Table of Contents

Advertisement

Quick Links

Operating Instructions

®

ProMinent

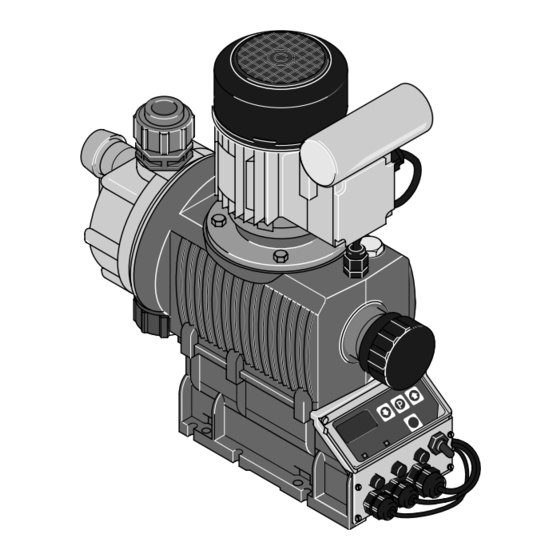

Sigma

SIBa (Basic Type)

SICa (Control Type)

SIBa

SICa

Affix type identification plate here!

®

Two sets of operating instructions are necessary to ensure the ProMinent

Sigma SIBa or SICa

metering pumps are operated safely and reliably for their intended purpose:

These product-specific Sigma operating instructions and the operating instructions for ProMinent

®

motor-driven metering pumps; both are only applicable in conjunction with each other!

Please completely read through these operating instructions first! • Do not discard!

The warranty shall be invalidated by damage caused by operating errors!

Version 1.0

Page 1 of 44

Part No. 987747

ProMinent Dosiertechnik GmbH • D-69123 Heidelberg • Germany

BA SI 008 08/00 GB

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for ProMinent Sigma SIBa

- Page 1 SICa Affix type identification plate here! ® Two sets of operating instructions are necessary to ensure the ProMinent Sigma SIBa or SICa metering pumps are operated safely and reliably for their intended purpose: These product-specific Sigma operating instructions and the operating instructions for ProMinent ®...

- Page 2 Imprint: ® Operating Instructions for ProMinent Sigma SIBa/SICa ProMinent Dosiertechnik GmbH, 1995 ProMinent Dosiertechnik GmbH Im Schuhmachergewann 5-11 D-69123 Heidelberg P.O. Box 101760 D-69007 Heidelberg info@prominent.de www.prominent.de Subject to technical modifications Type setting/DTP: Bartha Docuteam GmbH D-64625 Bensheim Issue 08/00, Version 1.0...

-

Page 3: Table Of Contents

Contents Page Device Identification/Identity Code ....................... 2 Device Identification/Identity Code ....................... 3 ® Notes on Safety of ProMinent Metering Pumps ................. 4 General Notes ........................4 Notes on Installation, Start-Up and Operation ..............4 Notes on Maintenance and Repair ..................6 Product Description SIBa/SICa ....................7 Identification of Pump Type ....................7... -

Page 4: Device Identification/Identity Code

PVDF insert union nut and stainless steel insert union nut and PVDF hose sleeve union nut and stainless steel hose sleeve Version: ® with ProMinent label (standard) without ProMinent ® label (standard) Electrical power supply: 3 ph, 230 V/400 V 50/60 Hz, 0,18 kW... -

Page 5: Device Identification/Identity Code

PVDF insert union nut and stainless steel insert union nut and PVDF hose sleeve union nut and stainless steel hose sleeve Version: ® with ProMinent label (standard) ® without ProMinent label (standard) Electrical power suppley: 1 ph. 230 V, 50 Hz, Euro plug 1 ph. -

Page 6: Notes On Safety Of Prominent Metering Pumps

• ProMinent ® metering pumps must not be assembled with parts which are not tested and recommended by ProMinent otherwise this can lead to injury to persons and damage to property for which no liability will be accepted! • Pumps must be accessible at all times to facilitate operation and maintenance. - Page 7 ® Notes on Safety of ProMinent Metering Pumps end before start-up! For this purpose, turn the pump through 180˚ and drain off the liquid end then flush with a suitable medium from above via the intake connection! • Do not connect mains voltage to the control cable! •...

-

Page 8: Notes On Maintenance And Repair

® Notes on Safety of ProMinent Metering Pumps Notes on Maintenance and Repair WARNING: • Only specially trained and authorized persons are permitted to carry out maintenance on metering pumps and their periphery! • If hazardous or unknown metering media are used, always... -

Page 9: Product Description Siba/Sica

2.2.1 Functional Description, Drive ® The ProMinent Sigma diaphragm-type metering pump is an oscillatory displacement pump with the stroke length adjustable in steps of 1%. It is driven by electric motor (1). The rotary drive of the electric motor is... -

Page 10: Stroke Movement

Product Description SIBa/SICa-005-D 2.2.2 Stroke Movement SIBa/SICa-006-D Set stroke length dependent on the required delivery capacity. SIBa/SICa-007-D Version 1.0 Page 8 of 44... -

Page 11: Metering Capacity Diagram

Product Description NOTE: A large stroke length and low metering frequency should be selected for very viscous media! A shorter stroke length and high frequency should be selected to achieve good mixing properties! 2.2.3 Metering Capacity Diagram SIBa/SICa SIBa/SICa SIBa/SICa HM12050 HM12090 HM12130... - Page 12 Product Description SIBa/SICa SIBa/SICa SIBa/SICa HM07120 HM07220 HM04350 Pressure in (bar) SIBa/SICa-017-D SIBa/SICa SIBa/SICa SIBa/SICa HM07220 HM07120 HM04350 Stroke length in (%) SIBa/SICa-018-D Version 1.0 Page 10 of 44...

-

Page 13: Functional Description, Delivery Unit

Product Description 2.2.4 Functional Description, Delivery Unit: ® The heart of the delivery unit is the DEVELOPAN metering diaphragm (2). It hermetically seals the delivery chamber of liquid end (4) and produces a displacement in the liquid end. The end disc (5) made of chemically resistant plastic together with safety diaphragm (13) sepa- rates the drive housing from the delivery unit and protects the drive from corrosion in the event of the diaphragm failing. -

Page 14: Integrated Overflow Valve With Bleeder Function

Product Description 2.2.5 Integrated Overflow Valve with Bleeder Function Task: The task of the overflow valve is to protect the motor and gear unit against impermissible overpressure caused by the metering pump. This function is produced by a spring-loaded ball. A pressure relief mechanism for the bleeder function is provided. - Page 15 Product Description Delivery unit overflow valve Sigma 12 bar SST Identity code type: * Colour of cap - grey 12050, 12090, 12130 Delivery unit overflow valve Sigma 4 bar SST Identity code type: 04350 * Colour of cap - red Identity code type: 07120, 07220 Delivery unit overflow valve Sigma 7 bar SST * Colour of cap - black...

- Page 16 Product Description Technical data Corresponding to the type of pump, overflow valves are available for pressure stages p 4, 7, 10 and 12 bar with (1.05 ... 1.15) xp opening pressure. Material in contact with metered medium Liqiud end: Overflow valve: Seals in overflow valve: Balls: Springs:...

-

Page 17: 2.2.6 Diaphragm Failure Monitor

Product Description 2.2.6 Diaphragm Failure Monitor Task: Monitoring the working diaphragm for leaks. Even after diaphragm failure, this liquid end can continue operation without leaks at full operating pressure in emergency mode until the diaphragm is changed. Design and functional description (refer to drawing No. 3162-4) The „Sigma“... - Page 18 Product Description FM 130 Id. code Type: 12050, 12090, 12130 FM 350 Id. code Type: 04350, 07120, 07220 SIBa/SICa-011-GB Material in contact with metered medium Liquid end: Parts of diaphragm failure monitor in contact with medium Lens, seals Intermediate disc Item 147, Item 148, 156, 159 intermediate bush Item 150 PVDF...

-

Page 19: Technical Data

Technical Data Technical Data Technical Data Sigma Basic Type SIBa 3.1.1 Capacity Data Technical Data at 50 Hz operation Capacity at max. Intake Permissible Connection Shipping max. stroke head admission intake/ weight backpressure frequency pressure delivery intake side side Pump type Strokes/ mwater G-DN... - Page 20 Technical Data NOTE The valves in the liquid end of the sigma type 07120, 07220 and 04350 are dimensioned DN25 (R 1 1/2"). Since a piping size of DN 20 is generally sufficient for these types (see Technical Data, connection intake/delivery side), the connection parts (e.g.

-

Page 21: Dimensions Siba

Technical Data 3.1.3 Dimensions SIBa (distance between centres) (distance between centres) (at 100 % stroke) SIBa/SICa-012-D 3.1.4 Dimensions SIBa with Actuator SIBa/SICa-013-D Version 1.0 Page 19 of 44... -

Page 22: Motor Data

Contact load: max. 42 V / 100 mA. Contact duration: 100 mS Start-Up/Maintanance ATTENTION: Observe the safety notes provided in Section 1. Start-Up The general information provided in the operating instructions „ProMinent ® Motor-Driven Metering Pumps“ applies here. Maintenance What requires maintenance? Check following points during the maintenance procedure: •... -

Page 23: Replacement Of Wearing Parts

The gear oil should be changed after approx. 5000 duty hours. Gear oil ISO viscosity class VG 460, e.g. Mobil Gear 634, ProMinent Part No. 555325 (Amount of oil approx. 0.5 l). The metering diaphragm is a wearing part whose service life is dependent on following parameters: •... - Page 24 Start-Up/Maintenance The tightening torques of the liquid end screws should be checked every 3 months for the PVT material version. SIBa/SICa-014-D NOTES FOR INSTALLING THE VALVES: In the case of suction problems during installation, place the valves on a firm surface and tap the PTFE ball seat disk lightly with a brass rod and a hammer weighing about 300 g.

-

Page 25: Special Features Of The Sica Metering Pump

Metering Pumps SICa Special Features of the SICa metering pump Functional Description of the Motor The drive motor is equipped with an integrated thermal overload protection device in all versions. This device responds when the maximum permitted winding temperature is exceeded and switches off the motor. When the motor has cooled down sufficiently in the stationary state, the thermal overload protection device switches on again automatically. -

Page 26: Plug Strip Connector, Symbols And Connections

Metering Pumps SICa Plug Strip Connector, Symbols and Connections SIBa/SICa-020-D 1. Two stage socket connector for level switch with preliminary warning and switch-off function (with function plug, not illustrated). 2. External socket connector for contact or analog control and floating switch-off circuit via the pause function (with function plug, not illustrated). - Page 27 Metering Pumps SICa Technical data for external input: Control system type 1 Pin 1 = Pause input (activation function) Voltage level: approx. 5 V via 10 kOhms Contact loading: approx. 0.5 mA Residual voltage: 0.7 V Pin 2 = Contact input (not active in analog mode) Pin 3 = Analog input...

- Page 28 Metering Pumps SICa Wiring diagram for the various types of control system Cable plugs viewed from the front Level switch Metering monitor (contact open - empty display) External/Contact cable (2-wire) Universal control cable (4 conductors) Close contact - Metering stroke External/Contact 2 white + 4 black/GROUND...

-

Page 29: Operation

Operation Operation Explanation of the Operating and Display Elements 6.1.1 Display Relais Error Pause Stop Minimum Mem. Manual Analog Contact flow SIBa/SICa-023-D = Display of an error message "Error" = Pump stopped using the "Pause" control function = Pump stopped with key (17) manually = Relay access = Display of the stroking rate f + i = Display of the pulse step-up or step-down ratio... -

Page 30: Control Panel: Keys And Display Lamps

Operation 6.1.2 Control Panel: Keys and Display Lamps STOP START SIBa/SICa-024-D 12 = Pulse/pilot display (yellow) 13a = Up key 13b = Down key 15 = Program selection key 16 = Display lamp (red) for low-level display and fault signalling 17 = Stop/start key Version 1.0 Page 28 of 44... -

Page 31: Overview Operating Plan - Control Version 0 And 1

Operation Overview Operating Plan - Control Version 0 and 1 Stop Manual Pump Pump STOP STOP stop operates START STOP START STOP START START Increase stroking rate Reduce stroking rate Metering monitor on Metering monitor off Prime Start pulse for contact Error acknowledgement <... -

Page 32: Operating Functions - Control Versions 0 And 1

Operation Operating Functions - Control Versions 0 and 1 6.3.1 Starting the Pump • Connect power plug. • Set the stroke length to 100% with the adjustment knob. • Switch on the mains switch on the pump. • Press the keys simultaneously and activate automatic fast priming or set the toggle switch (priming) on the pump upwards. -

Page 33: External "Contact" Operation

Operation Stop Manual STOP • Press the key. START • The pump is now operating with the max. stroking rate displayed e.g. 195 strokes per minute. Manual • During the stroke the yellow pilot light goes out briefly. • With the keys the desired stroking rate can now be set e.g. - Page 34 Factor max. number of incoming pulses (pulses/min) Example: Pump type 12130, max. metering frequency according to data sheet 195 strokes per minute (50 Hz). Control by means of ProMinent controllers with max. 6000 pulses/hour (= 100 pulses/minute) 195 strokes/minute Factor...

- Page 35 Operation Setting recommendations: Max. incomming pulses/ 12000 lmp./h 10000 lmp./h 8000 lmp./h 6000 lmp./h 4000 lmp./h 2000 lmp./h Drive - mains frequency 12050, 07120 F = 0.4 F = 0.5 F = 0.6 F = 0.8 F = 1.1 F = 2.2 50 Hz 12090, 07220 F = 0.7...

- Page 36 Operation Setting: • Press the key for approx. 2 seconds. The display Stop Manual Contact • or Stop • Press the keys until "Manual" and "Contact" can be selected. Stop Manual Contact • Confirm with the key. • Press the keys until "Contact"...

- Page 37 Operation The setting " " in the display enables the activation of the memory function "Mem". • Switch off the "Mem" with the key if it is not desired. Stop Contact • Confirm with the factor set e.g. 100 is displayed. Stop Contact •...

-

Page 38: Connecting A Float Switch

Operation After starting using an external contact or using the key, the preselected number of strokes is counted down on the display. When "1" is reached the pump stops and the display jumps back to the preselected number of strokes. If a new start contact takes place before the strokes to be executed are worked off, the preselected number of strokes is carried out again. -

Page 39: External On/Off (Control Function "Pause")

Operation Error Relay Minimum Contact PLEASE NOTE: If single-stage float switches already present should be used, adapter cables are available as a transition! Adapter cable with flat connector: Order No. 80.83.12.3 Adapter cable with jack: Order No. 80.83.13.1 ATTENTION: In order that the correct function (for empty warning "Contact open") is provided, the float of the single- stage float switch must be removed from the retaining tube and turned by 180°! Before plugging in the 3-pole float cable plug the function plug must... -

Page 40: Metering Monitor "Flow

Operation If the pump should operate without the control function, the function plug must always be plugged to input or for "external" control as described above the brown and black wires of the four-wire control cable must be bridged! 6.3.7 Metering Monitor "Flow"... -

Page 41: Selection Of The Display Functions "F", "N÷" Or "N

Operation 6.3.8 Selection of the Display Functions "f", "N↔" or "N": So that the factor "N↔" of the step-up or step-down ratio e.g. 3.00 is always displayed, or the metering strokes executed are counted by being added- on (stroke counter "N") the following settings are to be executed. Display Stop Contact... -

Page 42: Error Messages - Acknowledging Error Messages

Operation The stroke counter "N" counts the executed strokes in all operating modes. A maximum of 9999 strokes can be counted. After this the display starts at 1 again. The excess is marked in the display with a " ". •... -

Page 43: Operation Analog Control

Operation Operation Analog Control Analog signals such as current signals 0 - 20 or 4 - 20 mA can be used for direct proportional control of the stroking rate. PLEASE NOTE: 100% stroking rate in analog operation corresponds to the fixed number of strokes per minute in "Manual "... - Page 44 Operation Stop Analog • With the key, set the signal range desired - e.g. Stop Analog • Confirm with the key. • For the 0 mA signal you receive the display of the stroking rate 0 strokes per minute and the error message "Error" with "Analog" flashing, as the control signal is below 4 mA.

-

Page 45: Tests Sigma Siba/Sica

Test Sigma SIBa/SICa EG - Conformity Declaration ProMinent Dosiertechnik GmbH Im Schuhmachergewann 5 - 11 D - 69123 Heidelberg hereby declare that, on the basis of its functional concept and design and in the version brought into circula- tion by us, the product specified in the following complies with the relevant, fundamental safety and health stipulations laid down by EC directives. - Page 46 Version 1.0 Page 44 of 44...

Need help?

Do you have a question about the Sigma SIBa and is the answer not in the manual?

Questions and answers