Summary of Contents for Ruijie Reyee RG-NBS7006

- Page 1 Ruijie Reyee RG-NBS7006 Switch Hardware Installation and Reference Guide Document Version: V1.0 Date: Apirl 20, 2023 Copyright © 2023 Ruijie Networks...

- Page 2 Due to product version upgrades or other reasons, the content of this document will be updated from time to time. Ruijie Networks reserves the right to modify the content of the document without any notice or prompt. This manual is for reference only. Ruijie Networks endeavors to ensure content accuracy and will not shoulder...

- Page 3 Intended Audience This document is intended for: Network engineers Technical support and service engineers Network administrators Technical Support Official website of Ruijie Reyee: https://www.ruijienetworks.com/products/reyee Technical support website: https://ruijienetworks.com/support Case portal: https://caseportal.ruijienetworks.com Community: https://community.ruijienetworks.com ...

- Page 4 Note An alert that contains additional or supplementary information that if not understood or followed will not lead to serious consequences. Specification An alert that contains a description of product or version support. 3. Note This manual provides the device installation steps, hardware troubleshooting, module technical specifications, and specifications and usage guidelines for cables and connectors.

-

Page 5: Product Overview

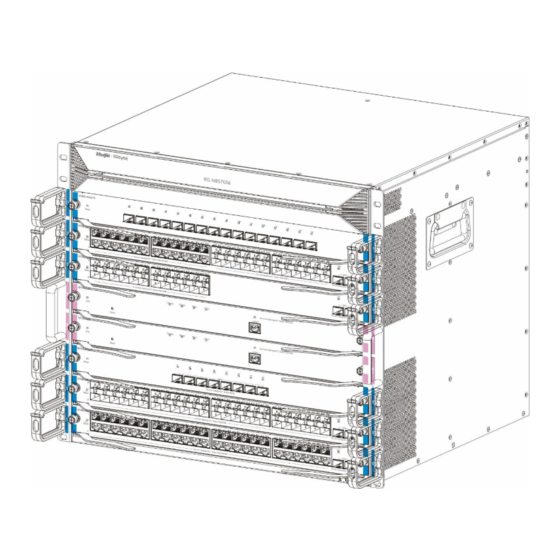

Hardware Installation and Reference Guide Product Overview Product Overview The RG-NBS7000 series switches are next-generation switches launched by Ruijie independently. The switch comes into two models: RG-NBS7006 and RG-NBS7006. RG-NBS7006: The switch provides two supervisor engine slots and six line card slots. - Page 6 Hardware Installation and Reference Guide Product Overview System modules: The switch provides two supervisor engine slots and six line card slots. The switch supports 1+1 supervisor engine redundancy. You are advised to configure supervisor engine redundancy. You can select different line cards as needed. ...

- Page 7 Hardware Installation and Reference Guide Product Overview Figure 1-2 Front Panel of the RG-NBS7006 Switch 1. Supervisor Engine Slot Cable Management Frame Line Card Slot Caution Ensure the line cards and power supply modules are removed from the chassis before you move the RG-NBS7006 chassis.

- Page 8 Hardware Installation and Reference Guide Product Overview Figure 1-3 Back Panel of the RG-NBS7006 Switch 1. Power Supply Module 4. Captive Screw 2. Fan Module 5. Nameplate 3. Fan Module Handle Power Supply The RG-NBS7006 switch adopts AC power input. ...

-

Page 9: Heat Dissipation

Hardware Installation and Reference Guide Product Overview 2. A fan module is not in place. 3. The supervisor engine is not functioning properly. The system is not functioning properly due to a fan fault, power fault, or system fault. Blinking red The switch may be damaged if it continues to work. - Page 10 Hardware Installation and Reference Guide Product Overview Figure 1-4 Air Intake Design 1. Air intakes for power supply modules 3. Air intakes for line cards and supervisor engines 2. Air intakes for line cards and supervisor engines...

- Page 11 Hardware Installation and Reference Guide Product Overview Figure 1-5 Air Exhaust Design 1. Air intakes for line cards and supervisor 1. Air intakes for power supply modules engines The line cards and the supervisor engine adopts side-to-rear airflow for proper ventilation. The power supply module adopts front-to-rear airflow for proper ventilation.

-

Page 12: Technical Specifications

Hardware Installation and Reference Guide Product Overview 1.1.7 Technical Specifications Model RG-NBS7006 Module Slot Two supervisor engine slots and six line card s lots Supervisor Engine M7006-CM Supervisor Engine Supported Redundancy The following seven line cards are available: M7000-16XS-EA M7000-48GT2XS-EA M7000-24GT2XS-EA Line Card M7000-24GT24SFP2XS-EA... - Page 13 Hardware Installation and Reference Guide Modules MTBF Over 200,000 hours dB at 35°C (95° F) Noise 70 dB at 50°C (122° F) Net weight: 25 kg (55.12 lbs), excluding line cards, supervisor engines and filler Weight panels Dimensions 442 mm x 410 mm x 396 mm (17.40 in. x 16.14 in. x 15.60 in., without cable management brackets), 9U (W x D x H) Note...

- Page 14 Hardware Installation and Reference Guide Modules Figure 2-1 Appearance of the M7006-CM Module Ports The M7006-CM module provides one external port: 10/100 Mbps MGMT port: 10/100BASE-T RJ45 Ethernet port. You can use a network cable to connect the port with the Ethernet port of a computer to load programs. Buttons The M7006-CM module provides a Reset button (the reset button of the switch) for resetting the switch system .

- Page 15 Hardware Installation and Reference Guide Modules Status LED Solid green The power supply module is operating normally. Blinking red The power supply module is not functioning properly. The switch is powered off. Solid green The fan module is operating normally. Fan Status LED FAN1 Blinking yellow...

-

Page 16: Line Cards

Hardware Installation and Reference Guide Modules Power < 30 W Consumption Safety GB 4943.1 Standard Operating 0° C to 50° C (32° F to 122° F) Temperature Storage –40° C to +70° C (–40° F to +158° F) Temperature Operating 10% to 90% RH (non-condensing) Humidity MTBF... - Page 17 Ports 16 x SFP+ ports For details, s ee Appendix B. (Copper cables are not supported.) SFP Modules The supported models may be subject to change without prior notice. Contact Ruijie and Cables Networks for details. Status LED Link/ACT LED...

- Page 18 Hardware Installation and Reference Guide Modules Weight Net weight: 1.75 kg (3.86 lbs) Dimensions 438.5 mm x 196 mm x 40.2 mm (17.26 in. x 7.72 in. x 1.58 in.) (W x D x H) 2. M7000-24GT24SFP2XS-EA Module Appearance Figure 2-3 Appearance of the M7000-24GT24SFP2XS-EA Module Ports The M7000-24GT24SFP2XS-EA module provides 24 x 10/100/1000BASE-T RJ45 ports, 24 x SFP ports, and 2...

- Page 19 Ports 2 x SFP+ ports For details, s ee Appendix B. (Copper cables are not supported.) SFP Modules The supported models may be subject to change without prior notice. Contact Ruijie and Cables Networks for details. Status LED Link/ACT LED...

- Page 20 Hardware Installation and Reference Guide Modules Temperature Operating 10% to 90% RH (non-condensing) Humidity MTBF Over 200,000 hours Net weight: 2.1 kg (4.63 lbs) Weight Dimensions 438.5 mm x 196 mm x 40.2 mm (17.26 in. x 7.72 in. x 1.58 in.) (W x D x H) 3.

- Page 21 10/100/1000BASE-T RJ45 ports Ports 2 x SFP+ ports For details, see Appendix B. (Copper cables are not supported.) SFP Modules The supported models may be subject to change without prior notice. Contact Ruijie and Cables Networks for details. Status LED Link/ACT LED...

- Page 22 Hardware Installation and Reference Guide Modules MTBF Over 200,000 hours Net weight: 2.05 kg (4.52 lbs) Weight Dimensions 438.5 mm x 196 mm x 40.2 mm (17.26 in. x 7.72 in. x 1.58 in.) (W x D x H) 4. M7000-24GT2XS-EA Module Appearance Figure 2-5 Appearance of the M7000-24GT2XS-EA Module...

- Page 23 Ports 2 x SFP+ ports For details, s ee Appendix B. (Copper cables are not supported.) SFP Modules The supported models may be subject to change without prior notice. Contact Ruijie and Cables Networks for details. Status LED Link/ACT LED...

- Page 24 Hardware Installation and Reference Guide Modules (W x D x H) 5. M7000-48SFP2XS-EA Module Appearance Figure 2-6 Appearance of the M7000-48SFP2XS-EA Module Ports The M7000-48SFP2XS-EA module provides 48 x SFP ports and 2 x SFP+ ports. The SFP port supports the 100/1000 Mbps auto-negotiation and hot swapping.

- Page 25 Ports 2 x SFP+ ports For details, s ee Appendix B. (Copper cables are not supported.) SFP Modules The supported models may be subject to change without prior notice. Contact Ruijie and Cables Networks for details. Status LED Link/ACT LED...

- Page 26 Hardware Installation and Reference Guide Modules Figure 2-7 Appearance of the M7000-24SFP2XS-EA Module Ports The M7000-24SFP2XS-EA module provides 24 x SFP ports and 2 x SFP+ ports. The SFP port supports the 100/1000 Mbps auto-negotiation and hot swapping. The SFP+ port supports 10GE SFP+ modules, 1GE SFP modules, and hot swapping.

- Page 27 Ports 2 x SFP+ ports For details, s ee Appendix B. (Copper cables are not supported.) SFP Modules The supported models may be subject to change without prior notice. Contact Ruijie and Cables Networks for details. Status LED Link/ACT LED...

- Page 28 Ports 8 x SFP+ ports For details, s ee Appendix B. (Copper cables are not supported.) SFP Modules The supported models may be subject to change without prior notice. Contact Ruijie and Cables Networks for details. Status LED Link/ACT LED...

-

Page 29: Power Supply Modules

Hardware Installation and Reference Guide Modules Consumption Safety GB 4943.1 Standards Operating 0° C to 50° C (32° F to 122° F) Temperature Storage –40° C to +70° C (–40° F to +158° F) Temperature Operating 10% to 90% RH (non-condensing) Humidity MTBF Over 200,000 hours... - Page 30 Hardware Installation and Reference Guide Modules Figure 2-9 Appearance of the RG-PA600I-FS Module Ports The RG-PA600I-FS module provides 12 V AC input to the RG-NBS7006 switch. The front panel of the power supply module provides a 3-pin connector, which can be connected to a standard 10 A power cord. LEDs Meaning DC/FLT...

-

Page 31: Fan Modules

Hardware Installation and Reference Guide Modules Module Model RG-PA600I-FS Rated Voltage 100 V AC to 120 V AC, 200 V AC to 240 V AC; 50 Hz/60 Hz Range Max Voltage 90 V AC to 264 V AC; 47 Hz to 63 Hz Range 90 V AC to 180 V AC;... - Page 32 Hardware Installation and Reference Guide Modules Captive Screw Handle Composition The M7006-FAN is the fan module of the RG-NBS7006 switch. Each fan module consists of a fan and a fan monitoring board. The fan draws air outwards to form convection for heat dissipation. Specifications Dimension 144 mm x 128 mm x 190.1 mm (5.67 in.

-

Page 33: Preparation Before Installation

Hardware Installation and Reference Guide Preparation before Installation Preparation before Installation Safety Suggestions Caution ● To avoid body injury and equipment damage, carefully read the safety suggestions before you install the RG-NBS7000 series switches. ● The following safety suggestions do not cover all possible dangers. 3.1.1 General Safety Precautions ... -

Page 34: Static Discharge Damage Prevention

Hardware Installation and Reference Guide Preparation before Installation Find out the location of the emergency power supply switch in the room before installation. First cut off the power supply in case of an accident. Be sure to make a careful check before you shut down the power supply. ... -

Page 35: Laser Safety

Hardware Installation and Reference Guide Preparation before Installation Caution ● For safety, use a multimeter to measure the resistance between yourself and the ground, which should range from 1 Ω to 10 Ω. ● Make sure that the switch is properly grounded when the anti-static wrist strap is connected to the ground by the jack on the chassis. -

Page 36: Installation Site Requirements

Hardware Installation and Reference Guide Preparation before Installation Installation Site Requirements You must use the RG-NBS7000 series switch indoors. To ensure the normal operation and prolonged service life of the device, the installation site must meet the following requirements. 3.2.1 Load Bearing Requirements Evaluate the load bearing requirements for the ground according to the weight of the switch and its accessories (such as the cabinet, chassis, line cards and power supply modules). -

Page 37: Humidity Requirements

Hardware Installation and Reference Guide Preparation before Installation Recommended cleaning periods: (1) Dust intake vents and exhaust vents of all modules every three months. (2) Dust line cards every one or two years. (3) Dust fan modules yearly. (4) Dust the chassis, including the backplane, every one or two years. Note If the device is in a dusty environment, please increase the dusting times. -

Page 38: Power Requirements

Hardware Installation and Reference Guide Preparation before Installation should be properly protected against the intrusion of harmful gases, such as sulfur dioxide, hydrogen sulfide, nitrogen dioxide, and chlorine gas. The following table lists limit values for harmful gases. Average (mg/m Maximum (mg/m Sulfur dioxide (SO Hydrogen sulfide (H... - Page 39 Hardware Installation and Reference Guide Preparation before Installation M7006-CM Caution ● The RG-NBS7006 switch provides 1+1 and 2+2 power redundancy. You are advised to use multiple power supplies for the equipment to ensure its continuous and stable operation by avoiding the impact of unexpected power failures on the equipment.

-

Page 40: Cabinet Mounting

Hardware Installation and Reference Guide Preparation before Installation The lightning protection system of facility is a separate system that consists of a lightning rod, down lead conductor and connector to the grounding system, which usually shares the power reference ground and yellow/green safety cable ground. - Page 41 Hardware Installation and Reference Guide Preparation before Installation Figure 3-2 19-inch Cabinet Be sure that the square hold strip is at least 125 mm (4.92 in.) far from the outboard front door and the door is at most 25 mm (0.98 in.) thick to ensure a minimum available distance of 100 mm (3.94 in.). The front door is at least 500 mm (19.69 in.) far from the back door.

-

Page 42: Installation Tools

Hardware Installation and Reference Guide Preparation before Installation Be sure that the front and back doors of the cabinet have porosities greater than 50% for good ventilation and heat dissipation. Installation Tools Phillips screwdriver, related Ethernet and fiber-optic cables, cage nuts, Common Tools diagonal plier, and cable ties Anti-static wrist strap, wire stripper, crimping plier, and wire cutter... -

Page 43: Installing The Switch

Hardware Installation and Reference Guide Installing the Switch Installing the Switch The RG-NBS7000 series switches must be used and fixed indoors. Note Ensure that you have carefully read Chapter 2 and make sure that the requirements in Chapter 2 are all met. Installation Procedure Before You Begin Carefully plan and arrange the installation location, networking method, power supply, and wiring before... - Page 44 Hardware Installation and Reference Guide Installing the Switch Mounting Cable Management Frames Note ● Wear an anti-static wrist strap and ensure that the anti-static wrist strap is grounded well. ● The cable management brackets are not mounted before delivery. See the following steps and figures for installation.

-

Page 45: Mounting The Cabinet

Hardware Installation and Reference Guide Installing the Switch Mounting the Cabinet Precautions When you install the cabinet, pay attention to the following s: All expansion bolts for fastening the cabinet base to the ground should be installed and tightened in sequence from bottom to up (large flat washer, spring washer, and nut), and the installation holes on the base and the expansion bolts are properly aligned. -

Page 46: Mounting The Switch To A Cabinet

Hardware Installation and Reference Guide Installing the Switch Figure 4-2 Slide Rail represents entire-U delimiters Caution ● Before installing a slide rail, make sure that the bearing capacity of the slide rail meets requirements. ● There are various slide rails. The rail appearance and installation method is subject to actual conditions. ●... - Page 47 Hardware Installation and Reference Guide Installing the Switch Installation Steps (1) Measure the height of the brackets and identify the location of the brackets based on the plane bearing the switch. Mark the location of the brackets and install the cage nuts. Figure 4-3 Slide Rail Installation Positions (2) Place the switch on the slide rail, and drive it smoothly into the cabinet until the bracket reaches...

-

Page 48: Grounding The Switch

Hardware Installation and Reference Guide Installing the Switch Figure 4-4 Mounting the Switch into a Standard 19-inch Cabinet Grounding the Switch Note A good grounding system protects your switch against lightning strikes and interferences and ensures its normal operation and reliability. Precaution ... -

Page 49: Installing A Power Supply Module

Hardware Installation and Reference Guide Installing the Switch (1) Remove the two screws on the rear of the switch. (2) Attach one end of the grounding wire to the switch with the two screws. Connect the other end of the grounding wire to the grounding wire of the cabinet or the grounding bar of the equipment room . -

Page 50: Installing A Fan Module

Hardware Installation and Reference Guide Installing the Switch ● Before inserting or removing the power supply module, verify whether the switch is well mounted. Because the switch is tall, prevent the switch from tumbling down when you are inserting or removing the power supply module. - Page 51 Hardware Installation and Reference Guide Installing the Switch Figure 4-7 Installing a M7006-FAN Module Caution ● Do not remove the fan module with force. Use the fan handle instead. Otherwise, components may be damaged and the distorted fan module cannot be removed.

- Page 52 Hardware Installation and Reference Guide Installing the Switch Figure 4-8 RG-NBS7006 Supervisor Engine Slots and Line Card Slots 2. Slot 2 (line card) Slot 1 (supervisor engine) (1) Rotate the ejector levers away from the front of the module, as shown in step 1 in Figure 3-9. (2) Insert the module into the slot along the rail and slide it slowly into the chassis, as shown in step 2 in Figure 3-9.

- Page 53 Hardware Installation and Reference Guide Installing the Switch Preparation (1) To avoid damages to SFP or SFP+ modules and electronic components in the device caused by the static electricity generated during the installation, wear an anti-static wrist strap close to your skin and have it properly grounded.

-

Page 54: Connecting The Power Cord

Hardware Installation and Reference Guide Installing the Switch the module. Do not touch the connecting finger on the module during installation. Do not squeeze, twist, fold or excessively bend the fiber-optic cable, which may cause system performance degradation or data loss. 4.11 Connecting the Power Cord Connect the power cord according to the instruction on the RG-PA600I-FS module panel. - Page 55 Hardware Installation and Reference Guide Installing the Switch Before powering up the switch, please verify the following requirements: Verify if the external power supply matches the distribution panel of the cabinet. After installing the equipment, verify if the front/back cabinet doors can be closed. ...

-

Page 56: Establishing The Configuration Environment

Hardware Installation and Reference Guide Verifying Operating Status Verifying Operating Status Establishing the Configuration Environment Configuring Terminal Parameters Figure 5-1 Configuration Environment of the RG-NBS7006 Connecting the Cable Connect the end of the cable with a crystal connector to the network port of the PC. ... - Page 57 Hardware Installation and Reference Guide Verifying Operating Status The cable is correctly connected; the terminal (can be a PC) used for configuratio n is already started; the parameters are already configured. Checking after Power-on (Recommended) After power-on, you are advised to perform the following checks to ensure the normal operation of follow -up configurations.

-

Page 58: Monitoring And Maintenance

Hardware Installation and Reference Guide Monitoring and Maintenance Monitoring and Maintenance Monitoring When the switch is running, you can monitor the status of each module by observing the status LEDs. When the status LED of the chassis is red, it means a module is faulty. Log in to the Web management system to perform troubleshooting. - Page 59 Hardware Installation and Reference Guide Monitoring and Maintenance Please contact the technical support representatives of Ruijie Networks for replacing fuses. Technical staff of Ruijie Networks will replace the fuse of the same model. The following table lists the specifications of the fuse for each module.

-

Page 60: Common Troubleshooting

Hardware Installation and Reference Guide Troubleshooting Troubleshooting Troubleshooting Flowchat Common Troubleshooting Fault 1: The power supply module does not work. Symptom The Status LED of each line card is off, the Status LED of the fan is off, and the fan does not work. The LED on the panel of the power module is off. - Page 61 Hardware Installation and Reference Guide Troubleshooting The Status LED of the line card is off or continuously blinking. The Link/ACT LED of the line card is solid on when no network cable or fiber-optic cable is connected. Suggested Action (1) Check if the line card is firmly inserted. If not, install the line card again and ensure that it is inserted into place before you tighten the captive screws on the two sides of the panel.

- Page 62 (4) Check whether the rates of the two sides match and whether the fiber-optic cable type meets requirements. In addition, for ports supporting different rates, check whether rate modes are configured correctly. Note If preceding methods do not take effect, please contact Ruijie Networks for technical support.

-

Page 63: Replacing Modules

Hardware Installation and Reference Guide Replacing Modules Replacing Modules Removing an SFP or SFP+ Module (1) Unplug the fiber-optic cable. (2) Turn down the handle of the module until it is horizontal. Pull the tab to take out the SFP or SFP+ module, as shown in Figure 8-1. - Page 64 Hardware Installation and Reference Guide Replacing Modules (7) As shown in step in Figure 8-2, rotate the ejector levers toward the front of the module. (8) As shown in step in Figure 8-2, tighten the captive screws on the filler panel. Figure 8-2 Replacing a Supervisor Engine or Line Card...

- Page 65 Hardware Installation and Reference Guide Replacing Modules...

-

Page 66: Replacing A Power Supply Module

Hardware Installation and Reference Guide Replacing Modules Caution ● In order to ensure the reliability of the system ventilation and heat dissipation performance and address the requirement of the dust-filter, filler panel needs to be installed in a vacant slot. ●... -

Page 67: Replacing A Fan Module

Hardware Installation and Reference Guide Replacing Modules Figure 8-3 Replacing the Power Supply Module The power supply module to be removed. The power supply module to be installed. Replacing a Fan Module Caution ● Do not touch any bare wire, terminal or the power instruction on the switch to avoid personal injury. ●... - Page 68 Hardware Installation and Reference Guide Replacing Modules Figure 8-4 Replacing a Fan Module...

-

Page 69: Bundling The Cables

Hardware Installation and Reference Guide Cables Cables Note This chapter describes the precautions and simple steps fo r cable connection and bundling. For details, see Cabling Recommendations Connecting External Port Cables Precautions Correctly distinguish single-mode and multi-mode fiber-optic cables and ports. ... - Page 70 Hardware Installation and Reference Guide Appendix Appendix 10.1 Connectors and Media 1000BASE-T/100BASE-TX/10BASE-T Port The 1000BASE-T/100BASE-TX/10BASE-T is a 10/100/1000 Mbps port with auto-negotiation, which supports auto MDI/MDIX Crossover at these three rates . The 1000BASE-T complies with IEEE 802.3ab standard, and uses up to 100 m of 100-ohm CAT5, CAT 5e or twisted pairs with higher standard.

- Page 71 Hardware Installation and Reference Guide Appendix Figure 10-3 Connections of the Twisted Pairs of the 100BASE-TX/10BASE-T Fiber-Optic Cable Connection For the optical ports, select single-mode or multimode fiber-optic cables for connections according to the optical module connected. Figure 10-4 shows the connection schematic diagram. Figure 10-4 Fiber-Optic Cable Connections...

- Page 72 SFP modules (mini-GBIC module) and 10GE SFP+ modules are available to cope with interface types of switch modules. You can select the mini-GBIC module to suit your specific needs. The models and technical specifications of some mini-GBIC and 10GE SFP+ modules are listed below. For details, see Ruijie module Installation and Reference Guide.

- Page 73 Hardware Installation and Reference Guide Appendix Table 10-2 Models of 1GE SFP Copper Module Standard Model DDM (Yes/No) 1000Base-T Mini-GBIC-GT Table 10-3 SFP Module Cabling Specification Fiber SFP Model Interface Type Core Size(μm) Cabling Type Distance 62.5/125 275 m MINI-GBIC-SX-MM850 50/125 550 m MINI-GBIC-LX-SM1310...

- Page 74 Hardware Installation and Reference Guide Appendix Category 5 (or above ) UTP or GE-SFP-GT RJ45 100 m Category 5 (or above ) UTP or SFP-GT RJ45 100 m Note ● For the optical module with the transmission distance exceeding 40 km (24.85 miles) or above, add one in-line optical attenuator on the link to avoid the overload of the optical receiver when short single -mode fiber-optic cables are used.

- Page 75 Hardware Installation and Reference Guide Appendix SFP+MM850 -7.3 -9.9 XG-SFP-LR-SM1270- 1270 -6.5 -14.4 BIDI XG-SFP-LR-SM1330- 1330 -6.5 -14.4 BIDI XG-LR-SM1310 1310 -8.2 -14.4 SFP+SM1310 1310 -8.2 -14.4 XG-SFP-LR-SM1310 1310 -8.2 -14.4 XG-eSFP-LR-SM131 1310 -8.2 -14.4 XG-SFP-ER-SM1550 1550 -4.7 -11.3 XG-SFP-ZR-SM1550 1550 SFP-S4-R1000P1 v2 1310...

- Page 76 Note The types/models of the SFP+ modules are being updated. If more accurate models of the module are required , contact Ruijie marketing staff or technical support engineers. The TX power of AOC cable can be displayed as “N/A”. Table 10-7...

-

Page 77: Lightning Protection

Hardware Installation and Reference Guide Appendix 10.3 Lightning Protection Installing AC Power Arrester (lightning protection cable row) The external lightning protection cable row must be used on the AC power port to prevent the switch from being struck by lightning when the AC power cable is introduced from the outdoor and directly connected to the power port of the switch. - Page 78 Hardware Installation and Reference Guide Appendix During the switch usage, the Ethernet port arrester must be connected to the s witch to prevent the switch damage by lightning before the outdoor network cable connects to the switch. Tools: cross or straight screwdriver, multimeter, and diagonal pliers Installation steps: (1) Tear one side of the protection paper for the double-sided adhesive tape and paste the tape to the framework of the Ethernet port arrester.

- Page 79 Hardware Installation and Reference Guide Appendix To prevent the performance of the Ethernet port arrester from being affected, note the following points: Reversed direction of the arrester installation: Connect the external network cable to the IN end and connect the switch Ethernet port to the OUT end.

-

Page 80: Cabling Recommendations

Hardware Installation and Reference Guide Appendix 10.4 Cabling Recommendations When RG-NBS7000 series switches are installed in standard 19-inch cabinets, cables are tied in the binding rack on the cabinet by the cabling rack, and top or bottom cabling is adopted according to the actual situation in the equipment room. - Page 81 Hardware Installation and Reference Guide Appendix Figure 10-7 Bundling Cables (1) Cables of different types (such as power cords, signal cables, and ground cables) should be separated in cabling and bundling. When they are close, crossover cabling can be adopted. In the cas e of parallel cabling, maintain a space of at least 30 mm (1.18 in.) for power cords and signal cables.

- Page 82 Hardware Installation and Reference Guide Appendix Figure 10-9 Bundling Cables (3) Cables not to be assembled or remaining parts of cables should be folded and placed in a proper position of the cabinet or cabling slot. The proper position will not affect device runnin g or cause device or cable damage during commissioning.

- Page 83 Hardware Installation and Reference Guide Appendix Do not use self-tapping screws to fasten terminals. Power cables of the same type in the same cabling direction should be bundled up into cable bunches, with clean and straight cables in cable bunches. ...

-

Page 84: Site Selection

Hardware Installation and Reference Guide Appendix 10.5 Site Selection The equipment room should be at least 5 km (3.11 miles) away from the heavy pollution source such as the smelter, coal mine, and thermal power plant, 3.7 km (2.30 miles) away from the medium pollution source such as the chemical industry, rubber industry, and electroplating industry, and 2 km (1.24 miles) away from the light pollution source such as the food manufacturer and leather plant.

Need help?

Do you have a question about the Reyee RG-NBS7006 and is the answer not in the manual?

Questions and answers