Subscribe to Our Youtube Channel

Summary of Contents for mercor mcr Prosmoke FS

- Page 1 Grzegorza z Sanoka 2 80-408 Gdańsk phone: +48 58 341 42 45 phone/fax: +48 58 341 39 85 OPERATION AND MAINTENANCE MANUAL (OMM) Automatic rolling curtain mcr PROSMOKE FS Gdańsk ver. 3.1.0 2017.11.24...

-

Page 2: Table Of Contents

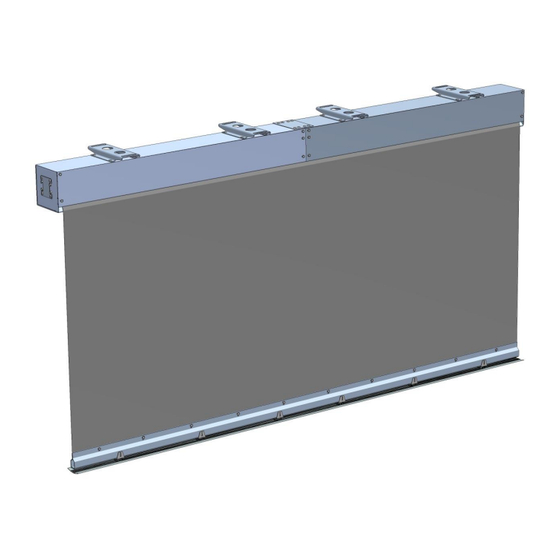

Complying with the recommendations included in the OMM will ensure proper functioning of the smoke venting systems as well as the safety of their users. MERCOR SA reserves the right to make changes to the product or to this document without prior notice. - Page 3 The masking element is an 80 mm wide aluminium profile painted to order in any RAL colour. The smoke-tight fabric used in mcr PROSMOKE FS curtains is not trimmed at the edges. Slight edge fraying is natural and does not affect the operation and product quality.

- Page 4 When planning the curtain installation, the presence of any elements projecting beyond the casing outline should be taken into account: USUÑ ZABE Fig. 1.1. Lengths of elements projecting beyond the mcr PROSMOKE FS curtain casing outline Mounting surface TYPE K CASING...

- Page 5 ROSMOKE PERATION AND AINTENANCE ANUAL Mounting surface TYPE L CASING Mounting surface TYPE K-T CASING Fig. 3. Curtain casing types – L, K-T Note: ensure straightness and flatness (5 mm/5000 mm) of the drop ceiling surface around the gap Fig. 4. Recommended position of casings relative to the ceiling. Gap width. Page 5 of 20...

-

Page 6: Operating Principle Of Mcr Prosmoke Fs Curtains

4. OPERATING PRINCIPLE OF mcr PROSMOKE FS CURTAINS When in standby mode, mcr PROSMOKE FS rolling curtains are hidden in casings. In case of fire, they automatically roll out to the predetermined height. In order to function properly, a mcr PROSMOKE FS rolling curtain must be connected to a mcr 9705-5A or mcr 0204 smoke vent control unit. -

Page 7: Transport And Delivery

ROSMOKE PERATION AND AINTENANCE ANUAL 5. TRANSPORT AND DELIVERY Curtains are generally supplied pre-assembled. Unloading must be carried out under the supervision of a person authorised by the manufacturer, using generally available means of handling (e.g. forklift trucks, cranes equipped with spreader boom slings) or manually, paying special attention to the protection of curtains against damage. - Page 8 ROSMOKE PERATION AND AINTENANCE ANUAL c. Unscrew the four screws securing the roller support located on the opposite side of the motor. d. Pull out the shaft end with a plug (opposite the motor). e. Remove the roller from the casing. 3.

- Page 9 Number of modules connected to the panels: 1. Maximum number of modules: mcr PROSMOKE FS modules in the mcr 9705 control unit – 12 modules mcr PROSMOKE FS modules in the mcr 0204 control unit – 8 modules. If a group of curtains with a higher number of modules is necessary, they should be divided into sections or an extension module should be used to power them.

- Page 10 ROSMOKE PERATION AND AINTENANCE ANUAL Blanking plug! Photo 1. Curtain motor limit switches Wide suspension bracket – TYPE A Narrow suspension bracket – TYPE B Page 10 of 20...

- Page 11 ROSMOKE PERATION AND AINTENANCE ANUAL Flat suspension bracket – TYPE C (installation directly to the ceiling only) Fig. 7. Suspension bracket types Fig. 8. Installation of a curtain without a suspension bracket Page 11 of 20...

- Page 12 ROSMOKE PERATION AND AINTENANCE ANUAL Fig. 9. A spot in the casing designed for connecting curtain modules CABLES Regular cable 2 x 1.5 mm (2.5 mm) NOTE Single curtain Multi-modular curtain In the case of multi-modular curtains, cables of the same length must be used to ensure the same supply voltage drop Control panel MCR 9705/MCR 0204...

- Page 13 ROSMOKE PERATION AND AINTENANCE ANUAL MECU XL Control panel – 24V 230V H1 – Removal of the jumper disconnects the brake H2 - Removal of the jumper disconnects rolling up the curtain Important: To roll the curtain down to the intermediate position, remove the jumper H2, then temporarily remove the jumper H1, until the curtain descends to the desired position.

- Page 14 ROSMOKE PERATION AND AINTENANCE ANUAL 2. H2 jumper – removal cuts off power supply 230V, prevent curtain roll up Description of wire terminals inside MECU XL 1, 2, 3, 4, 5, 6, 7, 8, PE Numbers of motor wires 230 V~ L 230 V~ PE Mains 230 V~ N...

- Page 15 ROSMOKE PERATION AND AINTENANCE ANUAL typically 250 … 200 Fig. 14. Typical gap sizes in the transverse direction in the case of vertical arrangement of curtain modules without fabrics overlapping Fig. 15. Typical gap sizes in the transverse direction in the case of butt arrangement of curtain modules with type K, C and L casings and with fabrics overlapping typically 250 …...

- Page 16 ROSMOKE PERATION AND AINTENANCE ANUAL Fig. 17. Reduction in gaps in a group of curtains by using a common bottom bar – type F casings arranged vertically and horizontally Fig. 18. Typical gap sizes in the transverse direction in the case of butt arrangement of curtains, type K, C and L casings where: L1 –...

- Page 17 ROSMOKE PERATION AND AINTENANCE ANUAL where: S – module width Fig. 20. Lengths of gaps in the longitudinal direction of mcr PROSMOKE FS curtains Fig. 21. Curtain ready to be fitted with side guides Curtain fabric Bottom bar for the guide...

- Page 18 ROSMOKE PERATION AND AINTENANCE ANUAL Side guide Casing Side guide Fabric Bottom bar Fig. 22. Method of installing side guides Page 18 of 20...

-

Page 19: Warranty Terms And Conditions

4. Liability under the Guarantee covers only defects resulting from causes inherent in the equipment sold. 5. “MERCOR” S.A. reserves the right to lengthen the repair time in the event of complicated repairs or those that require non-standard sub-assemblies [elements] or spare parts to be purchased. -

Page 20: Certificate

ROSMOKE PERATION AND AINTENANCE ANUAL 8. CERTIFICATE Page 20 of 20...

Need help?

Do you have a question about the mcr Prosmoke FS and is the answer not in the manual?

Questions and answers