Table of Contents

Advertisement

Quick Links

Maintenance Manual

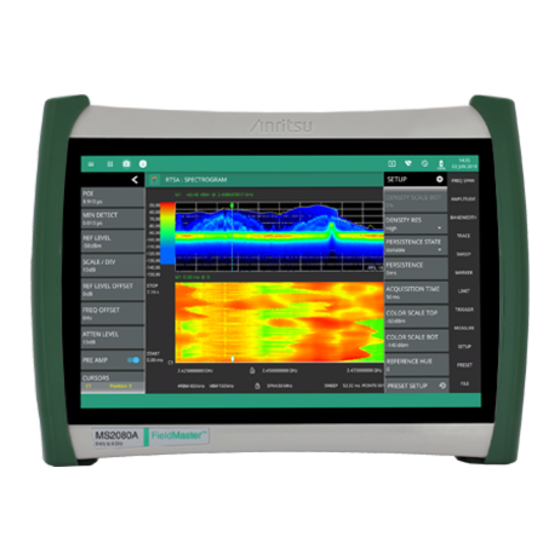

Field Master™ MS2070A/MS2080A

Handheld Spectrum Analyzer

MS2070A-703 9 kHz to 3 GHZ (Option 703)

MS2080A-704 9 kHz to 4 GHZ (Option 704)

Anritsu Company

P/N: 10580-00485

490 Jarvis Drive

Revision: B

Morgan Hill, CA 95037-2809

Published: February 2023

USA

Copyright 2023 Anritsu Company

http://www.anritsu.com

Advertisement

Table of Contents

Summary of Contents for Anritsu Field Master MS2070A-703

- Page 1 Handheld Spectrum Analyzer MS2070A-703 9 kHz to 3 GHZ (Option 703) MS2080A-704 9 kHz to 4 GHZ (Option 704) Anritsu Company P/N: 10580-00485 490 Jarvis Drive Revision: B Morgan Hill, CA 95037-2809 Published: February 2023 Copyright 2023 Anritsu Company http://www.anritsu.com...

- Page 2 This product and its manuals may require an Export License or approval by the government of the product country of origin for re-export from your country. Before you export this product or any of its manuals, please contact Anritsu Company to confirm whether or not these items are export-controlled.

-

Page 3: Table Of Contents

Contacting Anritsu ........ - Page 4 Table of Contents (Continued) Chapter 4—Troubleshooting Introduction ..............4-1 Level Accuracy Problems .

-

Page 5: Chapter 1- General Information

Anritsu recommends that you make a copy of the test records to document the measurements each time a Performance Verification is performed. Continuing to document this process each time it is performed provides a detailed history of instrument performance. -

Page 6: Contacting Anritsu

1-2 Contacting Anritsu General Information Updates, if any, can be downloaded from the Library tab on the Anritsu product page: https://www.anritsu.com/en-us/test-measurement/products/ms2080a https://www.anritsu.com/en-us/test-measurement/products/ms2070a Contacting Anritsu To contact Anritsu, visit the following URL and select the services in your region: http://www.anritsu.com/contact-us Required Test Equipment and Tools Table 1-2 provides a list of the test equipment used for the performance verification tests of the instrument. -

Page 7: Replaceable Parts

General Information 1-4 Replaceable Parts Table 1-3. Required Tools Tools Specification Wrench 5/16” Torx Screwdriver Torx Screwdriver T 20 Phillips Screwdriver Phillips Screwdriver Nut Driver 5.5 mm Hex Socket Driver 6 mm (1/4”) Replaceable Parts The MS20x0A replacement parts and their description are listed below in Table 1-4. - Page 8 1-4 Replaceable Parts General Information PN: 10580-00485 Rev. B MS20x0A MM...

-

Page 9: Chapter 2-Spectrum Analyzer Verification

Chapter 2 — Spectrum Analyzer Verification Introduction This chapter provides the verification procedures for the MS20x0A Field Master. Verification tests that are associated with other instrument options are described in Chapter 3, “Assembly Replacement”. Record the measurement results in the test record templates provided in Appendix A, “Test Records”. -

Page 10: Pass/Fail Determination For Instrument Key Parameter Performance Tests

2-1 Introduction Spectrum Analyzer Verification PASS/FAIL Determination for Instrument Key Parameter Performance Tests Figure 2-1 shows the rule that is used to determine the pass/fail status of test results that are associated with warranted specifications. + Uncertainty Measurement Point (Reading) –... -

Page 11: Frequency Accuracy

Use the following procedures to verify the frequency accuracy of the MS20x0A without GPS connection. Equipment Required • Anritsu MG36221A Synthesizer • Anritsu 15NN50-1.5C RF Coaxial Cable • Anritsu 34RKNF50 Ruggedized K(m) to N(f) Adapter • 10 MHz Frequency Reference • BNC(m) to BNC(m) Coaxial Cable • SMA(m) to BNC(f) Adapter Procedure 1. -

Page 12: With Gps Connection (Option 31)

Appendix Equipment Required • Anritsu MG36221A Synthesizer • 10 MHz Frequency Reference • Anritsu 34RKNF50 Adapter • Anritsu 15NN50-1.5C RF Coaxial Cable • SMA(m) to BNC(f) Adapter • BNC(m) to BNC(m) Coaxial Cable • GPS antenna Procedure 1. Connect the external 10 MHz Reference to the MG36221A. -

Page 13: Amplitude Accuracy

• Anritsu MG36221A Synthesizer • Weinschel 1870A Power Splitter • Weinshel 44-10 Attenuator • Rohde and Schwarz NRP18T Power Sensor • Anritsu 15NN50-1.5C RF Coaxial Cable • Anritsu 34NN50A Adapter • Anritsu 34RKNF50 Adapter • SMA(m) to BNC(f) Adapter • BNC(m) to BNC(m) Coaxial Cable •... - Page 14 2-3 Amplitude Accuracy Spectrum Analyzer Verification 10. Zero the NRP18T sensor. 11. On the MG36221A, press RF ON. 12. On the MG36221A, set the frequency to 50 MHz. 13. Adjust the NRP18T power level to +10.0 dBm. (The power level reading of MG36221A should be approximately +16 dBm.) 14.

-

Page 15: Amplitude Accuracy - Preamplifier On

• Weinschel 44-20 Attenuator • Rohde and Schwarz NRP18T Power Sensor • Anritsu 15NN50-1.5C RF Coaxial Cable • Anritsu 34NN50A Adapter, N(m) to N(m) • Ruggedized 34RKNF50 Adapter, K(m) to N(f) • 10 MHz Frequency Reference • BNC(m) to BNC(m) Coaxial Cable Procedure 1. -

Page 16: Single Side Band (Ssb) Phase Noise

Equipment Required • Anritsu MG36221A • Ruggedized 34RKNF50 Adapter, K(m) to N(f) • SMA(m) to BNC(f) Adapter • Anritsu 15NN50-1.5C Coaxial Cable, N(m) to N(m) • 10 MHz Frequency Reference • BNC(m) to BNC(m) coaxial cable Procedure 1. Connect the external 10 MHz Reference to both the MG36221A and MS20x0A. - Page 17 Spectrum Analyzer Verification 2-4 Single Side Band (SSB) Phase Noise For example: –80 dBc measured – 30 dB = –110 dBc/Hz 11. Change the Center Frequency to 1000.545 MHz and the Span to 1.1 MHz. Run the sweep of three averages and allow it to finish.

-

Page 18: Second Harmonic Distortion

Before continuing, allow a 30 minute warm-up for the internal circuitry to stabilize. Equipment Required • Anritsu MG36221A Synthesizer • Min-Circuits NLP-50 Low Pass Filter • Anritsu 15NN50-1.5C RF Cable • 10 MHz Frequency Reference • BNC(m) to BNC(m) Coaxial Cable • Ruggedized 34RKNF50 Adapter, K(m) to N(f) •... -

Page 19: Displayed Average Noise Level (Danl)

Note Before continuing, allow a 30 minute warm-up for the internal circuitry to stabilize. Equipment Required • Anritsu 28N50-2 Termination MS2070A Procedure 1. Attach the Termination to the RF input of the MS20x0A. 2. Set the MS2070A to spectrum analyzer mode and preset the instrument (PRESET > Preset Mode). - Page 20 2-6 Displayed Average Noise Level (DANL) Spectrum Analyzer Verification MS2080A Procedure 1. Attach the Termination to the RF input of the MS2080A. 2. Set the MS2080A to spectrum analyzer mode and preset the instrument (PRESET > Preset Mode). 3. Set the MS2080A parameters as follows: •...

-

Page 21: Danl - Preamplifier On

Note Before continuing, allow a 30 minute warm-up for the internal circuitry to stabilize. Equipment Required • Anritsu 28N50-2 Termination MS2070A Procedure 1. Attach the Termination to the RF input of the MS2070A. 2. Set the MS2070A to spectrum analyzer mode and preset the instrument (PRESET > Preset Mode). - Page 22 2-6 Displayed Average Noise Level (DANL) Spectrum Analyzer Verification MS2080A Procedure 1. Attach the Termination to the RF input of the MS2080A. 2. Set the MS2080A to spectrum analyzer mode and preset the instrument (PRESET > Preset Mode). 3. Set the MS2080A parameters as follows: •...

-

Page 23: Residual Spurs

Note Before continuing, allow a 30 minute warm-up for the internal circuitry to stabilize. Equipment Required • Anritsu 28N50-2 Termination MS2070A Procedure 1. Attach the Termination to the RF input of the MS2070A. 2. Set the MS2070A to spectrum analyzer mode and preset the instrument (PRESET > Preset Mode). - Page 24 2-7 Residual Spurs Spectrum Analyzer Verification MS2080A Procedure 1. Attach the Termination to the RF input of the MS2080A. 2. Set the MS2080A to spectrum analyzer mode and preset the instrument (PRESET > Preset Mode). 3. Set the MS2080A parameters as follows: •...

-

Page 25: Residual Spurs - Preamplifier Off

Appendix Equipment Required • Anritsu 28N50-2 Termination MS2070A Procedure 1. Attach the Termination to the RF input of the MS2070A. 2. Set the MS2070A to spectrum analyzer mode and preset the instrument (PRESET > Preset Mode). -

Page 26: Input Related Spurious

Before continuing, allow a 30 minute warm-up for the internal circuitry to stabilize. Equipment Required • Anritsu MG36221A Synthesizer • Anritsu 34RKNF50 Adapter • Anritsu 15NNF50-1.5C RF Cable • 10 MHz Frequency Reference • BNC(m) to BNC(m) Coaxial Cable • SMA(m) to BNC(f) Adapter MS2070A Procedure 1. - Page 27 Spectrum Analyzer Verification 2-8 Input Related Spurious MS2080A Procedure 1. Connect the 10 MHz Reference to the MG36221A and MS2080A. 2. Connect the output of the MG36221A to the RF In of the MS2080A. 3. Set the MS2080A to spectrum analyzer mode and preset the instrument (PRESET > Preset Mode). 4.

- Page 28 2-8 Input Related Spurious Spectrum Analyzer Verification 2-20 PN: 10580-00485 Rev. B MS20x0A MM...

-

Page 29: Chapter 3-Assembly Replacement

Chapter 3 — Assembly Replacement Introduction This chapter describes opening and closing the Field Master case along with basic parts replacement steps. The sections are as follows: • “Battery Pack Removal and Replacement” • “Bumpers Removal” • “Rear Case Removal” •... -

Page 30: Battery Pack Removal And Replacement

3-3 Battery Pack Removal and Replacement Assembly Replacement Battery Pack Removal and Replacement This section provides instructions for the removal and replacement of the instrument battery pack. 1. Locate the battery access door on the left side of the unit. 2. -

Page 31: Bumpers Removal

Assembly Replacement 3-4 Bumpers Removal Bumpers Removal The procedure below provides instructions for removing the bumpers of the instrument: 1. Remove the left and right bumpers by pulling them outward from the bottom. See Figure 3-3. Figure 3-3. Pulling of Side Bumpers 2. -

Page 32: Rear Case Removal

3-5 Rear Case Removal Assembly Replacement Rear Case Removal The procedure below provides instructions for removing the rear case of the instrument: 1. Remove the battery as shown in Section 3-3 “Battery Pack Removal and Replacement” on page 3-2. 2. Remove the side bumpers as shown in Section 3-4 “Bumpers Removal”... -

Page 33: Touchscreen/Lcd Removal

Assembly Replacement 3-6 Touchscreen/LCD Removal Touchscreen/LCD Removal This procedure provides instructions to replace LCD touchscreen. With the rear case removed as shown in Section 3-5 “Rear Case Removal” on page 3-4, the internal assemblies can be removed and replaced as explained below: 1. - Page 34 3-6 Touchscreen/LCD Removal Assembly Replacement 5. Remove the three Torx screws securing the battery shroud using a T10 Torx screw driver. See Figure 3-8. Figure 3-8. Battery Shroud Removal 6. Disconnect the battery cable and remove the battery shroud. See Figure 3-9.

- Page 35 Assembly Replacement 3-6 Touchscreen/LCD Removal 7. Carefully tilt the Main PCB/SPA PCB assembly to view the display cable. See Figure 3-10. Figure 3-10. Display Cable 8. Release the locking connector by slowing lifting the metal flap upwards to disconnect the display cable. Figure 3-11.

- Page 36 3-6 Touchscreen/LCD Removal Assembly Replacement 9. Carefully tilt the Main PCB/SPA PCB assembly to remove the two Wi-Fi antennas. Release the Wi-Fi Antennas by carefully prying the end slots using a straight screw driver. See Figure 3-12. Figure 3-12. Releasing the Wi-Fi antennas 10.

-

Page 37: Spa Pcb Assembly Removal

Assembly Replacement 3-7 SPA PCB Assembly Removal SPA PCB Assembly Removal 1. Remove the four nuts along with four lock washers from the SMA ports on the top connector panel using a 5/16" wrench. See Figure 3-14. Figure 3-14. SPA PCB Removal 2. - Page 38 3-7 SPA PCB Assembly Removal Assembly Replacement 3. Remove the eight Torx screws securing the SPA PCB Assembly to the Main PCB using a T10 Torx driver. Figure 3-16. Figure 3-16. SPA PCB Removal: Torx Screws 3-10 PN: 10580-00485 Rev. B MS20x0A MM...

-

Page 39: Main Pcb Removal

Assembly Replacement 3-8 Main PCB Removal Main PCB Removal The semi-rigid cable connecting the RF input adapter and the step attenuator on the SPA PCB is normally a part of the SPA PCB Assembly, which may be replaced independently. 1. Carefully remove the two Wi-Fi cables, the keypad cable, and shielded LCD cable connected to the Main PCB. -

Page 40: Fan Assembly Removal

3-9 Fan Assembly Removal Assembly Replacement Fan Assembly Removal The fan assembly sits in a slot in the front case and is plugged into the Main PCB. 1. Carefully disconnect the harness and lift the fan assembly out of the case. See Figure 3-18. -

Page 41: 3-10 Rf Input Adapter Removal

Assembly Replacement 3-10 RF Input Adapter Removal 3-10 RF Input Adapter Removal The RF input adapter consists of four T10 Torx screws that are secured to the SPA PCB Assembly. Follow the steps below to remove the RF input adapter: 1. -

Page 42: Reassembling The Unit

3-11 Reassembling the Unit Assembly Replacement 3-11 Reassembling the Unit Reassembling the unit is simply a process done in the reverse order of the removal procedure. Use caution while reassembling all the parts together: 1. Ensure to carefully align the cables of the Wi-Fi antenna into the littles grooves of the Main PCB to prevent the Wi-Fi antenna cables from being smashed or crimped. -

Page 43: Chapter 4-Troubleshooting

Chapter 4 — Troubleshooting Introduction This chapter describes the primary troubleshooting operations that can be performed by all Anritsu service centers. Perform the troubleshooting suggestions in the order they are listed. Only qualified Anritsu personnel should replace internal assemblies. Major subassemblies shown in Table 1-4 are typically the items that may be replaced. - Page 44 4-2 Level Accuracy Problems Troubleshooting PN: 10580-00485 Rev. B MS20x0A MM...

-

Page 45: Appendix A-Test Records

This appendix provides the test record templates to record the performance of the MS20x0A Field Master. Anritsu recommends that you make a copy of the following test record pages and document the measurements each time a performance verification is performed. Continuing to document this process each time it is performed provides a detailed history of instrument performance. -

Page 46: A-2 Test Records For Spectrum Analyzer Verification

A-2 Test Records for Spectrum Analyzer Verification Test Records MS20x0A Firmware Rev: ______________ Operator: ____________________ Date: ____________ Serial Number: _______________ Options: __________________________________________________ Table A-4. MS20x0A Power Level Accuracy at 50 MHz (Preamplifier Off) MS20x0A NRP18T Expected MS20x0A Input Reference Power Power Measured Measurement... - Page 47 Test Records A-2 Test Records for Spectrum Analyzer Verification MS20x0A Firmware Rev: ______________ Operator: ____________________ Date: ____________ Serial Number: _______________ Options: __________________________________________________ Table A-6. MS20x0A Spectral Purity - SSB Phase Noise Offset from 1 GHz Measured Delta with Calculated Value Measurement Specification Frequency...

- Page 48 A-2 Test Records for Spectrum Analyzer Verification Test Records Table A-10. MS2070A Displayed Average Noise Level (Preamplifier On) Start Stop Measurement Frequency Frequency Measured Value – 60 dB Uncertainty Specification 10 MHz 2 GHz 1 MHz 1 kHz 2.0 dB –161 dBm max 2 GHz 3 GHz...

- Page 49 Test Records A-2 Test Records for Spectrum Analyzer Verification Table A-14. MS2070A Residual Spurs (Preamplifier Off) Start Stop Measurement Frequency Frequency Measured Value Uncertainty Specification 10 MHz 500 MHz 300 Hz 100 Hz <–94 dBm, max 500 MHz 1000 MHz 300 Hz 100 Hz <–94 dBm, max...

- Page 50 A-2 Test Records for Spectrum Analyzer Verification Test Records PN: 10580-00485 Rev. B MS20x0A MM...

- Page 52 Anritsu Company 490 Jarvis Drive Anritsu utilizes recycled paper and environmentally conscious inks and toner. Morgan Hill, CA 95037-2809 http://www.anritsu.com...

Need help?

Do you have a question about the Field Master MS2070A-703 and is the answer not in the manual?

Questions and answers