Advertisement

Quick Links

COMMERCIAL DRYER

MODEL T-30 SWD VENDED

C-SERIES CONTROL, ELECTRC-HEATED

The dryer will operate correctly in ambient temperatures of +5°C to +45°C, in relative humidity up to

50% at +40°C and above 50% when below +40°C, and at altitudes up to 1000m above sea level,

must be transported and stored from -40°C to +140°C, and has been packaged to prevent damage

from humidity, vibration, and shock. Take measures to avoid harmful effects of occasional

condensation.

Post the following "For Your Safety" caution in a prominent location:

Do not store or use petrol or other flammable vapours and liquids or dry cleaning solvents in the

vicinity of this or any other appliance.

THIS MACHINE IS FOR DRYING ONLY FABRICS WASHED IN WATER.

To avoid possibility of fire, including spontaneous combustion, do not dry oiled floor mops, items

containing foam rubber or similarly textured rubberlike materials or any material on which you have

used a cleaning solvent or which contains flammable liquids or solids (such as petrol, kerosene, waxes,

etc.) Fabric softeners, or similar products, should be used per the fabric softener instructions. Remove

all objects from pockets such as lighters and matches.

WARNING – Risk of Fire

Clothes dryer installation must be performed by a qualified installer.

Install the clothes dryer according to the manufacturer's instructions and local codes.

Do not install a clothes dryer with flexible plastic venting materials. If flexible metal (foil type) duct is

installed, use duct that has been investigated and found acceptable for use with clothes dryers.

Flexible venting materials are known to collapse, be easily crushed, and trap lint. These conditions will

obstruct clothes dryer airflow and increase the risk of fire.

To reduce the risk of severe injury or death, follow all installation instructions.

This appliance can be used by children aged from 8 years and above and persons with reduced

physical, sensory or mental capabilities or lack of experience and knowledge if they have been

given supervision or instruction concerning use of the appliance in a safe way and understand the

hazards involved. Children shall not play with the appliance. Cleaning and user maintenance shall

not be made by children without supervision. Children of less than 3 years should be kept away

unless continuously supervised.

It is important that you read this Manual and retain it for future reference. For service or

replacement parts, contact the distributor in your area or manufacturer:

8514-293-001 REV C PAGE 1

OPERATOR'S MANUAL

INSTALLATION & OPERATION INSTRUCTIONS

FOR YOUR SAFETY

FOR YOUR SAFETY

Dexter Laundry, Inc.

2211 West Grimes Avenue

Fairfield, Iowa 52556, USA

Original Instructions

For GB & IE

Advertisement

Summary of Contents for Dexter Laundry T-30 SWD

- Page 1 COMMERCIAL DRYER Original Instructions MODEL T-30 SWD VENDED For GB & IE C-SERIES CONTROL, ELECTRC-HEATED OPERATOR’S MANUAL INSTALLATION & OPERATION INSTRUCTIONS The dryer will operate correctly in ambient temperatures of +5°C to +45°C, in relative humidity up to 50% at +40°C and above 50% when below +40°C, and at altitudes up to 1000m above sea level, must be transported and stored from -40°C to +140°C, and has been packaged to prevent damage...

- Page 2 TABLE OF CONTENTS Page No. Warnings about use and operation Dryer Specifications Dryer Dimensions Installation Instructions 6 – 11 Dryer Shutdown Operating Instructions Programming the Dryer Control 13 – 21 Servicing and Troubleshooting Preventative Maintenance Instructions WARNINGS ABOUT USE AND OPERATION Caution! There are sharp edges on various sheet metal parts internal to the enclosure.

- Page 3 WARNINGS ABOUT USE AND OPERATION continued THIS DRYER IS EQUIPPED WITH A MANUALLY RESETTABLE OVER-TEMPERATURE THERMOSTAT located above the motor on the rear of the cabinet. Should the dryer cease to heat, refer to your “Service Procedure and Parts Data” book for instructions. CHECK THIS THERMOSTAT WHEN INSTALLING DRYER to assure it is not tripped.

- Page 4 SPECIFICATIONS 30 lb. Commercial Dryer: T-30 SWD DCS030E_-79 (50Hz) Cabinet Height (As a stand-alone dryer) 38 7/8” 987 mm. (Assumes minimum leveling leg adjustment) Cabinet Height (Combo washer/dryer) 78 3/4” 2000 mm. Cabinet Width 31 1/2” 800 mm. Overall Depth 49 7/16 1256 mm.

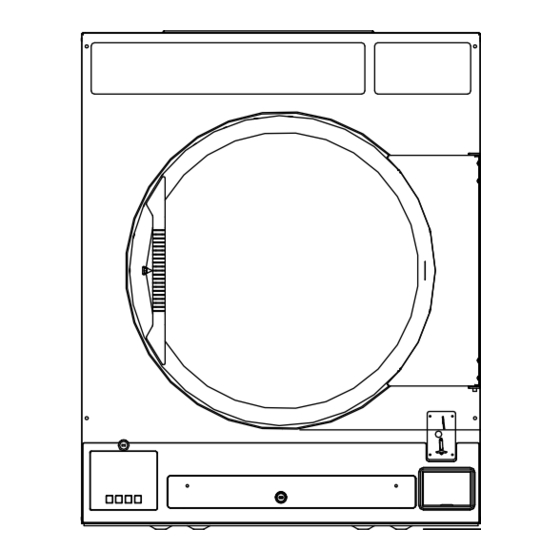

- Page 5 FIGURE 1 – DRYER DIMENSIONS inches [mm] 8514-293-001 REV C PAGE 5...

- Page 6 INSTALLATION INSTRUCTIONS This dryer may have been supplied as part of a washer/dryer stacked appliance. If so, refer to the washer instructions for uncrating and hard mounting the stacked unit to a concrete floor and observe the dryer clearances listed below. Note: A forklift, or a hand pallet truck or jack, must lift the washer/dryer and only from the front or rear of the washer/dryer with the washer bolted to the pallet and supported the full length of the washer/dryer.

- Page 7 VERTICAL CLEARANCE DIMENSIONS 3. MAKE-UP AIR. Adequate make-up air must be supplied to replace air exhausted by dryers on all types of installations. Provide a minimum air opening to the outside for each dryer as follows: Dryer Model Make-up Air Volume/Time Make-up Air Opening Size (minimum) DCS030E 450 CFM (12.7 m...

- Page 8 4. ELECTRICAL REQUIREMENTS: The electrical installation must be performed by a qualified electrical technician. The electrical power requirements necessary to operate the unit satisfactorily are listed on the serial plate located on the back panel of each dryer. The electrical connection should be made at the terminal blocks in the control box on the rear of the unit using conductors rated at 75 C (167 F) and a wire size adequate to handle the amperage and voltage listed on the serial plate (see table below for recommended minimum sizes).

- Page 9 CONTROL TRANSFORMER CONNECTIONS Adjustment for different voltages of supply mains. FOR -79C MODELS: FOR -79X MODELS: IMPORTANT: TRANSIENT VOLTAGE SURGE SUPPRESSORS Like most electrical equipment your new machine can be damaged or have its life shortened by voltage surges due to lightning strikes which are not covered by factory warranty. Local power distribution problems also can be detrimental to the life of electrical components.

- Page 10 are helped to have a longer useful life when they are supplied with the clean stable electrical power they like. 6. EXHAUST INSTALLATION. (Refer to Figure 3 at the end of section 6.) The exhaust duct connection near the top of the dryer will accept a 152 mm (6 in.) round duct. Exhausting of the dryer(s) should be planned and constructed so that no air restrictions occur.

- Page 11 NOTE: Never install the individual ducts at a right angle into the main discharge duct. The individual ducts from the dryers can enter at the sides or bottom of the main discharge duct. Figure 3 indicates the various round main duct diameters to use with the individual dryer ducts.

- Page 12 OPERATING INSTRUCTIONS Maximum Load Capacity: 13.6 kg Dry Weight for DCS030E STARTING THE DRYER 1. The display on the dryer control will show the required vend amount when in idle mode. Once the door is opened it will prompt the user to add money. Load clothes into the dryer. Close the door completely. 2.

- Page 13 PROGRAMMING THE DRYER CONTROL The dryer control can be programmed to prompt the user for alternate vend prices, change dryer cycle times, temperatures and many other options. This can be accomplished in two ways: 1. Manual programming utilizing the “Start”, “High”, “Medium” and “Low” buttons on the dryer. 2.

- Page 14 These alternate functions allow the user to move through a menu of options to choose various programmable settings. The figure below shows the top level menu. Choosing an option from the top level menu will then display the next level of options (the sub menu). Quick Test Option: When the Quick Test Option is chosen, the dryer will begin a shortened dry cycle without the displayed vend price being met.

- Page 15 4. “FREE SET TIME” is the cycle time that the customer has available if the Base Vend Price is set to “FREE”. 5. “EXTEND DRY” sets the price and time for additional drying time that becomes available after the customer has already met the Base Vend Price. To reset either the coin acceptor inputs or the vend price to factory default, press “Enter”...

- Page 16 Cycles Option: This option allows the user to set temperature and cooldown information for the drying cycle. It also allows the user to return the values to factory defaults. 1. “TEMP SETTINGS” allows the user to make adjustments, within a designated range, to the cycling temperature for each of the “Low”, “Medium”...

- Page 17 The figure below shows the sub menu options for Cycles: 8514-293-001 REV C PAGE 17...

- Page 18 Temperature Pricing Option: This option allows the user to require additional vend amounts be added based on the drying temperature chosen by the customer. This pricing adder is effective only for the Base Vend Price (it does not affect the Extend Dry Price). It allows a pricing adder separate for “Medium” and “Hot” temperature settings. Example- A store owner has programmed the control for the following: Vend Price $1.00...

- Page 19 7. “Shift Hours”: This feature allows the user to shift the time used by the control from the time kept internally by the control. The control uses a Real Time Clock (RTC) to internally track the time and date. The RTC continues operation even if the control loses external power. The RTC is set for Central Standard Time and no daylight savings.

- Page 20 The figure below shows the sub menu options for Settings: 8514-293-001 REV C PAGE 20...

- Page 21 Usage Menu: The Usage menu allows for the user to track data about machine usage. See below for detailed information on each sub menu option. 1. “Coin Audit”: The coin audit field shows the accumulation of coin pulses that were sent to the control over each of the left and right coin inputs.

- Page 22 Control Menu: The Control menu allows for the user to observe important technical information for the control. No changes can be made at this menu. See below for detailed information on each sub menu. 1. “Serial Number”: This is the control serial number. 2.

- Page 23 SERVICING AND TROUBLESHOOTING CAUTION: Label all wires prior to disconnection when servicing controls. Wiring errors can cause improper and dangerous operation. Verify proper operation after servicing. IMPORTANT: Clothes should be removed from the dryer as soon as possible after the cycle is completed and then folded or hung to prevent excessive wrinkling.

- Page 24 9555-057-002 SERVICE MANUAL 8533-086-001 For service and parts information, contact your local Dexter agent. If a Dexter agent is not available, contact Dexter Laundry, Inc. directly as listed below: Mailing Address: 2211 West Grimes Avenue Phone: 1-800-524-2954 Fairfield, IA 52556 USA Website: www.dexter.com/...

- Page 25 DOW CORNING -- MOLYKOTE BR2-S GREASE -- 9150-00K000170 ================== Product Identification ===================== Product ID: MOLYKOTE BR2-S GREASE MSDS Date: 01/01/1985 FSC: 9150 NIIN: 00K000170 MSDS Number: BBZNK ==================== Responsible Party ===================== Company Name: DOW CORNING Emergency Phone Number: 517-496-5900 CAGE: 5D028 ================== Contractor Identification =================== Company Name: DOW CORNING CORP Address: 3901 S SAGINAW RD Box: 997...

- Page 26 Machinery Directive on machinery safety, 2006/42/EC Conforming Commercial Drying System Machinery: Model Numbers: DC30X2E, DC0030E, DC0050E, DC0080E, DCS030E Serial Numbers: Manufacturer: Dexter Laundry, Inc. 2211 West Grimes Avenue Fairfield, IA 52556 USA Harmonised EN ISO 12100:2010 Safety of machinery. General principles for Standards design.

- Page 27 WITH COUNCIL DIRECTIVE 2004/108/EC Directive: Electromagnetic Compatibility Directive 2004/108/EC Conforming Commercial Drying System Machinery: Model Numbers: DC30X2E, DC0030E, DC0050E, DC0080E, DCS030E Manufacturer: Dexter Laundry, Inc. 2211 West Grimes Avenue Fairfield, IA 52556 USA Harmonised EN 55014-1:2006/A2:2011 Electromagnetic compatibility. Requirements Standards...

- Page 28 Declaration of Noise Emission The Dexter Laundry Commercial Drying System Models Sound Pressure Levels per EN ISO 11202 as measured on similarly constructed models are as follows: Model DCBD30KC-64FN Operating Idle (Operator Position) 61 dB (A) 54 dB (A) (Bystander Position)

Need help?

Do you have a question about the T-30 SWD and is the answer not in the manual?

Questions and answers