Summary of Contents for ESAB CIGWELD Arcmaster 649 Payday

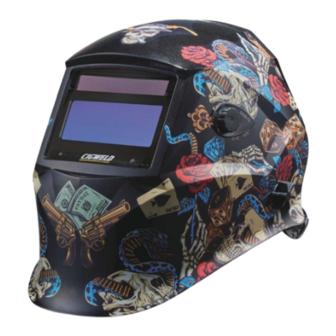

- Page 1 AUTO-DARKENING AUTO-DARKENING Arcmaster 649 Payday, Part Number WHAM1649 Arcmaster Welding Helmet Version No: AA | Issue Date: 06-10-2022 | Manual No: 0-5658...

- Page 2 The Brand of Choice for Contractors and Fabricators Worldwide. CIGWELD is the Market Leading Brand of Arc Welding Products for ESAB. We are a mainline supplier to major welding industry sectors in the Asia Pacific and emerging global markets including; Manufacturing, Construction, Mining, Automotive, Engineering, Rural and DIY.

- Page 3 Arcmaster Welding Helmet WARNINGS Read and understand this entire Manual and your employer’s safety practices before installing, operating, or servicing the equipment. While the information contained in this Manual represents the Manufacturer’s best judgement, the Manufacturer assumes no liability for its use. Auto-Darkening Welding Helmet Instruction Manual Number 0-5658 for: Arcmaster 649 Auto Darkening Welding Helmet (Payday)

- Page 4 Arcmaster Welding Helmet Arcmaster Welding Helmet Table of Contents SECTION 1: ARC WELDING SAFETY INSTRUCTIONS AND WARNINGS ........5 1.01 Safety Instructions ....................5 1.02 Declaration of Conformity ..................7 1.03 Limited Warranty ......................8 SECTION 2: INTRODUCTION ................10 2.01 How to Use This Manual ..................10 2.02 Equipment Identification ..................10 2.03 Receipt of Equipment ....................10 SECTION 3: GENERAL INFORMATION ..............

- Page 5 Arcmaster Welding Helmet SECTION 1: Arc Welding Safety Instructions and Warnings WARNING ARC WELDING can be hazardous. Protect yourself and others from possible serious injury or death. Keep children away. Do not lose these instructions. Read operating manual before installing, operating or servicing this product. Welding products and welding processes can cause serious injury or death, or damage to other equipment or property, if the operator does not strictly observe all safety rules and take precautionary actions.

- Page 6 Arcmaster Welding Helmet Be alert that welding sparks and hot materials from welding can easily go through small cracks and openings to adjacent areas. Watch for fire, and keep a fire extinguisher nearby. WELDING can cause fire or explosion. Be aware that welding on a ceiling, floor, bulkhead, or partition can cause fire on the hidden side.

- Page 7 Arcmaster Welding Helmet 1.02 Declaration of Conformity Manufacturer: CIGWELD Address: 71 Gower St, Preston Victoria 3072 Australia Description of equipment: Safety Equipment. CIGWELD Arcmaster Auto-Darkening Welding Helmet. National Standard and Technical Specifications The product is designed and manufactured to a number of standards and technical requirements among them are: a.

- Page 8 CONSEQUENTIAL DAMAGES, SUCH AS, BUT NOT LIMITED TO, LOST PROFITS AND BUSINESS INTERRUPTION. The remedies of the Purchaser set forth herein are exclusive and the liability of CIGWELD/ESAB with respect to any contract, or anything done in connection therewith such as the performance or breach thereof, or from the manufacture, sale, delivery, resale, or use of any goods covered by or furnished by CIGWELD/ESAB whether arising out of contract, negligence, strict tort, or under any warranty, or otherwise, shall not, except as expressly provided herein, exceed the price of the goods upon which such liability is based.

- Page 9 Note: • No employee, agent, or representative of CIGWELD or ESAB is authorized to change this warranty in any way or grant any other warranty, and CIGWELD/ESAB shall not be bound by any such attempt. Correction of nonconformities, in the manner and time provided herein, constitutes fulfilment of CIGWELD/ESAB’s obligations to purchaser with respect to the product.

- Page 10 Arcmaster Welding Helmet SECTION 2: Introduction 2.02 Equipment Identification 2.01 How to Use This Manual The product identification number is printed on the outer shipping This Operating Manual usually applies to just the underlined carton. Record this number for future reference. specification or part numbers listed.

- Page 11 Arcmaster Welding Helmet SECTION 4: Personal Protection WARNING Prior to welding check operation of the filter lens, if the lens does not darken DO NOT COMMENCE WELDING. If during welding the filter does not darken IMMEDIATELY STOP WELDING. The radiation from an electric arc during the welding process can seriously harm eyes and skin. It is essential that the following precautions be taken: When electric arc welding, it is a requirement to use a welding helmet or welding handshield that complies to a relevant standard.

- Page 12 Arcmaster Welding Helmet Recommended Protective Filters for Electric Welding Approximate Range of Minimum Shade Number of Description of Process Welding Current in Amps Filter(s) Air - Arc Gouging Less than or equal to 400 Less than or equal to 300 300 to 400 Flux-cored Arc Welding (FCAW) - with or without shielding gas...

- Page 13 Arcmaster Welding Helmet SECTION 5: Specifications 5.01 Arcmaster Auto-Darkening Filter Lens Description Filter Lens Auto-Darkening Filter Lens - Ultra View True Colour (with Blue Light Filter) Filter Lens Dimensions 120mm x 100mm x 18mm Viewing Area Dimensions 98mm x 43mm Reaction Time 0.2ms Sensors...

- Page 14 Arcmaster Welding Helmet SECTION 6: Harness Adjustment Prior to use, the Welding Helmet must be adjusted for maximum comfort and protection. The Helmet should be adjusted such that it is effectively positioned over the eyes and face to ensure adequate protection and comfort whilst welding. Please refer to the Harness adjustment instructions below.

- Page 15 Arcmaster Welding Helmet SECTION 7: Installation of Magnification Lens (Optional) CIGWELD magnification lenses magnify the work area substantially to assist the welder in maintaining the high standard required. WARNING Before installing the magnification lens, ensure that the rear cover lens is in place. 1.

- Page 16 Arcmaster Welding Helmet SECTION 8: Changing of Front and Rear Cover Lenses If any of the Cover Lenses are broken, plainly worn, distorted or contaminated they should be replaced immediately with a genuine Cigweld replacement part. REPLACING FRONT COVER LENS 1.

- Page 17 Arcmaster Welding Helmet Section 10: Batteries and Battery Compartment Battery Compartment To replace batteries remove the lithium batteries from the control/battery housing on each side. This can be done by removing the retaining screw, depressing the two grooved sections of the housing and pulling downwards. Replace with 2 x CR2450 Lithium Batteries. WARNING Swallowing batteries may lead to serious injury in as little as 2 hours or death, due to chemical burns and potential perfo- ration of the oesophagus.

- Page 18 Arcmaster Welding Helmet Section 11: Spare Parts WARNING CIGWELD cannot be held responsible for the continuing performance of this Welding Helmet if non-genuine spare parts are used. Figure 10-1 Exploded View of ArcMaster Auto-Darkening Welding Helmet Parts List SPARE PARTS – CIGWELD ARCMASTER AUTO-DARKENING WELDING HELMET Item No Part Number Description...

- Page 19 Arcmaster Welding Helmet SECTION 12: Basic Troubleshooting FAULT CAUSE REMEDY Irregular darkening dimming. Headband has been set unevenly Reset the headband to reduce the and there is an uneven distance difference to the filter from the eyes to the filter lens. Auto-Darkening filter does not Front cover lens is soiled or Clean Cover Lens with a soft cloth.

- Page 20 CIGWELD Pty Ltd Singapore - Malaysia - Indonesia - CIGWELD An ESAB Brand ESAB Asia Pacific No 14 Jalan Teknologi 3/1 JI. Pulogadung No. 45 71 Gower Street, Preston VIC 3072 Australia 38 Joo Koon Circle Selangor Science Park 1...

Need help?

Do you have a question about the CIGWELD Arcmaster 649 Payday and is the answer not in the manual?

Questions and answers