Table of Contents

Advertisement

Quick Links

ProMinent ProMix 'DB' & 'PB' Polymer Feeder

Please completely read through these operating instructions first! Do not discard!

The warranty shall be invalidated by damage caused by operating errors!

ProMinent Fluid Controls, Inc. (USA) 136 Industry Drive, Pittsburgh, PA 15275

ProMix Series MA Batch/Inline User Manual

Operating Instructions

ProMinent

(Batch/Inline Controls)

Polymer Blending System

ProMix_MB_IOM (02/21/2020): – P/N: 984703 Rev B.

Tel: (412) 787-2484

®

ProMix-M

www.prominent.us Fax: (412) 787-0704

1

Advertisement

Table of Contents

Summary of Contents for ProMinent ProMix Series

- Page 1 Please completely read through these operating instructions first! Do not discard! The warranty shall be invalidated by damage caused by operating errors! ProMix_MB_IOM (02/21/2020): – P/N: 984703 Rev B. ProMinent Fluid Controls, Inc. (USA) 136 Industry Drive, Pittsburgh, PA 15275 Tel: (412) 787-2484 www.prominent.us Fax: (412) 787-0704...

-

Page 2: Table Of Contents

ProMinent ProMix ‘DB' & 'PB’ Polymer Feeder Table of Contents i. Overview: ..............................4 ii. ProMix Systems: ............................6 Diaphragm Pump Type GXLA (DB Series): ....................6 Progressive Cavity Pump Type (PB Series): .................... 7 iii. Polymer Pumps used on M Models ......................8 iv. - Page 3 ProMinent ProMix ‘DB' & 'PB’ Polymer Feeder 2.11 Troubleshooting Guide ........................37 3.0 SPARE PARTS & PREVENTIVE MAINTENANCE ................40 3.1 GAMMA XL (GXLA) Pump Spare Parts .................... 40 3.2 SEEPEX Pump Spare Parts ......................40 3.3 PVC Mixing Chamber Spare Parts ....................40 3.4 Piping Components Spare Parts ......................

-

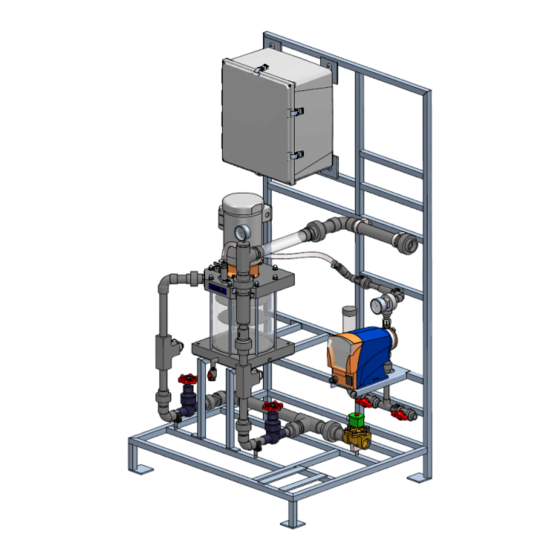

Page 4: Overview

ProMinent ProMix ‘DB' & 'PB’ Polymer Feeder i. Overview: The ProMix M Polymer Feeder is a skid system designed to control feed water and polymer and combine them to produce a high quality solution. The system is designed to receive liquid neat polymer while mixing it with feed water to produce and discharge a quality solution from the system. - Page 5 ProMinent ProMix ‘DB' & 'PB’ Polymer Feeder The ProMix M Polymer Feeder is equipped with all the necessary components for installation, reliable performance and safe operation. Two indicating lights on the front controller door provide operational status. The design incorporates an electric solenoid valve (water inlet), primary and secondary flow meters,...

-

Page 6: Promix Systems

ProMinent ProMix ‘DB' & 'PB’ Polymer Feeder ii. ProMix Systems: Diaphragm Pump Type GXLA (DB Series): PART MODEL PUMP TYPE NUMBER CAPACITY 1048382 300X2-2.3DB GXLA 1020-120 3.24 GPH 1048383 600X2-3.8DB GXLA 1020-200 5.18 GPH 1048384 1500X2-6.2DB GXLA 0730-200 7.76 GPH 1048385 1500X2-10.3DB... -

Page 7: Progressive Cavity Pump Type (Pb Series)

ProMinent ProMix ‘DB' & 'PB’ Polymer Feeder Progressive Cavity Pump Type (PB Series): PART MODEL PUMP TYPE NUMBER CAPACITY 1048386 1500X2-5.0PB Seepex MD 5.0 GPH 1048387 1500X2-10.0PB Seepex MD 10.0 GPH 1048388 1500X2-24.0PB Seepex MD 24.0 GPH **Refer to Appendix C for proper sizing** Overall Skid Dimensions ................. -

Page 8: Polymer Pumps Used On M Models

0.11 12.95 GXLAUS0450PVT2V000UV4030EN Notes: 1. ProMinent – Gamma XL Solenoid Driven Metering Pump 2. Original Pump GPH rating is derated 20% due to Polymer viscosity. The actual deration may vary depending on the polymer used 3. Control Modes Available * a. -

Page 9: Progressive Cavity Polymer Pumps Used On M Models

ProMinent ProMix ‘DB' & 'PB’ Polymer Feeder iv. Progressive Cavity Polymer Pumps used on M Models: Flowrate (GPH) Pressure Series Identification Code (PSIG) MD 003-12 / A6-A7-A7-H0-GA-X 0.50 MD 006-12 / A6-A7-A7-H0-GA-X 1.00 10.0 MD 012-12 / A6-A7-A7-H0-GA-X 2.40 24.0 Notes: 1. -

Page 10: Installation & Quick Start Guide

ProMinent ProMix ‘DB' & 'PB’ Polymer Feeder 1.0 INSTALLATION & QUICK START GUIDE 1.1 Safety: Utilize appropriate protective safety gear when operating or maintaining this equipment. Recommended safety gear is as follows: Personal Protective Equipment (PPE): • Hard Hats (Where overhead hazards exist) •... -

Page 11: Installation Guidelines

ProMinent ProMix ‘DB' & 'PB’ Polymer Feeder 1.4 Installation Guidelines: 1. Unpack and position equipment on sturdy level surface. Fasten to prevent movement. 2. Do not install equipment in areas of extreme heat, cold, dust or humidity. Avoid areas where objects or fluids can drop from overhead. -

Page 12: Quick Start Guide

ProMinent ProMix ‘DB' & 'PB’ Polymer Feeder h. Allow provisions for draining the system piping. Skid components will require maintenance. Ensure that chemicals can be evacuated from the skid piping and components for servicing. 8. Electrical Supply Needed for the System: a. - Page 13 ProMinent ProMix ‘DB' & 'PB’ Polymer Feeder 5. Verify motor rotation on Mixing Chamber motor and Seepex pump motor, if applicable. Normal rotation is CCW. 6. Do not run the mixing chamber motor dry. Damage to the mechanical seal could occur.

-

Page 14: Promix Mode And Polymer Settings

ProMinent ProMix ‘DB' & 'PB’ Polymer Feeder 1.6 ProMix Mode and Polymer Settings Begin by first selecting mode of operation (Batch or Inline) and type of polymer (Emulsion or Mannich) see section 2.5. The user must choose the mode of operation from a keypad menu Batch or Inline selection. - Page 15 ProMinent ProMix ‘DB' & 'PB’ Polymer Feeder Batch / Emulsion door switch options System Start Polymer Pump ON-OFF-REMOTE LOCAL-REMOTE PROMIX OPERATION controller door controller door switch switch Remote Start Contact: N/A Keypad Local Setpoint: 0 – 1.0% concentration LOCAL Remote Setpoint: N/A Max.

- Page 16 ProMinent ProMix ‘DB' & 'PB’ Polymer Feeder Batch / Mannich door switch options System Start Polymer Pump ON-OFF- LOCAL- REMOTE REMOTE PROMIX OPERATION controller door controller door switch switch Remote Start Contact: N/A Keypad Local Setpoint: 0 – 10.0% concentration...

- Page 17 ProMinent ProMix ‘DB' & 'PB’ Polymer Feeder Inline / Emulsion door switch options System Start Polymer Pump ON-OFF- LOCAL- REMOTE REMOTE PROMIX OPERATION controller door controller door switch switch Remote Start Contact: N/A Keypad Local Setpoint: 0 – 100% pump speed...

- Page 18 ProMinent ProMix ‘DB' & 'PB’ Polymer Feeder Inline / Mannich door switch options System Start Polymer Pump ON-OFF- LOCAL- REMOTE REMOTE PROMIX OPERATION controller door controller door switch switch Remote Start Contact: N/A Keypad Local Setpoint: 0 – 100% pump speed...

-

Page 19: Servicing Guidelines

ProMinent ProMix ‘DB' & 'PB’ Polymer Feeder 1.7 Servicing Guidelines: • Disconnect electrical power to the equipment prior to servicing. • Relieve all pressure from the unit prior to servicing. • Close all suction and discharge valves. • Verify dilution water is closed. -

Page 20: Controller

ProMinent ProMix ‘DB' & 'PB’ Polymer Feeder 2.0 CONTROLLER 2.1 Keypad Navigation The ProMinent ProMix MB Polymer Feeder uses a fixed configuration to deliver the operation required to operate the feeder. The main board and top board are not interchangeable with other ProMinent controller hardware. -

Page 21: Main Menu

ProMinent ProMix ‘DB' & 'PB’ Polymer Feeder 2.2 Main Menu Top of Main Menu. Displays current feeder state. Batch 0.37% ENTER @ to view & adjust System settings Local RUN You can always key EXIT until you get to this screen... -

Page 22: Main Menu (Continued)

ProMinent ProMix ‘DB' & 'PB’ Polymer Feeder 2.2 Main Menu (continued) Mixer 1.34hrs Mixer displays when the mixer motor is running. Alternates with "ENTER = Flush" for mix chamber flushing when manually selected.* Feed Verify 2745 mL If the Feed Verify option is selected... -

Page 23: Adjust Setpoint

ProMinent ProMix ‘DB' & 'PB’ Polymer Feeder 2.3 Adjust Setpoint Adjust Setpoint Key down to PolymerFeed and Key ENTER. Local PolymerFeed Setpoint controls the feed when the enclosure door switch Feed @ 8.74% is in the Local position. Displays current setpoint. -

Page 24: Modify Timing

ProMinent ProMix ‘DB' & 'PB’ Polymer Feeder 2.4 Modify Timing PolymerFeed 1.314 G ENTER @ PolymerFeed. Local Setpoint controls the feed when the LocalSetpoint enclosure door switch is in the Local position. 0.33% Wait for Flow is the time that the feeder waits to measure a... -

Page 25: Change Feed Mode And Polymer Type

ProMinent ProMix ‘DB' & 'PB’ Polymer Feeder 2.5 Change Feed Mode and Polymer type Batch 0.37% Local RUN Top of Main Menu. Displays current feeder state. ENTER @ to view & adjust System settings Configure You can always key EXIT until you get to this screen Time &... -

Page 26: Browser Controls

ProMinent ProMix ‘DB' & 'PB’ Polymer Feeder 2.6 Browser Controls 2.6.1 The Site View Ethernet connect to the controller with a PC, notebook, netbook or via the site LAN. Refer to the separate Browser manual (Reference Documents) if you have not previously browsed a ProMix type controller. -

Page 27: Diagnostic View

ProMinent ProMix ‘DB' & 'PB’ Polymer Feeder 2.6.2 Diagnostic View ProMix Series MA Batch/Inline User Manual... -

Page 28: Operation Configuration

ProMinent ProMix ‘DB' & 'PB’ Polymer Feeder Operation Configuration 2.7.1 Setpoints Control of the neat polymer feed pump is set by the System Start and Polymer Pump switches located on the ProMix control panel door. The type of polymer, either emulsion or Mannich, and the operation, either Inline or Batch, are selected via the controller keypad or browser interface. - Page 29 ProMinent ProMix ‘DB' & 'PB’ Polymer Feeder 7. Using the controller keypad, enter the calculated pump rate in gph (see section 2.4 pump settings) 8. Place the pump back into the analog mode. Follow the same procedure for a Seepex pump but do not use water for testing and/or calibration.

-

Page 30: Feeder States

ProMinent ProMix ‘DB' & 'PB’ Polymer Feeder 2.8 Feeder States Auxiliary STOP OFF: Solenoid Remote or Local OFF: Mixer selected & OFF: Pump Start Low Tank Level OFF selected or OFF: Run DO Auxiliary open or :Water Loss Start closed (programmable) - Page 31 ProMinent ProMix ‘DB' & 'PB’ Polymer Feeder LCD TEXT Next 2 Way Remote Contact OFF Remote Contact ON 1 Way No Ext.Run STOP Feed on ENTER : Solenoid : Solenoid OFF selected Remote Contact : Mixer : Mixer or No Flow...

- Page 32 ProMinent ProMix ‘DB' & 'PB’ Polymer Feeder Remote RUN ON : Auto LED Feed Verify : Fail-to-Feed : Solenoid : Mixer : Pump ON : Run DO OFF:Water Loss Fail-to-Feed is active whenever :Run LED the Polymer Pump is ON.

-

Page 33: Enclosure Lights & Status

ProMinent ProMix ‘DB' & 'PB’ Polymer Feeder 2.9 Enclosure Lights & Status STOP Auto & STOP AUTO Feed @ The enclosure door lights complement the LCD state Setpoint display messages & understandably can be seen from a Manual & greater distance than the LCD display. - Page 34 ProMinent ProMix ‘DB' & 'PB’ Polymer Feeder There has be polymer in the tank and both the flow switch has to be closed and the Primary flow rate greater than 0.2GPM for the feeder to operate. Note that in either Remote or Local mode the user can transition between modes by changing the System Start door switch from one position to the other without pausing at OFF.

-

Page 35: Status Message Summary

ProMinent ProMix ‘DB' & 'PB’ Polymer Feeder 2.10 Status Message Summary LCD & Browser Status Feeder State System Off ON-OFF-REMOTE switch at OFF Can be programmed for any interlock purpose. Alarm in Auxiliary STOP open or close programmable, e.g. tank level... - Page 36 ProMinent ProMix ‘DB' & 'PB’ Polymer Feeder Polymer feed @ 4-20mA input controlled setpoint. Exits on no flow, auxiliary contact, control<0%, flush, feed Polymer Pump Remote verify fail, Remote Start open, mixer @ >1% or 10%, pump at max SPM or ON-OFF-REMOTE = OFF.

-

Page 37: Troubleshooting Guide

ProMinent ProMix ‘DB' & 'PB’ Polymer Feeder 2.11 Troubleshooting Guide Adjustment and bypass fixes to operational problems. LCD & Browser Status Operational Problem If you have a level switch fault, jumper controller input terminal ‘O’ to the adjacent Ground symbol, Auxiliary STOP terminal &... - Page 38 ProMinent ProMix ‘DB' & 'PB’ Polymer Feeder This fault occurs because the feeder isn’t getting confirming pulses from the pump or the flow measuring device on the pump outlet. Verify the wiring is tightly connected to controller input terminal ‘R’ to and an adjacent Ground symbol terminal.

- Page 39 ProMinent ProMix ‘DB' & 'PB’ Polymer Feeder All of the feeder inputs and outputs can have alarms set on value, volume, time… Feeder Alarms These alarms will not prevent polymer feed but may be used to flag operational, setpoint, usage or maintenance problems.

-

Page 40: Spare Parts & Preventive Maintenance

ProMinent ProMix ‘DB' & 'PB’ Polymer Feeder 3.0 SPARE PARTS & PREVENTIVE MAINTENANCE 3.1 GAMMA XL (GXLA) Pump Spare Parts P/N: Description: 1027082 GXLA1020 Spare Parts Kit** 1000249 GXLA1020 Diaphragm 1017393 GXLA1020 Liquid End 1027083 GXLA0730 Spare Parts Kit** 1000250 GXLA0730 Diaphragm... -

Page 41: Piping Components Spare Parts

ProMinent ProMix ‘DB' & 'PB’ Polymer Feeder 3.4 Piping Components Spare Parts P/N: Description: 1019883 1/2" PVC Back Pressure/Pressure Relief Valve SOC pfc 7745788 0-160PSI, Gauge, SS, 2-1/2, Bottom MTD 7746152 0-160PSI 316SS Back gauge & CPVC/PTFE Isolator 7744091 1/2" ID PVC Nylobraid Hose 7741354 1/2"... -

Page 42: Maintenance And Lubrication Schedule

ProMinent ProMix ‘DB' & 'PB’ Polymer Feeder 3.6 Maintenance and Lubrication Schedule MAINTENANCE Description / Task Remarks Frequency Visual inspection of unit Weekly Every 3 Months Check dosing line fittings and valves for (Approx 30% tightness continuous operation.) No leaks or abnormal... - Page 43 ProMinent ProMix ‘DB' & 'PB’ Polymer Feeder MAINTENANCE Description / Task Remarks Frequency Check Universal Joint Seal, Bushing and Upon rotor/stator joint integrity. Replace Grease (Seepex See Lubrication Chart replacement Pump) Check Motor RPM/amperage. Drain. Check fan cover for obstruction or Dirt...

- Page 44 ProMinent ProMix ‘DB' & 'PB’ Polymer Feeder LUBRICATION Description / Task Lubrication Frequency Mixing Chamber Motor 1-1/2 HP (See 5,000 Hours of Service Ball Bearing Grease Chart Below) per Year Check Gear Reducer Oil Level (Seepex 210cSt @ 40°C (Gulf EP...

- Page 45 ProMinent ProMix ‘DB' & 'PB’ Polymer Feeder Mixing Chamber Motor Details: ProMix Series MA Batch/Inline User Manual...

-

Page 46: Appendix A - Db & Pb Series Bill Of Material

ProMinent ProMix ‘DB' & 'PB’ Polymer Feeder Appendix A – DB & PB Series Bill of Material Mechanical & Electrical List General Mechanical Layout ProMix M DB ProMix Series MA Batch/Inline User Manual... - Page 47 ProMinent ProMix ‘DB' & 'PB’ Polymer Feeder PROMIX M (DB SERIES) BILL OF MATERIAL ITEM PART DESCRIPTION PART NO GXLA 1020 SERIES PUMP ON HV2 SETTING GXLAUS1020PVT4V000UV4030EN GXLA 1020 SERIES PUMP GXLAUS1020PVT4V000UV4030EN GXLA 0730 SERIES PUMP GXLAUS0730PVT4V000UV4030EN GXLA 0450 SERIES PUMP...

- Page 48 ProMinent ProMix ‘DB' & 'PB’ Polymer Feeder General Mechanical Layout ProMix M PB ProMix Series MA Batch/Inline User Manual...

- Page 49 ProMinent ProMix ‘DB' & 'PB’ Polymer Feeder PROMIX M (PA SERIES) BILL OF MATERIAL ITEM PART DESCRIPTION PART NO PUMP, 5 GPH, SEEPEX MODEL MD-003-012 1048415 PUMP, 10 GPH, SEEPEX MODEL MD-006-012 1048416 PUMP, 24 GPH, SEEPEX MODEL MD-012-012 1048417...

- Page 50 ProMinent ProMix ‘DB' & 'PB’ Polymer Feeder P/N: 7747253 Mixing Chamber Components ProMix Series MA Batch/Inline User Manual...

- Page 51 ProMinent ProMix ‘DB' & 'PB’ Polymer Feeder PROMIX M - MIXING CHAMBER BILL OF MATERIALS P/N: 7747253 ITEM USA P/N DESCRIPTION 7746491 O-RING, CHAMBER, VITON, PROMIX-M 7747246 ROD, 316SS, 3/8-16 X 14.75, PROMIX-U 7746492 NUT, ACORN, 3/8-16, 18-8 SST 7747252 PLATE, TOP, PVC, 1.75, PROMIX-M, SG...

-

Page 52: Appendix B - Control Panel "B Controls

ProMinent ProMix ‘DB' & 'PB’ Polymer Feeder Appendix B – Control Panel “B Controls” B.1 Controller Board Layout The controller consists of three circuit boards, a front Measure circuit board, a back Power board, and an auxiliary digital input board. - Page 53 ProMinent ProMix ‘DB' & 'PB’ Polymer Feeder Terminals ‘O’ through ‘V’ and a ground terminal. 5VDC limited by 10K puts 1/2mA through a closed contact set. Hall effect Turbines and Paddlewheel water meters are powered by the 15-22VDC controller supply, thermally fused at 100mA.

-

Page 54: Controller Wiring (Db/Pb Series)

ProMinent ProMix ‘DB' & 'PB’ Polymer Feeder B.2 Controller Wiring (DB/PB Series) ProMix Series MA Batch/Inline User Manual... - Page 55 ProMinent ProMix ‘DB' & 'PB’ Polymer Feeder ProMix Series MA Batch/Inline User Manual...

- Page 56 ProMinent ProMix ‘DB' & 'PB’ Polymer Feeder ProMix Series MA Batch/Inline User Manual...

- Page 57 ProMinent ProMix ‘DB' & 'PB’ Polymer Feeder ProMix Series MA Batch/Inline User Manual...

- Page 58 ProMinent ProMix ‘DB' & 'PB’ Polymer Feeder ProMix Series MA Batch/Inline User Manual...

- Page 59 ProMinent ProMix ‘DB' & 'PB’ Polymer Feeder ProMix Series MA Batch/Inline User Manual...

- Page 60 ProMinent ProMix ‘DB' & 'PB’ Polymer Feeder ProMix Series MA Batch/Inline User Manual...

- Page 61 ProMinent ProMix ‘DB' & 'PB’ Polymer Feeder ProMix Series MA Batch/Inline User Manual...

- Page 62 ProMinent ProMix ‘DB' & 'PB’ Polymer Feeder ProMix Series MA Batch/Inline User Manual...

- Page 63 ProMinent ProMix ‘DB' & 'PB’ Polymer Feeder ProMix Series MA Batch/Inline User Manual...

-

Page 64: Appendix C - Polymer Sizing / Dosage

ProMinent ProMix ‘DB' & 'PB’ Polymer Feeder Appendix C – Polymer Sizing / Dosage The ProMix M Polymer Pump switch on the controller door enables the user to select either LOCAL or REMOTE operation. In ‘LOCAL’, the polymer concentration setpoint is selectable from 0 - 1% for emulsion polymer and 0 –... -

Page 65: Appendix D - Reference Documents

ProMinent ProMix ‘DB' & 'PB’ Polymer Feeder Appendix D – Reference Documents Mechanical General Arrangement Drawings: 1048382 -200 ProMix M SG 300X2-2.3DB System 1048383 -200 ProMix M SG 600X2-3.8DB System 1048384 -200 ProMix M SG 1500X2-6.2DB System 1048385 -200 ProMix M SG 1500X2-10.3DB System 1048386 -200 ProMix M SG 1500X2-5.0PB System... -

Page 66: Appendix E - Operation Modes & Controller Switch Settings

ProMinent ProMix ‘DB' & 'PB’ Polymer Feeder Appendix E – Operation Modes & Controller Switch Settings System Start Polymer Pump Inline/ Emulsion/ ON-OFF-REMOTE LOCAL-REMOTE PROMIX OPERATION Batch Mannich controller door controller door mode polymer switch switch Remote Start Contact: N/A Keypad Local Setpoint: 0 –... - Page 67 ProMinent ProMix ‘DB' & 'PB’ Polymer Feeder System Start Polymer Pump Inline/ Emulsion/ ON-OFF-REMOTE LOCAL-REMOTE PROMIX OPERATION Batch Mannich controller door controller door mode polymer switch switch Remote Start Contact: N/A Keypad Local Setpoint: N/A REMOTE Batch Mannich Remote Setpoint: 4-20 mA = 0-10.0% concentration Max.

- Page 68 ProMinent ProMix ‘DB' & 'PB’ Polymer Feeder System Start Polymer Pump Inline/ Emulsion/ ON-OFF-REMOTE LOCAL-REMOTE PROMIX OPERATION Batch Mannich controller door controller door mode polymer switch switch Keypad Local Setpoint: N/A Remote Setpoint: 4-20 mA = 0-1.0% concentration Max. chamber concentration: 1.0%...

Need help?

Do you have a question about the ProMix Series and is the answer not in the manual?

Questions and answers