Summary of Contents for Maytag MLG52

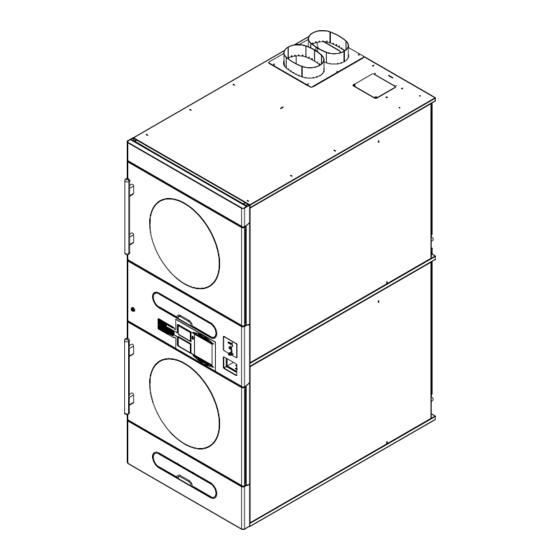

- Page 1 MLG52 Installation Manual RETAIN THESE INSTRUCTIONS IN A SAFE PLACE FOR FUTURE REFERENCE Part No. 113284-1...

- Page 2 – L’installation et l’entretien doivent être assurés par un installateur ou un service d’entretien qualifié ou par le fournisseur de gaz. Maytag Co. 113284 - 1...

- Page 3 Fuel Gas Code, ANSI Z223.1/NFPA 54 or the Canadian Natural Gas and Propane Installation Code, CSA B149.1. The dryer must be electrically grounded in accordance with local codes, or in the absence of local codes, with the National Electrical Code, ANSI/NFPA 70 or Canadian Electrical Code, CSA C22.1. 113284 -1 Maytag Co.

-

Page 4: Table Of Contents

Inches of Water Column Cleaning .............. 15 L.C.D. Liquid Crystal Display Adjustments ............15 L.P. Liquid Propane Data Label Information ......... 16 Underwriters Laboratory NOTES __________________________________________________________________________________________________________________________ _________________________________________________________________________________________________________________________________ _________________________________________________________________________________________________________________________________ _________________________________________________________________________________________________________________________________ _________________________________________________________________________________________________________________________________ _________________________________________________________________________________________________________________________________ _________________________________________________________________________________________________________________________________ _________________________________________________________________________________________________________________________________ _________________________________________________________________________________________________________________________________ _________________________________________________________________________________________________________________________________ _________________________________________________________________________________________________________________________________ _________________________________________________________________________________________________________________________________ Maytag Co. 113284 - 1... -

Page 5: Specifications

N / A INLET PIPE CONNECTION 1/2” M.N.P.T. PER POCKET Shaded areas are stated in metric equivalents 10/30/12 NOTE: The manufacturer reserves the right to make changes in specifications at any time without notice or obligation. 113284 -1 Maytag Co. - Page 6 Specifications _____________________________________________________________________ NOTE: The manufacturer reserves the right to make changes in specifications at any time without notice or obligation. Maytag Co. 113284 - 1...

-

Page 7: Installation Procedures

The dryer must be installed with adequate clearance for air openings into the combustion chamber. IMPORTANT: The dryer must be installed in a location/ environment, which the ambient temperature remains between 40° F (4.44° C) and 130° F (54.44° C). 113284 -1 Maytag Co. -

Page 8: Dryer Enclosure Requirements

It is not necessary to have a separate make-up air opening for each dryer. Common make-up air openings are acceptable. However, they must be set up in such a manner that the make-up air is distributed equally to all the dryers. Maytag Co. 113284 - 1... - Page 9 In either case, allow at least twice the diameter of the duct between the duct opening and the nearest obstruction (refer to the diagram). IMPORTANT: Do not use screens, louvers, or caps on the outside opening of the exhaust ductwork. 113284 -1 Maytag Co.

-

Page 10: Electrical Information

10-inches (25.4 cm). electric codes for making all service connections. IMPORTANT: No more than four dryers should be connected to one main common duct. Maytag Co. 113284 - 1... - Page 11 UL listed power cord/pigtail (wire size must conform to rating of dryer), or the dryer can be hard wired directly to the service breaker panel. In both cases, a strain relief must be installed where the wiring enters the dryer. 113284 -1 Maytag Co.

-

Page 12: Gas Information

(header), then a 1/2” (12.7 mm) line connection by a qualified service technician. is sufficient. However, if the top and bottom tumbler MLG52 L.P. Conversion Kit: 887297 connections are connected together, the supply from the header must be increased to 3/4” (19.05 mm). There should It is your responsibility to have all plumbing connections, be a minimum 6-inch (15.24 cm) clearance between the back... - Page 13 32.23 3.988 *Liquid Propane 2,500 11.0 110,000 32.23 2.184 Shaded areas are stated in metric equivalents * Gas valve’s internal regulator disabled. ** Consult factory for elevations over 2,000 feet (610 meters) for correct orifice size. 113284 -1 Maytag Co.

-

Page 14: Preparation For Operation / Start-Up

NOTE: When ordering replacement parts from the Maytag Each microprocessor controller (computer) has been distributor or the Maytag Co. be sure to give them the preprogrammed by the factory with the most commonly used correct model number and serial number so that your parts parameter (program) selections. -

Page 15: Routine Maintenance

NOTE: To prevent damage, avoid cleaning and/or touching ____________________________________________________________ ignitor/flame-probe assembly. ____________________________________________________________ Remove lint from gas valve burner area with a dusting brush or vacuum cleaner attachment. ____________________________________________________________ Clean any lint accumulation in and around the motor(s) casing opening. ____________________________________________________________ ____________________________________________________________ ____________________________________________________________ 113284 -1 Maytag Co. -

Page 16: Data Label Information

____________________________________________________________ ____________________________________________________________ ____________________________________________________________ ____________________________________________________________ ____________________________________________________________ When contacting Maytag, the information on the data label ____________________________________________________________ is required to ensure proper service/parts assistance. The data label is located at the upper left rear of the dryer behind the back guard. ____________________________________________________________ 1.

Need help?

Do you have a question about the MLG52 and is the answer not in the manual?

Questions and answers