Trox Technik FKRS-EU Installation And Operating Manual

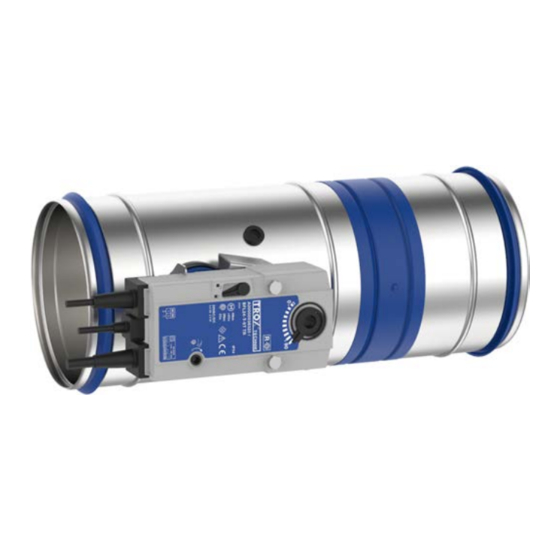

Fire damper

Hide thumbs

Also See for FKRS-EU:

- Installation and operating manual (263 pages) ,

- Supplementary installation manual (24 pages) ,

- Installation and operating manual (176 pages)

Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Trox Technik FKRS-EU

- Page 1 GB/en Fire damper Type FKRS-EU according to Declaration of Performance DoP / FKRS-EU / DE / 005 Short version This is a content-reduced short version. The full version is available at www.trox-docs.com. Read the instructions prior to performing any task!

- Page 2 TROX GmbH Heinrich-Trox-Platz 47504 Neukirchen-Vluyn Germany Phone: +49 (0) 2845 202-0 Fax: +49 (0) 2845 202-265 E-mail: trox@trox.de Internet: http://www.troxtechnik.com Translation of the original A00000092711, 1, GB/en 04/2023 © 2021 Fire damper Type FKRS-EU...

- Page 3 To ensure that your request is processed as quickly as possible, please keep the following information ready: Product name TROX order number Delivery date Brief description of defect or issue Online www.trox.de Phone +49 2845 202-0 Fire damper Type FKRS-EU...

- Page 4 Warning – danger zone. NOTICE! Potentially hazardous situation which, if not avoided, may result in property damage. ENVIRONMENT! Environmental pollution hazard. Tips and recommendations Useful tips and recommendations as well as informa- tion for efficient and fault-free operation. Fire damper Type FKRS-EU...

-

Page 5: Table Of Contents

2.3 FKRS-EU with spring return actuator ..2.4 FKRS-EU with spring return actuator and duct smoke detector ........ 14 2.5 FKRS-EU with fusible link and cover grille on both sides as an upstream shutter for the air transfer unit ........ -

Page 6: Safety

The fire dampers may only be operated in com- pliance with these installation instructions and the technical data in these installation and operating instructions. Modifying the fire damper or using spare parts that have not been approved by TROX is not permitted. Fire damper Type FKRS-EU... -

Page 7: Qualified Staff

Trained personnel are individuals who have sufficient professional or technical training, knowledge and actual experience to enable them to carry out their assigned duties, understand any potential hazards related to the work under consideration, and recognise and avoid any risks involved. Fire damper Type FKRS-EU... -

Page 8: Technical Data

Non-condensing operation or without moisture entry via the fresh air intake. For explosion-proof constructions of the FK-EU see the corresponding operating manual. Leakage rate of the fire damper system tested at 300 Pa and 500 Pa negative pressure. Fire damper Type FKRS-EU... - Page 9 Ä Chapter 4.1 ‘Overview of installation situations’ Notified body The last two digits of the year in which the CE on page 18 marking was affixed Type Year of manufacture Order number Fire damper Type FKRS-EU...

-

Page 10: Fkrs-Eu With Fusible Link

Technical data FKRS-EU with fusible link 2.2 FKRS-EU with fusible link Dimensions and weight Fig. 2: FKRS-EU with fusible link Y Keep clear to provide access for operation A Installation side B Operating side Limit switch Connecting cable length / cross section 1 m / 3 ×... -

Page 11: Fkrs-Eu With Spring Return Actuator

Fig. 3: FKRS-EU with Belimo spring return actuator Y Keep clear to provide access for operation A Installation side B Operating side Ä 10 . Weight of FKRS-EU with fusible link + approx. 1 kg, see table Spring return actuator BFL... Construction 230-T TR... - Page 12 Fig. 4: FKRS-EU with Siemens spring return actuator Y Keep clear to provide access for operation A Installation side B Operating side Ä 10 . Weight of FKRS-EU with fusible link + approx. 1 kg, see table Spring return actuator GRA... Construction 326.1E 126.1E...

- Page 13 Technical data FKRS-EU with spring return actuator FKRS-EU with Schischek explosion-proof spring return actuator The FKRS-EU can also be supplied with Schischek explosion-proof spring return actuator on request: ExMax-15-BF-TR RedMax-15-BF-TR For further information, see "Supplementary oper- ating manual for explosion-proof fire dampers Type FKRS-EU".

-

Page 14: Fkrs-Eu With Spring Return Actuator And Duct Smoke Detector

2.4 FKRS-EU with spring return actuator and duct smoke detector Dimensions and weight Fig. 5: FKRS-EU with Belimo spring return actuator and duct smoke detector, drawn in a square air duct (on-site) Y Keep clear to provide access for operation... -

Page 15: Fkrs-Eu With Fusible Link And Cover Grille On Both Sides As An Upstream Shutter For The Air Transfer Unit

Dimensions and weight Fig. 7: FKRS-EU with fusible link and cover grille on both sides as an upstream shutter for the air transfer unit Y Keep clear to provide access for operation A Installation side B Operating side Note: Air transfer units may require a building inspectorate licence. -

Page 16: Fkrs-Eu With Spring Return Actuator And Duct Smoke Detector Used As An Air Transfer Damper

2.6 FKRS-EU with spring return actuator and duct smoke detector used as an air transfer damper Dimensions and weight Fig. 8: FKRS-EU with spring return actuator and duct smoke detector used as an air transfer damper Y Keep clear to provide access for operation A Installation side B Operating side Weight of FKRS-EU with fusible link + approx. -

Page 17: Supply Package, Transport And Storage

Store the product in a dry place and remote from direct sunlight. Do not expose the unit to the effects of weather (not even in its packaging). Do not store the product below -40 °C or above 50 °C. Fire damper Type FKRS-EU... -

Page 18: Installation

N = Mortar-based installation Ø see the complete operating E = Installation kit Thickness increased near the installation opening and installation manual at W = Fire batt www.trox-docs.com Depending on local conditions E = Dry mortarless installation Fire damper Type FKRS-EU... - Page 19 The class of performance depends on the installation details Ø see the complete operating E = Installation kit and installation manual at Thickness increased near the installation opening W = Fire batt www.trox-docs.com Depending on local conditions E = Dry mortarless installation Fire damper Type FKRS-EU...

- Page 20 The class of performance depends on the installation details Ø see the complete operating E = Installation kit Thickness increased near the installation opening and installation manual at W = Fire batt www.trox-docs.com Depending on local conditions E = Dry mortarless installation Fire damper Type FKRS-EU...

- Page 21 The class of performance depends on the installation details Ø see the complete operating E = Installation kit and installation manual at Thickness increased near the installation opening W = Fire batt www.trox-docs.com Depending on local conditions E = Dry mortarless installation Fire damper Type FKRS-EU...

-

Page 22: Safety Notes Regarding Installation

– Do not remove the transport and installation pro- – Be careful when carrying out any work. tection (if any) until installation is complete. – Wear protective gloves, safety shoes and a hard hat. Fire damper Type FKRS-EU... - Page 23 provide sufficient clearance for inspection. piece. Load-bearing structures When installing the FKRS-EU, the statics of the sup- This includes solid ceiling slabs, concrete beams porting construction (wall/ceiling) must be ensured and load-bearing solid walls. by others, even in the event of a fire.

- Page 24 C - s2, d0, may be used according to the specifications of the MVV TB (since 2019/1). This requirement is met by Armaflex Ultima insulation mate- rial from Armacell, for example. The applicable local building regulations have to be observed. Fire damper Type FKRS-EU...

- Page 25 (0 to 360°). The position of the release mechanism is not critical but the mechanism must remain accessible for maintenance. Fig. 12: FKRS-EU with spring return actuator and duct smoke detector used as an air transfer damper Y Keep clear for operation and maintenance Fig.

- Page 26 Installation into separate installation openings With shortened cover plate Minimum distance depending on fire resistance duration and supporting construction. Distance between installation block(s) Supporting construction, Ä ‘Installation orientation (see installation details for fire resistance)’ on page 27 Fire damper Type FKRS-EU...

- Page 27 In/combined with a solid wood ceiling E/A, B, D – F E/– In/combined with a wooden beam ceiling E/A, B, D – F E/– In historical wood beam ceilings * The following applies to Germany: Installation requires a project-related type approval. Fire damper Type FKRS-EU...

- Page 28 The gap must be large enough so that mortar can be filled in. We recommend a gap of at least 20 mm (note the minimum installation opening size). Reinforcement should meet structural require- ments. Fire damper Type FKRS-EU...

- Page 29 The installation is carried out on a mortared- in, wall-flush shortened air duct with additional reinforcing board made of calcium silicate, d = 30 - 50 mm or mineral wool, ≥ 1000 °C, ³ ≥ 140 kg/m , d = 50 mm. Fire damper Type FKRS-EU...

- Page 30 If cavities are present, they must be com- pletely sealed with mortar all around to a depth of ≥ 100 mm. Fire batt systems are not suitable for use below flex- ible ceiling joints. Fire damper Type FKRS-EU...

- Page 31 Ablative coating Würth Ablationsbeschichtung I ('Ablation coating I') Ablative coating PYRO-SAFE Flammotect Combi S90 Fire-resistant sealant AGI Flammotect COMBI S90 FLAMRO BML Fire protection coating ablative BMS Fire protection sealant ablative Fire damper Type FKRS-EU...

- Page 32 Dimensions and distances for fire batt systems for Installation with combined penetration seal wall installation Mixed ducts of fire dampers FKRS-EU and FK2-EU, together with cables and pipes in a Hilti fire batt system (CFS-CT, CP 670 and CP 673), are permitted in the Trox combined penetration seal.

- Page 33 6.19, 6.20 or 6.24 as an alternative 7.10 Trim panels, fire-resistant, double-layered, required for wall thicknesses < 200 mm Mixed penetrations of FKRS-EU fire dampers 8.21 Fire-resistant sealant CFS-S ACR CW together with cable and cable trays are permitted Air duct/extension piece with a Hilti fire protection brick system (CFS-BL).

- Page 34 Requirements for wall and ceiling systems FKRS-EU fire dampers may be installed in wall and Fig. 20: Distance from the FKRS-EU to other TROX fire ceiling systems if these walls and ceilings have been dampers in mortar-based installation...

- Page 35 ≥ 1000 °C, ≥ 115 kg/m³ Trim panels and reinforcing boards have to be made Wall thickness ≥ 100 mm – 200 mm of cladding material and have to be fixed to the frame. Fire damper Type FKRS-EU...

- Page 36 supplementary fire-resistant cladding. Wooden beam ceilings Wooden beam or gluelam construction. Ceiling thickness D ≥ 142.5 mm (ceiling-dependent) with supplementary fire-resistant cladding. Historic wooden beam ceilings structurally F30 or fire protection-technically F30-approved. Fire damper Type FKRS-EU...

-

Page 37: Installation Kits

4.4.1 Overview of installation block and installation kits Fig. 21: Overview of installation block and installation kits FKRS-EU 2.11 Installation kit TQ2 Installation kit WA2 2.12 Installation kit GL2 Installation kit WE 2 2.18 Installation block ER with cover plate Fire damper Type FKRS-EU... -

Page 38: Installation Block Er

Fig. 22: Supply package and installation of installation block ER for dry mortarless installation FKRS-EU 2.18 Installation block ER with cover plate Dimensions of installation opening/cover plate [mm] Nominal size ÆD1* ☐B Installation opening tolerance ±2 mm * Diameter of the core drill hole in solid walls and ceilings Fire damper Type FKRS-EU... -

Page 39: Installation Kit Tq2

Installation of installation kit TQ2 Place half shells (2.11a) and (2.11b) of the instal- lation kit (2.11) around the FKRS-EU so that the cover plate is flush with the bead. Fix the installa- tion kit with two connecting clamps (2.11c) (any installation position of the FKRS-EU). -

Page 40: Installation Kit Wa2

Installation of installation kit WA2 Place half shells (2.5a) and (2.5b) of the installa- tion kit (2.5) around the FKRS-EU so that it is flush with the bead. Fix the installation kit with two connecting clamps (2.5c) (any installation position of the FKRS-EU). -

Page 41: Installation Kit We 2

Half shell 2 Mounting installation kit WE2 Place half shells (2.6a) and (2.6b) of the installa- tion kit (2.6) around the FKRS-EU so that it is flush with the bead. Fix the installation kit with two connecting clamps (2.6c) (any installation position of the FKRS-EU). -

Page 42: Installation Kit Gl2

The installation kit can also be ordered subsequently. Fig. 26: Supply package and installation of installation kit GL2 for dry mortarless installation FKRS-EU Half shell 2 2.12 Installation kit GL2, consisting of: Connecting clamp (2 ×) Half shell 1 Bracket Fire damper Type FKRS-EU... - Page 43 Cover (supplied by customer) Half shell 2 Fig. 28: Steel angle for dry mortarless installation with installation kit GL2 in lightweight partition wall if there is no rear fastening possibility 8.37 Steel bracket, supplied by customer Welded seam Fire damper Type FKRS-EU...

- Page 44 Installation of installation kit GL2 Place half shells (2.12a) and (2.12b) of the instal- lation kit (2.12) around the FKRS-EU so that it is flush with the bead. Fix the installation kit with two connecting clamps (2.12c) (any installation posi- tion of the FKRS-EU).

-

Page 45: Solid Walls

Solid walls > General information 4.5 Solid walls 4.5.1 General information Fig. 30: Solid walls – arrangement/distances FKRS-EU Solid wall Mortar Perimeter gap, Fire batt with ablative coating Distance between the fire dampers, Ä ‘Dis- tances’ on page 26 Fire damper Type FKRS-EU... - Page 46 Depending on fire resistance duration Distance between the installation blocks Installation opening tolerance ± 2 mm Additional requirements: solid walls Ä Solid wall, on page 34 Ä Distances and installation orientation, ‘Dis- tances’ on page 26 Fire damper Type FKRS-EU...

-

Page 47: Mortar-Based Installation

FKRS-EU Up to EI 120 S for s2 = 40 – 225 mm Mortar Up to EI 90 S for s2 = 10 – 225 mm Solid wall Fire damper Type FKRS-EU... - Page 48 Note for installation in gypsum wallboards with W = 80 to < 100 mm: Distance between two fire dampers ≥ 200 mm in separate installation openings at W ≥ 100 mm, distances Fig. 31 to Fig. 33 Fire damper Type FKRS-EU...

- Page 49 Installation Solid walls > Mortar-based installation Mortar-based installation into a solid wall, com- bined, FKRS-EU and FK2-EU Additional requirements: mortar-based installation into solid walls Ä Solid wall, on page 34 Mortar-based installation in opening or cut hole General installation information, Ä...

-

Page 50: Lightweight Partition Walls

Fig. 35: Lightweight partition walls with metal support structure – arrangement/distances FKRS-EU Lightweight partition wall, cladding on both sides Mortar Perimeter gap, Fire batt with ablative coating Distance between the fire dampers, Ä ‘Dis- tances’ on page 26 Fire damper Type FKRS-EU... - Page 51 Dry mortarless installation 40 – 600 10/40 – 600 with fire batt Note the maximum size for the fire batt Depending on fire resistance duration Installation opening tolerance ± 2 mm Installation into separate installation openings Fire damper Type FKRS-EU...

- Page 52 Lightweight partition walls > General information Lightweight partition wall with metal support structure and cladding on both sides Fig. 36: Lightweight partition wall with metal support structure and cladding on both sides, explanation see Fig. 37 Fire damper Type FKRS-EU...

- Page 53 Installation near the ceiling analogous to B UW section Installation opening ☐A 7.1a UW section, either cut in and bent or cut off ☐A1 Opening in the metal support structure CW section (without trim panels: ☐A = ☐A1) Fire damper Type FKRS-EU...

- Page 54 Fig. 38: Metal support structure for a compartment wall, single stud system and double stud system Dry wall screw UW section Hexagon head screw M6 CW section Carriage bolt L ≤ 50 mm with washer and nut UA section Steel rivet Installation opening according to installation 5.14 Angle bracket details Fire damper Type FKRS-EU...

- Page 55 Option 3: After cladding the wall, create a square wall opening (clear installation opening ≤ 475 mm) between the regular studs and brace it with a perimeter metal section. Screw metal sections onto both sides over the cladding, spaced approx. 100 mm apart. Fire damper Type FKRS-EU...

-

Page 56: Dry Mortarless Installation Into A Lightweight Partition Wall, With Installation Kit Tq2

Air duct/extension piece metal stud frame optional Mineral wool, ≥ 1000 °C, ≥ 40 kg/m³ – Up to EI 120 S Mineral wool (depending on wall construction) 6.11 Insulating strip (depending on wall construction) UW section UA section Fire damper Type FKRS-EU... - Page 57 Up to EI 120 S Mineral wool, ≥ 1000 °C, ≥ 40 kg/m³ Up to EI 60 S Mineral wool (depending on wall construction) EI 30 S – UW section Steel support structure (box section) Fire damper Type FKRS-EU...

- Page 58 Cover plate shortened by others Mineral wool (depending on wall construction) – EI 30 S 6.11 Insulating strip (depending on wall construction) EI 30 S – EI 120 S 6.13 Mineral wool strips A1, alternatively gypsum mortar UW section Fire damper Type FKRS-EU...

- Page 59 Dry wall screw, min. 10 mm screwed into the Installation near the floor as in metal stud frame Fastening to at least two metal post profiles Mineral wool (depending on wall construction) Up to EI 120 S UW section Fire damper Type FKRS-EU...

- Page 60 ≥ 200 mm distance between two fire dampers in separate installation openings General installation information, Ä 4.3 ‘General installation information’ on page 22 ff General information on installation with installation Ä kit TQ2, on page 29 Fire damper Type FKRS-EU...

-

Page 61: Dry Mortarless Installation With Fire Batt

6.19, 6.20 or 6.24 as an alternative remain accessible Installation near the floor as in 6.20 Sleeve (to be ordered separately) Ä 62 – See table Note: The fire resistance properties of depend on the nominal width and 6.10*. Fire damper Type FKRS-EU... - Page 62 224 – 315 EI 90 S – 100 – 200 EI 120 S – 224 – 315 EI 120 S 100 – 315 EI 60 S – – 100 – 315 EI 30 S – – Fire damper Type FKRS-EU...

- Page 63 Fig. 45: Dry mortarless installation into a lightweight partition wall, with a fire batt, flange to flange, illustration shows side by side installation (applies also to installation of dampers on top of each other) FKRS-EU 6.24 Elastomeric foam (flame-resistant, non-drip- Fire batt with ablative coating ping) Fire damper Type FKRS-EU...

- Page 64 – – 10 – 600 * For a distance of 10 mm, mineral wool ≥ 1000 °C, ≥ 80 kg/m with d = 10 mm and width nominal width/2 shall be provided between the fire dampers. Fire damper Type FKRS-EU...

- Page 65 Compartment wall or safety partition wall with – F 30 metal support structure, cladding on both sides F 60 Solid ceiling slab/solid floor F 30 – F 120 Mineral wool (depending on wall construction) 6.11 Insulating strip Fire damper Type FKRS-EU...

- Page 66 Ä Chapter 4.7 ‘Fixing the fire damper’ on page 67 General installation information, Ä 4.3 ‘General installation information’ on page 22 ff General information on installation with fire batt, Ä on page 30 Fire damper Type FKRS-EU...

-

Page 67: Fixing The Fire Damper

15 Note: Each fire damper has to be suspended both on 2.6 ‘FKRS-EU with spring return actuator and the operating side and on the installation side. duct smoke detector used as an air transfer damper’... - Page 68 1.5 m. The fire dampers must then be connected on both sides with elastic spigots (length of elastic area ≥ 100 mm when installed), which are installed in such a way that shear and tensile forces can be absorbed. Fire damper Type FKRS-EU...

- Page 69 Danger of falling off! Do not step onto the fire batt! The fire batt cannot carry any loads. Adequate means, e.g. a permanent barrier, must be installed to prevent people from stepping onto the fire batt. Fire damper Type FKRS-EU...

- Page 70 ® HUS-6 or equivalent 5.19 L-bracket according to EN 10056-1, 20 × 20 × 3 mm galvanised, painted or similar. 5.20 L-bracket according to EN 10056-1, 35 × 35 × 4 mm galvanised, painted or similar. Fire damper Type FKRS-EU...

-

Page 71: Fire Damper Remote From Walls And Ceilings

Installation Fixing the fire damper > Fire damper remote from walls and ceilings 4.7.3 Fire damper remote from walls and ceilings Fig. 52: FKRS-EU in a cladded duct FKRS-EU Threaded rod M10 Solid wall Hilti ® mounting rail MQ 41 × 3 mm or equivalent Lightweight partition wall with metal support struc- ®... -

Page 72: Electrical Connection

Fig. 53 see "Supplementary operating manual for explosion- Indicator lights or relays may be connected as long proof fire dampers Type FKRS-EU". as the performance specifications are taken into consideration. Connection boxes must be fixed to the adjoining ... -

Page 73: Functional Test

They may also indicate the need for additional measures which help to maintain the sys- tem's function, e.g. removing heavy contamination (dust in extract air systems). Fire damper Type FKRS-EU... -

Page 74: Fire Damper With Fusible Link

The handle (1.6) swivels automatically in the direction of the arrow. The damper blade is closed and the handle (1.6) shows that the damper blade is closed. Fig. 57: Damper blade position indicator Damper blade is closed Damper blade is open Fire damper Type FKRS-EU... -

Page 75: Fire Damper With Spring Return Actuator

Release the button (1). ð Power is supplied again, and the damper blade opens. Fig. 59: Damper blade position indicator Check if the damper blade is OPEN, check run Damper blade is closed time. Damper blade is open Fire damper Type FKRS-EU... - Page 76 Turn the crank handle in the direction of the arrow (2) to just short of the travel stop and hold it. Set the interlock (3) to "Lock " ð The damper blade remains in the OPEN posi- tion. Remove the crank handle. Fire damper Type FKRS-EU...

-

Page 77: Commissioning

This action closes the damper blade. CLOSED fire dampers Fire dampers which close while the ventilation system is running must be inspected before they are opened again in order to ensure their correct function. Fire damper Type FKRS-EU... -

Page 78: Index

10 , 29 , 37 , 39 , 40 , 41 , 42 Technical Data............. 8 Installation position............ 25 Threaded rods............67 Installation side........10 , 11 , 12 , 15 Timber stud walls............Installation situations..........18 Transport..............17 Transport damage............. 17 Fire damper Type FKRS-EU... - Page 79 Index Warranty claims............3 Weights......10 , 11 , 12 , 14 , 15 , 16 Wall attachment............18 Wooden beam ceilings........18 , 36 Wall duct..............18 Fire damper Type FKRS-EU...

Need help?

Do you have a question about the FKRS-EU and is the answer not in the manual?

Questions and answers