Summary of Contents for Xtool D1-PRO

- Page 1 此页不印刷 xTool D1 Pro_快速指南_英文_D1.1.3_KD010460000 成品尺寸: 210*280mm 展开尺寸: 420*280mm 材质: 封面157g铜版纸, 内页100g铜版纸 工艺: 封面覆哑膜, 双面CMYK印刷, 骑马钉...

- Page 2 Quick Start Guide D1.1.3_KD010460000...

- Page 3 Dear xTooler: Thank you for purchasing xTool D1 Pro. We are so grateful for your recogni- tion, and sincerely hope you will enjoy this product! xTool D1 Pro is a high-accuracy and high-power laser engraver and laser cutter. From novice to expert, from home use to business, xTool D1 Pro is ready to give you the best laser engraving &...

-

Page 4: Table Of Contents

Unbox and check Assemble xTool D1 Pro Meet your xTool D1 Pro Set up xTool D1 Pro Download and install software Create with example projects Use Rotary Attachment 2 Clean the laser module... -

Page 5: Unbox And Check

Unbox and check Plate components Power adapter & cable USB cable Motor cable Cable tie pack Limit switch connection cable TF card Coupling Screwdriver Hex key Parts storage box Shaft Screw M4*8 Screw M4*16 Screw M4*25 Nozzle connector components Laser module Safety goggles Material pack Quick Start Guide/... -

Page 6: Assemble Xtool D1 Pro

Assemble xTool D1 Pro No scissors are included in the pack. The secret to getting ahead is getting started. Are you ready to embark on a creative journey? Let's go! You can visit support.xtool.com or scan the QR code to find Tips the tutorial video. - Page 7 1 : 1 × 16...

- Page 8 1 : 1 × 2 If you can't put the shaft through the timing belt, the possible cause is that Tips the timing belt is set too tight. You can adjust its tension by turning the screw. The screws are used to set the tension of the timing belts. Do not fully tighten them.

- Page 9 Slide the two sliders down against the front plate.

- Page 10 此页不印刷 xTool D1 Pro_快速指南第二部分_英文_D1.1.3_KD010460000...

- Page 11 Pay attention to the front and back sides Tips of the connector. Insert it properly. Fully tighten the two screws.

- Page 12 No scissors are included in the pack. Cut off the white cable ties, and keep the gray ones. No scissors are included in the pack.

- Page 13 1 : 1 × 4 × 1 1 : 1 The screw is used to set the tension of the timing belt. Do not fully tighten it. Otherwise, the timing belt may be damaged.

- Page 14 80% done! Excited to see your laser cutter begins to take shape! Success is just around the corner!

- Page 16 Use the thumb screw to fit the laser module Turn the handle clockwise Hold the handle to draw it Rotate the handle to stop it away from the thread part from being blocked Release the handle Turn the handle clockwise again You may need to repeat this process multiple times to tighten the thumb screw.

- Page 17 Rotate the handle to stop it from being blocked thread part The screw is not tightened or loosened. Insert the TF card before using xTool D1 Pro. Otherwise, some functions may fail, such as Wi-Fi connection-based processing, Release the handle Rotate the handle to tighten or loosen the screw offline processing, and Framing in processing preview.

-

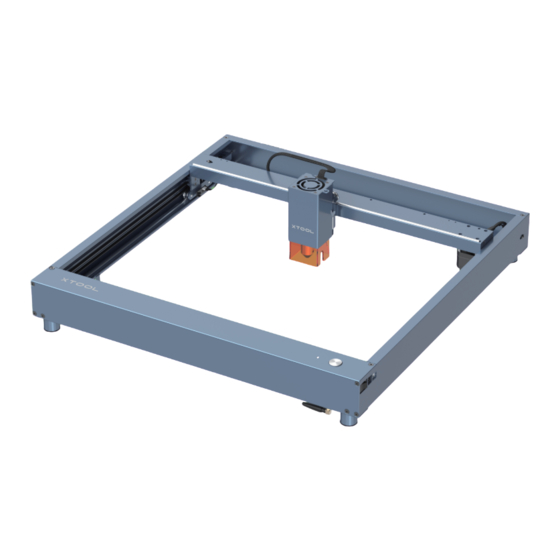

Page 18: Meet Your Xtool D1 Pro

Meet your xTool D1 Pro Hole for fitting an exhaust pipe Focal length setting bar Nozzle connector Congratulations! You have completed the installation! We've got a little surprise in our software to make your first project creative and memorable. Indicator... - Page 19 此页不印刷 xTool D1 Pro_快速指南第三部分_英文_D1.1.3_KD010460000...

-

Page 20: Set Up Xtool D1 Pro

Try to set the timing belts on the right and left plates to the same tension, so that xTool D1 Pro can cut and engrave materials properly. -

Page 21: Download And Install Software

Set the position of the rear plate on the laser module (Applicable only to the laser module of 20W) You can download xTool Creative Space (XCS) at our official website xtool.com or use the third-party software LightBurn to operate xTool D1 Pro. -

Page 22: Create With Example Projects

Before creating your works, you can place the aluminium sheet in the working area of xTool D1 Pro to protect your desk or floor from being smoked or burned. Before starting your creation, you are advised to test the parameter settings and engraving performance first to prevent waste of materials. -

Page 23: Use Rotary Attachment 2

Use Rotary Attachment 2 You can connect xTool D1 Pro to Rotary Attachment 2 to engrave cylindrical or irregular materials. Tips Rotary Attachment 2 needs to work with a device and software. For details about how to use it, visit... - Page 24 Place Rotary Attachment 2 parallel to the working area of xTool D1 Pro. Level C: d>60mm Before you connect it to xTool D1 Pro, you may need to set its level based on the diameter of the material to be processed.

- Page 25 Use the support module Set the level Use the changing of the level from C to B as an example. The support module is applicable to the processing of irregular objects or objects that are too long for Rotary Attachment 2. You can place the support module as required.

-

Page 26: Clean The Laser Module

Set the support module Clean the laser module For the 20W laser module, you are advised to clean it, including the inner and outer frames of the light shield, lens, and red light outlet, Tips every time after it has been used for one consecutive hour. When the light shield is dirty or laser beams can't cut a material, you need to clean the laser module. - Page 27 3. Clean the inner and outer frames of the light shield with tissues or dust-free cloth moistened with alcohol; and clean the lens and red light outlet with a cotton swab moistened with alcohol.

Need help?

Do you have a question about the D1-PRO and is the answer not in the manual?

Questions and answers