Table of Contents

Advertisement

Operating Manual

Translation of the original operating manual

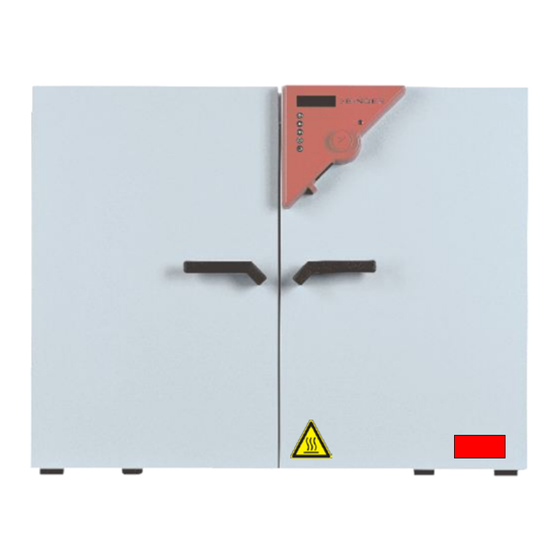

BD / BD-UL (E2) – Incubators with natural convection

ED / ED-UL (E2) – Drying and heating ovens with natural convection

FD / FD-UL (E2) – Drying and heating ovens with forced convection

with microprocessor temperature controller

Modell

Model version

BD023-230V

BD 23

BD023UL-120V

BD053-230V

BD 53

BD053UL-120V

BD115-230V

BD 115

BD115UL-120V

BD240-230V

BD 240

BD240UL-120V

BD400-230V

BD400

BD400UL-120V

BD720-230V

BD720

BD720UL-120V

ED023-230V

ED 23

ED023UL-120V

ED053-230V

ED 53

ED053UL-120V

ED115-230V

ED 115

ED115UL-120V

BINDER GmbH

Address: Post office box 102, 78502 Tuttlingen, Germany Phone: +49 7462 2005 0

Fax: +49 7462 2005 100 Internet: http://www.binder-world.com

E-mail: info@binder-world.com Service Hotline: +49 7462 2005 555

Service Fax: +49 7462 2005 93 555 Service E-Mail: service@binder-world.com

Service Hotline USA: +1 866 885 9794 or +1 631 224 4340 x3

Service Hotline Asia Pacific: +852 390 705 04 or +852 390 705 03

Service Hotline Russia and CIS: +7 495 988 15 16

Issue 03/2019

Art. No.

Modell

9010-0187

ED 240

9010-0189

9010-0081

ED400

9010-0179

9010-0088

ED720

9010-0181

9010-0095

FD 23

9010-0183

9010-0073

FD 53

9010-0176

9010-0074

FD 115

9010-0177

9010-0190/0191

FD 240

9010-0192/0193

9010-0078/0079

9010-0131/0132

9010-0096/0097

9010-0164/0165

Model version

Art. No.

ED240-230V

9010-0101

ED240UL-208V

9010-0167

ED400-230V

9010-0075

ED400UL-208V

9010-0168

ED720-230V

9010-0076

ED720UL-208V

9010-0169

FD023-230V

9010-0194

FD023UL-120V

9010-0196

FD053-230V

9010-0082

FD053UL-120V

9010-0128

FD115-230V

9010-0102

FD115UL-120V

9010-0129

FD240-230V

9010-0104

FD240UL-208V

9010-0130

Art. No. 7001-0026

Advertisement

Table of Contents

Need help?

Do you have a question about the BD 53 and is the answer not in the manual?

Questions and answers