Advertisement

Quick Links

Product Installation Guidelines

®

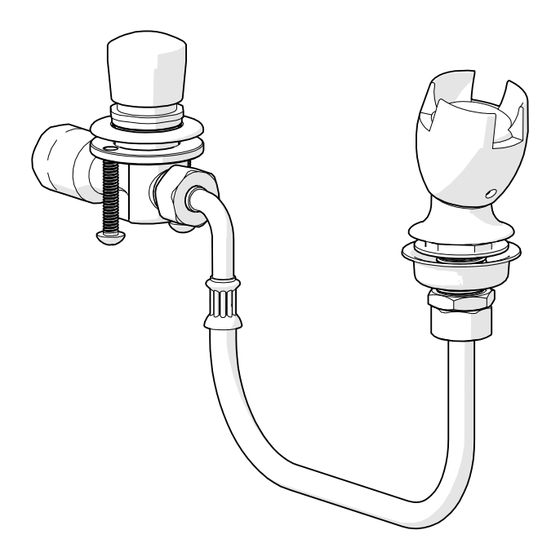

Ezy-Drink

Lead Safe™ SS316 Remote

Push Button Drinking Bubbler

PRODUCT CODE:

- TD15XP

SPECIFICATIONS

−

The innovative design and 316 Stainless Steel construction ensures there is no risk of lead leaching

into the water from the tapware.

−

Drinking taps are designed to operate at full mains pressure.

−

The rubber mouthguard is resistant to fungal and bacterial attack and has a high resistance to sunlight.

−

Vandal resistant handle.

−

Adjustable built-in flow restrictor.

IMPORTANT: All Ezy-Drink

our premises in good working order.

TECHNICAL DATA

Inlet

Outlet

Headwork

Working Pressure Range (kPa)

Working Temperature Range (°C)

Nominal Flow Rate (LPM)

Construction

Finish

NOTE: Galvin Specialised continually strive to improve their products. Specifications may change without

notice.

TOOLS REQUIRED

−

Power drill

−

Wrench

−

2mm Hex Key (provided)

−

Screwdriver

© Galvin Engineering Pty Ltd

®

remote bubbler taps are tested in accordance with AS/NZS 3718 and leave

Version 4, 25

½" BSP - Female

Rubber mouthguard

Push button

Min

50

Max

500

Min

5

Max

60

2

316 Stainless Steel

Satin

th

October 2022, Page 1 of 5

Advertisement

Summary of Contents for Galvin Engineering Ezy-Drink Lead Safe SS316

- Page 1 Nominal Flow Rate (LPM) Construction 316 Stainless Steel Finish Satin NOTE: Galvin Specialised continually strive to improve their products. Specifications may change without notice. TOOLS REQUIRED − Power drill − Wrench − 2mm Hex Key (provided) − Screwdriver © Galvin Engineering Pty Ltd...

- Page 2 INSTALLATION IMPORTANT: Galvin Engineering products must be installed in accordance with these installation instructions and in accordance with AS/NZS 3500, the PCA and your local regulatory requirements. Water and/or electrical supply conditions must also comply to the applicable national and/or state standards. Failing to comply with these provisions shall void the product warranty and may affect the performance of the product.

- Page 3 1. Remove the blanking screw . 2. Adjust the water height by turning the regulator screw . 3. Replace blanking screw. Note: The full range from minimum flow to maximum flow is only ¼ turn. © Galvin Engineering Pty Ltd...

- Page 4 Regrease spindle if required WARRANTY The warranty set forth herein is given expressly and is the only warranty given by the Galvin Engineering Pty Ltd. With respect to the product, Galvin Engineering Pty Ltd makes no other warranties, express or implied.

Need help?

Do you have a question about the Ezy-Drink Lead Safe SS316 and is the answer not in the manual?

Questions and answers