questions and answers