Summary of Contents for KANSAI SPECIAL DX9902-3U

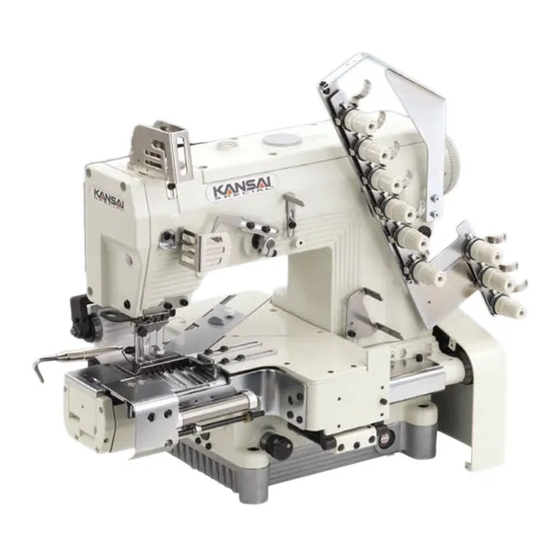

- Page 1 INSTRUCTION Industrial Sewing Machines DX9902-3U DX9900-4U First published : July 1997 No. 970038...

- Page 2 INTRODUCTION INTRODUCTION INTRODUCTION Thank you for your purchasing Kansai Special's DX Series. Read and study this instruction manual carefully before beginning any of the procedures and save it for later use. This instruction manual describes adjustments and maintenance procedures on this machine.

- Page 3 CONTENTS CONTENTS CONTENTS CONTENTS 1. NEEDLES & THREADING THE MACHINE 9. STITCH FORMATION 1-1 Needles 9-1 Position of the needle thread guides ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ ・・・・・・ 1-2 Replacing the needle 9-2 Position of the thread guide on the needle thread ・・・・・・・・・・・・・・・・・・・・・・ 1-3 Threading the machine take-up ・・・・・・・・・・・・・・・・・・・...

- Page 4 【1】NEEDLES & THREADING THE MACHINE 1 1 1 1 - - - - 1 Needles 1 Needles 1 Needles 1 Needles TV×5 of Schmetz or Organ Select the proper needle for the fabric and thread. < Needles and needle size > Schmetz Nm80 Nm90...

- Page 5 【2】MACHINE SPEED 2 2 2 2 - - - - 1 Machine speed & direction in which the machine pulley runs 1 Machine speed & direction in which the machine pulley runs 1 Machine speed & direction in which the machine pulley runs 1 Machine speed &...

- Page 6 3 3 3 3 - - - - 1 Oil 1 Oil 1 Oil 1 Oil Use Kansai Special’s genuine oil. (Part No. 28-613 : 1000cc) 3 3 3 3 - - - - 2 Oiling 2 Oiling 2 Oiling 2 Oiling ■...

- Page 7 【4】SEWING MACHINE INSTALLATION 4 4 4 4 - - - - 1 Cutting the machine table 1 Cutting the machine table 1 Cutting the machine table 1 Cutting the machine table...

- Page 8 4 4 4 4 - - - - 2 Installing the machine 2 Installing the machine 2 Installing the machine 2 Installing the machine ■ Non-submerged installation Install machine correctly referring to the illustration. Install the bolts and nuts to the machine table.

- Page 9 5 5 5 5 - - - - 2 Looper left 2 Looper left- - - - to to to to- - - - right movement right movement 2 Looper left 2 Looper left right movement right movement The point of the looper should be approximately 1.2~1.5mm above the top of the left needle’s eye when the looper moves to the left on the back side of the needles.

- Page 10 5 5 5 5 - - - - 4 Needle height 4 Needle height 4 Needle height 4 Needle height The point of the looper should be 1.2~1.5mm above the top of the left needle's eye on the back side of the needle when the point of the looper has reached the center of the left needle with the machine pulley turning in the operating direction (see 5-2).

- Page 11 5 5 5 5 - - - - 6 Changing the looper orbit 6 Changing the looper orbit 6 Changing the looper orbit 6 Changing the looper orbit When the looper moves around the needles, the point of the looper on 2-needle and 3-needle machines barely touches the right needle and the clearance between the point of the looper and the left needle is approximately 0.2~0.3mm.

- Page 12 5 5 5 5 - - - - 7 Changing the amount of the looper front 7 Changing the amount of the looper front- - - - to to to to- - - - back movement back movement 7 Changing the amount of the looper front 7 Changing the amount of the looper front back movement back movement...

- Page 13 【6】ADJUSTING THE NEEDLE GUARDS (FRONT AND REAR) 6 6 6 6 - - - - 1 Position of the needle guard (rear) (2 1 Position of the needle guard (rear) (2 1 Position of the needle guard (rear) (2 1 Position of the needle guard (rear) (2- - - - 3U) ■...

- Page 14 6 6 6 6 - - - - 3 Position of the needle guard (front) (2 3 Position of the needle guard (front) (2- - - - 3U) 3 Position of the needle guard (front) (2 3 Position of the needle guard (front) (2 When the point of the looper has reached the center of the left needle, there should be a clearance of 0~0.03mm between the left needle and needle guard...

- Page 15 7 7 7 7 - - - - 2 Feed dog left 2 Feed dog left- - - - to to to to- - - - right position right position 2 Feed dog left 2 Feed dog left right position right position The feed dog should be centered left to right.

- Page 16 【8】PRESSER FOOT 8 8 8 8 - - - - 1 Presser foot pressure 1 Presser foot pressure 1 Presser foot pressure 1 Presser foot pressure The presser foot pressure should be as light as possible, yet be sufficient to feed the fabric and produce uniform stitches.

-

Page 17: Position Of The Needle Thread Guides

【9】STITCH FORMATION 9 9 9 9 - - - - 1 Position of the needle thread guides 1 Position of the needle thread guides 1 Position of the needle thread guides 1 Position of the needle thread guides The distance from the center of the eyelet of the needle thread guide to that of the set screw should be approximately 25mm (see the illustration). -

Page 18: Position Of The Thread Support

9 9 9 9 - - - - 4 Position of the thread support 4 Position of the thread support 4 Position of the thread support 4 Position of the thread support When the needle bar is at the bottom of its stroke, the top surface of needle thread support B should be level with the centers of the eyes on needle bar thread eyelet A, and A should be parallel with B. -

Page 19: Adjusting The Cutting Width

【10】ADJUSTING THE KNIFE DEVICE 10- - - - 1 Adjusting the cutting width 1 Adjusting the cutting width 1 Adjusting the cutting width 1 Adjusting the cutting width Loosen screw D on the lower knife holder. Adjust the cutting width as required by moving the upper and lower knife holders simultaneously to the left or right. -

Page 20: Overlap Of The Upper And Lower Knives

10- - - - 4 Overlap of the upper and lower knives 4 Overlap of the upper and lower knives 4 Overlap of the upper and lower knives 4 Overlap of the upper and lower knives When upper knife J is at the bottom of its stroke, adjust the overlap of the upper and lower knives as shown in the illustration. - Page 21 【11】ADJUSTING THE ROLLERS AND THE GUIDES 11- - - - 1 Installing the rollers 1 Installing the rollers 1 Installing the rollers 1 Installing the rollers ■ Install tension roller bracket A as shown in the illustration. ■ Install roller brackets B properly on the underside of the table.

-

Page 22: Adjusting The Rollers

11- - - - 2 Sewing 2 Sewing 2 Sewing 2 Sewing Raise the presser foot. Place elastic tape on guide B and tension roller (upper) D. Position the fabric on the elastic tape and along the fabric guide (right). Raise the presser foot. -

Page 23: Adjusting The Guides

11- - - - 4 Adjusting the guides 4 Adjusting the guides 4 Adjusting the guides 4 Adjusting the guides ■ Height adjustment Clearance between elastic tape guard D and needle plate mounting plate factory approximately 5.0mm. Adjust the clearance according to the fabric to be used. - Page 24 ■Adjusting the cutting width Adjust the cutting width by loosening screws G and moving fabric guide (left) H to the left or right as required. 【12】ADJUSTING THE REAR PULLER 12- - - - 1 Position of the hand lever and the stopper 1 Position of the hand lever and the stopper 1 Position of the hand lever and the stopper 1 Position of the hand lever and the stopper...

- Page 25 12- - - - 3 To adjust the feeding amount of the rear puller 3 To adjust the feeding amount of the rear puller 3 To adjust the feeding amount of the rear puller 3 To adjust the feeding amount of the rear puller The feeding amount of the rear puller should be the same as that of the feed dog.

-

Page 26: To Place The Timing Belt

13- - - - 3 To place the timing belt 3 To place the timing belt 3 To place the timing belt 3 To place the timing belt Install the timing belt, bearing, plates, timing pulley, pulley and cover by performing the reverse procedure of 13-2 (3).

Need help?

Do you have a question about the DX9902-3U and is the answer not in the manual?

Questions and answers