Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for RASOR DD120ML

- Page 1 DD120ML THREE-PHASE CUTTING UNIT USE MANUAL...

- Page 2 All the parts of the devices have been planned and produced to guarantee an optimum performance. In order to keep the high quality level and the long reliabilty of the Rasor ® products, it is recommended using only original spare parts and to contact the head office...

-

Page 3: General Safety Rules

1. GENERAL SAFETY RULES This manual is an integral part of cutting unit DD120ML and must be carefully read before using it since it gives important indications with regards to its safe installation, use and maintenance. Keep it with care. - Page 4 Moreover, they cannot work in case of rain. In case of damage or malfunction, cutting unit DD120ML must not be used until the Customer Care Technical Service has repaired them.

-

Page 5: Transport And Packing

In such a case, the operator is the only person responsible. READ THE INSTRUCT ION MANUAL Model Serial number DD120ML DD______ USE METAL GLOVES 380/400-3ph 0,52 Electric data... -

Page 6: Product Description

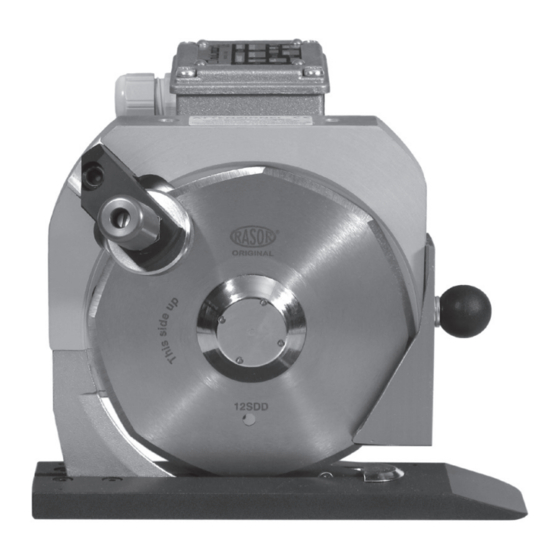

4. PRODUCT DESCRIPTION The fixture described in this manual is a cutting unit model DD120ML which can be assembled on automatic machines (e.g. spreaders, computerized cutting) by means of proper holes located in the motor rest. DD120ML can operate continuously and it can cut at various heights by means of multiple installation. -

Page 7: Technical Features

The technical data are only indicative and they can be changed without notice. 6. NOISE LEVEL The maximum acoustic pressure level emitted by cutting unit DD120ML is about 60 dB (A). Noise tests have been carried out in compliance with Standard UNI EN ISO 11202:2010. The device noise levels, measured at different distances (without any sound wave filtering system), vary in the extent of few db (A). -

Page 8: Use Warnings

• Always pay attention to the electric cable position to prevent it from being cut or damaged by the blade. • It is allowed to assemble cutting unit DD120ML on machines O.E.M. on condition that their original structure is not modified. Otherwise, the intervention must be certified by Rasor ®... -

Page 9: Residual Risks

The cutting unit is provided with earthing (yellow-green cable). Possible faulty earthing connections may cause unsafe working conditions. Possible damages are not at RASOR s.r.l. charge. ® The electric feeding must be supplied by a line protected against overcurrent by means of the automatic switch (magnetothermal) or delayed fuses with a suitable dimensions. -

Page 10: Installation And Use

6) Carry out the cutting operation. NOTE Cutting unit DD120ML can work in a fixed position (the material has to be moved) or it can move forward while the material is kept in the same position. Make sure the material to be cut is properly stretched, preventing it from curling. -

Page 11: Blade Replacement

Rasor can be seen by the operator. 6) Assemble all the components again and carry out... -

Page 12: Troubleshooting

SW122100 SHAFT HEAD FIXING SCREW SW1290M RIGHT BASE WITH BEVEL, Monster RIGHT COUNTERBLADE COATED WITH GRT12M19 MOTOR FAN SW1081TN SW122300 STEEL STUD BOLT SW1290MSCPL COMPLETE BASE DD120ML TITANIUM GRT12M21 UPPER MOTOR COVER SW108200 COUNTERBLADE FIXING SCREW SW122400 STEEL WASHER SW129100 SHARPENER BUSH... -

Page 14: Warranty

The warranty covers all manufacturing and material defects. Replacement and repair operations are covered only if carried out by our company and at our workshop. If in-warranty goods need to be repaired, the customer must always send the complete machine to Rasor ®... - Page 15 RASOR ELETTROMECCANICA SRL Via Vincenzo Caldesi 6 20161 Milan ∙ Italy ph. +39 02 66 22 12 31 fax +39 02 66 22 12 93 info@rasor-cutters.com www.rasor-cutters.com FOLLOW US:...

Need help?

Do you have a question about the DD120ML and is the answer not in the manual?

Questions and answers