Table of Contents

Advertisement

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for KANSAI SPECIAL BX Series

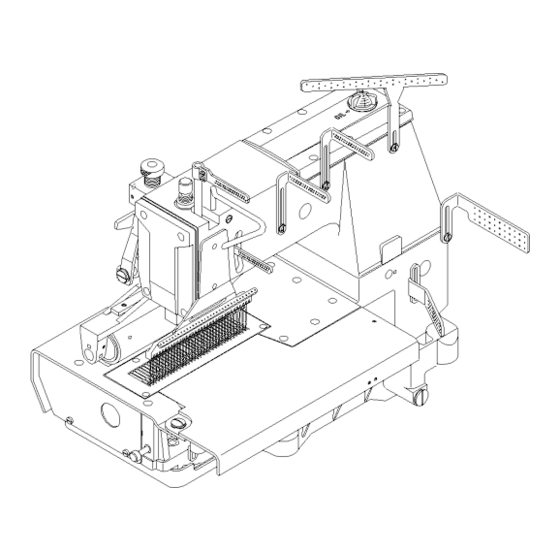

- Page 1 INSTRUCTION INSTRUCTION INSTRUCTION INSTRUCTION Industrial Industrial Industrial Industrial Sewing Sewing Sewing Sewing Machines Machines Machines Machines BX1425P,PSM,PTV BX1433P,PSM,PTV BX1025P,PSM BX1033P,PSM First published : November 1997 No. 970112...

- Page 2 INTRODUCTION INTRODUCTION INTRODUCTION Thank you for your purchasing Kansai Special's BX Series. Read and study this instruction manual carefully before beginning any of the procedures and save it for later use. This instruction manual describes adjustments and maintenance procedures on this machine.

-

Page 3: Table Of Contents

CONTENTS CONTENTS CONTENTS CONTENTS 1. SPECIFICATIONS 10. ADJUSTING THE PRESSER FOOT 1-1 Stitch type 10-1 Presser foot pressure ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ ・・・・・・・・・・・・・・・・・・・ 1-2 Model 10-2 Position of the presser foot ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ ・・・・・・・・・・・・・・ 2. NEEDLES & THREADING THE MACHINE 11. ADJUSTING THE REAR PULLER DEVICE 2-1 Needles 11-1 Manual lever ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・... -

Page 4: Specifications

【1】SPECIFICATIONS 1 1 1 1 - - - - 1 Stitch type 1 Stitch type 1 Stitch type 1 Stitch type JIS401 double chainstitch machines 1 1 1 1 - - - - 2 Model 2 Model 2 Model 2 Model BX1033 Model BX1433... -

Page 5: To Thread The Machine

2 2 2 2 - - - - 3 To thread the machine 3 To thread the machine 3 To thread the machine 3 To thread the machine Thread the machine correctly by referring to pages 3 to 8. Incorrect threading may cause skip stitching, thread breakage and/or uneven stitch formation. - Page 6 ■ T hreading diagram for BX1425P...

- Page 7 ■ T hreading diagram for BX1433P...

- Page 8 ■ T hreading diagram for BX1025...

- Page 9 ■ T hreading diagram for BX1033...

- Page 10 ■ T hreading diagram for BX1425PSM...

- Page 11 ■ T hreading diagram for BX1433PSM...

-

Page 12: Machine Speed

【3】MACHINE SPEED 3 3 3 3 - - - - 1 Machine speed & direction in which the machine pulley runs 1 Machine speed & direction in which the machine pulley runs 1 Machine speed & direction in which the machine pulley runs 1 Machine speed &... -

Page 13: Lubrication

4 4 4 4 - - - - 1 Oil 1 Oil 1 Oil 1 Oil Use Kansai Special’s genuine oil. (Part No. 28-611) 4 4 4 4 - - - - 2 To fill the machine with oil 2 To fill the machine with oil... -

Page 14: Sewing Machine Installation

【5】SEWING MACHINE INSTALLATION 5 5 5 5 - - - - 1 Cutting the machine table 1 Cutting the machine table 1 Cutting the machine table 1 Cutting the machine table... -

Page 15: How To Install The Machine

5 5 5 5 - - - - 2 How to install the machine 2 How to install the machine 2 How to install the machine 2 How to install the machine Install the brackets on the underside of the table board (see the illustration below). Fit the rubber cushions onto the brackets. -

Page 16: Looper Left-To-Right Movement

6 6 6 6 - - - - 2 Looper left 2 Looper left 2 Looper left- - - - to to to to- - - - right movement 2 Looper left right movement right movement right movement When the looper passes the needle, the point of the looper, moving to the right, should be 1.5mm above the top of the needle's eye. -

Page 17: Needle Height

6 6 6 6 - - - - 4 Needle height 4 Needle height 4 Needle height 4 Needle height When the needle bar is at the top of its stroke, remove side cover plate A, loosen screw C on needle bar clamp B with a hexagonal wrench and then move the needle bar up or down as required. -

Page 18: Timing Of The Retainer Looper To The Needle

7 7 7 7 - - - - 2 Timing of the retainer looper to the needle 2 Timing of the retainer looper to the needle 2 Timing of the retainer looper to the needle 2 Timing of the retainer looper to the needle When the needle, moving from the top to bottom of its stroke, enters the triangle of the looper thread, the retainer looper should be at the extreme right end of its travel. -

Page 19: Stitch Length

9 9 9 9 - - - - 2 Stitch length 2 Stitch length 2 Stitch length 2 Stitch length The stitch length can be adjusted from 2 to 5mm with no step. The following table shows the stitch length with the number of stitches within 1 inch (25.4mm) and 30mm. No. -

Page 20: Adjusting The Rear Puller Device

【11】ADJUSTING THE REAR PULLER DEVICE 11- - - - 1 Manual lever 1 Manual lever 1 Manual lever 1 Manual lever To position or remove the fabric, raise manual lever A. 11- - - - 2 To adjust the puller pressure 2 To adjust the puller pressure 2 To adjust the puller pressure 2 To adjust the puller pressure... -

Page 21: Adjusting The Needle Thread Guard

1 1 1 1 2 2 2 2 - - - - 3 Adjusting the needle thread 3 Adjusting the needle thread 3 Adjusting the needle thread 3 Adjusting the needle thread guard guard guard guard With the needle bar at the bottom of its stroke, the top surface of needle thread guard A should be level and parallel with the centers of the eyes on needle bar eyelet B. -

Page 22: Producing Decorative Stitches

13- - - - 2 Producing decorative stitches 2 Producing decorative stitches 2 Producing decorative stitches 2 Producing decorative stitches Install cam 1 on the outside to use the lower two spreaders. Install any one of cams No.2 to No.9 on the inside to use the upper spreader. Thread spreaders' eyes marked ●. Following the above procedures automatically produces the decorative stitches below (refer to decorative stitches No.2 to No.9). - Page 23 No.5 No.5 No.5 No.5 No.6 No.6 No.6 No.6 No.7 No.7 No.7 No.7 No.8 No.8 No.8 No.8 N N N N o.9...

-

Page 24: Replacing The Cams

13- - - - 3 Replacing the cams 3 Replacing the cams 3 Replacing the cams 3 Replacing the cams To replace outside cam B, remove nut A (note that this nut has a left-hand thread). To replace inside cam H, loosen screws C and D, and remove the collar. -

Page 25: Adjusting The Spreaders

13- - - - 5 Adjusting the spreaders 5 Adjusting the spreaders 5 Adjusting the spreaders 5 Adjusting the spreaders The clearance between spreader K,L and M and needles should be 1~1.2mm. Spreader up-and-down adjustment is made with screws Q. Spreader tilt adjustment is made with screws R. -

Page 26: Adjusting The Binder Up And Down

14- - - - 2 Adjusting the binder up and down 2 Adjusting the binder up and down 2 Adjusting the binder up and down 2 Adjusting the binder up and down Adjust the binder up and down according to the fabric to be used.

Need help?

Do you have a question about the BX Series and is the answer not in the manual?

Questions and answers