Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for RASOR DD120

- Page 1 DD120 THREE-PHASE CUTTING UNIT USE MANUAL...

- Page 2 All the parts of the devices have been planned and produced to guarantee an optimum performance. In order to keep the high quality level and the long reliabilty of the Rasor ® products, it is recommended using only original spare parts and to contact the head office...

-

Page 3: General Safety Rules

Do not use large clothes or accessories that might get stuck in the moving parts. • GOGGLES AND PROTECTIVE METAL MESH GLOVES. Always use goggles, protective metal mesh gloves approved by Rasor during ® use and maintenance operations (according to UNI EN 388:2017 standard). -

Page 4: Informative Letter

The original configuration of the cutting unit must not be changed at all. On receiving the machine make sure the supply corresponds to what has been ordered. In case of non-compliance immediately inform Rasor ® Also make sure the cutting unit has not been damaged during transport. -

Page 5: Transport And Packing

2. TRANSPORT AND PACKING The cutting unit is delivered in a cardboard box, inside which there are various options. The code of the ordered product and its serial number are indicated outside the package (see picture 1). The following accessories are contained in a bag inside the package: Poligonal blade;... -

Page 6: Product Description

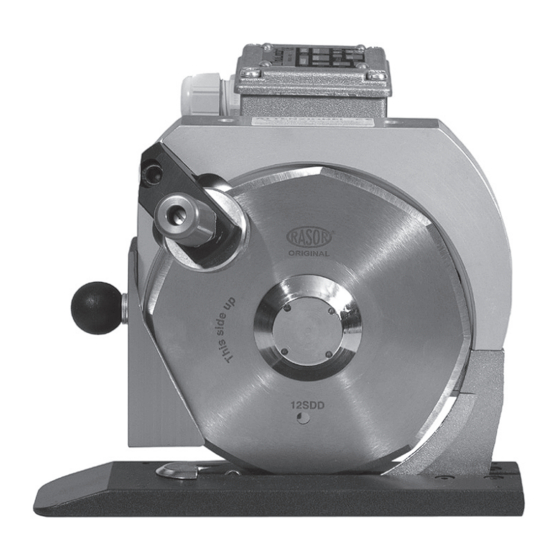

4. PRODUCT DESCRIPTION The fixture described in this manual is a cutting unit model DD120MR which can be assembled on automatic machines (e.g. spreaders, computerized cutting) by means of proper holes located in the motor rest. DD120MR can operate continuously and it can cut at various heights by means of multiple installation. -

Page 7: Technical Features

5. TECHNICAL FEATURES DD120MR cutting unit features Features of the available blades 120 mm with hard metal Blade diameter 12CDD Circular blade Ø 120 mm, HSS Steel counterblade coated with titanium Blade speed 2600 rev./min 12SDD 8 side blade Ø 120 mm, HSS Steel Cutting working depth about 4 cm Three-phase-Asynchronous, 180 W... -

Page 8: Use Warnings

• It is allowed to assemble cutting unit DD120MR on machines O.E.M. on condition that their original structure is not modified. Otherwise, the intervention must be certified by Rasor ® 9. ELECTRIC CONNECTION Firstly make sure that the lines are able to feed the cutting unit correcltly, in compliance with the safety rules (for the feature required see par. -

Page 9: Residual Risks

The cutting unit is provided with earthing (yellow-green cable). Possible faulty earthing connections may cause unsafe working conditions. Possible damages are not at RASOR s.r.l. charge. ® The electric feeding must be supplied by a line protected against overcurrent by means of the automatic switch (magnetothermal) or delayed fuses with a suitable dimensions. -

Page 10: Installation And Use

11. INSTALLATION AND USE To install and use the cutting unit, proceed as follows: 1) Fix the cutting unit on level squares or angles by using the two threaded holes “A” for M8 screws located in the blade holder support (see picture 4). NOTE The cutting unit can be installed in any position/angle: vertically, laterally and it can be turned upside down. -

Page 11: Blade Replacement

Rasor can be seen by the operator. 6) Assemble all the components again and carry out... -

Page 12: Troubleshooting

8 SIDE BLADE Ø 120 mm, IN H.S.S. 12SDD GRT12M28 COMPENSATION RING SW109000 EMERY SPRING Ø 6 mm SW124000 UPRIGHT SUPPORT SCREW STEEL COMPLETE MOTOR SERIES DD120, 3- SW1244MDD GMT12DD GRT12M29 FASTENING NUT SW109100 SHARPENER CAP WITH BEARING RIGHT ALUMINIUM PROTECTION COVER... - Page 13 ® dal 1946...

-

Page 14: Warranty

The warranty covers all manufacturing and material defects. Replacement and repair operations are covered only if carried out by our company and at our workshop. If in-warranty goods need to be repaired, the customer must always send the complete machine to Rasor ®... - Page 15 RASOR ELETTROMECCANICA SRL Via Vincenzo Caldesi 6 20161 Milan ∙ Italy ph. +39 02 66 22 12 31 fax +39 02 66 22 12 93 info@rasor-cutters.com www.rasor-cutters.com FOLLOW US:...

Need help?

Do you have a question about the DD120 and is the answer not in the manual?

Questions and answers