Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for RASOR D 86PS

- Page 1 USE MANUAL English CUTTING UNIT MOD. D 86PS ED.1-02/09...

- Page 2 All the parts of the devices have been planned and produced to guarantee an optimum performance. In order to keep the high quality level and the long reliabilty of the Rasor ® products, it is recommended to use only original spare parts and to contact the head...

-

Page 3: General Safety Rules

1. GENERAL SAFETY RULES This manual is an integral part of cutting unit D 86PS and must be carefully read before using it since it gives important indications with regards to its safe installation, use and maintenance. Keep it with care. - Page 4 Moreover, they cannot work in case of rain. In case of damage or malfunction, cutting unit D 86PS must not be used until the Customer Care Technical Service has repaired them.

-

Page 5: Transport And Packing

In such a case, the operator is the only person responsible. Class II double insulation Model Serial number D 86PS 220 230 50 60 Electric data Year of production R EAD... -

Page 6: Product Description

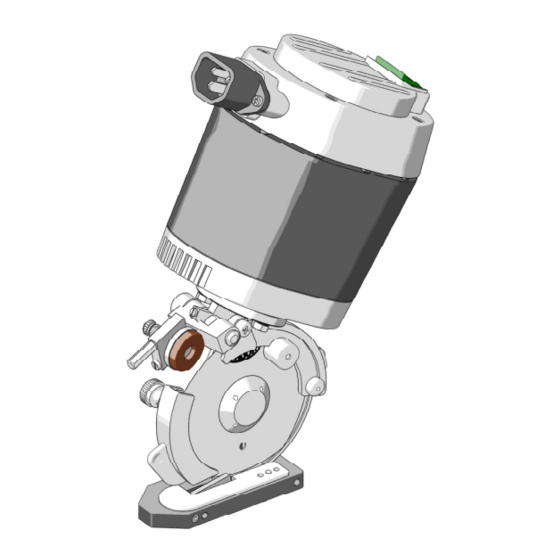

4. PRODUCT DESCRIPTION The fixture described in this manual is a small cutting unit model D 86PS which can be assembled on automatic machines (e.g. spreaders, computerized cutting) by means of proper holes located in the motor support. D 86PS can operate continuously and it can cut at various widths by means of multiple installation. -

Page 7: Technical Features

The technical data are only indicative and they can be changed without notice. 6. NOISE LEVEL The maximum acoustic pressure level emitted by cutting unit D 86PS is about 60 dB (A). Noise tests have been carried out in compliance with Standard ISO 11202 (1995). The device noise levels, measured at different distances (without any sound wave filtering system), vary in the extent of few db (A). -

Page 8: Use Warnings

· Always pay attention to the electric cable position to prevent it from being cut or damaged by the blade. · It is allowed to assemble cutting unit D 86PS on machines O.E.M. on condition that their original structure is not modified. Otherwise, the intervention must be certified by Rasor ®... -

Page 9: Residual Risks

5) Enable the switch; once it has been enabled, it lights with a green light (see picture 8). NOTE Cutting unit D 86PS can work in a fixed position (the material has to be moved) or it can move forward while the material is kept in the same position. Make sure the material to be cut is properly stretched, preventing it from curling. -

Page 10: Motor Brush Replacement

To carry out this operation, remove the protective plug “A” located on the motor support of the cutting unit and fill it with lubricating grease Rasor. Screw plug “A” again a few turns. Screw plug “A” a few turns every 2-3 working hours (see picture 11). -

Page 11: Blade Replacement

Rasor positioned towards the external side of the cutting unit. 6) Assemble all the components again and carry out the... -

Page 12: Troubleshooting

16. TROUBLE SHOOTING PROBLEM SOLUTION à Check the distance between the blade and the counterblade Check the kind of fabric Sharpen the blade The fabric is not cut or it gets stuck between the Check the fabric thickness blade and the counterblade Check the compatibility between blade and fabric Make sure that the motor turns correctly Reduce the feeding speed... - Page 13 ® dal 1946...

-

Page 14: Warranty

WARRANTY Rasor Elettromeccanica S.r.l. cutting unit has a 12 month warranty from the date indicated ® on the last page of this manual, except in case of different written agreements. The warranty covers all manufacturing and material defects. Replacement and repair operations are covered only if carried out by our company and at our workshop. -

Page 15: Declaration Of Conformity

UNI EN 414:2002, UNI EN ISO 12100-1:2005 and UNI EN ISO 12100-2:2005. Noise tests have been carried out according to UNI EN ISO 11202 Standards. Cutting unit D 86PS has been produced according to workmanlike standards. We declare that the above-mentioned goods comply with the standards in force concerning safety and hygiene at work that can be applied to the material itself according to art. - Page 16 Authorized dealer (Stamp)

Need help?

Do you have a question about the D 86PS and is the answer not in the manual?

Questions and answers